Light-tight polymeric membrane and production method thereof

A manufacturing method and technology of light-transmitting film, applied in chemical instruments and methods, layered products, lamination, etc., can solve problems such as opacity, pungent odor, etc., achieve long service life, reduce heat entry, design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in combination with specific embodiments.

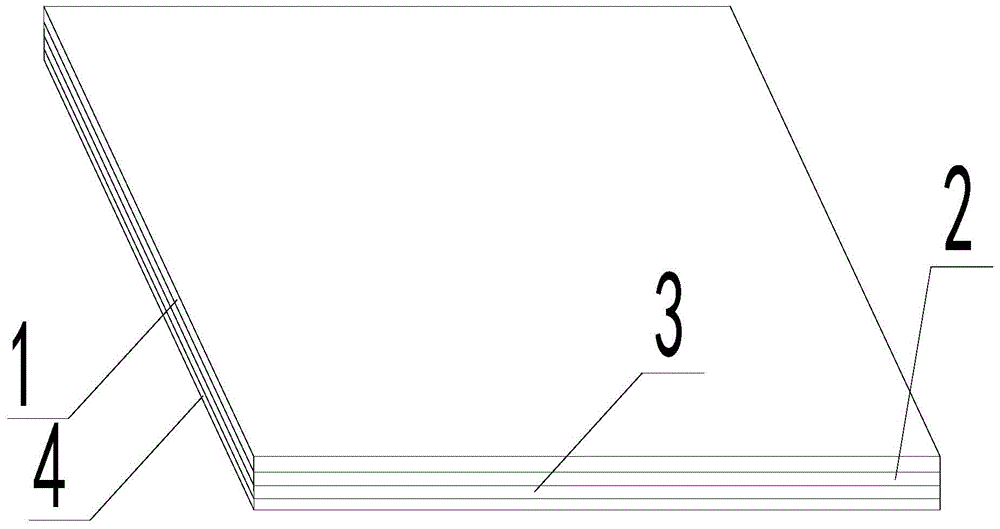

[0015] A polymer opaque film, such as figure 1 As shown, it includes a PET layer 1, one side of the PET layer 1 is provided with a metal electroplating layer 2, and one side of the metal electroplating layer 2 is provided with a black polymer material polyvinyl chloride layer 3 Molecular formula [-CH2--CHCl-] n, the black polymer material polyvinyl chloride layer 3 molecular formula [—CH2——CHCl—]n is provided with a polymer material polyvinyl chloride color layer 4 molecular formula [—CH2——CHCl—]n.

[0016] The first step is material pretreatment and machine preheating;

[0017] The second step is to electroplate the PET metal layer.

[0018] The third step is to combine the electroplated metal PET layer with two layers of polymer material polyvinyl chloride molecular formula [-CH2--CHCl-]n, and one side of the metal plating layer is provided with a black polymer materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com