Multifunctional inorganic interior wall coating and preparation method thereof

An interior wall coating, multi-functional technology, applied in fireproof coatings, antifouling/underwater coatings, alkali metal silicate coatings, etc. Formaldehyde and other organic pollutants, the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

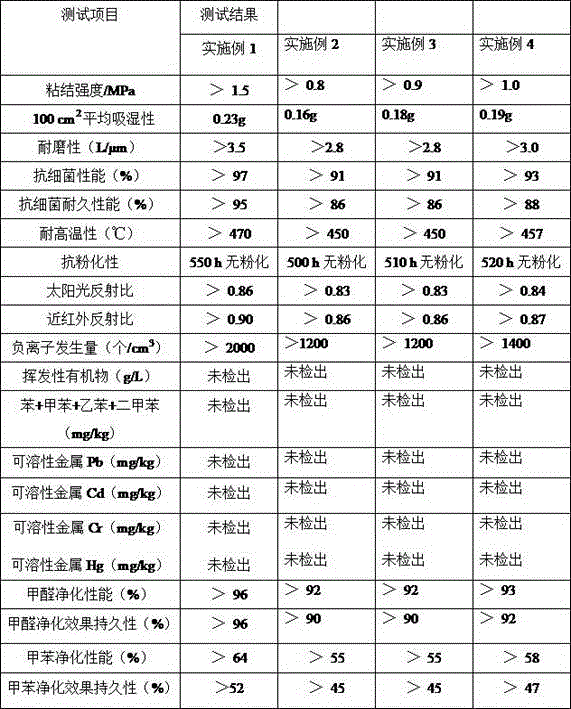

Examples

Embodiment 1

[0044] The formula of multi-functional interior wall paint is: potassium silicate 9%, lithium silicate 3%, silica sol 13%, diatomaceous earth 9%, shell powder 7%, photosensitizing additive loaded tourmaline powder 11%, anti-radiation- Bactericidal additive loaded bentonite 11%, nano-SiO 2 Dispersion liquid 5%, calcined kaolin 4%, anatase titanium dioxide 6%, alumina powder 4%, water 18%.

[0045] The preparation method is as follows:

[0046] 1. Preparation of Photosensitizing Auxiliary Loaded Tourmaline Powder

[0047] (1) Add tourmaline powder into water according to the weight ratio of solid-liquid ratio of 1:5, stir and mix and carry out ultrasonic dispersion to form tourmaline powder suspension, and add 20% concentration of tourmaline powder to the suspension under stirring Glycine solution to a pH value of 6.0, then filtered, washed, and dried in a constant temperature oven at 60°C to obtain pretreated tourmaline powder;

[0048] (2) According to the volume ratio of e...

Embodiment 2

[0069] The formula of multi-functional interior wall paint is: 15% potassium silicate, 5% lithium silicate, 5% silica sol, 5% diatomaceous earth, 9% shell powder, 15% tourmaline powder loaded with photosensitizing additive, anti-radiation- Bactericidal additive loaded bentonite 5%, nano-SiO 2 Dispersion liquid 10%, calcined kaolin 2%, anatase titanium dioxide 3%, alumina powder 2%, water 24%.

[0070] The preparation method is the same as in Example 1.

Embodiment 3

[0072] The formula of multifunctional interior wall paint is: 5% potassium silicate, 2% lithium silicate, 10% silica sol, 15% diatomaceous earth, 5% shell powder, 5% tourmaline powder loaded with photosensitizing additive, anti-radiation- Bactericidal additive loaded bentonite 15%, nano-SiO 2 Dispersion liquid 2%, calcined kaolin 8%, anatase titanium dioxide 12%, alumina powder 8%, water 13%.

[0073] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com