Hollow spherical aluminum foam material and its preparation method and filled sphere used in the preparation

A foamed aluminum and hollow ball technology, which is applied in the field of filled balls and foamed aluminum materials, can solve the problems of long warm-up time, high energy consumption and water consumption, and difficult cleaning, so as to achieve uniform foam body, improve product quality, and improve sound-absorbing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

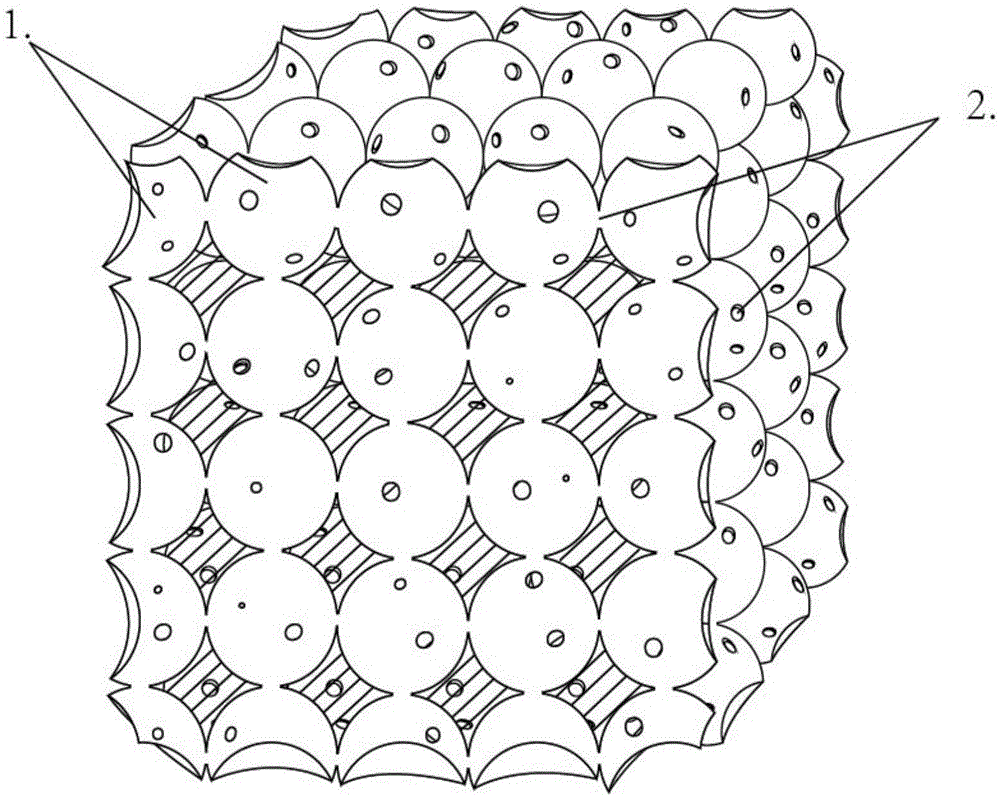

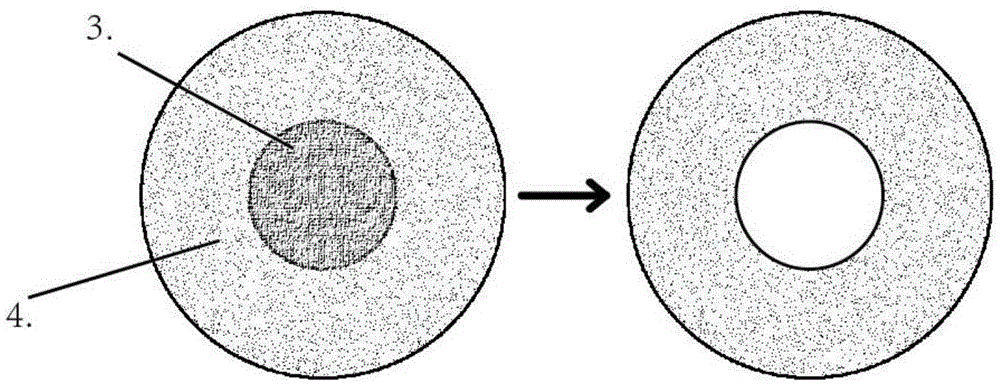

[0036] Prepare filled spheres earlier: by weight, 10% wood charcoal is prepared into the wood charcoal bead that diameter is 3mm with granulator earlier, stand-by; % vermiculite powder, put the mixture and wood charcoal pellets into the granulator, and continuously spray water in the machine, like a snowball, so that the mixture is evenly coated on the surface of the wood charcoal pellets, making Filled spheres with a coating layer of 2 mm and a diameter of 5 mm were air-dried for later use.

[0037] Put the dried filled sphere into a mold of 1000*500*100cm, make it dense, and start preheating. When the preheating temperature reaches about 300°C, the filled sphere forms a hollow filled sphere, forming a hollow filled sphere. Continue to preheat to a temperature of 600°C, keep the temperature constant for 25 minutes, and then carry out the operation of infiltrating aluminum liquid, controlling the weight ratio of filled spheres to aluminum liquid to be 1:3. The vacuum pump con...

Embodiment 2

[0039] Prepare filled spheres first: by weight, first prepare 15% wood charcoal with a granulator into wood charcoal pellets with a diameter of 5mm, and set aside; air-dried naturally for later use. Then mix 30% sepiolite, 40% bentonite and 15% vermiculite powder, put the mixture into the granulator together with wood charcoal pellets, and spray water continuously in the machine at the same time, like a snowball Similarly, the mixture is evenly coated on the surface of the wood charcoal pellets to make a filled sphere with a coating layer of 2.5mm and a diameter of 7.5mm, air-dried naturally, and set aside.

[0040] Put the dried filled sphere into a 400*400*150 mold, vibrate to make it compact, and start preheating. When the heating temperature reaches about 350°C, the filled sphere will form a hollow filled sphere, and continue to preheat. Heat to a temperature of 650°C, keep the temperature constant for 30 minutes, and then carry out the operation of seepage aluminum liquid...

Embodiment 3

[0043] By weight, first 12% wood charcoal is prepared into wood charcoal pellets with a diameter of 5.5mm with a granulator, stand-by; then 35% sepiolite, 38% nano-bentonite and 15% vermiculite powder Mixing, put the mixture and wood charcoal pellets into the granulator, and spray water continuously in the machine at the same time, like a snowball, so that the mixture is evenly coated on the surface of the wood charcoal pellets to form a coating layer Filled spheres with a diameter of 2.5 mm and a diameter of 8 mm were air-dried for later use.

[0044] Put the prepared filled sphere into a 500*500*150 mold, vibrate to make it dense, and start preheating. When the preheating temperature reaches 350°C, the filled sphere will start to burn and form a hollow filled sphere. Continue Preheat to a temperature of 650°C, keep the temperature constant for 40 minutes, and then perform the operation of percolating molten aluminum, controlling the weight ratio of filled spheres to molten a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com