A kind of magnetic bactericidal thermal insulation coating and preparation method thereof

A thermal insulation coating and magnetic technology, applied in magnetic coatings, conductive coatings, anti-corrosion coatings, etc., can solve the problems of single coating performance, low mechanical strength, poor water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

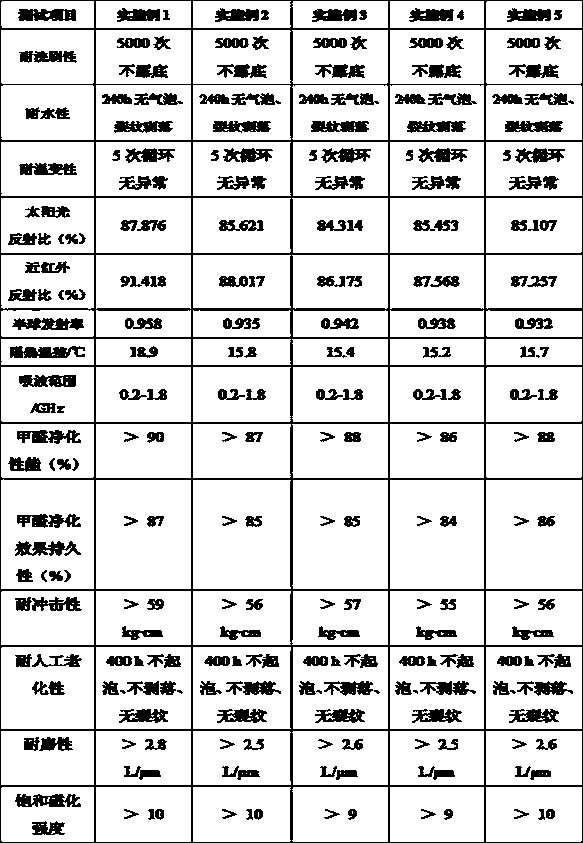

Examples

Embodiment 1

[0040] The formula of the magnetic bactericidal thermal insulation coating is (wt%): 19% acrylic emulsion, 11% hollow glass microspheres, 12% magnetic-absorbing-bactericidal additives, SiO 2 Base insulation composite fiber 13%, rutile titanium dioxide 7%, sepiolite powder 7%, calcined kaolin 8%, polyethylene glycol 200 dispersant 1%, silicone defoamer 1%, cellulose acetate thickener 3 %, water 18%.

[0041] The preparation method is as follows:

[0042] 1. Preparation of MFe 2 o 4 hollow fiber

[0043] (1) Fe(CH 3 COO) 3 and Mn(CH 3 COO) 2 Added into absolute ethanol, stirred to obtain a transparent solution, then added PVP, stirred for 12 h, obtained a transparent solution of iron and manganese, wherein, Fe(CH 3 COO) 3 The concentration in the transparent solution is 0.16 mol / L, PVP and Fe(CH 3 COO) 3 The molar ratio of PVP is 1:0.15, and the molar amount of PVP is calculated according to the molar amount of its polymerized monomer;

[0044] According to the molar...

Embodiment 2

[0062] The formula of the magnetic bactericidal thermal insulation coating is (wt%): 15% acrylic emulsion, 8% hollow glass microspheres, 8% magnetic-absorbing-bactericidal additives, SiO 2 Base insulation composite fiber 18%, rutile titanium dioxide 5%, sepiolite powder 10%, calcined kaolin 5%, polyethylene glycol 200 dispersant 1%, silicone defoamer 1%, cellulose acetate thickener 2 %, water 27%.

[0063] The preparation method is the same as in Example 1.

Embodiment 3

[0065] The formula of the magnetic bactericidal thermal insulation coating is (wt%): 15% acrylic emulsion, 15% hollow glass microspheres, 18% magnetic-absorbing-bactericidal additives, SiO 2 Base insulation composite fiber 8%, rutile titanium dioxide 5%, sepiolite powder 5%, calcined kaolin 10%, polyethylene glycol 200 dispersant 2%, silicone defoamer 1%, cellulose acetate thickener 3 %, water 18%.

[0066] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com