Eccentric skin-core-type antibacterial-functional composite polyester fibre and preparation method thereof

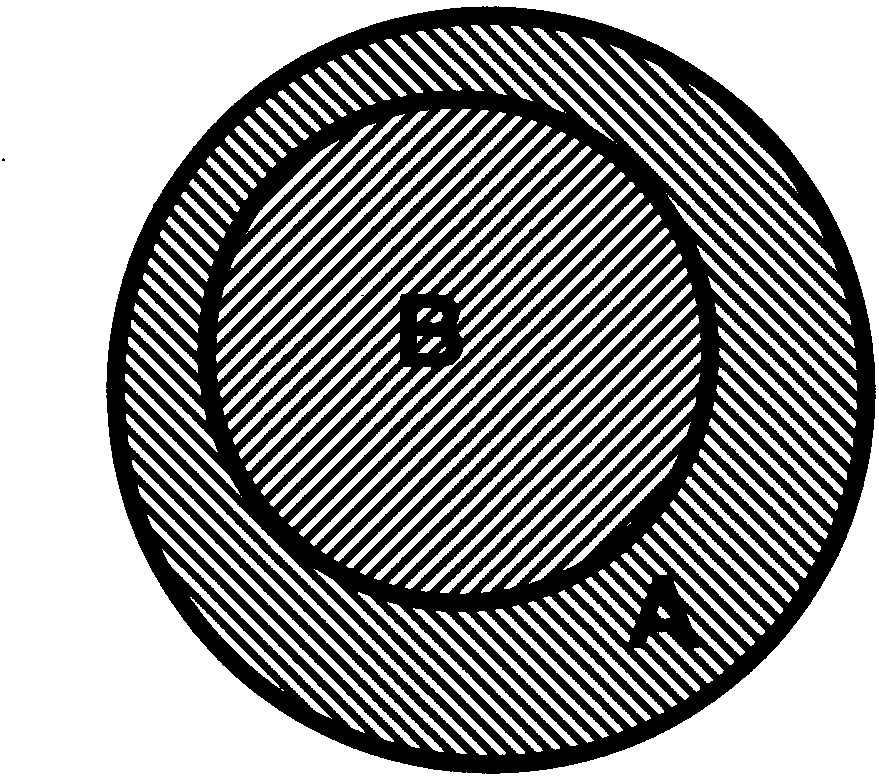

A composite polyester, sheath-core technology, applied in fiber treatment, fiber chemical characteristics, conjugated synthetic polymer artificial filament, etc., can solve the problem of low localization rate of PTT fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Pre-knead 20 kilograms of nano-silver antibacterial agent and 80 kilograms of PTT polyester chips, the kneading temperature is 120 ° C, and the kneading time is 60 minutes; then melt blending through a twin-screw extruder to obtain a nano-antibacterial agent content of 20wt%. granules, fully dried for later use.

[0016] 99.5 kilograms of cortex PTT chips (pre-dispersed with 0.5 kilograms of antibacterial masterbatches, wherein the antibacterial agent content accounts for 0.1wt% of the total mass of the cortex polyester) and 400 kilograms of core layer PET chips are respectively used with twin-screw extruder and single The screw extruder unit melts and conveys. Among them, the temperature of the PTT component twin-screw unit is set at 230-265°C, and the box temperature is 260°C; the temperature of the PET component single-screw unit is set at 260-295°C, and the box temperature is 292°C; the common box temperature is 290°C. The melts enter the spinning box body through ...

Embodiment 2

[0018] 10 kg of nano-silver antibacterial agent and 90 kg of PTT polyester chips are pre-kneaded, the kneading temperature is 120 ° C, and the kneading time is 60 min; then melted and blended through a twin-screw extruder to obtain a nano-antibacterial agent content of 10wt%. granules, fully dried for later use.

[0019] 99 kilograms of cortex PTT chips (pre-dispersed with 1 kilogram of antibacterial masterbatch, wherein the antibacterial agent content accounts for 0.1wt% of the total mass of the cortex polyester) and 400 kilograms of core layer PET chips are respectively used with twin-screw extruder and single The screw extruder unit melts and conveys. Among them, the temperature of the PTT component twin-screw unit is set at 230-265°C, and the box temperature is 260°C; the temperature of the PET component single-screw unit is set at 260-295°C, and the box temperature is 292°C; the common box temperature is 290°C. The melts enter the spinning box body through the distributi...

Embodiment 3

[0021] Pre-knead 10 kg of nano-silver antibacterial agent with 90 kg of PTT polyester chips, the kneading temperature is 140 ° C, and the kneading time is 30 min; then melt blending through a twin-screw extruder to obtain a matrix with a nano-antibacterial agent content of 10 wt%. granules, fully dried for later use.

[0022]95 kilograms of cortex PTT slices (pre-dispersed with 5 kilograms of antibacterial masterbatches, wherein the antibacterial agent content accounts for 0.5wt% of the total mass of cortex polyester) and 400 kilograms of core layer PET chips are respectively used twin-screw extruder and single The screw extruder unit melts and conveys. Among them, the temperature of the PTT component twin-screw unit is set at 230-265°C, and the box temperature is 260°C; the temperature of the PET component single-screw unit is set at 260-295°C, and the box temperature is 292°C; the common box temperature is 290°C. The melts enter the spinning box body through the distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com