Permanent magnet synchronous motor for shielded pump

A permanent magnet synchronous and motor technology, applied in the field of motors, can solve the problems of no shielding sleeve and inability to achieve shielding in the motor, and achieve the effects of less magnetic leakage, simple structure and strong overload capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further describe content of the present invention below in conjunction with accompanying drawing and embodiment:

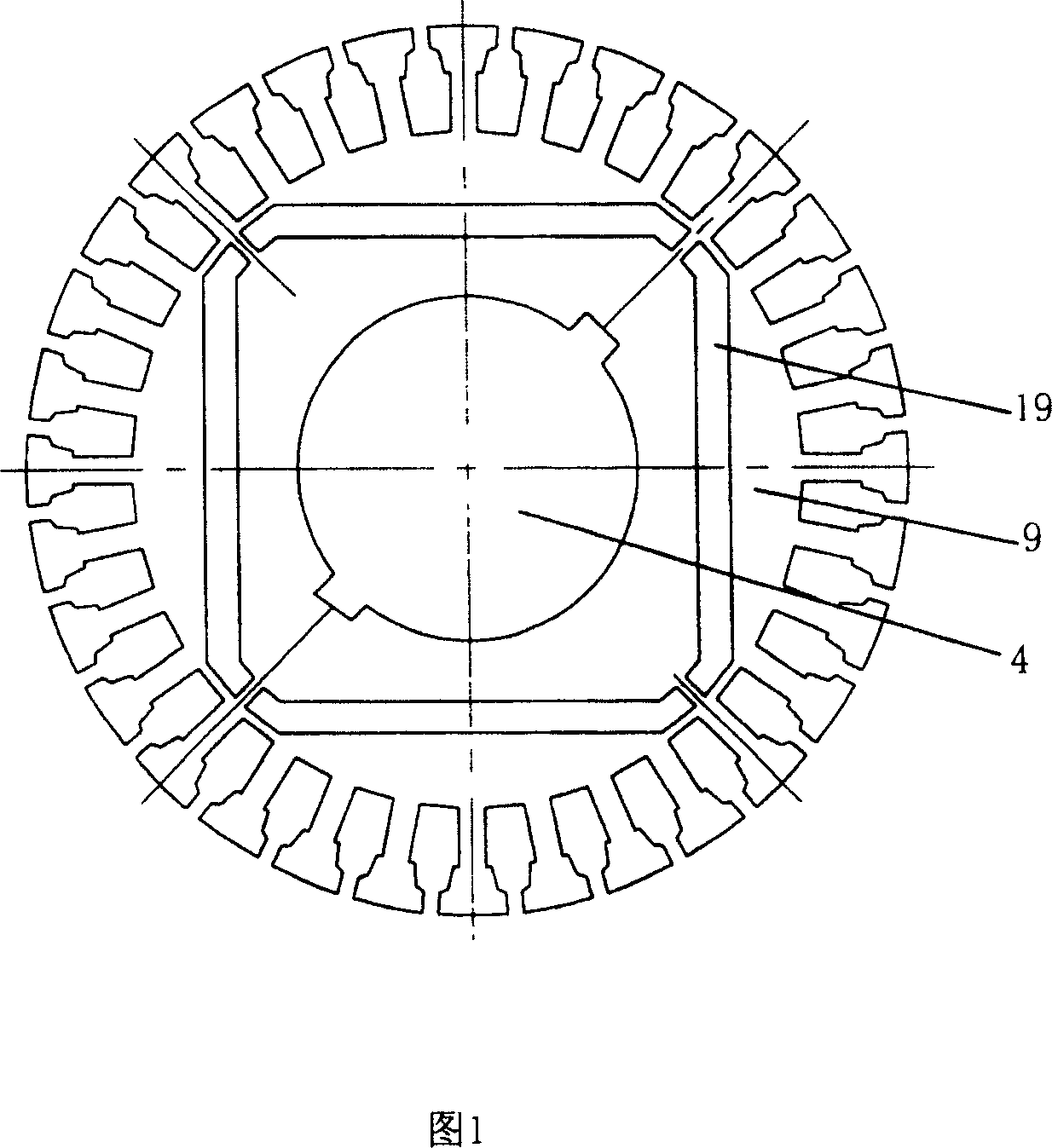

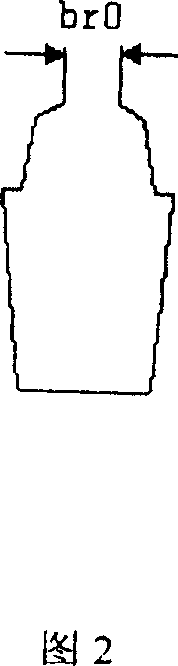

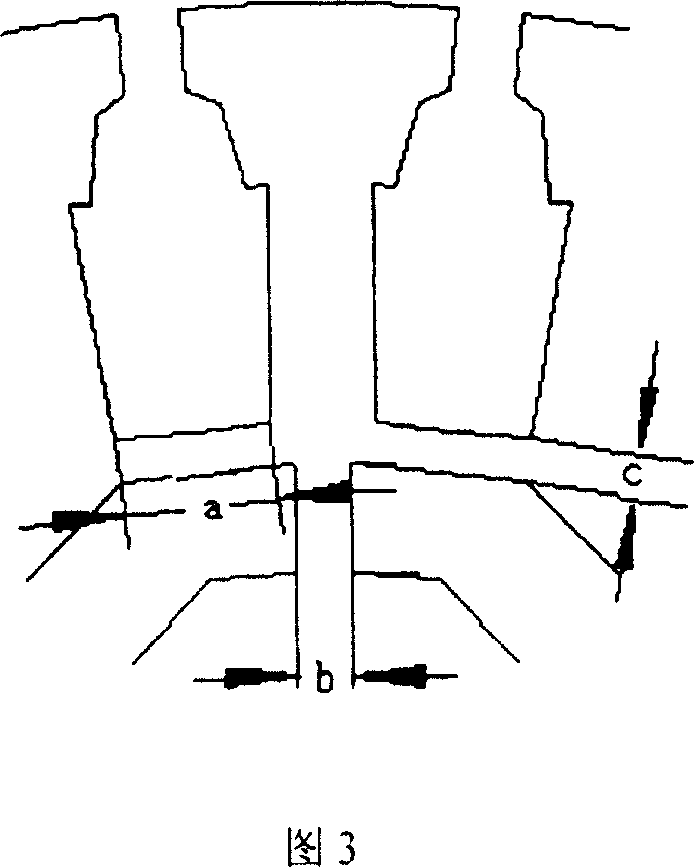

[0014] In the mechanical structure of the present invention, the rotor core 9 is provided with a permanent magnet 10 inside, and the other structures are the same as those of the squirrel-cage induction motor. As shown in Figure 3: it includes the front bearing chamber 1, the rear bearing chamber 18 and the bearing 15 and bearing sleeve 16 inside, the shaft 4, the rotor, and the stator. Sleeve 6, rotor core 9, rotor baffle 12, auxiliary impeller 13, also includes permanent magnet 10, permanent magnet baffle 11, inside the rotor core 9 there is a permanent magnet groove 19 along the radial direction, and the permanent magnet 10 is embedded in the permanent magnet groove In 19 (rotor stamping figure as shown in Figure 1), fix with permanent magnet baffle plate 11; Permanent magnet groove 19 is positioned at rotor groove inside, and there is magnetic isolation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com