Patents

Literature

37results about How to "No high temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

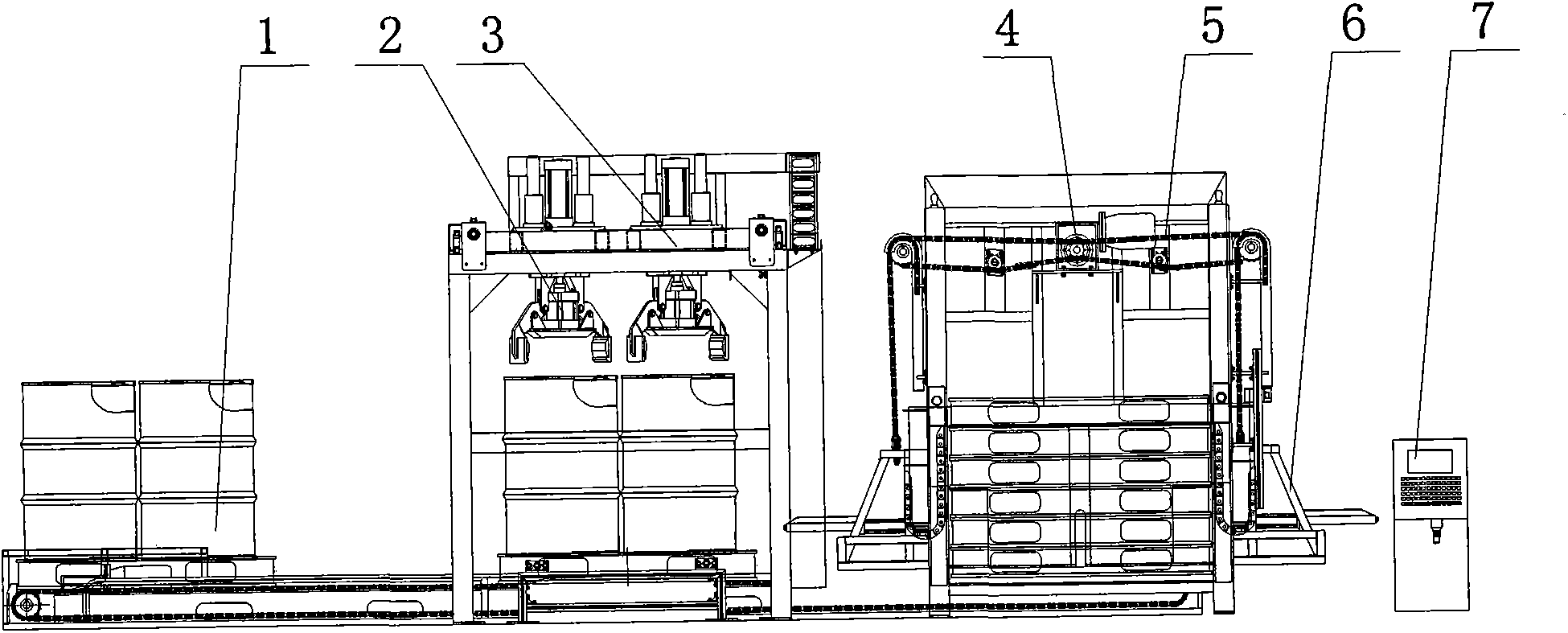

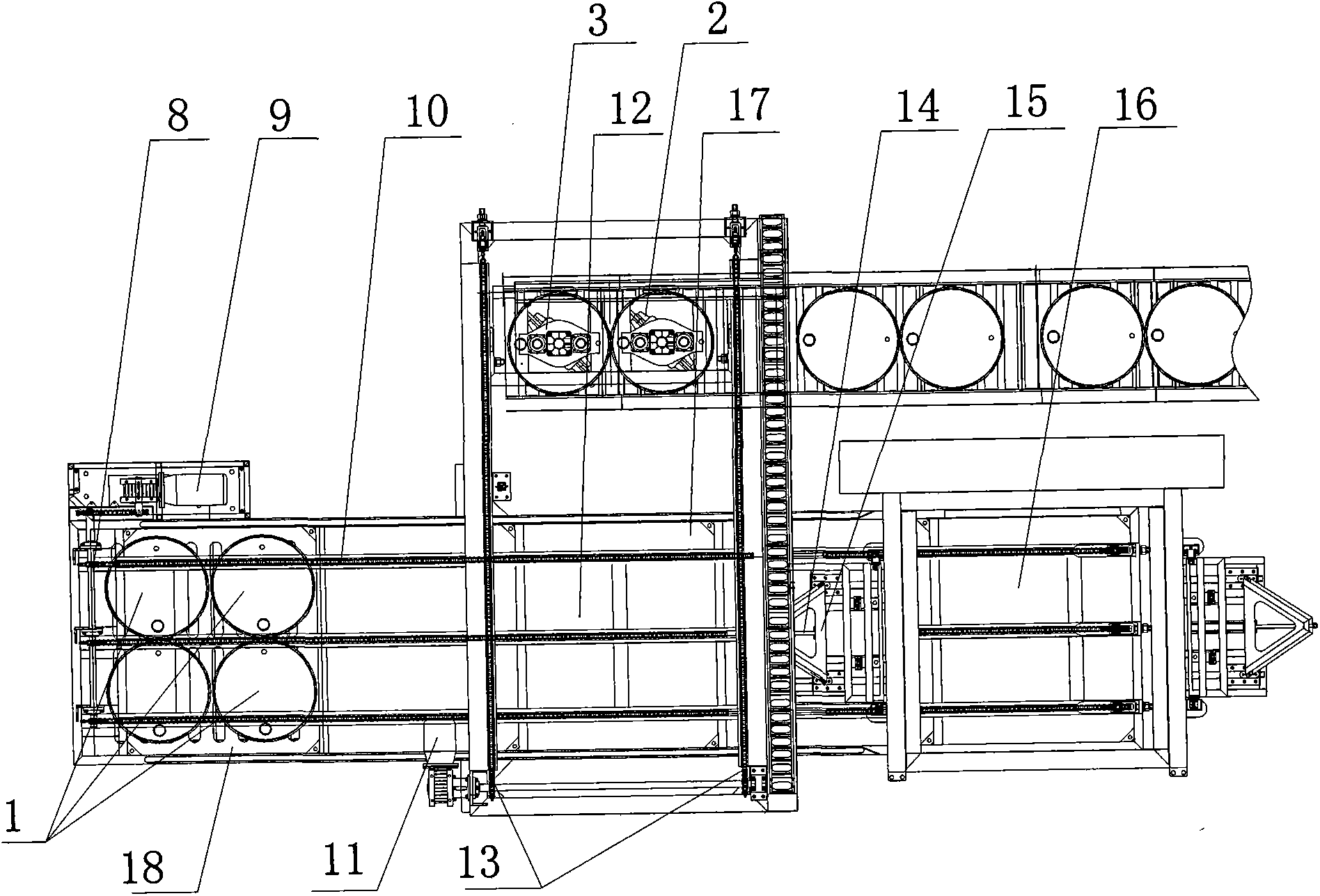

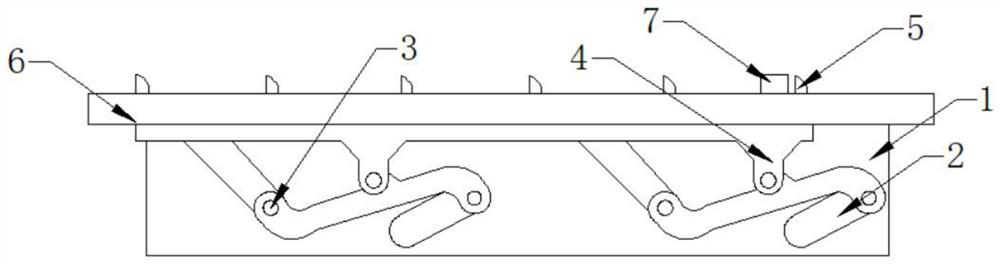

Full-automatic 200L steel drum transfer type stacking system and transfer stacking method thereof

The invention discloses a full-automatic 200L steel drum transfer type stacking system and a transfer stacking method thereof. The system comprises a PLC processing controller used for controlling the full-automatic 200L steel drum transfer type stacking system to automatically operate, and is characterized by further comprising a drum grabbing device used for grabbing a material drum and then placing the material drum into the next procedure, a tray conveying device used for conveying the material drum to the next procedure, and a tray prestoring separation device used for separating the material drum from a tray, wherein the drum grabbing device, the tray conveying device and the tray prestoring separation device are all connected with the PLC processing controller. The full-automatic 200L steel drum transfer type stacking system has the advantages of being free of manual operation, pollution-free, and resistant to corrosion and a high temperature, and achieving unmanned operation of automatic transfer stacking operation on inflammable, highly toxic and highly corrosive operating sites.

Owner:CHANGCHUN BEIFANG INSTR EQUIP

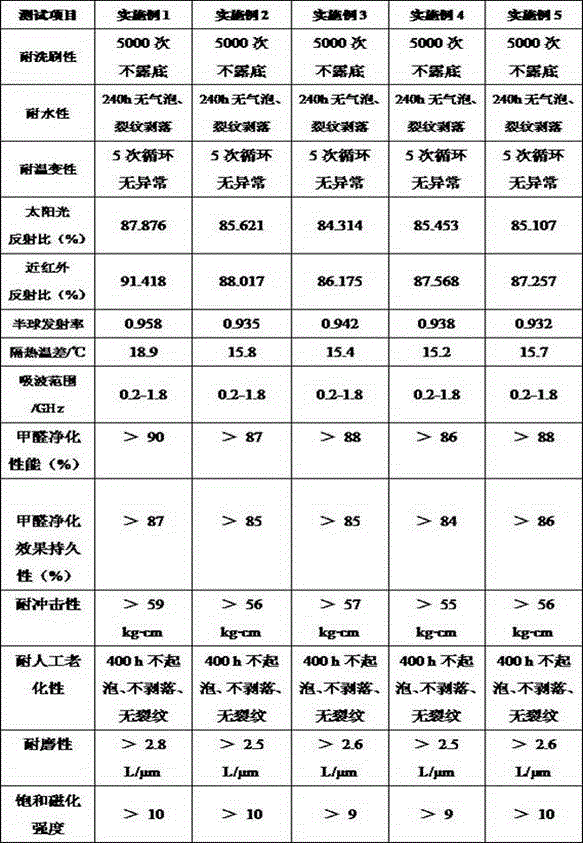

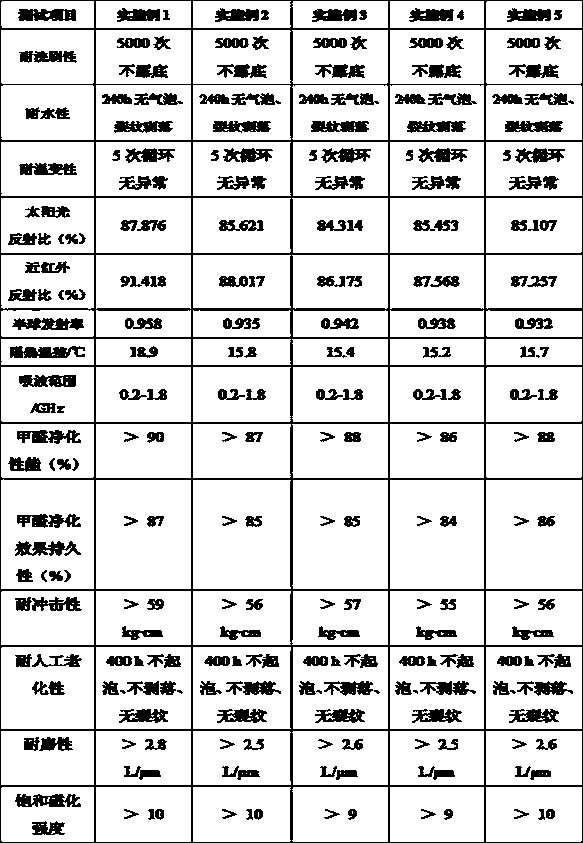

Magnetic sterilizing heat-insulation coating and preparation method thereof

ActiveCN106519854AIncreased versatilityGuaranteed VersatilityFireproof paintsAntifouling/underwater paintsEnvironmental resistanceFiber

The invention discloses a magnetic sterilizing heat-insulation coating and a preparation method thereof. The magnetic sterilizing heat-insulation coating is prepared from, by weight percent, 15-30% of acrylic emulsion, 8-15% of hollow glass beads, 8-18% of magnetic-wave absorbing-sterilizing assistant, 8-18% of SiO2 based heat insulation composite fiber, 5-10% of rutile titanium dioxide, 5-10% of sea-foam stone powder, 5-10% of calcined kaolin, 1-2% of dispersing agent, 1-2% of anti-foaming agent, 2-5% of thickening agent, and 15-30% of water. Through nanometer modified technology, the magnetic-wave absorbing-sterilizing assistant and the SiO2 based heat insulation composite fiber are introduced to a heat-insulation coating domain, thus the multifunctional property of the heat-insulation coating is significantly widened; the coating has relatively ideal heat insulation effect while is toxic-free, odor-free, magnetic, wave-absorbable, green and environment-friendly, sterilized, self-cleaning, fire-proof and flame-retarding, and heat-resisting, and other functions; besides, the magnetic sterilizing heat-insulation coating has good market application prospect in the field of internal and external wall coatings of a building.

Owner:UNIV OF JINAN

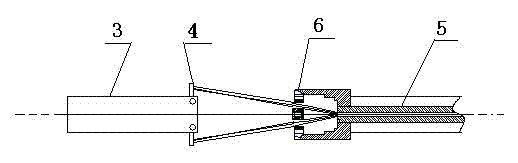

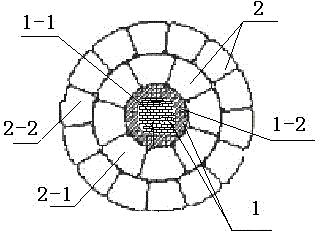

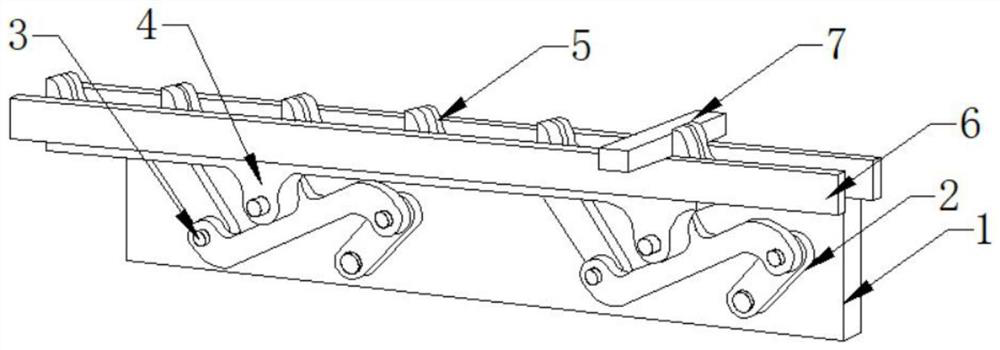

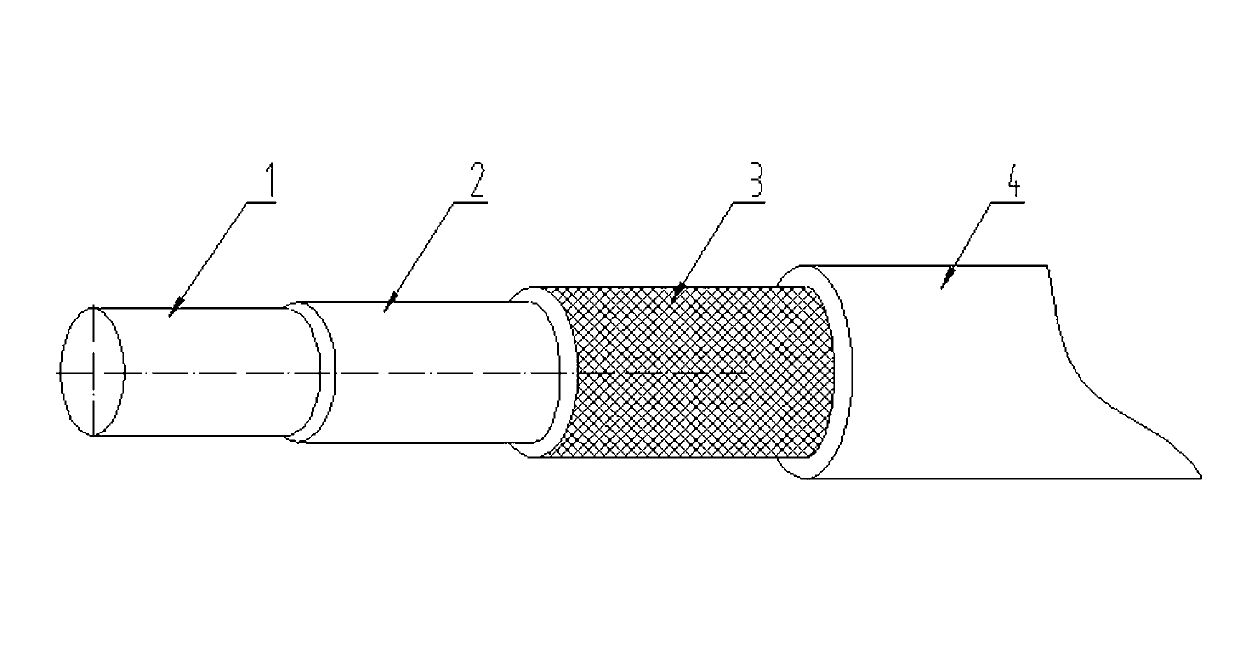

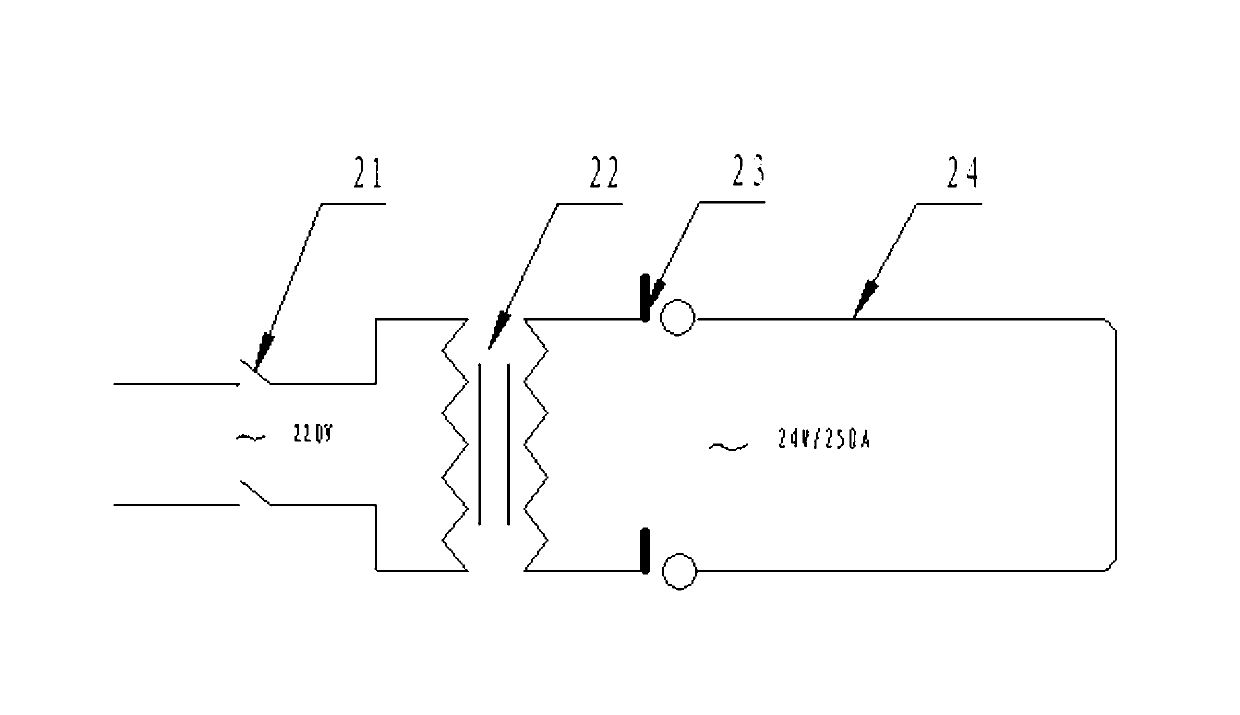

Carbon fiber composite material cable and preparation method of cable core thereof

ActiveCN102810346AImprove straightnessGuaranteed tensionNon-insulated conductorsPower cablesFiberGlass fiber

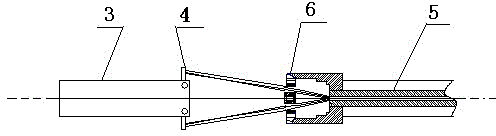

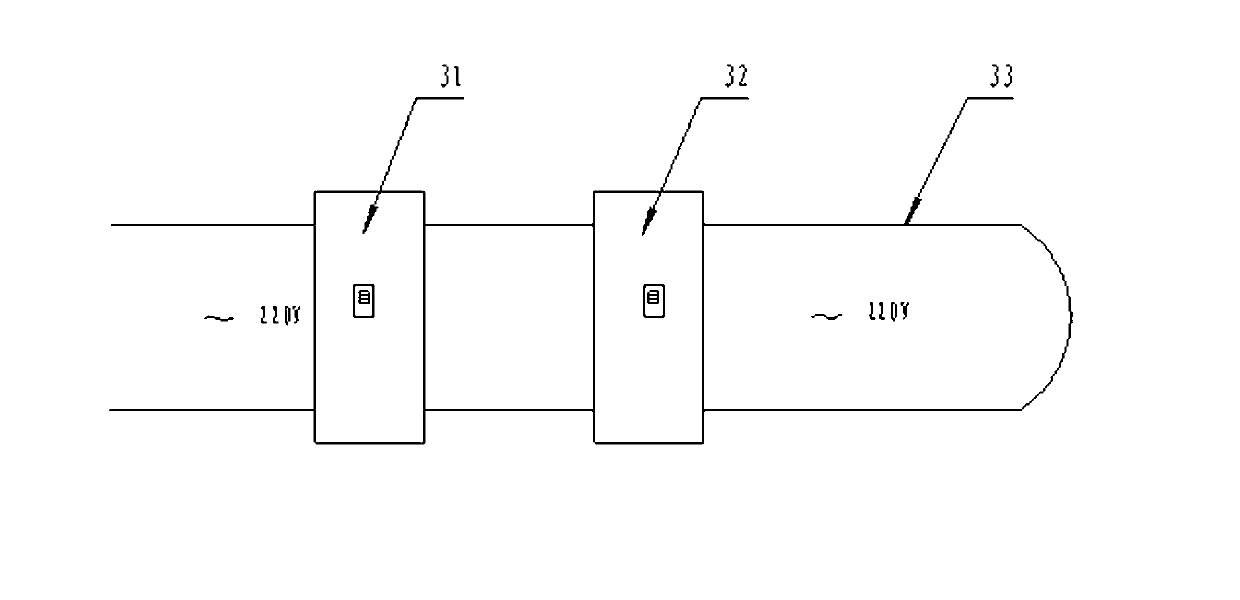

The invention discloses a carbon fiber composite material cable and a preparation method of a cable core of the carbon fiber composite material cable. The preparation method comprises the following steps: testing and adjusting the tensile forces of carbon fibers and glass fibers; dewatering; pulling the carbon fibers into a procuring die (3) by infiltrating adhesive in a constant temperature adhesive groove; operating the glass fibers to pass through a rectangular splitting plate (4); pulling the carbon fibers into a curing die (5); feeding the glass fibers through a planar guide plate (6), and then puling into the curing die (5) so as to wrap the surrounding parts of the carbon fibers with the glass fibers, thus obtaining the carbon fiber composite material cable core. The method provided by the invention has high operability and relatively high production efficiency, can saves large amount of manpower and materials, and has low cost of production; and the carbon fiber composite material cable core prepared by the method has relatively high linearity, high roundness, no eccentricity, no bending, and high consistency in color; and as the detecting results shown, the carbon fiber composite material cable core has the advantages of high temperature resistance, lower energy consumption, long service life, no eccentricity, and good performance.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

Method for preparation of graphite surface silicon carbide coating

The invention discloses a method for preparation of a graphite surface silicon carbide coating. The method includes: mixing 99.99% of a graphite material with silane in a weight ratio of 1:1 to prepare a graphite-silane mixed material, then conducting furnace pretreatment, energization warming, secondary warming and heat preservation, third warming and heat preservation, fourth warming and heat preservation, and cooling. Specifically, nitrogen charging is carried out during the furnace pretreatment and the energization warming, and charging of a nitrogen-hydrogen mixed gas is performed during the fourth warming and heat preservation. A graphite carbon material workpiece treated by the method can endure a high temperature up to 1600DEG C, is not oxidized below 2000DEG C under an aerobic state, and can resist corrosion of various acid and alkali salts.

Owner:QINGDAO TIANDI CARBON

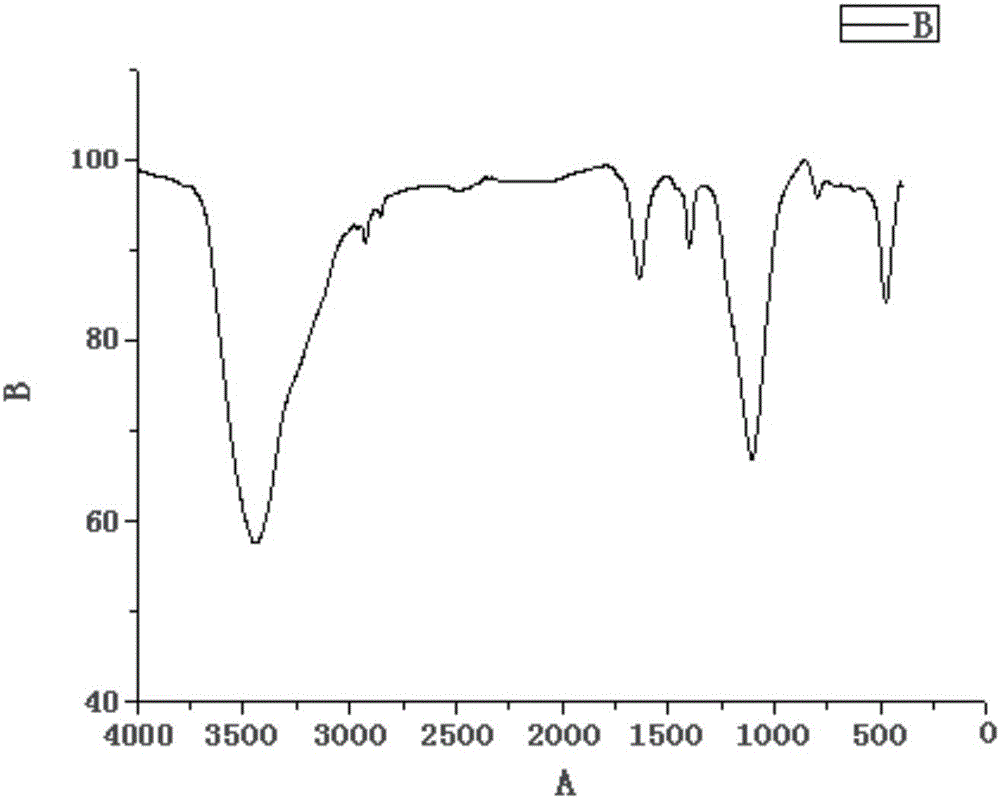

Method for relieving shrinkage of alkali slag binding material

ActiveCN106431037ASmall shrinkageNo high temperature resistanceCement productionSlagMaterial technology

Provided is a method for relieving shrinkage of an alkali slag binding material. The invention relates to the method for relieving the shrinkage of the binding material, and aims to solve the problems that the shrinkage of the alkali slag binding material is big and the application and popularization of the alkali slag binding material are limited. On the premise that high strength and good resistance to high temperature of the alkali slag binding material are not influenced, the method for relieving the shrinkage of the alkali slag binding material is achieved. The method comprises the steps of conducting preparatory work; preparing neat paste of the alkali slag binding material; conducting sample maintaining; conducting sample crushing; preparing a component of the alkali slag binding material. The method for relieving the shrinkage of the alkali slag binding material is used in the technical field of civil engineering materials.

Owner:HARBIN INST OF TECH

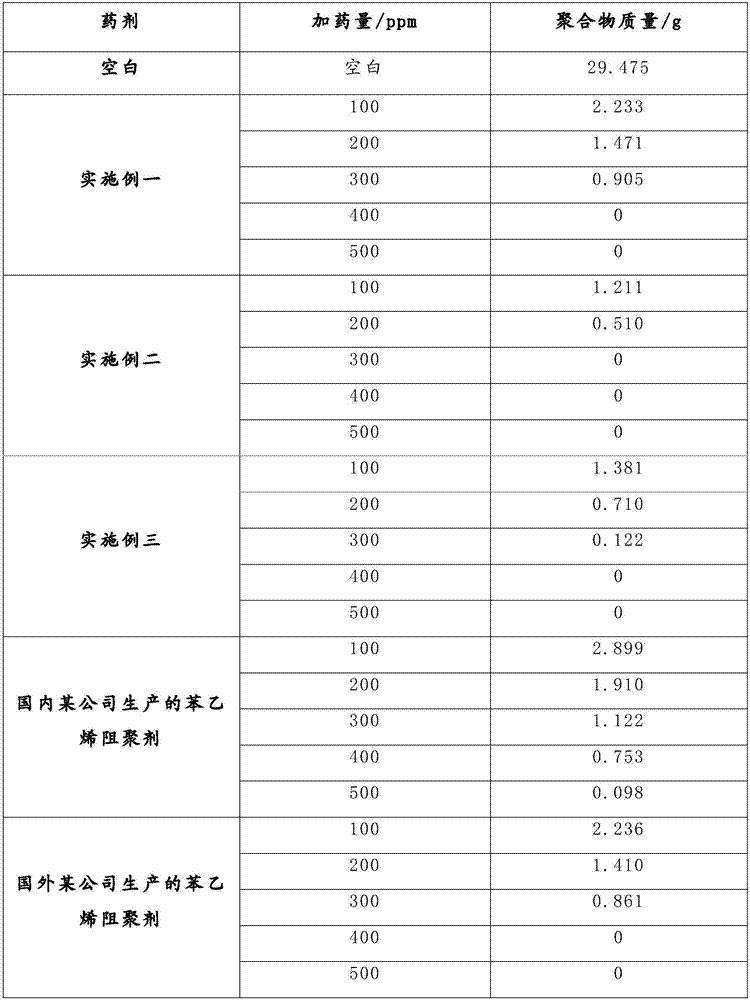

Hydroxypropyl hydroxylamine and synthesizing method thereof

InactiveCN106957240AAvoid cloggingNo high temperature resistanceHydrocarbon purification/separationHydrocarbonsHydroxylamineOrganic synthesis

Owner:威海翔泽新材料科技有限公司

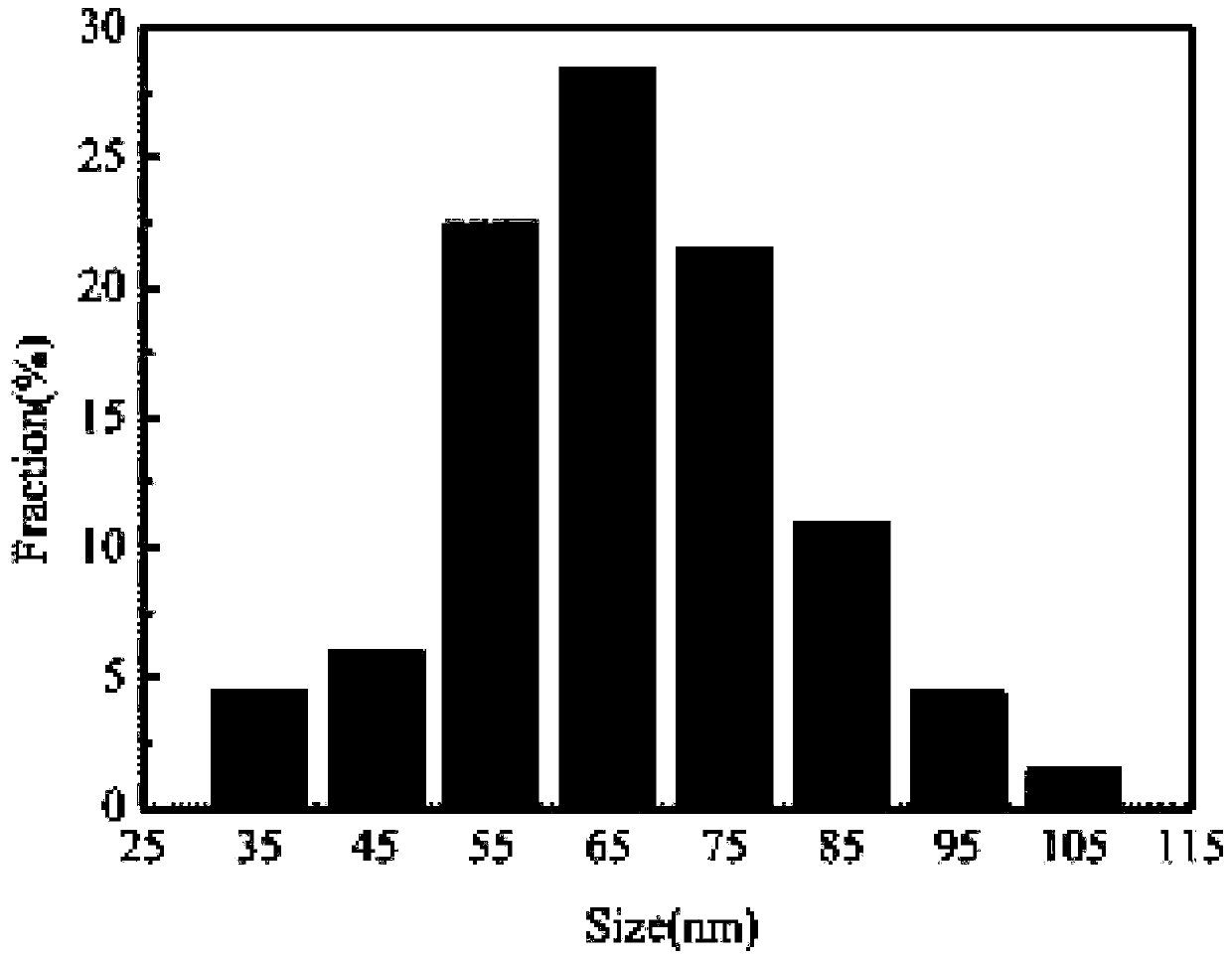

Nano-material with air purifying function and preparation method thereof

The invention provides a nano-material with an air purifying function and a preparation method thereof, belonging to the technical field of nano-materials. The nano-material with the air purifying function comprises the following raw materials by weight: 60 to 80 parts of a polyurethane high-polymer material, 9 to 15 parts of quartz stone flour, 10 to 14 parts of ethyl stearate, 5 to 15 parts of palmitic acid, 2 to 4 parts of nanometer silica, 2 to 4 parts of nanometer calcium carbonate, 10 to 16 parts of nanometer titanium dioxide, 3 to 5 parts of a stabilizing agent additive, 0.5 to 0.9 part of a coupling agent, 0.3 to 0.7 part of an anti-oxidant and 0.4 to 0.8 part of a foaming agent. The preparation method comprises the following steps: (1) weighing of the raw materials; (2) preparation of a mixture a; (3) preparation of a mixture b; (4) preparation of a mixture c; and (5) charging of a mold and molding. The nano-material prepared in the invention has the advantages of high strength, good heat insulation performance and air purifying performance.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

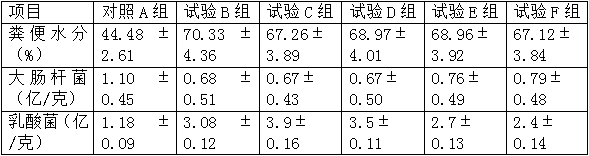

Special anaerobic biological fermented feed for pregnant swine and preparation method

The invention discloses a special anaerobic biological fermented feed for pregnant swine. The feed mainly comprises bran, soybean hulls, sugar beet pulp and lactobacillus and belongs to the technicalfield of animal nutrition and feeds; the feed disclosed by the invention is particularly suitable for the pregnant swine, not only takes an obvious effect on the intestinal constipation problem of thepregnant swine, but also can effectively prevent a series of complications caused by constipation of the pregnant swine and supplement nutrients for intestinal canals of the pregnant swine.

Owner:日照普惠动物营养科技有限公司

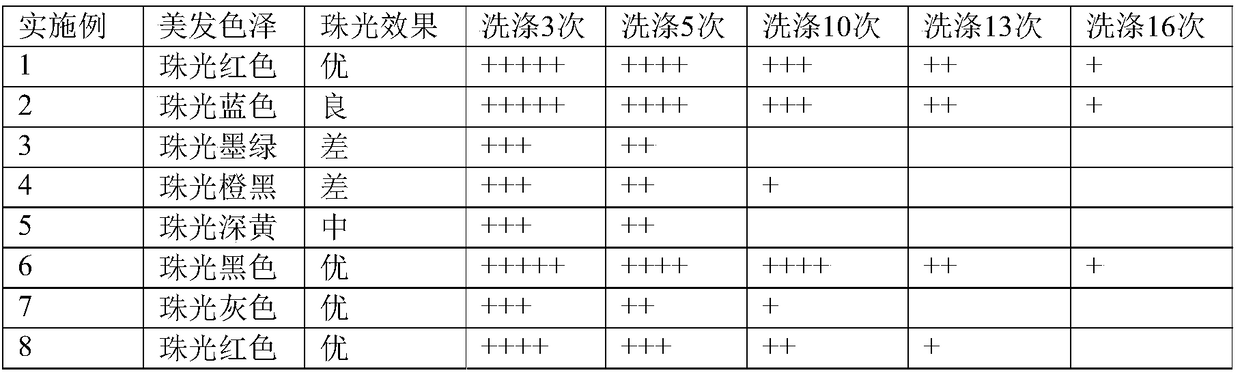

Graphene hair dyeing agent composition containing mica iron pearlescent pigment

InactiveCN109453046AEliminates cancer riskEliminate pollutionCosmetic preparationsHair cosmeticsChemical synthesisWater resistant

The invention discloses a graphene hair dyeing agent composition containing mica iron pearlescent pigment, and relates to the technical field of hair dyeing agents. The graphene hair dyeing agent composition comprises a first agent and a second agent, wherein the first agent is prepared from the mica iron pearlescent pigment, graphene and alginate; the second agent is prepared from polyvalent metal salt and boric acid. The graphene hair dyeing agent composition has the advantages that the mica iron pearlescemt pigment, the graphene and the alginate belong to green materials, and contain no harmful chemical compound; the organosilicone synthesizing process is avoided, the organosilicone derivative is not contained, the technology is simple, and the pollution to environment is avoided; by adding the boric acid into the second agent, proofed by experiment, the water-resistant property and detergent-resistant property are obviously improved, and better practicality is realized.

Owner:QINGDAO UNIV

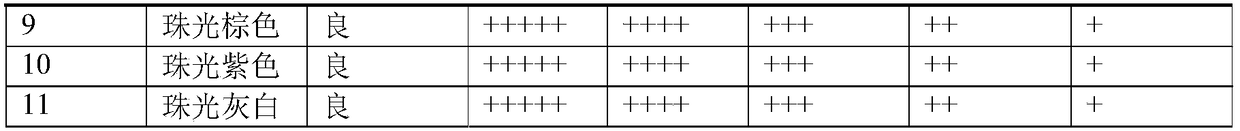

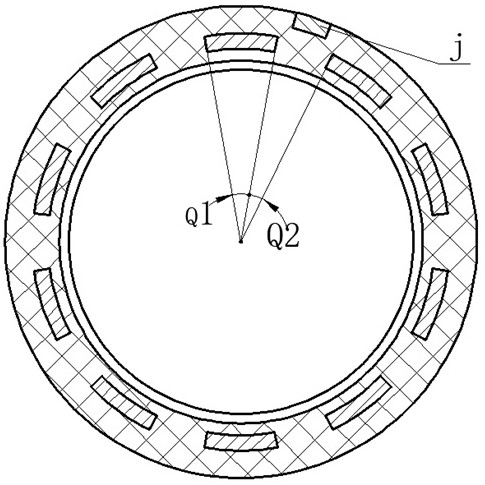

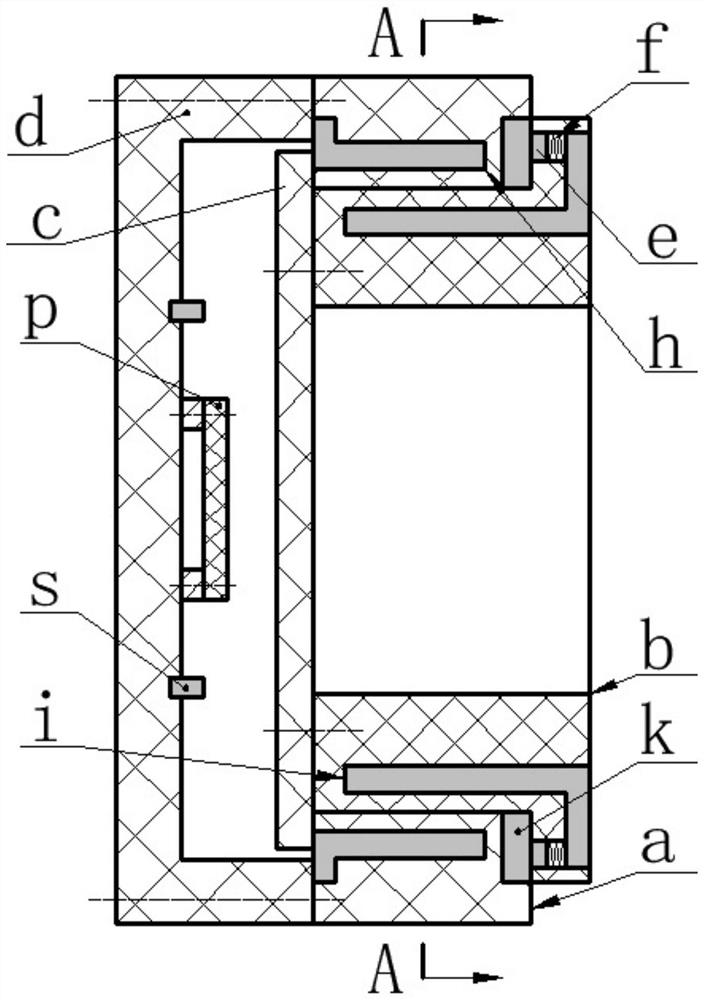

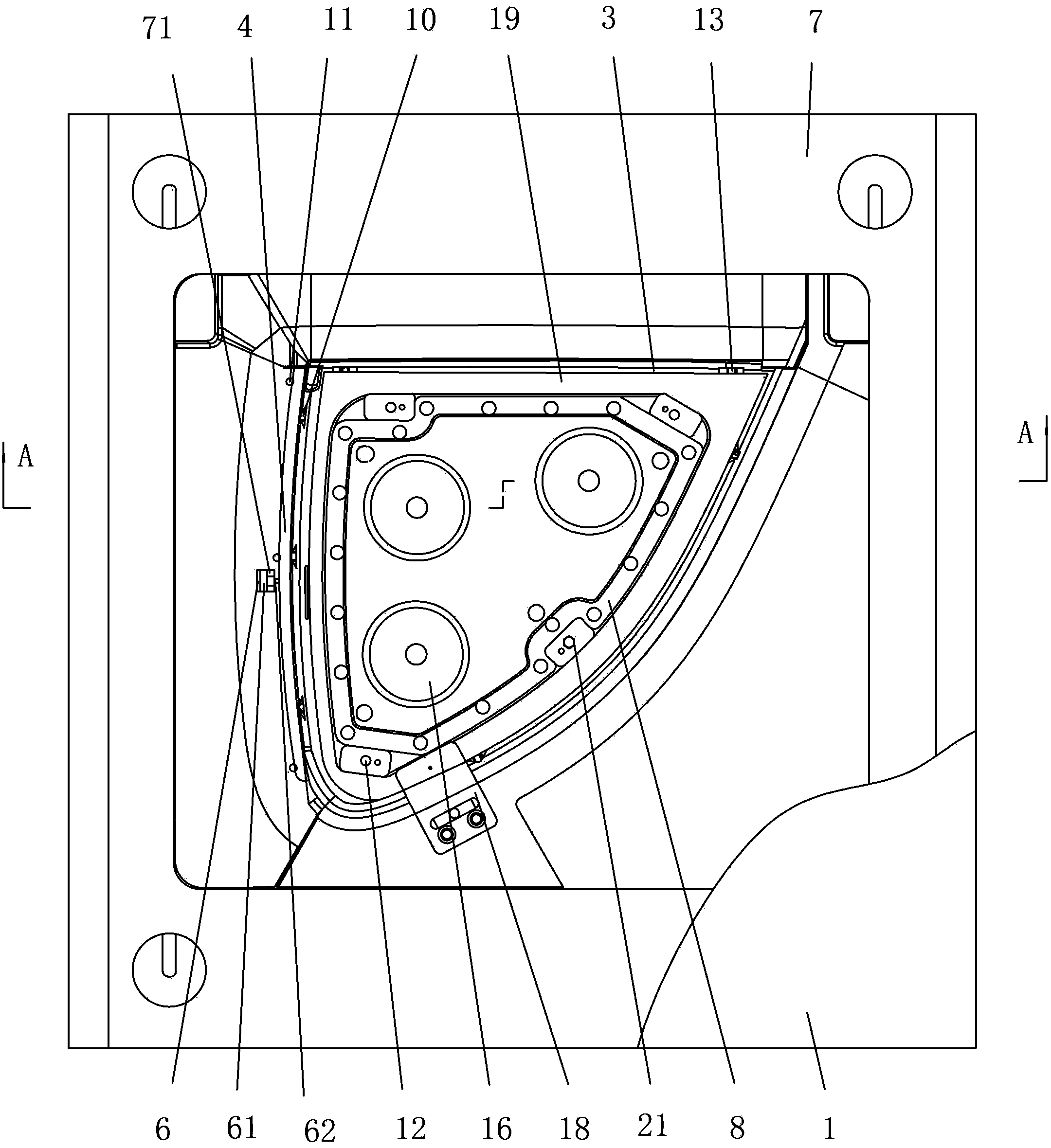

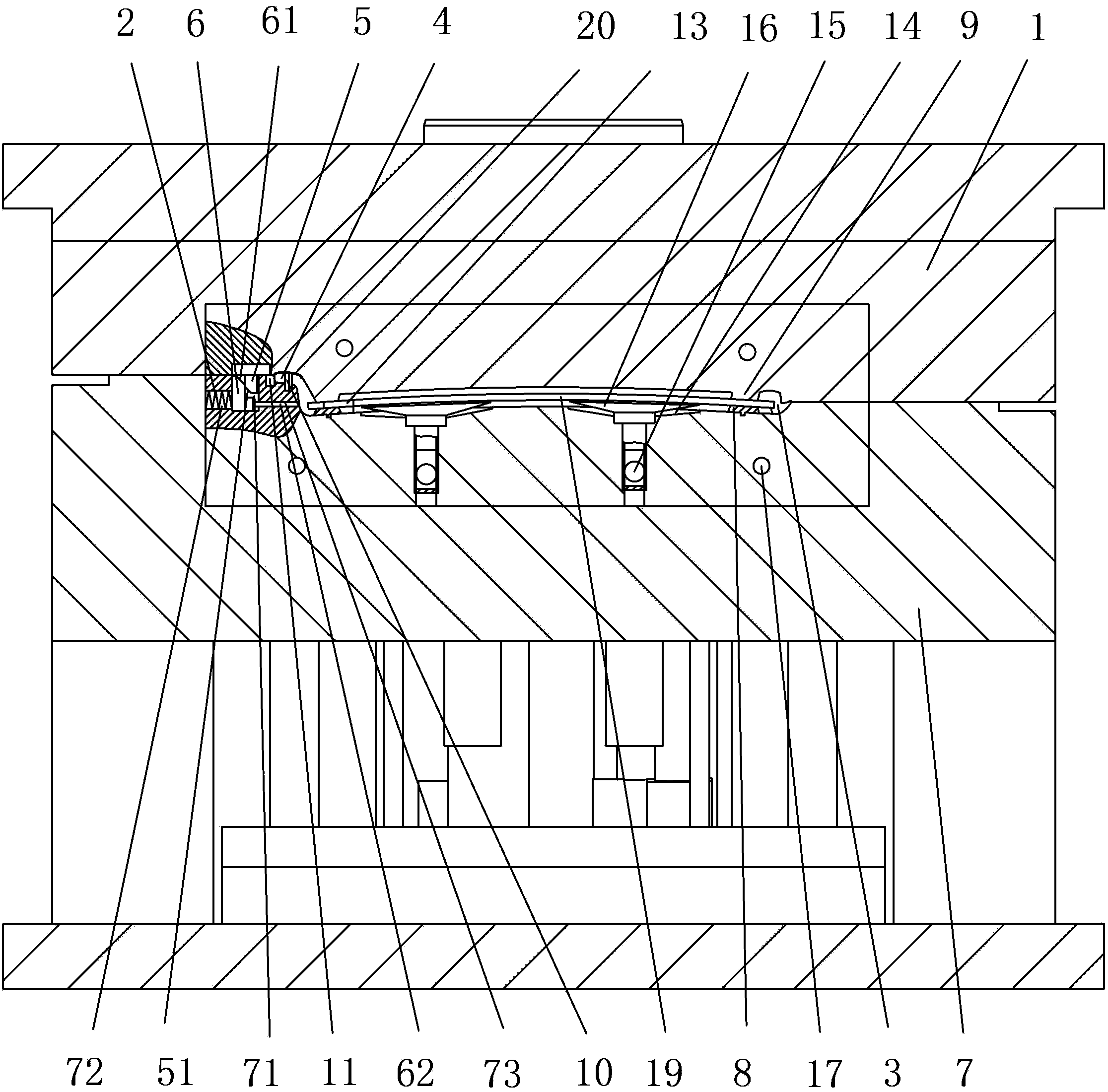

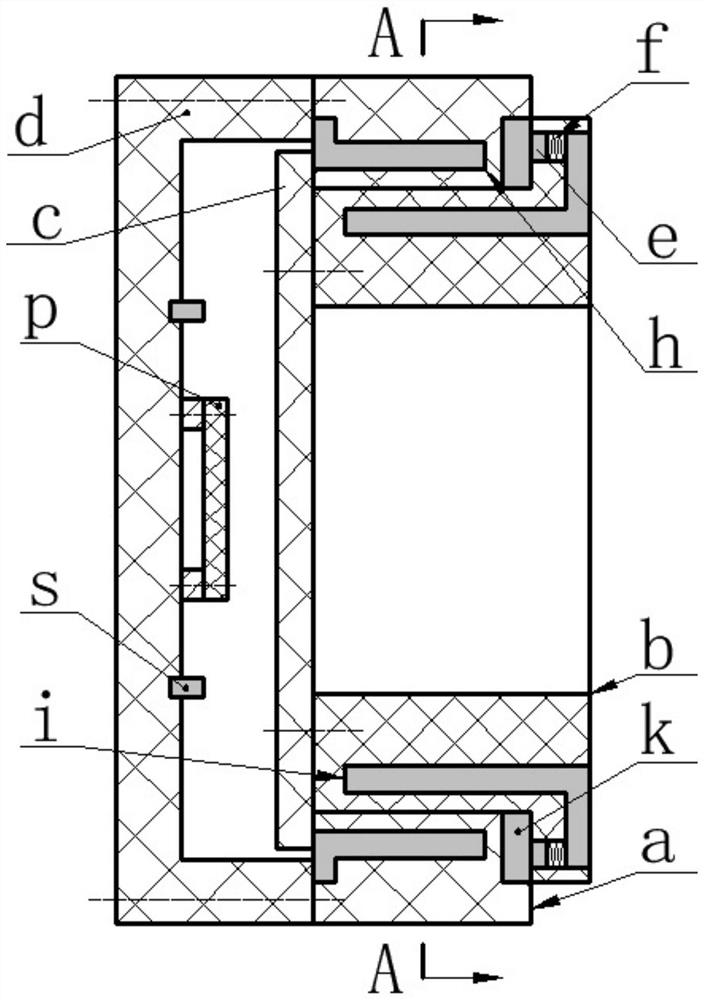

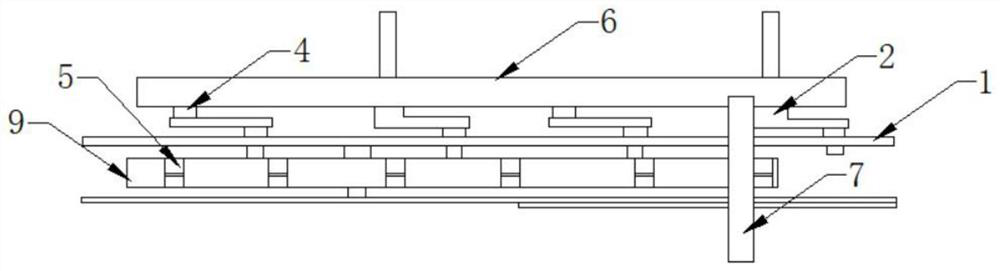

Roller bearing capable of realizing self-power-generation monitoring

ActiveCN112747032ASimple structureReduce volumeRoller bearingsBearing assemblyAuxiliary electrodeElectric energy

The invention relates to a roller bearing capable of realizing self-power-generation monitoring, and belongs to the technical fields of bearing monitoring and new energy. An outer ring is arranged on an inner ring, a shell bottom is arranged at the end part of the outer ring, a circuit board, a sensor and a binding post are arranged on the shell bottom, an auxiliary electrode is arranged on the shell bottom or the outer ring, and the sensor, the binding post and the auxiliary electrode are connected with the circuit board through different conductive wire groups; an electrode is arranged in the outer ring, the outer ring is of a split structure or an integral structure, the electrode is composed of an electrode ring, electrode fingers and a lead terminal, the electrode ring and the electrode fingers are embedded in the outer ring, and rollers are not overlapped with the electrode ring in the length direction and is completely overlapped with the electrode fingers; different friction charges can be generated in the rolling contact process of the rollers and the outer ring, and the rollers are alternately overlapped with and separated from the electrode fingers in the rolling process, so that the potential difference between the rollers and the electrode fingers is alternately increased and decreased, and then mechanical energy is converted into electric energy; and the generated electric energy is supplied to the sensor and a transmitting unit on the circuit board after being processed by a conversion circuit on the circuit board.

Owner:ZHEJIANG NORMAL UNIVERSITY

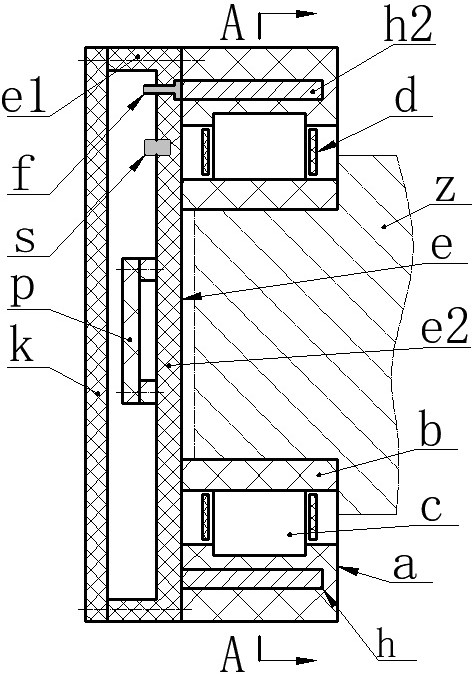

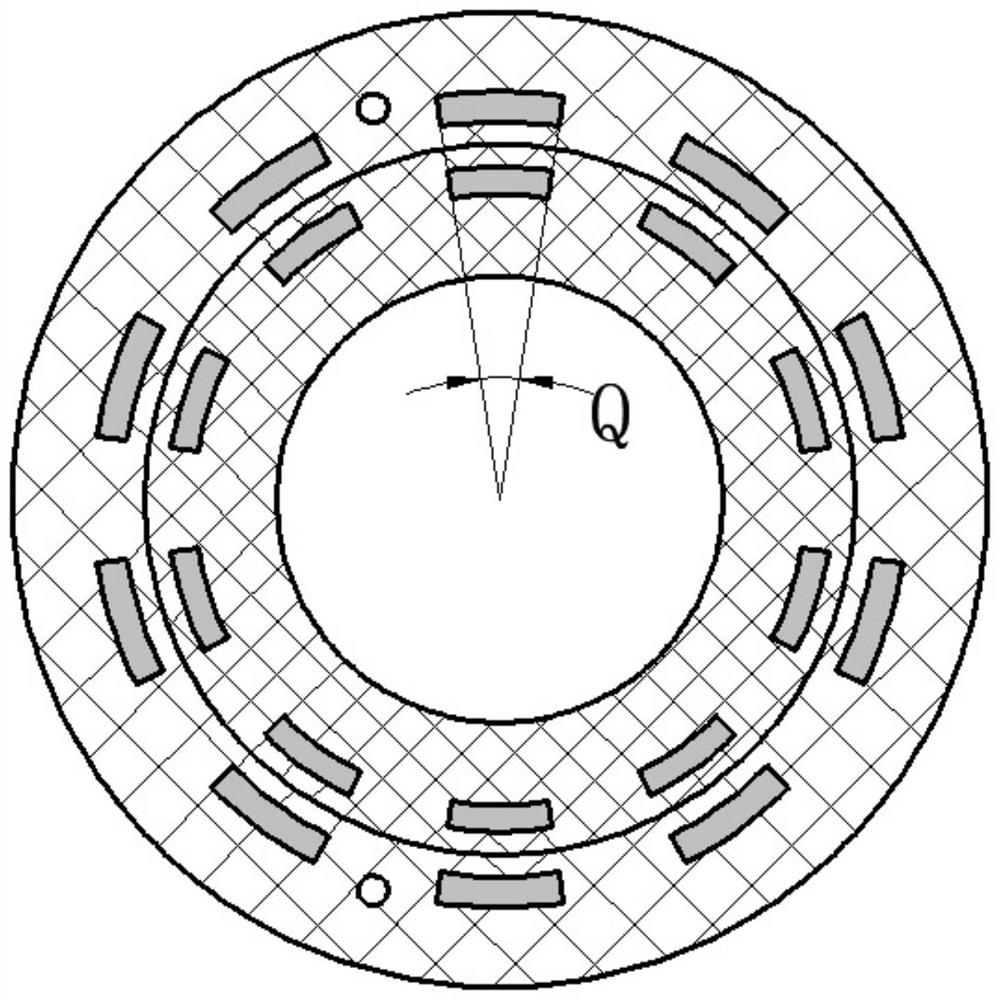

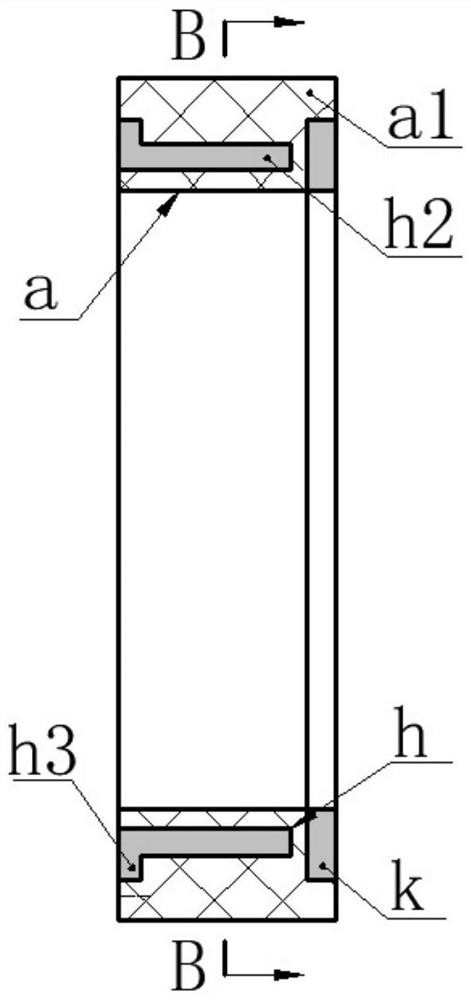

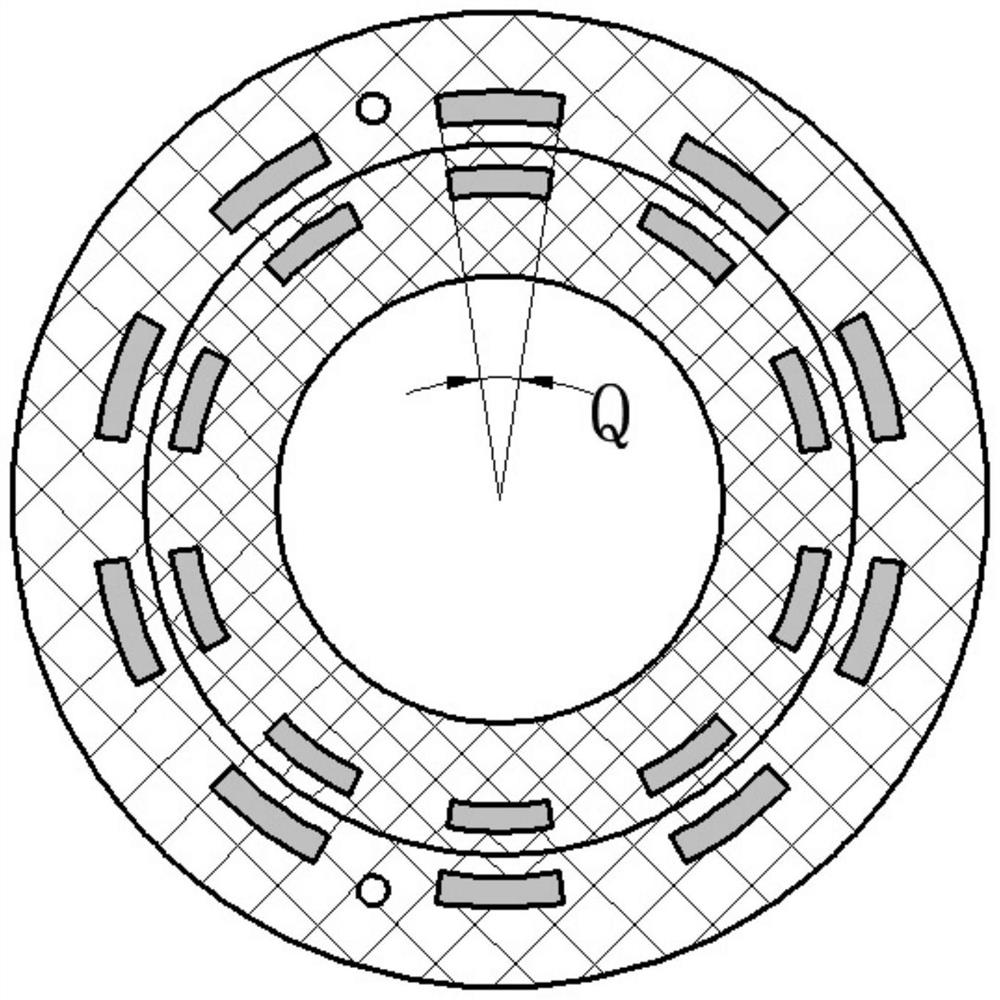

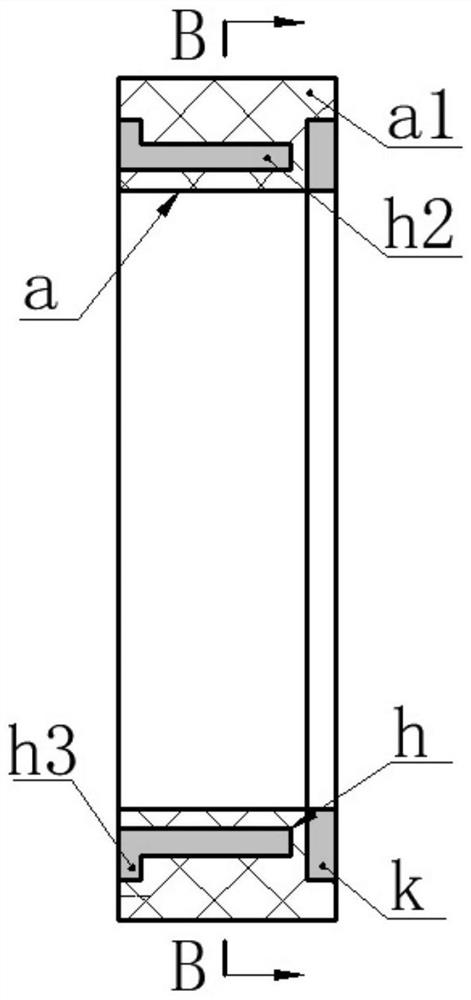

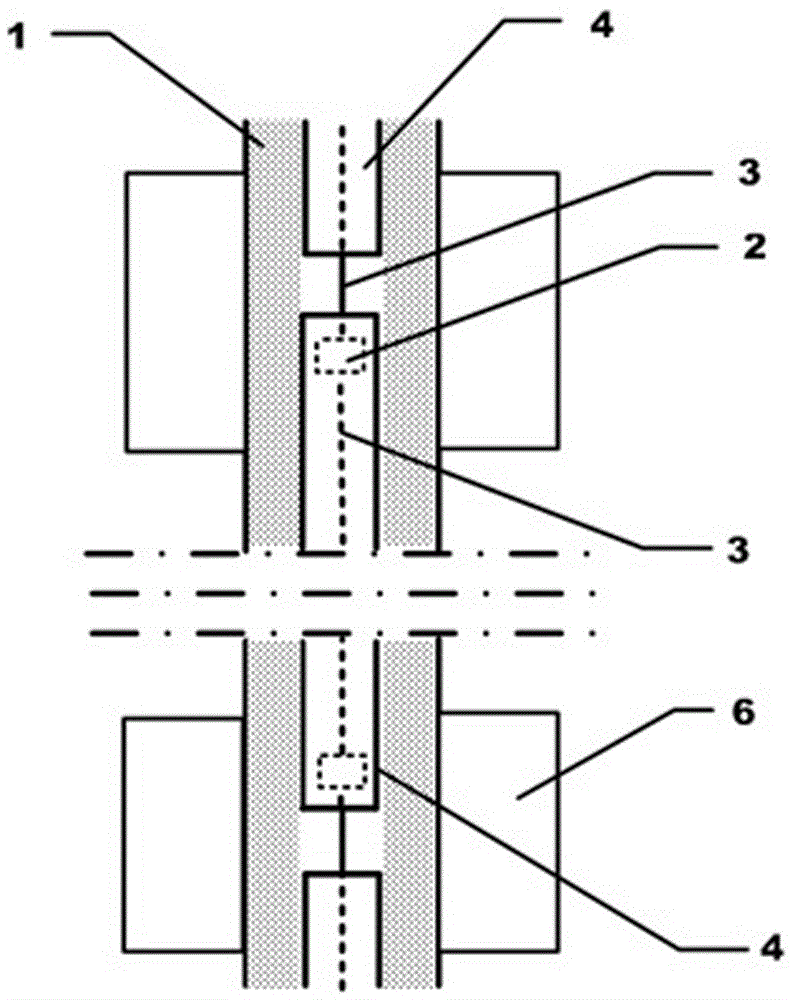

Sliding bearing

ActiveCN112747031ASimple structureReduce volumeBearing componentsSliding contact bearingsNew energySlider bearing

The invention relates to a sliding bearing, and belongs to the technical fields of bearing monitoring and new energy. The sliding bearing comprises an inner ring, an outer ring, a baffle, a shield, a sensor and a circuit board, wherein the outer ring is composed of an outer ring body and an outer electrode, the outer electrode is composed of an outer electrode ring, outer electrode fingers and an outer terminal, and the outer electrode fingers are arranged in the outer ring body; the inner ring is composed of an inner ring body and an inner electrode, the inner electrode is composed of an inner electrode ring and inner electrode fingers, the inner electrode fingers are arranged in the inner ring body, and the electrode ring is in sliding contact with the inner electrode ring through a conductive block; the inner electrode fingers and the outer electrode fingers are equal in number and central angle; the inner ring and the outer ring are made of two kinds of high polymer materials with friction electricity sequences far away from each other, inductive charges with different attributes are arranged between contact surfaces in the relative rotation process of the inner ring and the outer ring, and potential difference is generated between the adjacent inner electrode finger and outer electrode finger in the two circumferential directions; and the inner electrode fingers and the outer electrode fingers are alternately overlapped and separated in the circumferential direction, so that the potential difference between the inner electrode and the outer electrode is alternately increased and decreased, mechanical energy is converted into electric energy, and the generated electric energy is supplied to a sensor and an information transmitting system after being treated.

Owner:ZHEJIANG NORMAL UNIVERSITY

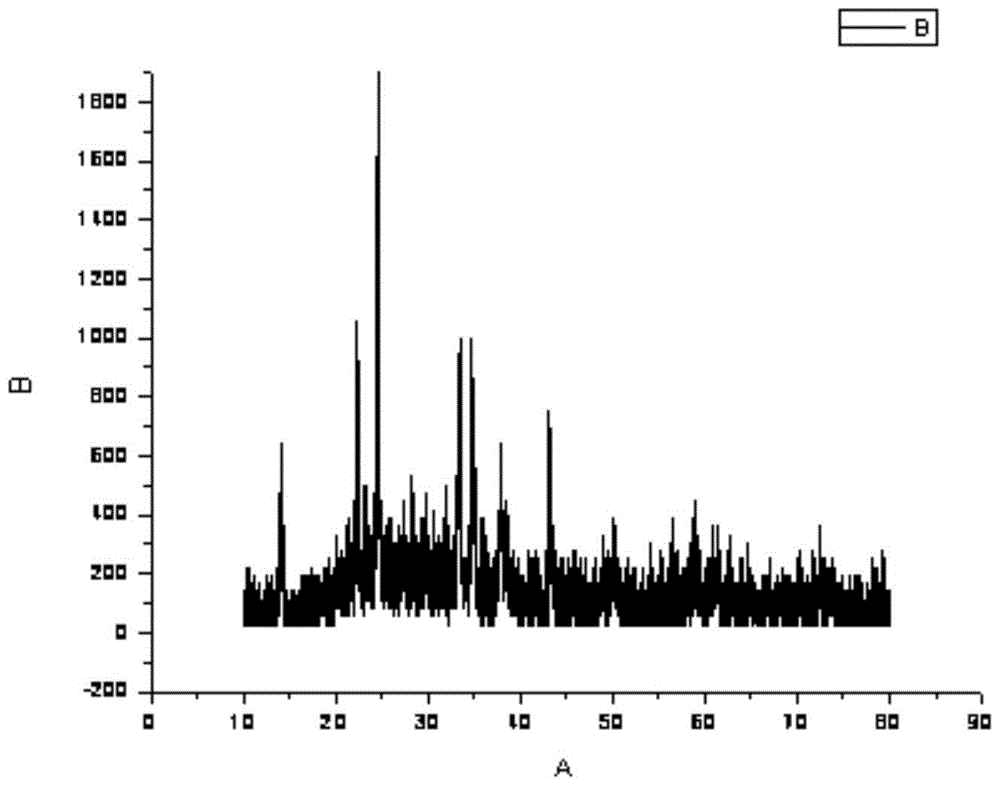

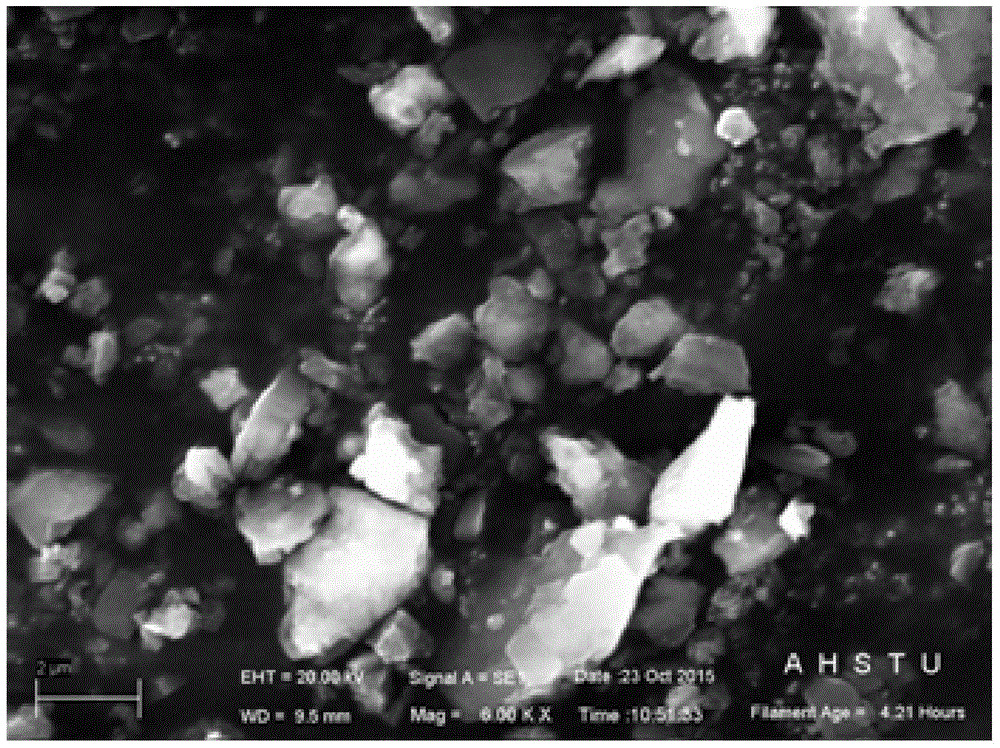

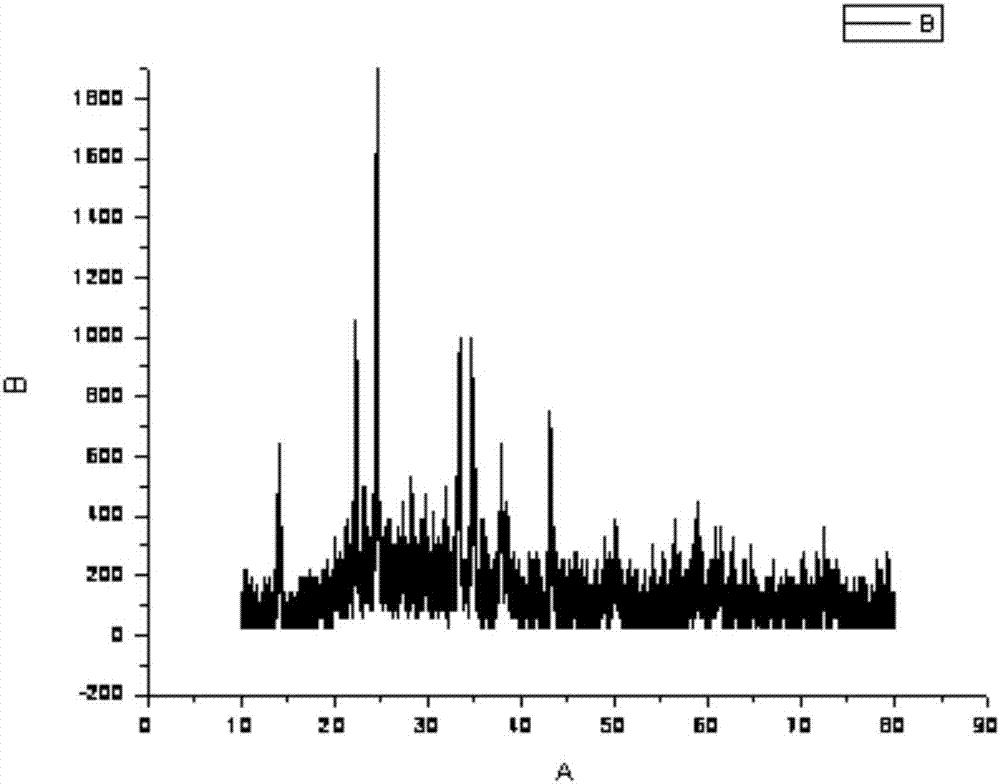

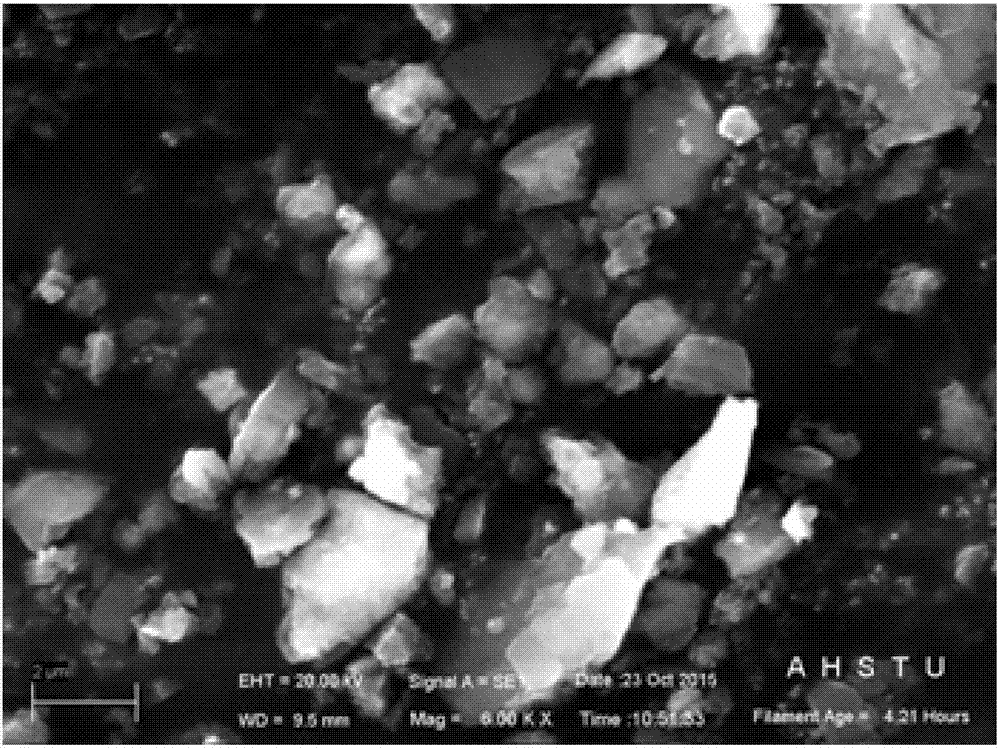

Method for preparing high-purity silicon by energy-saving and environmental protection technology

ActiveCN105668572AReduce energy consumptionThe preparation process is simpleChemical industrySilicon compoundsThermal insulationCarbon black

A method for preparing high-purity silicon by an energy-saving and environmental protection technology comprises the following steps: uniformly mixing quartz sand or white carbon black and a reducing agent according to the weight ratio of (0.8-1.2): (1.2-1.6) to obtain a mixture, putting the mixture into a heating furnace with furnace chamber volume being 10-30 liters; spraying carbon powder of 100-325 meshes onto the surface of the mixture with the mass ratio of the carbon power to the mixture being (0.1-0.5): (2.0-2.8); heating the furnace chamber of the heating furnace to 200-260 DEG C for 0.5-1 h, and carrying out thermal insulation for 1-2h; heating the furnace chamber of the heating furnace to 300-400 DEG C for 0.5-1 h, and carrying out thermal reaction for 3-6 h to obtain a reaction product; cooling the reaction product to room temperature, washing the reaction product with normal-temperature distilled water for several times to obtain a washed product; and drying the washed product at the temperature of 90-110 DEG C to obtain elemental silicon. The method is green and environmentally friendly, has advantages of low energy consumption, simple process, low cost and few and simple equipment, and is easy to use at large scale in the industry. In addition, purity of the prepared elemental silicon is high.

Owner:ANHUI SCI & TECH UNIV

Carbon fiber composite material cable and preparation method of cable core thereof

ActiveCN102810346BLarge capacityReduce energy consumptionNon-insulated conductorsPower cablesFiberGlass fiber

The invention discloses a carbon fiber composite material cable and a preparation method of a cable core of the carbon fiber composite material cable. The preparation method comprises the following steps: testing and adjusting the tensile forces of carbon fibers and glass fibers; dewatering; pulling the carbon fibers into a procuring die (3) by infiltrating adhesive in a constant temperature adhesive groove; operating the glass fibers to pass through a rectangular splitting plate (4); pulling the carbon fibers into a curing die (5); feeding the glass fibers through a planar guide plate (6), and then puling into the curing die (5) so as to wrap the surrounding parts of the carbon fibers with the glass fibers, thus obtaining the carbon fiber composite material cable core. The method provided by the invention has high operability and relatively high production efficiency, can saves large amount of manpower and materials, and has low cost of production; and the carbon fiber composite material cable core prepared by the method has relatively high linearity, high roundness, no eccentricity, no bending, and high consistency in color; and as the detecting results shown, the carbon fiber composite material cable core has the advantages of high temperature resistance, lower energy consumption, long service life, no eccentricity, and good performance.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

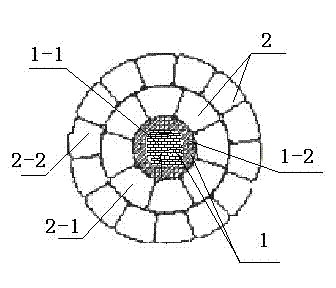

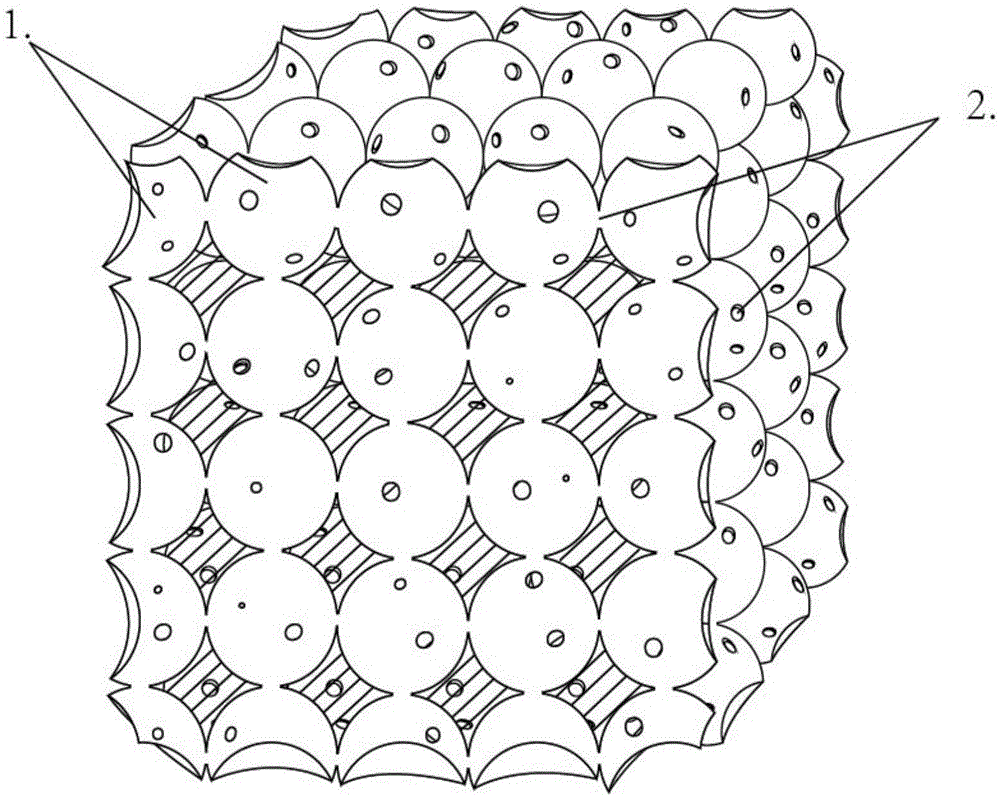

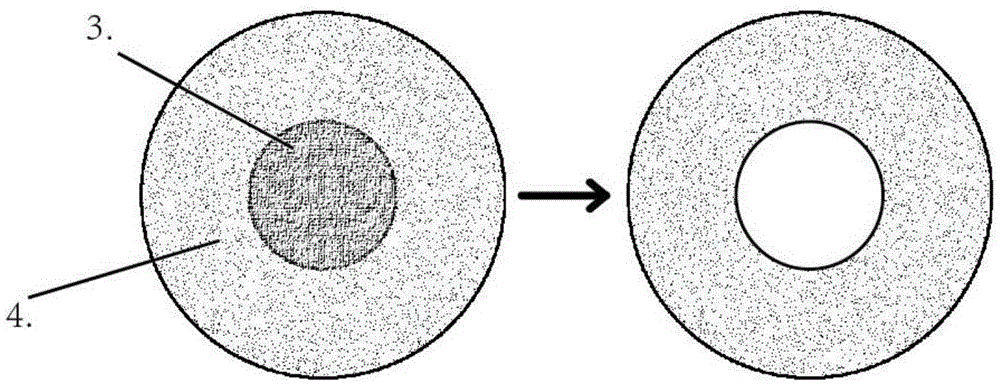

Hollow spherical aluminum foam material and its preparation method and filled sphere used in the preparation

The invention discloses a hollow ball foamed aluminum material, a preparation method of the hollow ball foamed aluminum material and filling spheres used by the preparation method. The hollow ball foamed aluminum material comprises multiple hollow balls which are connected with each other and have individual bubbles and communicated holes are formed between the hollow balls so that an open pore-close pore mixed structure is formed. The preparation method comprises the following steps of preparing the core-shell filling spheres comprising 10-15% of charcoal as a core, 30-45% of sepiolite, 35-40% of sodium bentonite and 10-15% of vermiculite powder as a coating, putting the spheres into a mold so that the spheres are compact, carrying out molten aluminum transfusion according to a weight ratio of the filling spheres to the molten aluminum of 1: 3 to 1: 4, carrying out gas exhaust at the bottom side of the mold by a vacuum pump so that the molten aluminum permeates into gaps between the hollow filling spheres, carrying out cooling, removing the mold, and carrying out cleaning by water to obtain the hollow ball foamed aluminum material. The hollow ball foamed aluminum material solves the problem that the existing material is cleaned difficultly and is heated for a long time, greatly reduces energy consumption and effectively improves anti-compression performances and sound-absorbing effects.

Owner:王宁伟

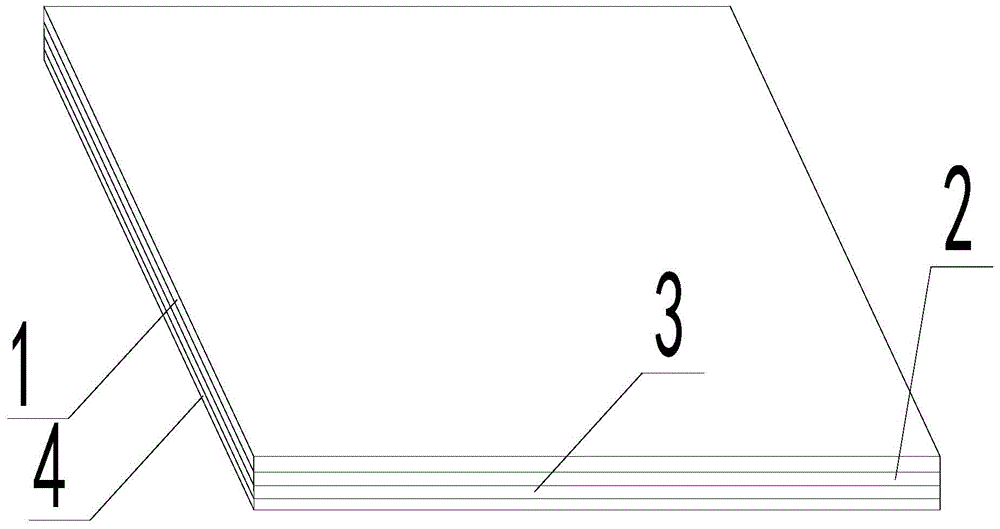

Light-tight polymeric membrane and production method thereof

InactiveCN105196648AReduce entryReasonable designLamination ancillary operationsSynthetic resin layered productsPolyethylene terephthalate glycolPolyethylene terephthalate

The invention provides a light-tight polymeric membrane. The light-tight polymeric membrane comprises a PET (polyethylene terephthalate) layer, wherein a metal plating layer is arranged on one side of the PET layer, a black high polymer material polyvinyl chloride layer with the molecular formula of [-CH2--CHCl-]n is arranged on one side of the metal plating layer, and a high polymer material polyvinyl chloride color layer with the molecular formula of [-CH2--CHCl-]n is arranged on one side of the black high polymer material polyvinyl chloride layer with the molecular formula of [-CH2--CHCl-]n. The light-tight polymeric membrane is reasonable in design and reliable in structure, potential quality problems are avoided, the membrane is totally light-tight, ultraviolet rays prevented, entering heat is reduced, sunlight is reflected, and the membrane has the characteristics of no toxicity, no odor, high temperature resistance, aging resistance, long service life and the like, has different colors and patterns for matching and can be used for spatial decoration in a room.

Owner:瑞年科技(广东)有限公司

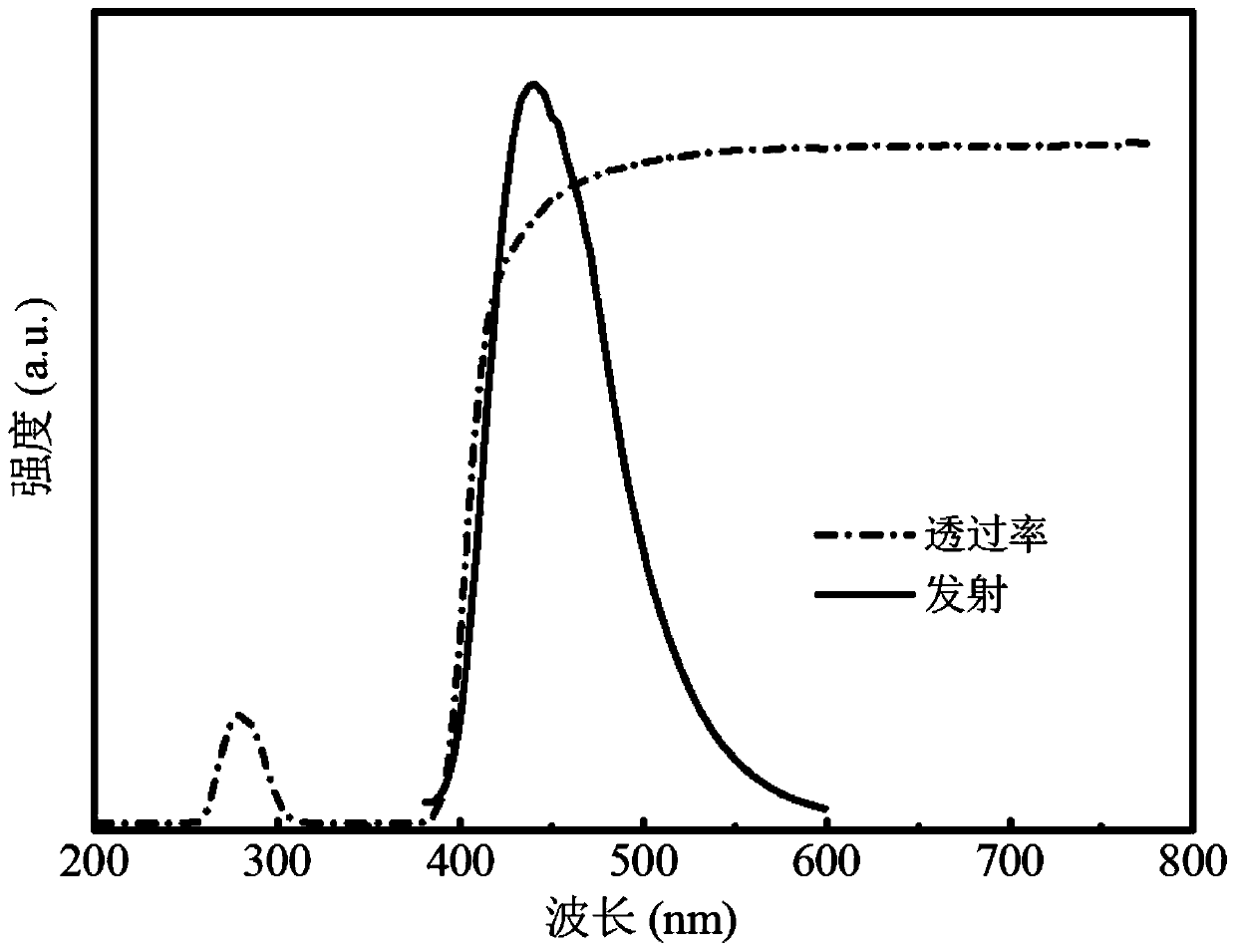

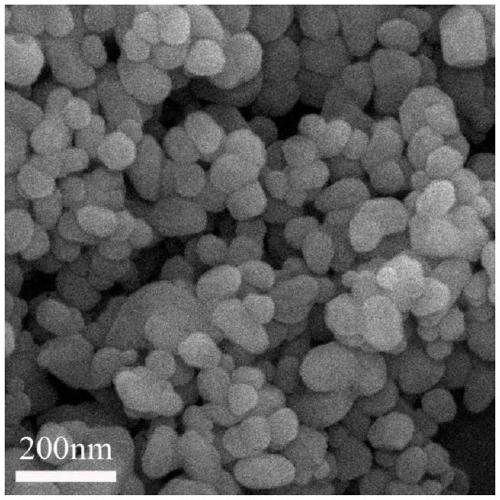

Carbon dot composite nanoparticles, carbon dot/fluoride composite material, preparation method and application

The invention provides carbon quantum dot composite nanoparticles, and a carbon quantum dot / fluoride composite material, a preparation method and applications thereof, wherein carbon quantum dots arecompounded into the interior of fluoride crystals in carbon quantum dot / fluoride composite nanoparticles, such that the carbon quantum dots can achieve the advantages of solid-state light emitting, notoxicity, high-temperature resistance, decomposition resistance and good stability, and can absorb UV and be converted into blue light required for plants. The invention further provides a one-step preparation scheme of the carbon quantum dot / fluoride composite nanoparticles, wherein the one-step preparation scheme has characteristics of simple process and low cost, and is suitable for industrialproduction. The invention further provides a carbon quantum dot / fluoride / polymer composite material, which compounds the carbon quantum dot / fluoride nanoparticles and a polymer material, has high transparency, and further has light conversion, toughening or anti-aging effect, wherein the preparation method is simple and easy-performing, can be used for the preparation of agricultural films or rubber products, and has good industrialization prospect.

Owner:SOUTH CHINA AGRI UNIV

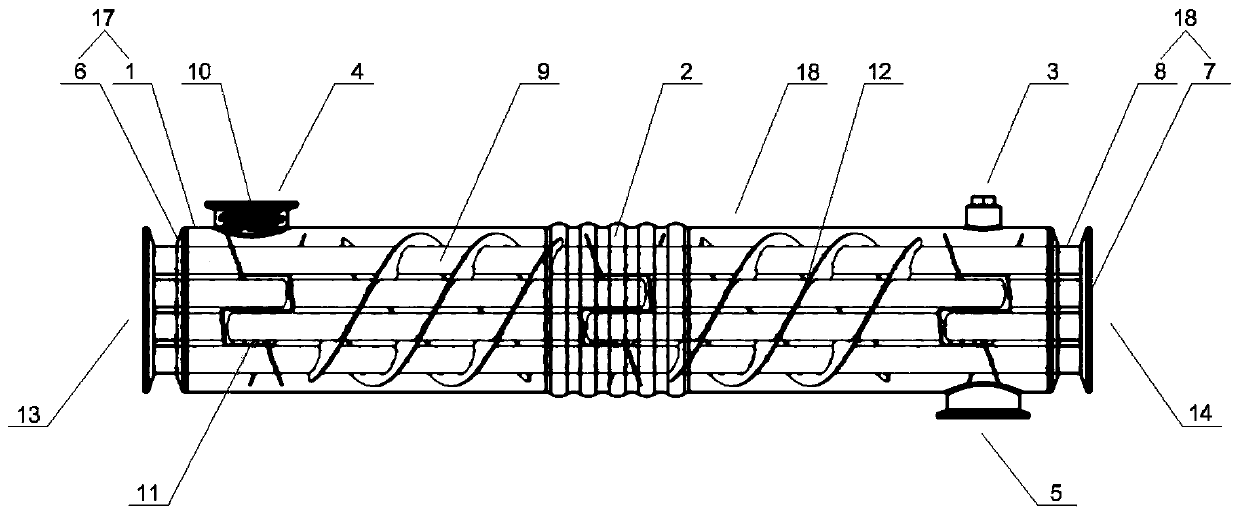

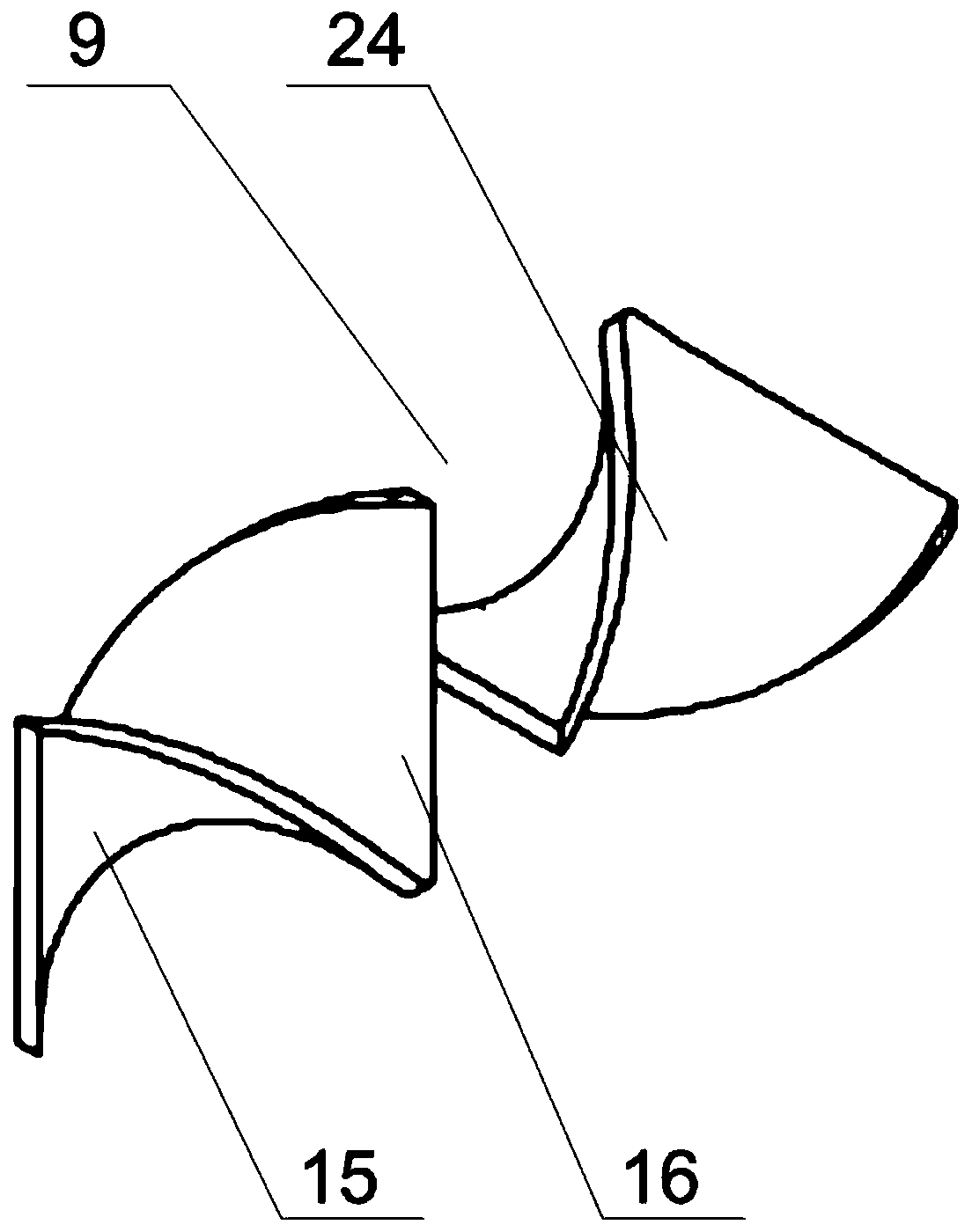

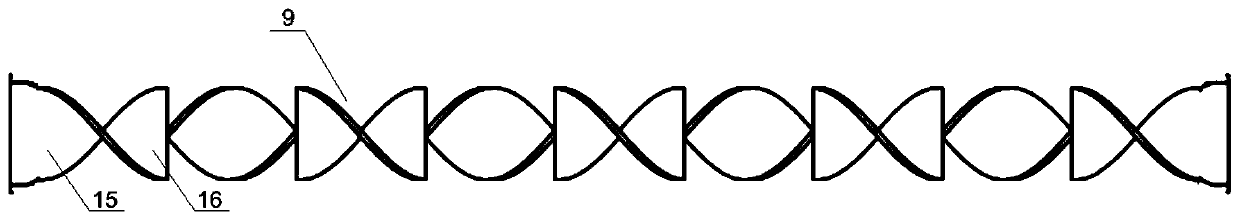

Cutting type spiral distribution sanitary heat exchanger

InactiveCN111271990ASpeed up heat exchangeChange directionHeat exchanger casingsStationary tubular conduit assembliesThermodynamicsEngineering

The invention discloses a cutting type spiral distribution sanitary heat exchanger. The cutting type spiral distribution sanitary heat exchanger comprises an outer tube side (17) and an inner tube side (18) arranged in the outer tube side (17); the outer tube side (17) is internally provided with a first turbulator (10), a second turbulator (11) and a baffle plate (12); the inner tube side (18) comprises a plurality of medium tubes (8) for allowing mediums to circulate; and the medium tubes (8) are internally provided with spiral distributors (9). According to the cutting type spiral distribution sanitary heat exchanger, impact of cold / hot mediums to the medium tubes can be reduced, damage of medium pressure to the medium tubes is reduced, meanwhile, the medium flowing direction is changed, and retention zones are decreased; and the mediums circulate spirally in the medium tubes, residual mediums on the walls of the tubes are decreased, the mediums can conduct heat exchange more easily, and the heat exchange efficiency is improved.

Owner:NA SHENG CLEAN TECH SUZHOU CO LTD

a sliding bearing

ActiveCN112747031BSimple structureReduce volumeBearing componentsSliding contact bearingsInformation transmissionNew energy

Owner:ZHEJIANG NORMAL UNIVERSITY

A kind of magnetic bactericidal thermal insulation coating and preparation method thereof

ActiveCN106519854BIncreased versatilityGuaranteed VersatilityFireproof paintsAntifouling/underwater paintsFiberFoaming agent

The invention discloses a magnetic sterilizing heat-insulation coating and a preparation method thereof. The magnetic sterilizing heat-insulation coating is prepared from, by weight percent, 15-30% of acrylic emulsion, 8-15% of hollow glass beads, 8-18% of magnetic-wave absorbing-sterilizing assistant, 8-18% of SiO2 based heat insulation composite fiber, 5-10% of rutile titanium dioxide, 5-10% of sea-foam stone powder, 5-10% of calcined kaolin, 1-2% of dispersing agent, 1-2% of anti-foaming agent, 2-5% of thickening agent, and 15-30% of water. Through nanometer modified technology, the magnetic-wave absorbing-sterilizing assistant and the SiO2 based heat insulation composite fiber are introduced to a heat-insulation coating domain, thus the multifunctional property of the heat-insulation coating is significantly widened; the coating has relatively ideal heat insulation effect while is toxic-free, odor-free, magnetic, wave-absorbable, green and environment-friendly, sterilized, self-cleaning, fire-proof and flame-retarding, and heat-resisting, and other functions; besides, the magnetic sterilizing heat-insulation coating has good market application prospect in the field of internal and external wall coatings of a building.

Owner:UNIV OF JINAN

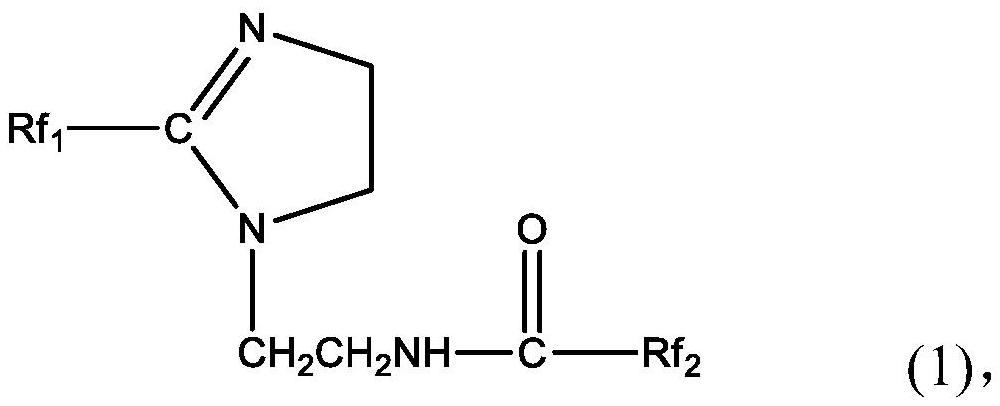

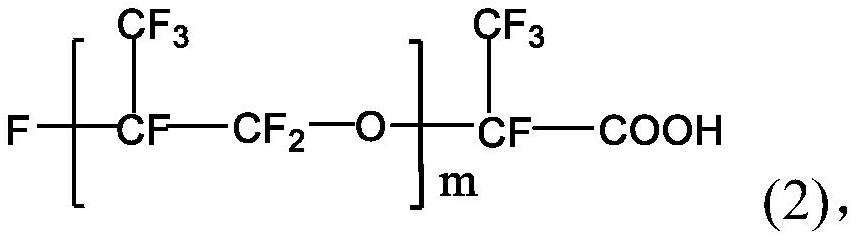

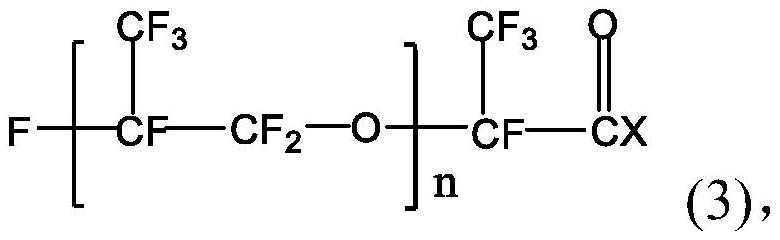

A kind of perfluoropolyether imidazoline compound and its preparation method and application

ActiveCN110698406BNo high temperature resistanceNo bioaccumulative toxicityOrganic chemistryPerfluoropolyetherCarboxylic acid

The invention relates to the technical field of metal corrosion inhibitors, and discloses a perfluoropolyether imidazoline compound, a preparation method and application thereof. The perfluoropolyether imidazoline compound is prepared from perfluoropolyether carboxylic acid, diethylenetriamine and perfluoropolyether halide as raw materials, and has a simple preparation method and high yield. When the prepared perfluoropolyether imidazoline compound is used as a metal corrosion inhibitor to treat metal substrates, it has the characteristics of strong adsorption, high temperature resistance, and high corrosion inhibition rate. Corrosion and other characteristics, and the compound has no bioaccumulative toxicity, has little environmental pollution, and meets the requirements of green environmental protection.

Owner:RUYUAN DONGYANG LIGHT FLUORIDE CO LTD

Feeding device for producing cigarettes from tobacco

InactiveCN113317552AStable positionImprove impact resistanceCigarette manufactureThermodynamicsAgricultural science

The invention discloses a feeding device for producing cigarettes from tobacco, which comprises a device main body, a clamping structure, an air cooling structure and a pushing assembly, wherein the pushing assembly is installed on one side of the device main body, the clamping structure is arranged on one side of a stabilizing plate, an elastic cushion is installed on one side of the clamping structure, the air cooling structure is installed in a bottom plate, a cooling plate is arranged on one side of the air cooling structure, and a fan structure is installed on the other side of the air cooling structure. According to the invention, tobacco is transported through the clamping structure, and the material used by the elastic cushion on the clamping structure enables the device to have good impact resistance and fatigue resistance, high impact strength and low-temperature flexibility, and when the temperature rises, good performance, high tear strength, high friction resistance, environmental protection, no toxicity, no pollution, excellent low temperature resistance, high temperature resistance, soft touch and excellent surface quality are maintained, so that tobacco clamping is more stable, and the air cooling structure arranged in the bottom plate at the bottom of the clamping structure is used for cooling the tobacco.

Owner:郑华丽

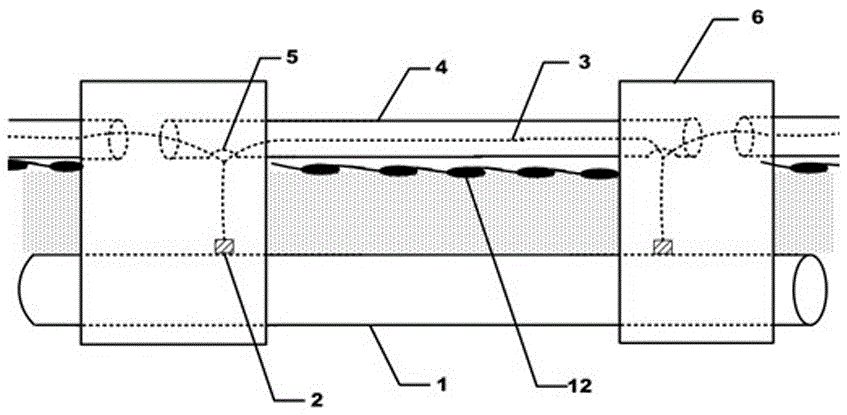

Casing-type underground pipeline leakage warning system and method based on fiber Bragg grating

ActiveCN103912792BMonitoring leak hazardsLeak hazards are accurate and effectivePipeline systemsFiberEarly warning system

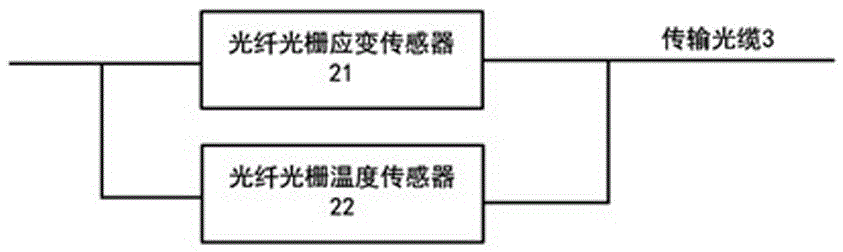

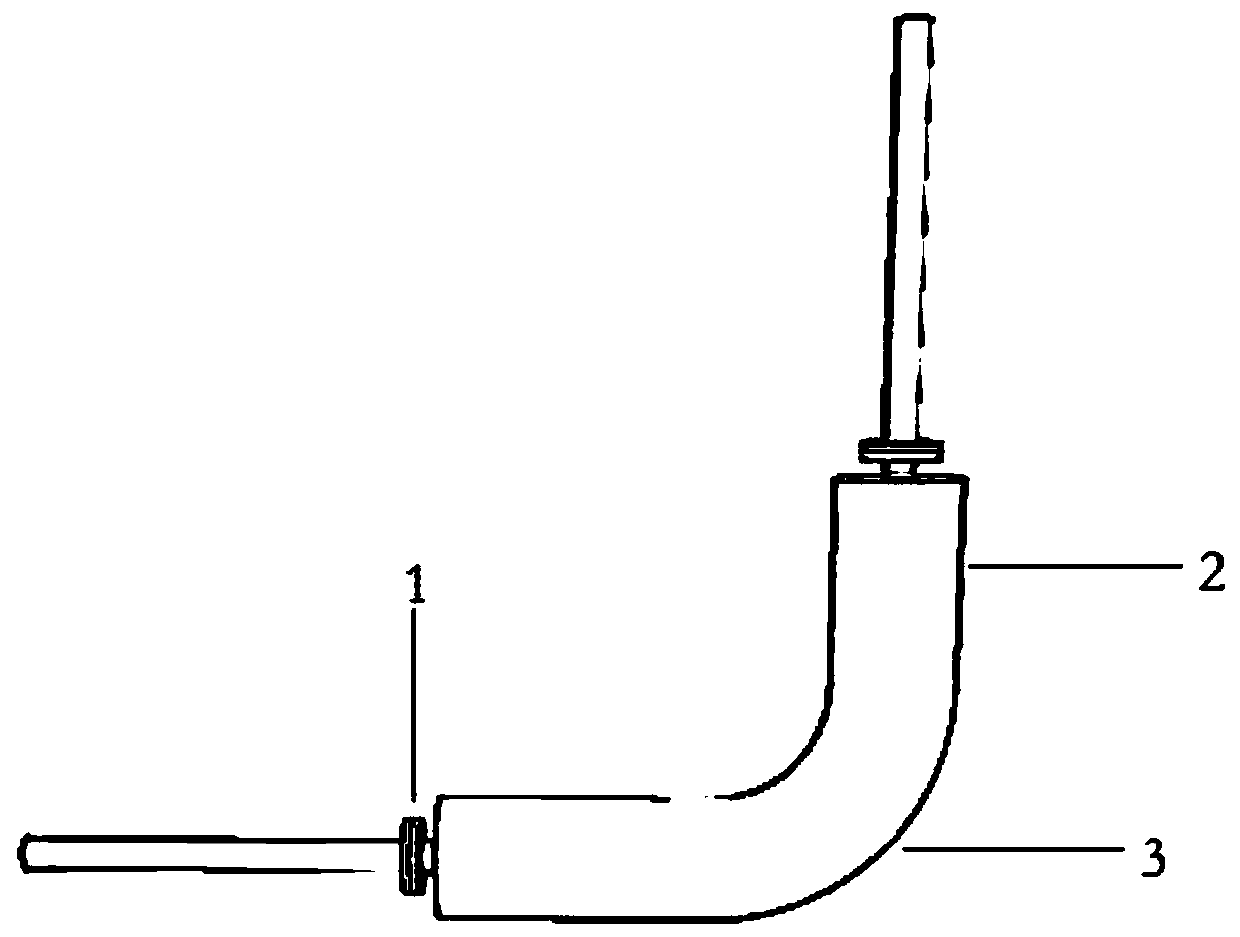

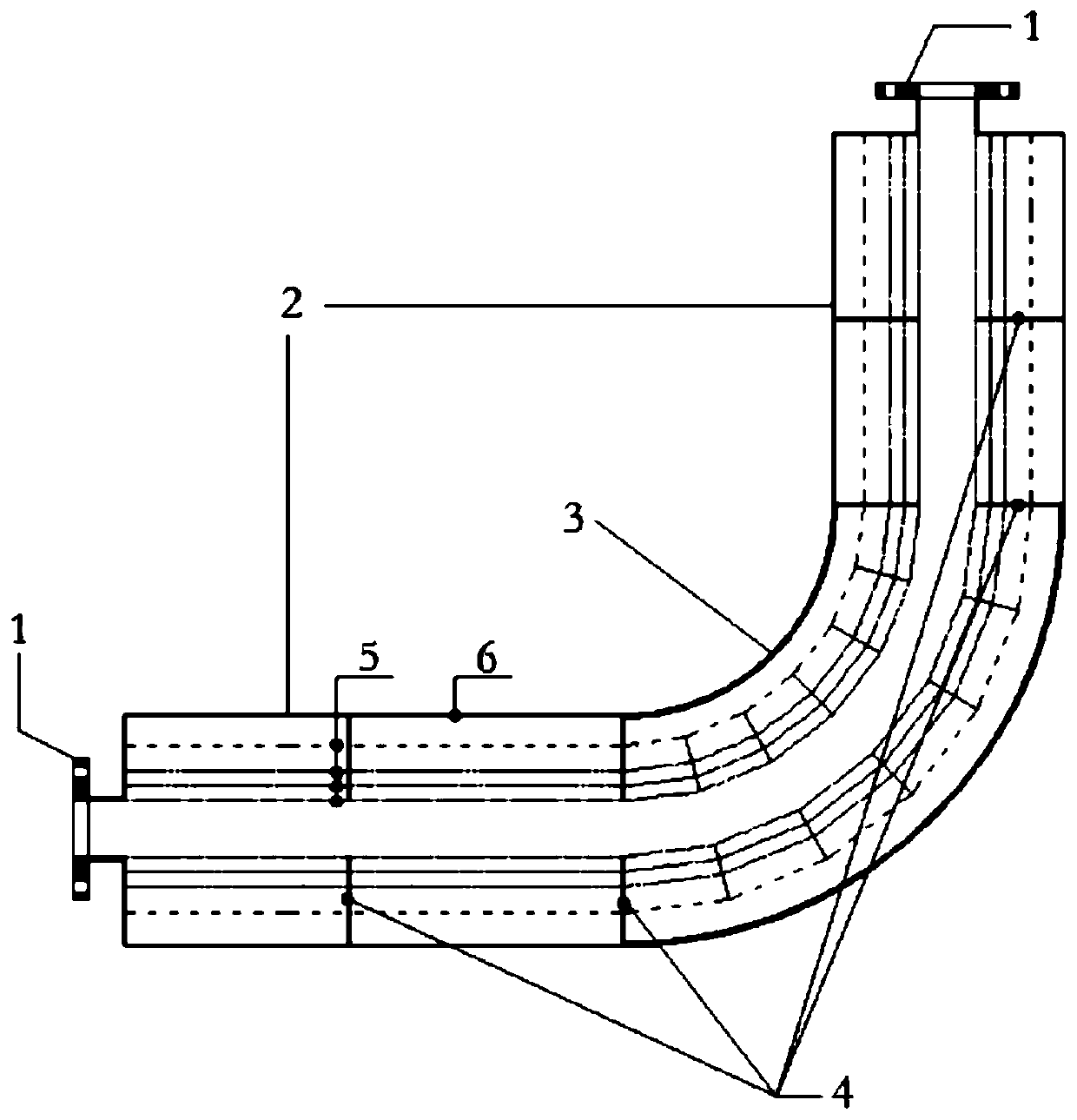

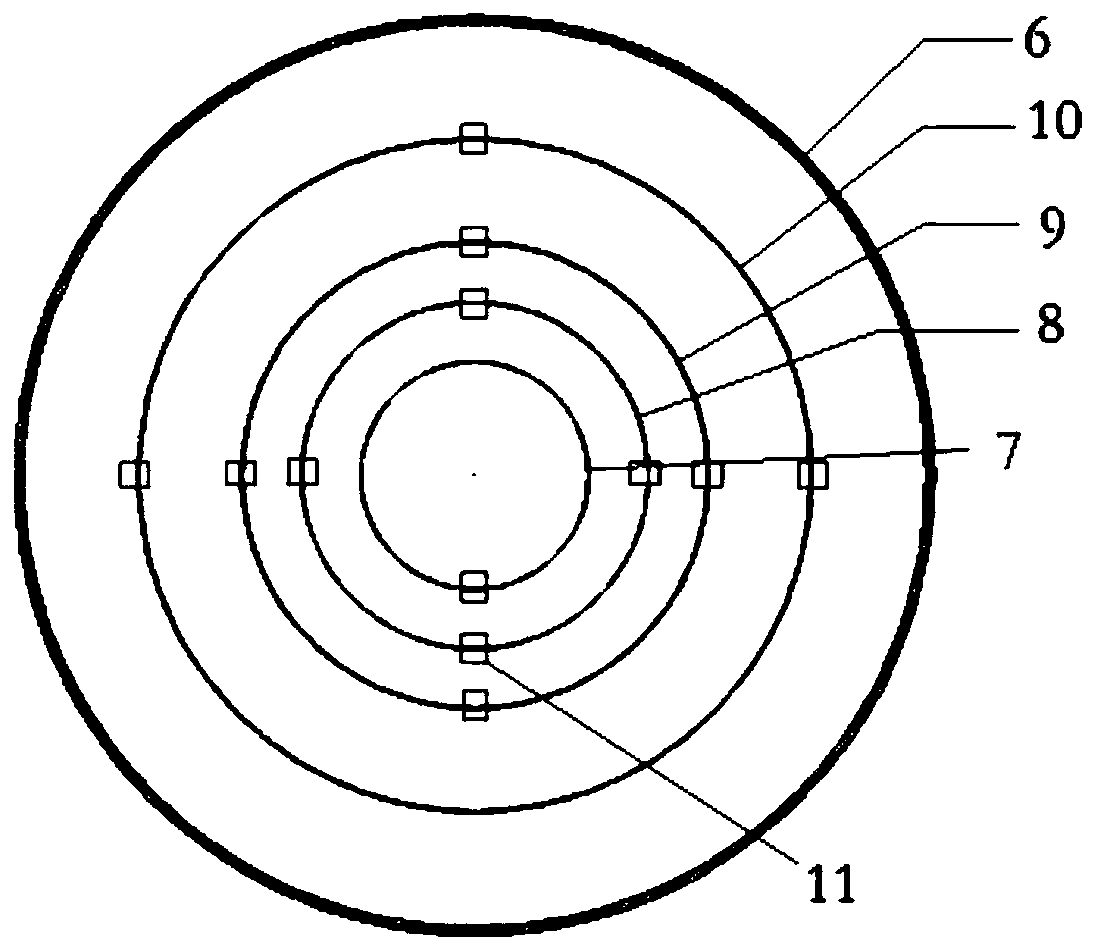

The invention discloses a telescoping underground pipeline leakage warning system on the basis of fiber gratings and a method implemented by the telescoping underground pipeline leakage warning system. The telescoping underground pipeline leakage warning system comprises an underground pipeline, fiber grating sensors, a transmission optical cable and mark belts. A protective sleeve sleeves the transmission optical cable, sensor holes are formed in the outer wall of the bottom of the protective sleeve, and the fiber grating sensors extend out of the protective sleeve via the sensor holes and are fixed onto the outer wall of the underground pipeline; the mark belts are buried between the upper side of the underground pipeline and the earth surface, bent portions are arranged on each mark belt at intervals, and chip assemblies are arranged on the mark belts; a well is arranged at a position corresponding to each fiber grating sensor, so that the fiber grating sensors and the transmission optical cable can be conveniently replaced and maintained. The telescoping underground pipeline leakage warning system and the method have the advantages that the fiber grating sensors include fiber grating strain sensors and fiber grating temperature sensors which are connected with one another in parallel, strain and the temperature of the outer wall of the underground pipeline are simultaneously monitored at each monitoring point, leakage events can be two-dimensionally responded, and accordingly leakage potential hazards of an underground pipe network can be accurately and effectively monitored.

Owner:QINGDAO HOUKE INFORMATION ENG

Water resistant construction method for architectures

InactiveCN1198035CImprove breathabilityThere will be no phenomenon that evaporation will not go outBuild-up roofsPolyesterEvaporation

The invention discloses a building waterproof construction method. After cleaning the leveling layer on the layer to be waterproofed, evenly apply the paste-like mixture of anti-seepage liquid mixed with cement, and then stick a layer of non-woven fabric on it, and then Apply a layer of anti-seepage liquid mixed with cement paste mixture, after the above anti-seepage liquid mixed with cement layer is slightly dry, then apply a layer of cement mortar on it as a protective layer, so that multiple layers can be made repeatedly; non-woven fabrics are For polyester non-woven fabrics, the anti-seepage solution is to heat water to 100°C and then add polyvinyl alcohol. The weight ratio of water to polyvinyl alcohol is 100:3. The non-woven fabric selected by the present invention has good air permeability, which can prevent the waterproof layer from cracking, and prevent the water from evaporating, resulting in damage to the waterproof layer. Therefore, the project constructed by the method of the present invention has a long service life, and can be maintained for ten, twenty, thirty or even one hundred years without deformation of the building.

Owner:徐方伟

Reinforced anti-swelling efficient sand-carrying fluid for sand prevention and yield increase measures of sensitive oil and gas reservoirs

PendingCN113956861ANo residueNo high temperature resistanceDrilling compositionInorganic saltsSoil science

The invention relates to the field of oilfield exploitation, in particular to enhanced anti-swelling efficient sand-carrying fluid for sand prevention and yield increase measures of sensitive oil and gas reservoirs. The enhanced anti-swelling efficient sand-carrying fluid comprises the following components in percentage by volume: 0.5%-1.5% of a viscoelastic surfactant, 1%-0.5% of inorganic salt, 0.5%-1.5% of a hydration retarder, 2%-3% of a clay stabilizer and the balance of water. The enhanced anti-swelling efficient sand-carrying fluidcan play a role of prepad fluid and also can play a role of fracturing fluid, has the characteristics of temperature resistance, shearing resistance, low friction resistance, easiness in sand carrying, good gel breaking property, no damage to strata and the like, improves the transformation effect of the fracturing sand-prevention measure to the greatest extent, and can solve the problem that sand-carrying fluid used in the current fracturing and sand prevention construction process causes large-range pollution to a super-sensitive oil and gas reservoir stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pipe multilayer micro perforated plate silencer and machining method thereof

PendingCN110847980AAnechoic frequency bandwidthNo pollution in the processPump componentsEngine componentsFiberMicro perforated plate

The invention is suitable for the field of the acoustic technique, and provides a pipe multilayer micro perforated plate silencer. The pipe multilayer micro perforated plate silencer comprises an outer pipe and micro perforated pipes. The multiple micro perforated pipes are arranged and are arranged on the outer pipe in the radial direction of the outer pipe, and the multiple micro perforated pipes are nested in sequence and used for silencing. The two ends of the outer pipe are closed, and an avoiding hole communicating with the micro perforated pipe located on the innermost layer is formed in the outer pipe. The pipe multilayer micro perforated plate silencer has the beneficial effects that super micropore plates are adopted inside, no fiber sound absorption material is adopted, and thepipe multilayer micro perforated plate silencer has the advantages of being long in service life, free of pollution and resistant to high temperature, dampness and high-speed airflow impacting and isespecially suitable for occasions with high requirements for the environment and occasions with severe environments; and the multiple layers of micropore plates are connected in parallel, the attribute and interlayer spacing of the multiple layers of micropore plates are subjected to acoustic design, and therefore the silencing audio frequency of the silencer is widened, and the silencing performance is improved.

Owner:上海钟音环保设备有限公司

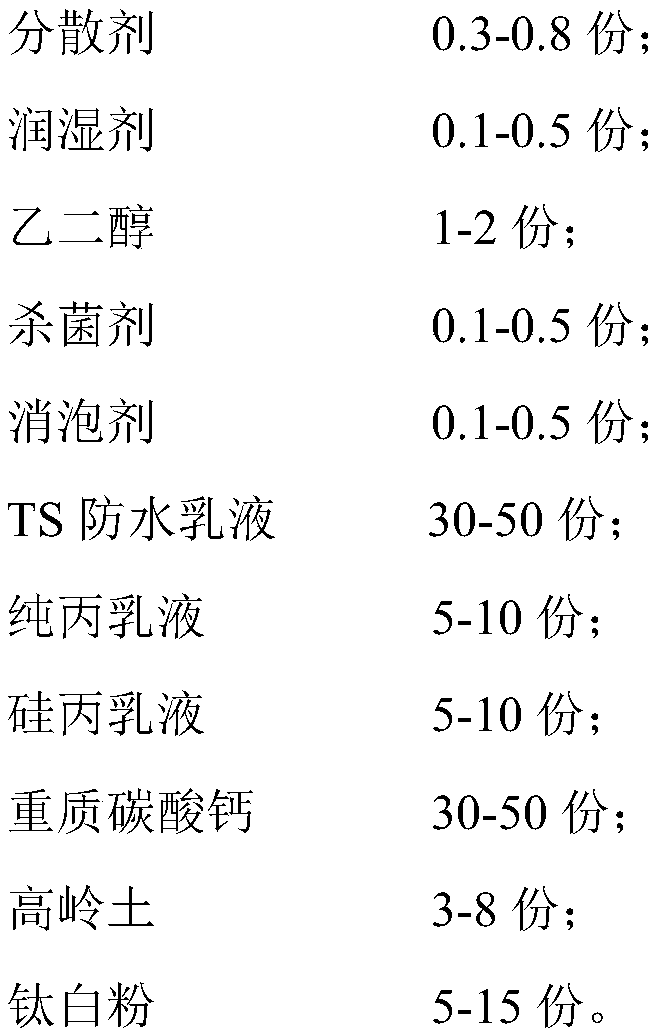

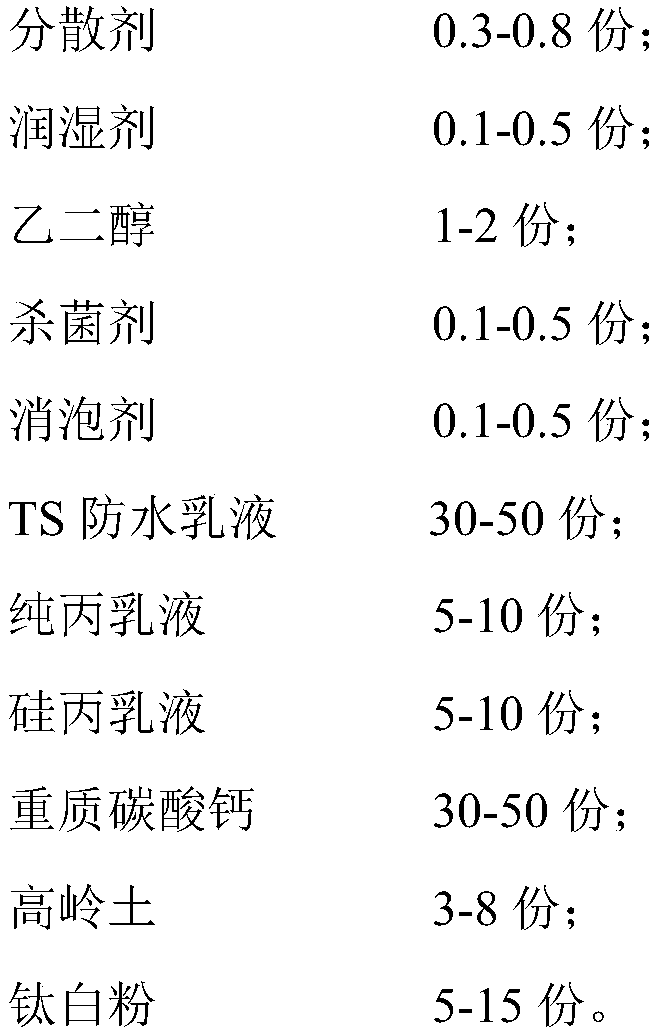

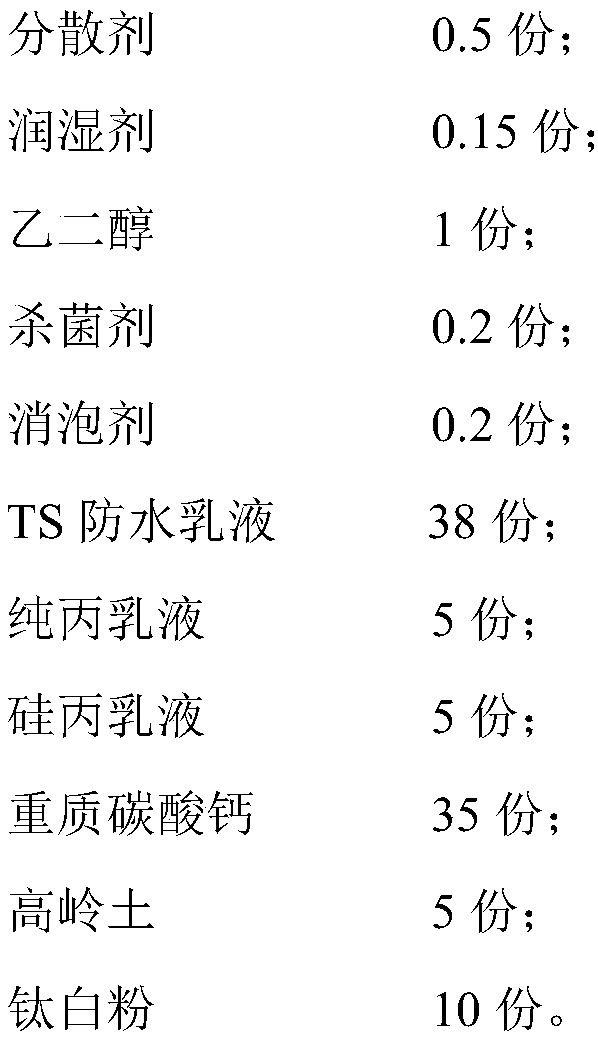

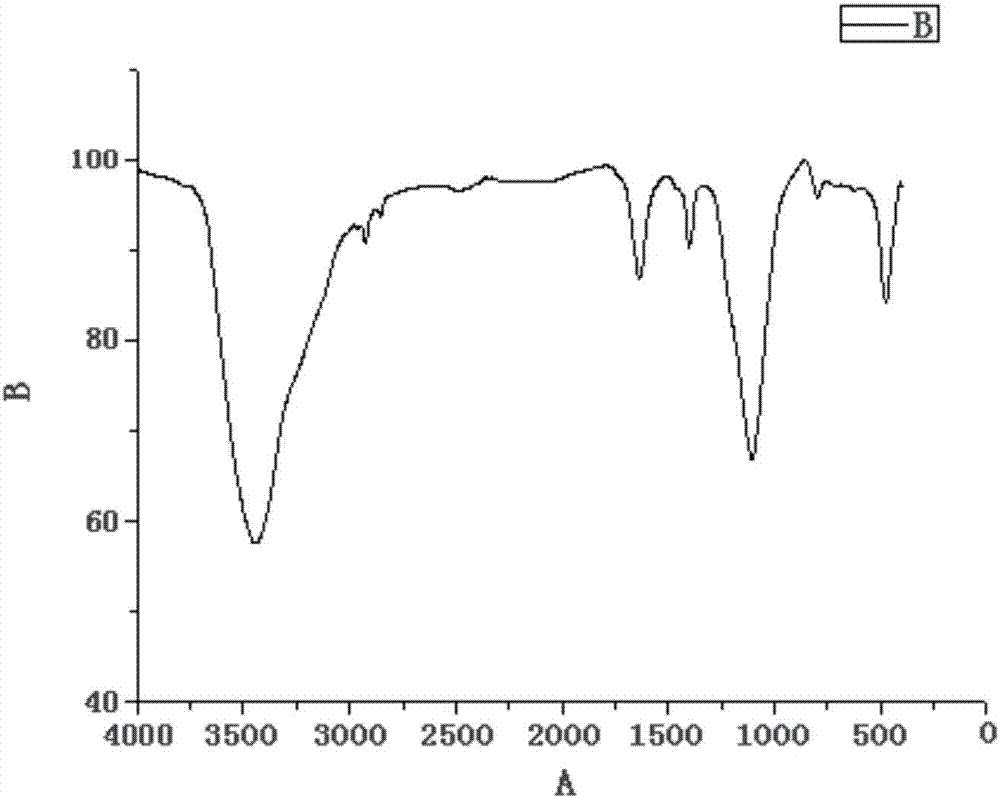

Anticorrosion waterproof coating special for light steel and preparation method thereof

InactiveCN109355018ANo pollution in the processHigh temperature resistantAnti-corrosive paintsEmulsionPliability

The invention belongs to the technical field of coatings and particularly relates to anticorrosion waterproof coating special for light steel and a preparation method thereof. The anticorrosion waterproof coating special for light steel is made from, by mass, 0.3-0.8 part of a dispersant, 0.1-0.5 part of a wetting agent, 1-2 parts of ethylene glycol, 0.1-0.5 part of a bactericide, 0.1-0.5 part ofa defoaming agent, 30-50 parts of TS waterproof emulsion, 5-10 parts of pure acrylic emulsion, 5-10 parts of silicone acrylic emulsion, 30-50 parts of ground calcium carbonate, 3-8 parts of kaolin, and 5-15 parts of titanium dioxide. The anticorrosion waterproof coating special for light steel has the advantages of zero toxicity, zero odor, zero pollution, high temperature resistance, low temperature resistance, aging resistance, acid and base resistance, good flexibility, low cost and the like. The preparation method provided herein is scientific and reasonable, is simple and provides convenience of construction.

Owner:江照珂

A method for improving shrinkage of alkali slag cementitious material

ActiveCN106431037BSmall shrinkageNo high temperature resistanceCement productionSlagMaterials science

Provided is a method for relieving shrinkage of an alkali slag binding material. The invention relates to the method for relieving the shrinkage of the binding material, and aims to solve the problems that the shrinkage of the alkali slag binding material is big and the application and popularization of the alkali slag binding material are limited. On the premise that high strength and good resistance to high temperature of the alkali slag binding material are not influenced, the method for relieving the shrinkage of the alkali slag binding material is achieved. The method comprises the steps of conducting preparatory work; preparing neat paste of the alkali slag binding material; conducting sample maintaining; conducting sample crushing; preparing a component of the alkali slag binding material. The method for relieving the shrinkage of the alkali slag binding material is used in the technical field of civil engineering materials.

Owner:HARBIN INST OF TECH

A method for producing high-purity silicon using energy-saving and environment-friendly technology

ActiveCN105668572BReduce energy consumptionEasy to purifyChemical industrySilicon compoundsThermal insulationMass ratio

A method for preparing high-purity silicon by an energy-saving and environmental protection technology comprises the following steps: uniformly mixing quartz sand or white carbon black and a reducing agent according to the weight ratio of (0.8-1.2): (1.2-1.6) to obtain a mixture, putting the mixture into a heating furnace with furnace chamber volume being 10-30 liters; spraying carbon powder of 100-325 meshes onto the surface of the mixture with the mass ratio of the carbon power to the mixture being (0.1-0.5): (2.0-2.8); heating the furnace chamber of the heating furnace to 200-260 DEG C for 0.5-1 h, and carrying out thermal insulation for 1-2h; heating the furnace chamber of the heating furnace to 300-400 DEG C for 0.5-1 h, and carrying out thermal reaction for 3-6 h to obtain a reaction product; cooling the reaction product to room temperature, washing the reaction product with normal-temperature distilled water for several times to obtain a washed product; and drying the washed product at the temperature of 90-110 DEG C to obtain elemental silicon. The method is green and environmentally friendly, has advantages of low energy consumption, simple process, low cost and few and simple equipment, and is easy to use at large scale in the industry. In addition, purity of the prepared elemental silicon is high.

Owner:ANHUI SCI & TECH UNIV

Fire-proof electric wire and manufacturing method thereof

InactiveCN103295690ANo high temperature resistanceAll spontaneous combustionPower cablesInsulating conductors/cablesCopper conductorYarn

The invention discloses a fire-proof electric wire which resists aging, does not self-ignite, is safe and free of fire risks and self-igniting pollution, and is capable of normally supplying electricity in open fire of 850 DEG C. The fire-proof electric wire does not self-ignite in the process of bearing overload currents or short-circuit currents to the process of fusing of a copper conductor, and liquid copper produced in the fusing process does not flow out. The fire-proof electric wire integrates with the advantages of being economic, practical, saving in energy, environmental friendly and the like, and prevents the fire when the fire is not burned. A thermal insulation fire-proof layer, a fire-proof insulation layer and a waterproof insulation layer are sequentially wrapped outside the copper conductor. The invention further provides a manufacturing method of the fire-proof electric wire. The manufacturing method comprises the steps that the thermal insulation fire-proof layer which is made of ceramic fiber yarn is wound outside the copper conductor; the fire-proof insulation layer which is woven by alkali-free glass fiber yarn in a crossing mode is arranged outside the thermal insulation fire-proof layer; the waterproof insulation layer which is squeezed and wrapped by rubber compounds or polyvinyl chloride compounds is further arranged outside the fireproof insulation layer.

Owner:张金胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com