Casing-type underground pipeline leakage warning system and method based on fiber Bragg grating

A fiber grating and underground pipeline technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of oil and gas pipelines that cannot be reused, single temperature monitoring, and replacement cannot be completed, so as to save cables and construction cost, no connection loss, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

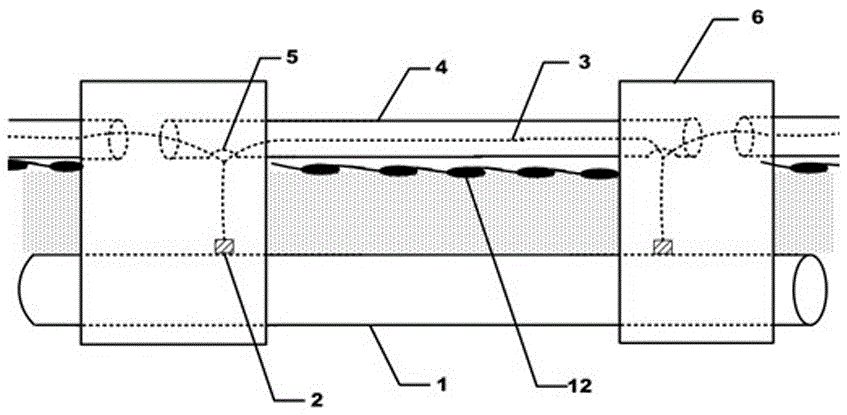

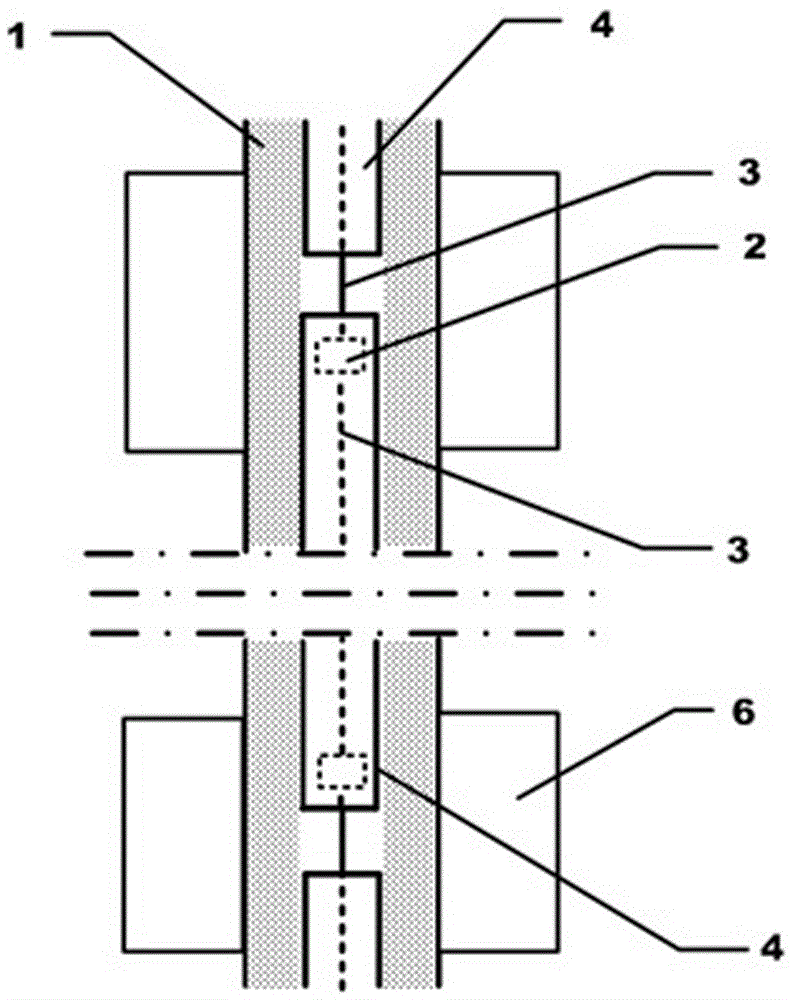

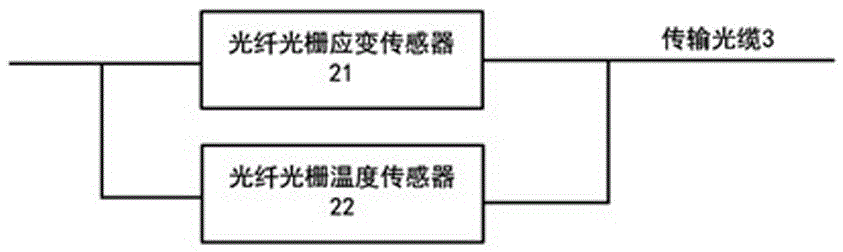

[0038] Such as figure 1 and figure 2 As shown, the sleeve-type underground pipeline leakage early warning system based on fiber gratings includes an underground pipeline 1 and an identification band 12 buried between the top of the underground pipeline 1 and the ground surface. Specifically, the identification band 12 is buried above the underground pipeline 1. 70cm; a protective sleeve 4 is laid above the identification tape 12, a sensor hole 5 is arranged on the outer wall of the bottom of the protective sleeve 4, a transmission optical cable 3 is arranged inside the protective sleeve 4, and a fiber grating sensor 2 is connected to the transmission optical cable 3. The grating sensor 2 extends out of the protective sleeve 4 through the sensor hole 5 and is fixed on the outer wall of the underground pipeline 1; a pit 6 is set at the position corresponding to each fiber grating sensor 2, and the pit 6 extends from the surface to the underground pipeline 1 side, the fiber gra...

Embodiment 2

[0052] The present invention also discloses a method for applying the above-mentioned casing-type underground pipeline leakage warning system based on optical fiber grating, including the following steps:

[0053] a. Lay the identification tape 12 between the top of the underground pipeline 1 and the ground surface, and lay the protective casing 4 on the identification tape 12. The outer wall of the bottom of the protective casing 4 is provided with a sensor hole 5, and the protective casing 4 is laid A transmission optical cable 3, the optical fiber grating sensor 2 is connected to the transmission optical cable 3, and the optical fiber grating sensor 2 protrudes out of the protective sleeve 4 through the sensor hole 5;

[0054] b. Set up a pit 6 at the corresponding position where the sensor 4 needs to be installed, the pit 6 extends from the surface to the outside of the underground pipeline 1, and the fiber grating sensor 2 reaches the outer wall of the underground pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com