Patents

Literature

34 results about "Ethyl stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl stearate is a flavouring ingredient. Metabolite Description from Human Metabolome Database (HMDB) Ethyl octadecanoate is an octadecanoate ester obtained by formal condensation between the carboxy group of octadecanoic (stearic) acid and the hydroxy group of ethanol .

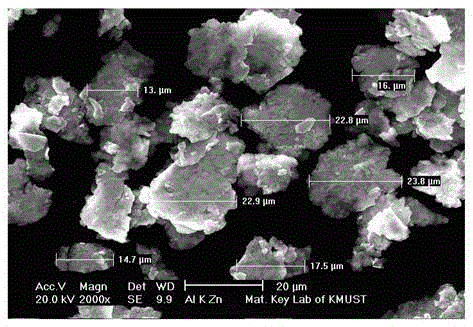

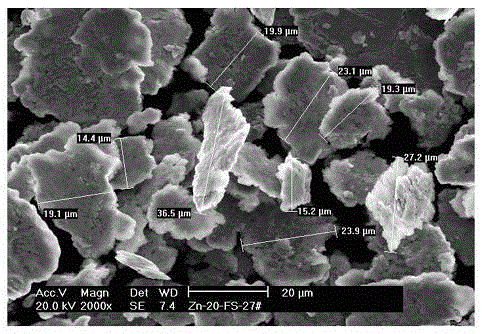

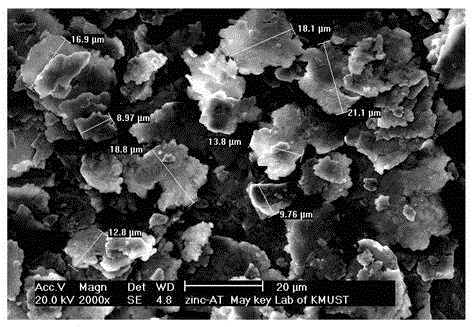

Method for manufacturing superfine flaky zinc powder with high corrosion resistance

The invention provides a method for manufacturing superfine flaky zinc powder with high corrosion resistance, and belongs to the technology of metallurgical waste utilization and metal powder material manufacturing. Raw zinc powder is commercially available waste sieved out in a battery zinc powder process, the raw zinc powder, industrial auxiliary agents and grinding media are placed into a horizontal type blade high-powered stirring grinder to be ground, the mass ratio of the grinding media to the raw zinc powder is 10:1-20:1, the mass of the industrial auxiliary agents is 1.0-3.0% of the mass of the raw zinc powder, the industrial auxiliary agents are one or two of hexadecanoic acid, dodecyl alcohol, ethyl stearate and silane coupling agents, the grinding media are bearing steel balls with the diameters being 5-7 millimeters, vacuum pumping is conducted firstly, and then inert gas is fed two times for protection; the ground flaky zinc powder is placed in a mixer, and mixing and passivation are conducted in air; the mixed flaky zinc powder is placed in a cyclone classifier and classified so as to obtain the superfine flaky zinc powder. The metallurgical waste can be used; the superfine flaky zinc powder has the high corrosion resistance, and production cost is reduced.

Owner:昆明海创兴科技有限公司

Decorative PVC (Polyvinyl Chloride) film

The invention discloses a decorative PVC (Polyvinyl Chloride) film. The decorative PVC film is prepared from the following raw materials in parts by weight: PVC440 resin powder, nano-tic, chitosan-grafted polyacrylic acid, polyoxyethylene sorbitan monostearate, tetrabutyl titanate, ethyl stearate, stearyl clcohol, titanium bis(triethanolamine)diisopropoxide, saturated fatty alcohol multiple carboxylic ester, sodium antimonate, zinc chromate, plasticizer, stabilizer and antioxidant. Through reasonable combination in a formula, the obtained decorative PVC film has the advantages of aging resistance, high toughness, good thermal stability and high flame resistance. Meanwhile, the decorative PVC film further has the characteristic of acid and alkali resistance.

Owner:黄山豪泰塑胶有限公司

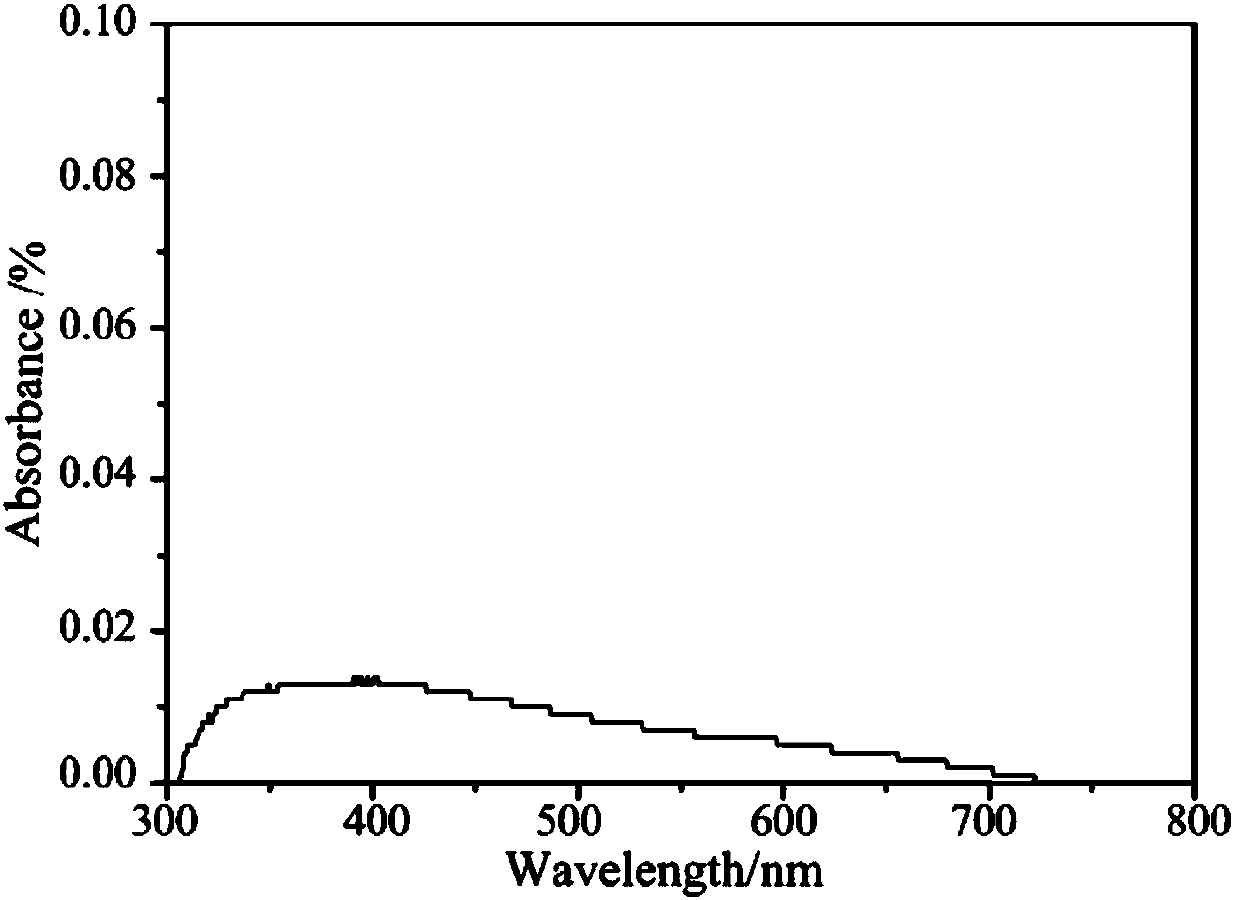

Method for preparing nano titanium dioxide coating on surface of base material made of transparent glass and polymer

InactiveCN104163575AControllable surface structureImprove photocatalytic activityCoatingsEthyl stearateStearic acid

The invention discloses a method for preparing a nano titanium dioxide coating on the surface of a base material made of transparent glass and polymer. The method is characterized by comprising the following steps: taking TiCl4 as the titanium source to obtain a precursor reaction fluid, using a rotation coating instrument to paint 10 to 20 [mu]L of the precursor reaction fluid on a substrate, which has been subjected to a pretreatment, so as to obtain a uniform liquid membrane on the substrate; covering a BOPP film on the substrate, subjecting the substrate to light radiation in an ultraviolet lamp cabinet, taking out the substrate after 5 to 10 minutes, removing the BOPP film, washing the substrate, and finally drying so as to obtain the transparent TiO2 surface coating. If an ethyl stearate solution is painted on the substrate surface before the precursor reaction liquid is spin-painted on the substrate, and the post operations are not changed, a porous transparent TiO2 coating will be formed on the substrate surface. The precursor reaction fluid is prepared by the following steps: taking TiCl4 as the titanium source, and then orderly adding TiCl4 and H2O2 into an acidic water solution of HNO3 under stirring. The provided TiO2 film is composed of pure anatase crystalline phase having a high photocatalytic activity, and the surface structure of the TiO2 film is controllable. The technology is simple, the used facilities are convenient and easily available, the film-forming speed is fast, the post-treatment is convenient, and the reaction mediums are nontoxic and harmless.

Owner:BEIJING UNIV OF CHEM TECH

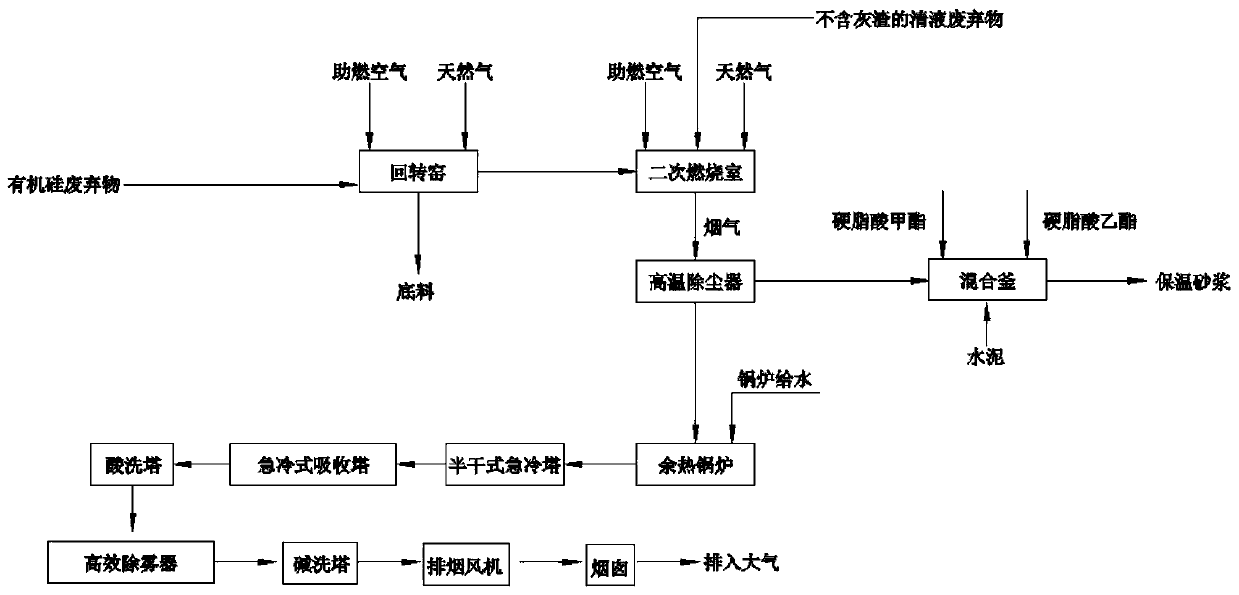

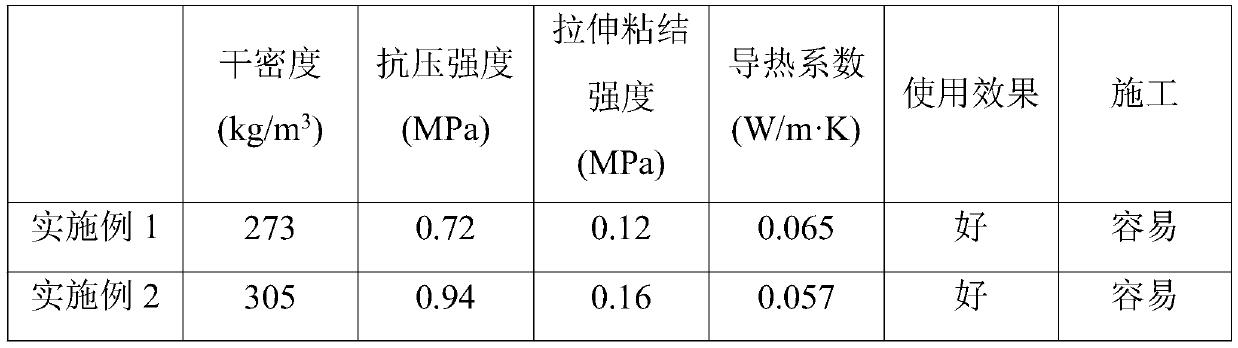

Method for preparing heat-insulation mortar through organic silicone waste

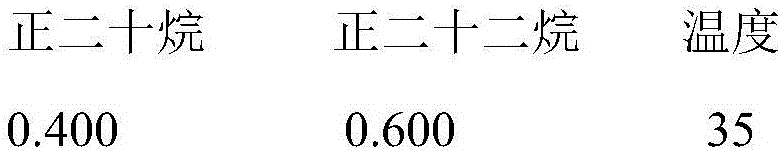

The invention discloses a method for preparing heat-insulation mortar through organic silicone waste. The method includes the following steps that (1) the organic silicone waste is converted into coarse SiO2 to serve as a skeleton of the heat-insulation mortar; (2) methyl stearate and ethyl stearate are mixed in a mixing kettle to synthesize a phase-change material; and (3) the coarse SiO2 and thephase-change material are mixed with the mass ratio being 1:(0.15 to 0.3), then a mixture and cement are blended with the mass ratio being 1:(8 to 12), and after even stirring, the heat-insulation mortar is prepared. Copper and silicon are removed through rotary kiln roasting, then a methyl chlorosilane mixed solution is converted into the coarse SiO2 to serve as aggregate in an oriented mode through a secondary combustion chamber, skeleton materials such as expanded vermiculite, expanded perlite, shale ceramisite, bentonite and montmorillonite conventionally applied in the current market arereplaced, the heat-insulation mortar is prepared by combining the phase-change material with the cement, thus economic benefits can be produced, and environmental pollution can further be reduced.

Owner:ZHENJIANG JIANGNAN CHEM

Petroleum ester oxide barium soap corrosion inhibitor

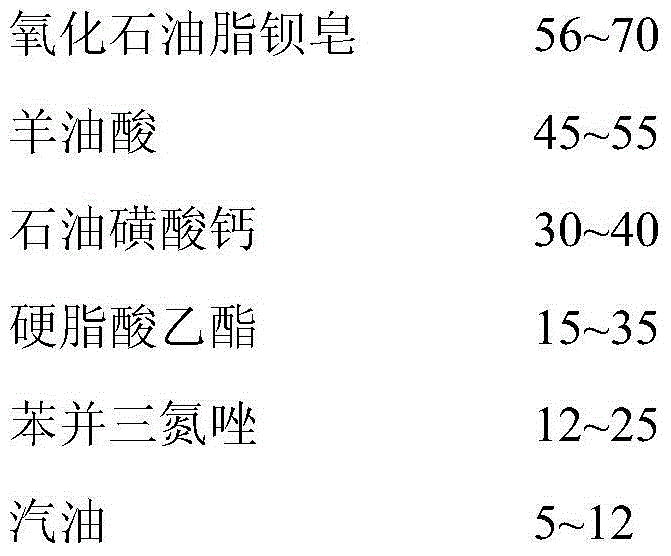

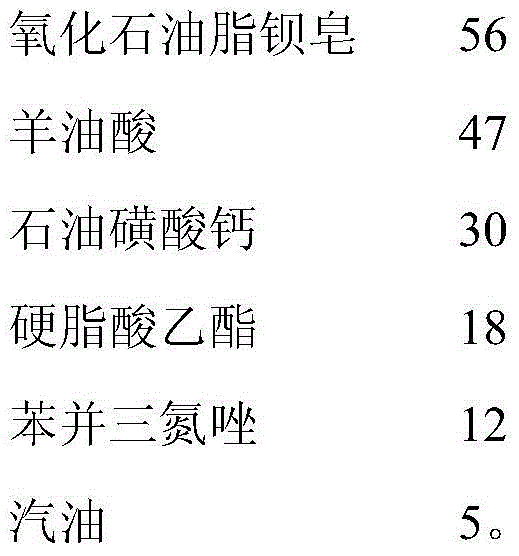

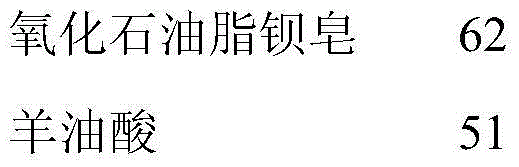

The invention provides a petroleum ester oxide barium soap corrosion inhibitor. The petroleum ester oxide barium soap corrosion inhibitor comprises petroleum ester oxide barium soap, caproic acid, calcium petroleum sulfonate, ethyl stearate, benzotriazol and gasoline. The corrosion inhibitor is prepared by uniformly mixing above components at room temperature according to a formula. Petroleum ester oxide has a good corrosion inhibition effect. The molecule of the petroleum ester oxide contains a carboxyl group, a hydroxyl group and other polar groups, so the petroleum ester oxide has very strong adsorption ability to the metal surface and also has good oil solubility; and the hydroxyl group can emulsify water on the metal surface.

Owner:QINGDAO HAOTAI WATER

Preparation technology of molybdenum-niobium alloy sputtering target material

ActiveCN105887027ALower surface energyAvoid sticky ballsTransportation and packagingMetal-working apparatusEthyl stearatePolyvinyl alcohol

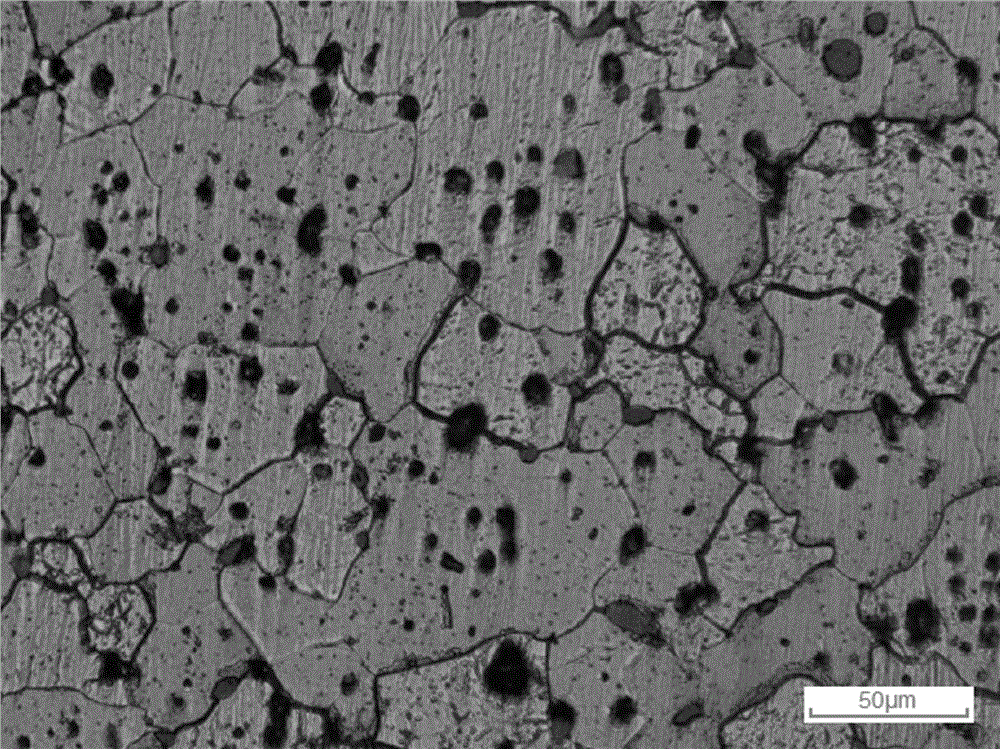

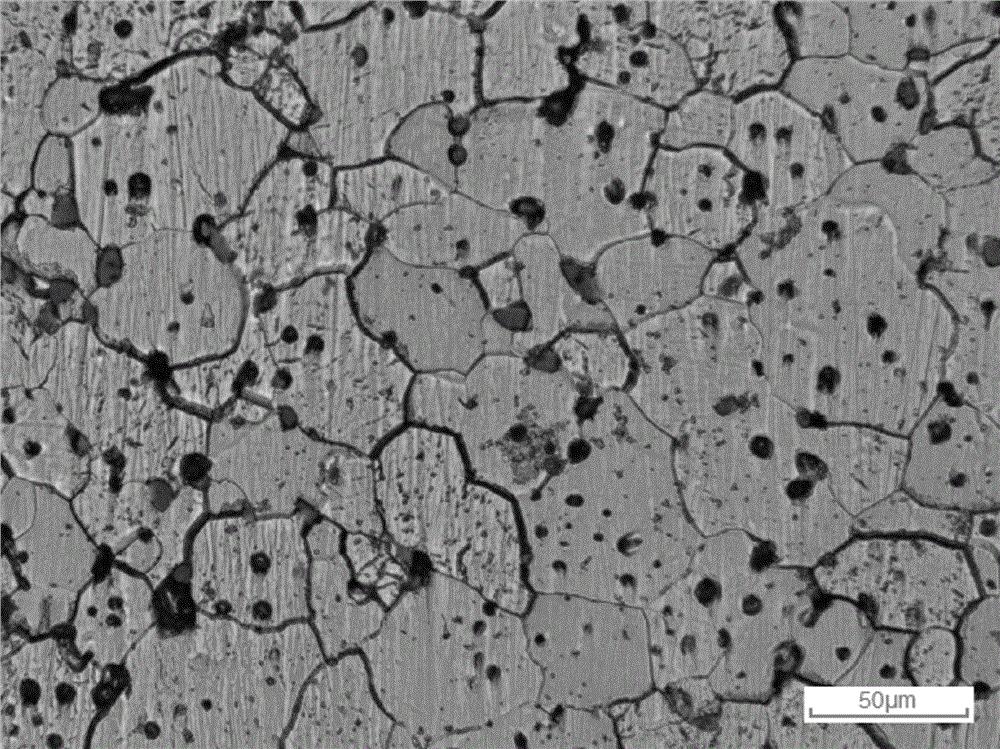

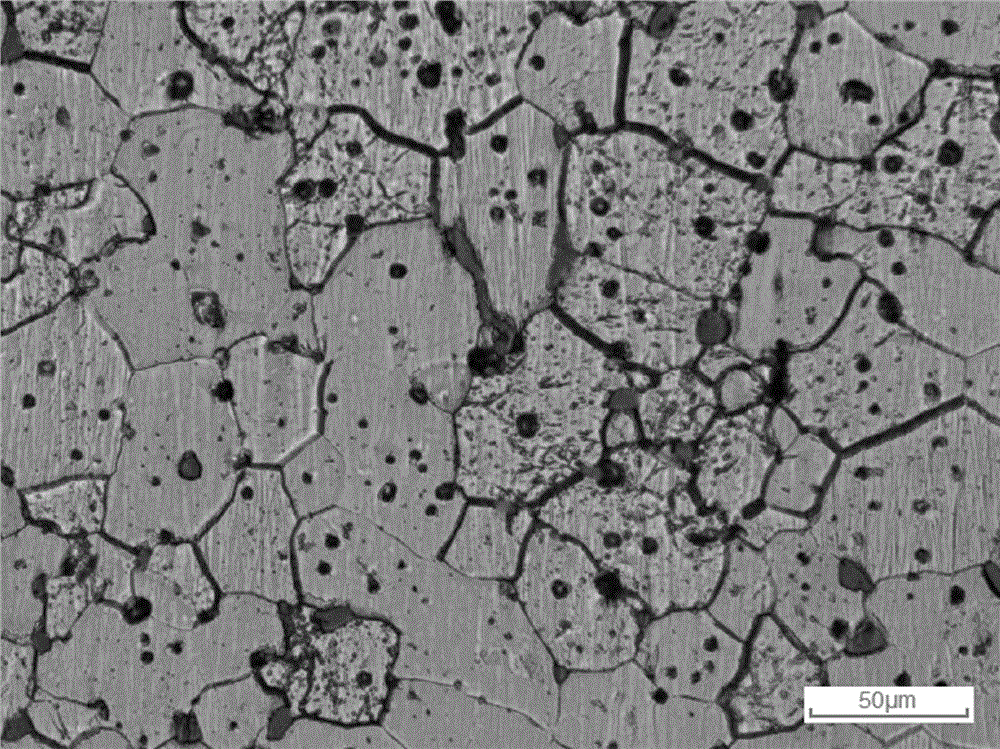

The invention belongs to the technical field of metallurgy materials, and particularly relates to a preparation technology of a molybdenum-niobium alloy sputtering target material. The preparation technology comprises the steps of milling, molding, vacuum sintering, machining, and the like, wherein the milling process comprises the steps of putting molybdenum powder and columbium powder into a ball mill according to the principle that the ratio of molybdenum powder to columbium powder is (6 to 10) to 1; then, adding a process control agent and zirconia grinding balls; carrying out ball milling under argon protection; sieving; and separating to obtain molybdenum-niobium alloy composite powder; weights of the process control agent and the zirconia grinding balls are respectively (0.01 to 0.05) times and (5 to 20) times the total weight of molybdenum powder and columbium powder; and the process control agent is one or more of zinc stearate, palmitic acid, ethyl stearate, polyvinyl alcohol and stearic acid. According to the preparation technology, the obtained molybdenum-niobium alloy sputtering target material is a single phase structure, the structure is uniform and free of holes, the average grain size is 40 to 65 [mu]m, the density is 9.85 g / cm<3> or above, the performance is excellent, and the molybdenum-niobium alloy sputtering target material can be widely applied to the fields such as flat displays.

Owner:洛阳丰联科绑定技术有限公司

Nano-material with air purifying function and preparation method thereof

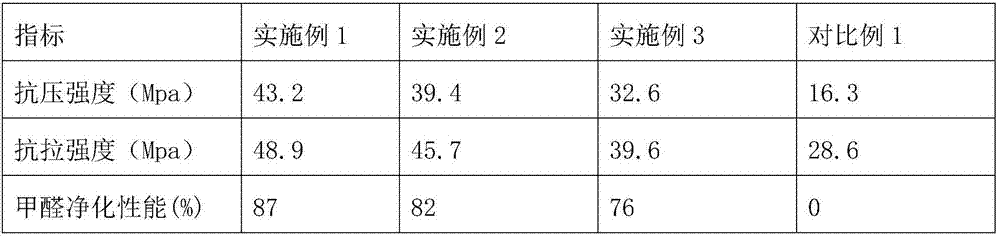

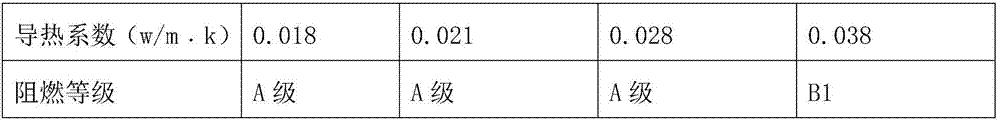

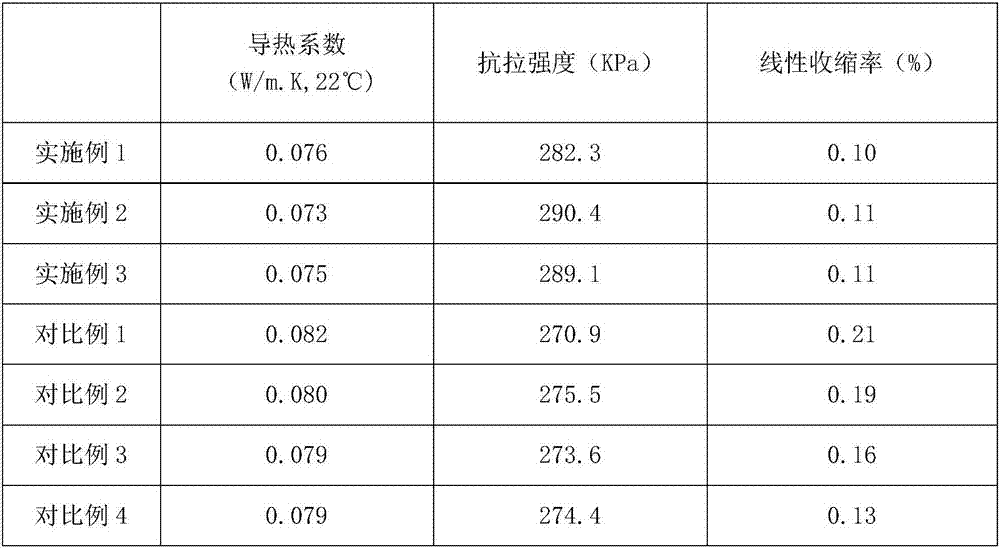

The invention provides a nano-material with an air purifying function and a preparation method thereof, belonging to the technical field of nano-materials. The nano-material with the air purifying function comprises the following raw materials by weight: 60 to 80 parts of a polyurethane high-polymer material, 9 to 15 parts of quartz stone flour, 10 to 14 parts of ethyl stearate, 5 to 15 parts of palmitic acid, 2 to 4 parts of nanometer silica, 2 to 4 parts of nanometer calcium carbonate, 10 to 16 parts of nanometer titanium dioxide, 3 to 5 parts of a stabilizing agent additive, 0.5 to 0.9 part of a coupling agent, 0.3 to 0.7 part of an anti-oxidant and 0.4 to 0.8 part of a foaming agent. The preparation method comprises the following steps: (1) weighing of the raw materials; (2) preparation of a mixture a; (3) preparation of a mixture b; (4) preparation of a mixture c; and (5) charging of a mold and molding. The nano-material prepared in the invention has the advantages of high strength, good heat insulation performance and air purifying performance.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Ceiling material and preparation method thereof

Relating to the field of building materials, the invention provides a ceiling material and a preparation method thereof. The ceiling material comprises the following raw materials by weight: a polyurethane polymer material, fly ash, ethyl stearate, palmitic acid, nano silica, nano calcium carbonate, nano titanium oxide, bamboo charcoal, zirconium oxide, boron carbide, glass fiber, attapulgite, glass wool, aluminum silicate, a heat stabilizer, a light stabilizer, a coupling agent, an antioxidant, and a foaming agent. The preparation method comprises the steps of: (1) weighing the raw materials, (2) preparing a mixture a, (3) preparing a mixture b, (4) preparing a mixture c, and (5) conducting molding in a die. The ceiling material prepared by the method provided by the invention has the advantages of air purification, high compressive strength, high tensile strength, good heat insulation effect and good fire prevention effect.

Owner:肥西县碧涛建材有限公司

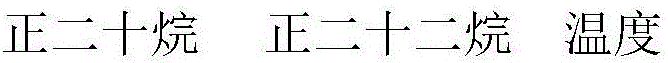

Disposable annular thermometer

ActiveCN105907377ALow costDisinfection safetyDiagnostic recording/measuringSensorsN-Octadecanoic acidEthyl stearate

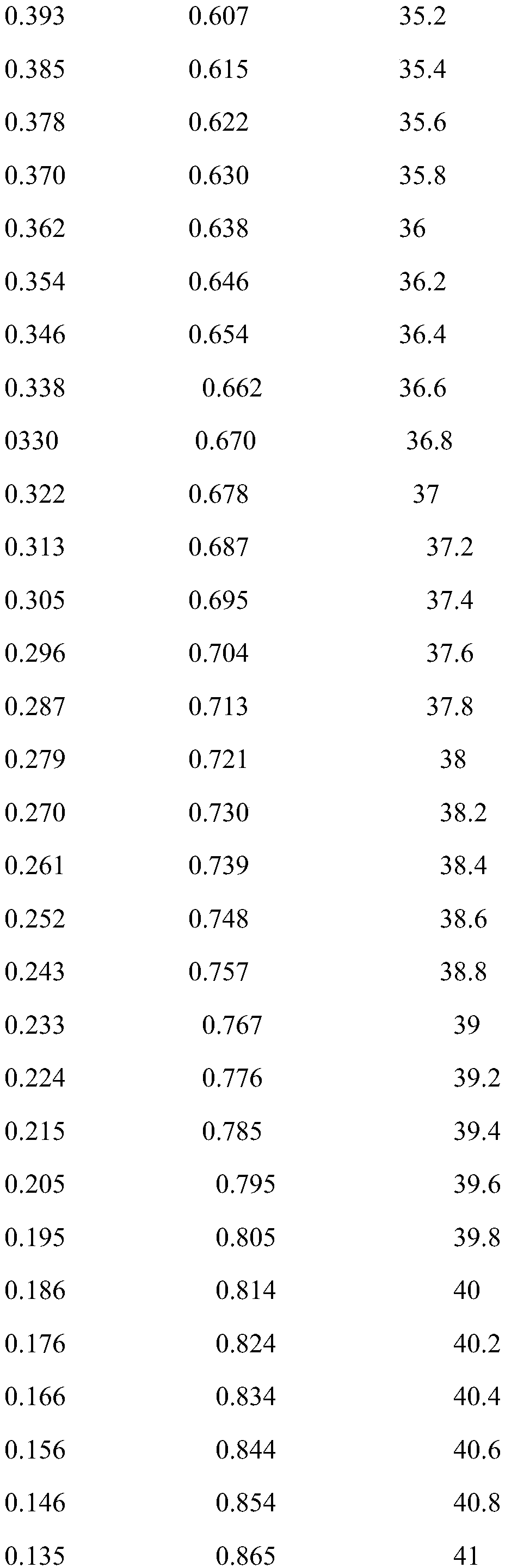

The invention discloses a disposable annular thermometer. The disposable annular thermometer is mainly used for measuring a body temperature. The disposable annular thermometer is prepared from organic matters and can be burned after use. Phase-change material powder is arranged in a plastic annular container and a body temperature is characterized through phase change of different phase-change materials at different temperatures. The phase-change materials comprise aliphatic hydrocarbons, fatty alcohols, aliphatic acids and aliphatic esters. The aliphatic hydrocarbons comprise n-nonadecane to n-tetracosane. The fatty alcohols comprise n-tridecanol to n-hexadecanol. The aliphatic acids comprise n-decadecanoic acid to n-octadecanoic acid. The aliphatic esters comprise methyl stearate, ethyl stearate, methyl nonadecanoate, ethyl nonadecanoate, methyl arachidate and ethyl eicosadioate. The phase-change material with different phase-change temperatures is a mixture of two or three different phase-change materials. The disposable annular thermometer is cheap, does not need disinfection and can be treated easily.

Owner:DONGHUA UNIV

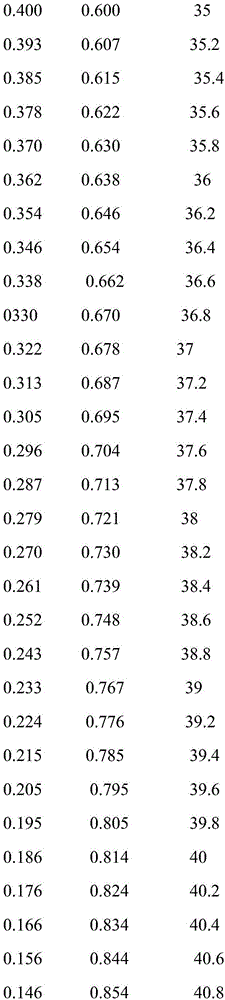

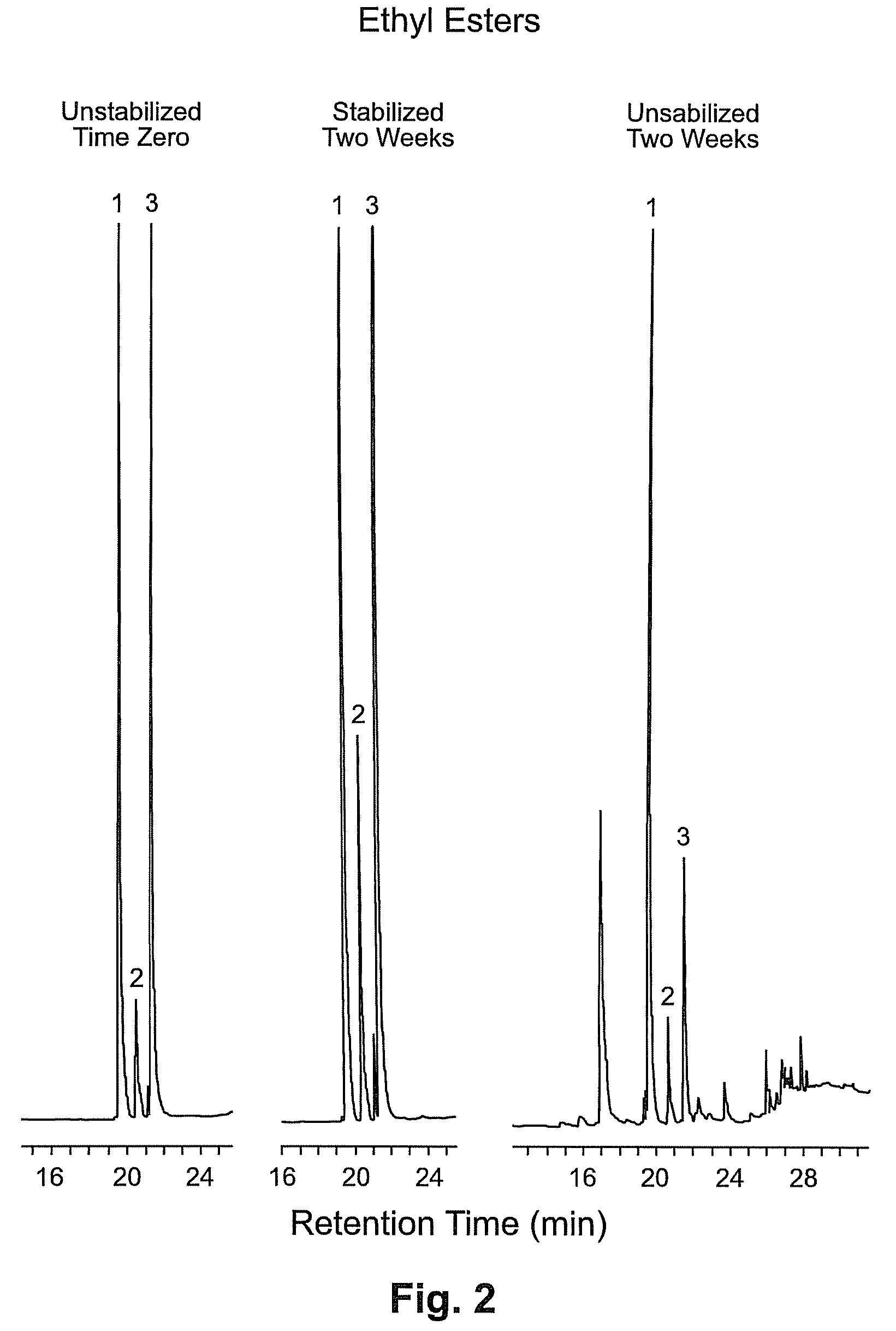

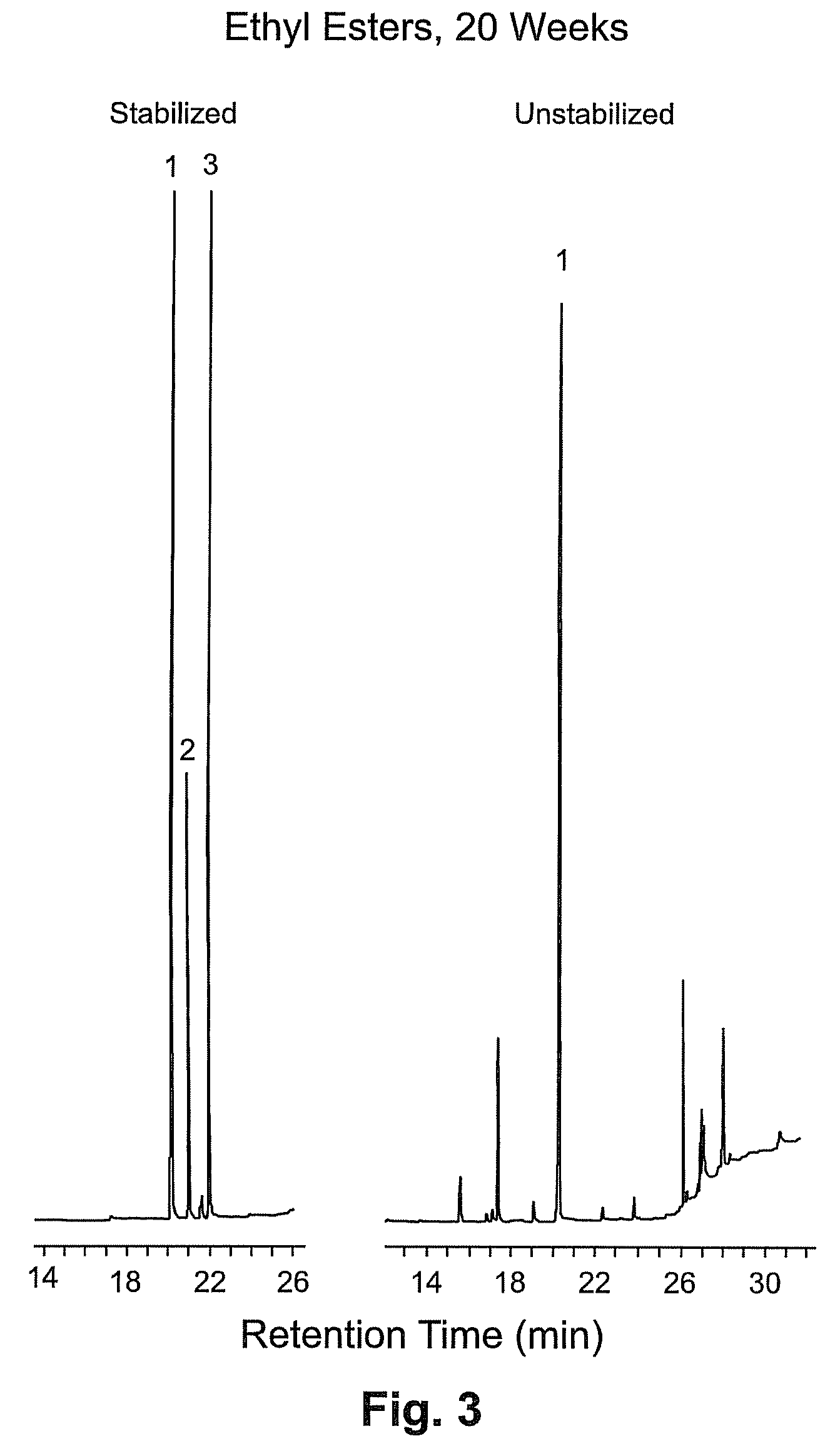

Stabilized brood pheromone for manipulating the behavior and physiology of honey bees

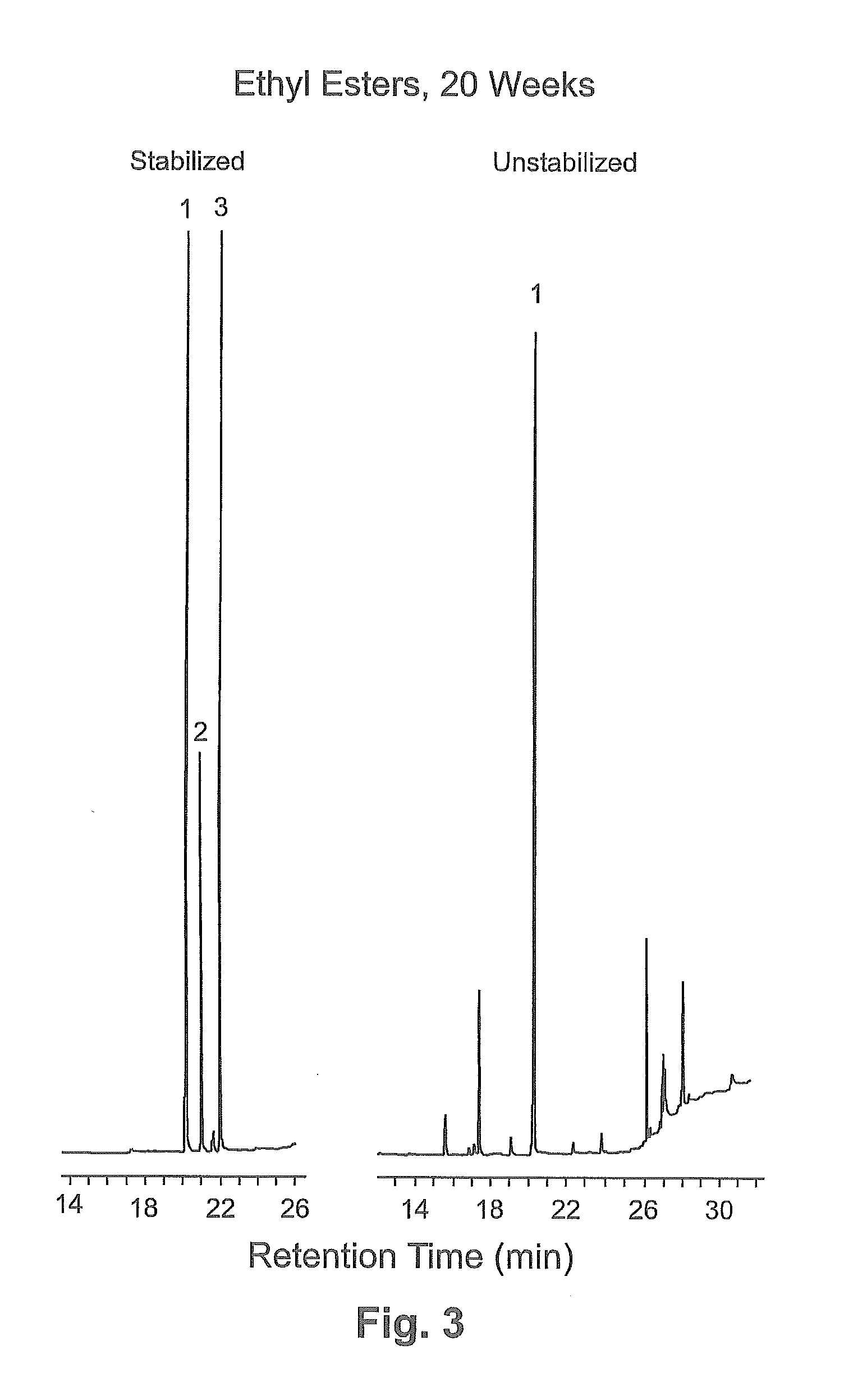

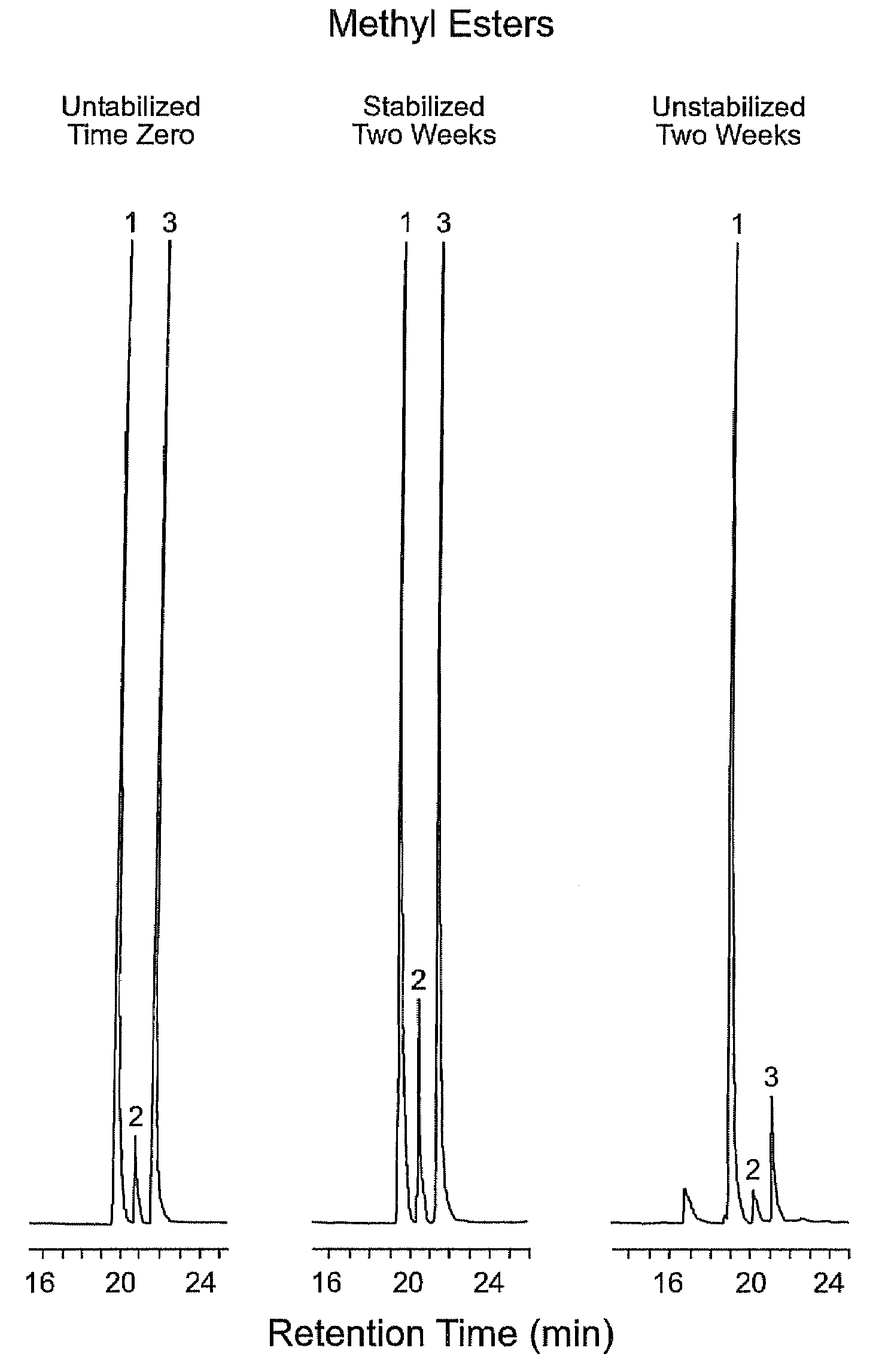

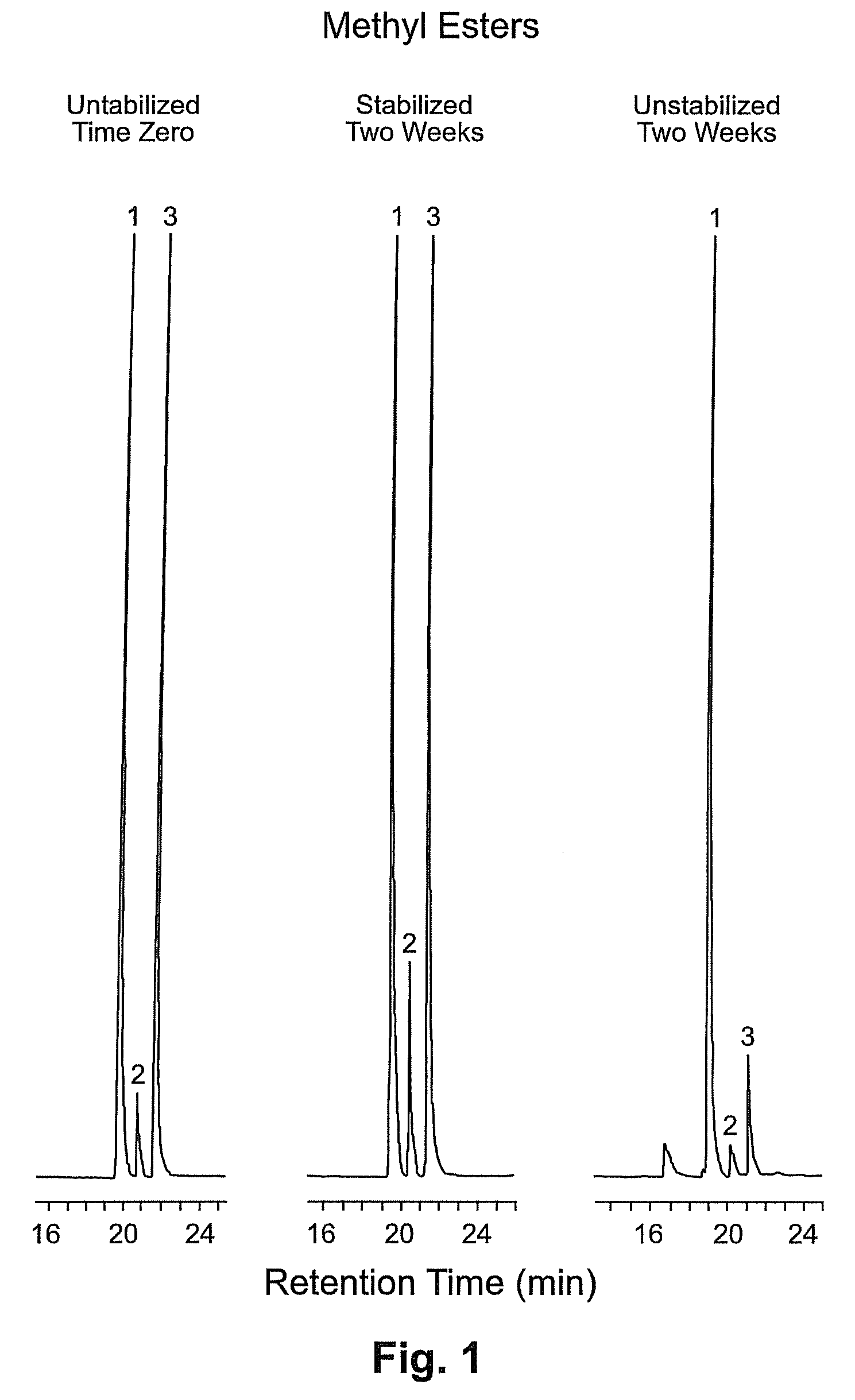

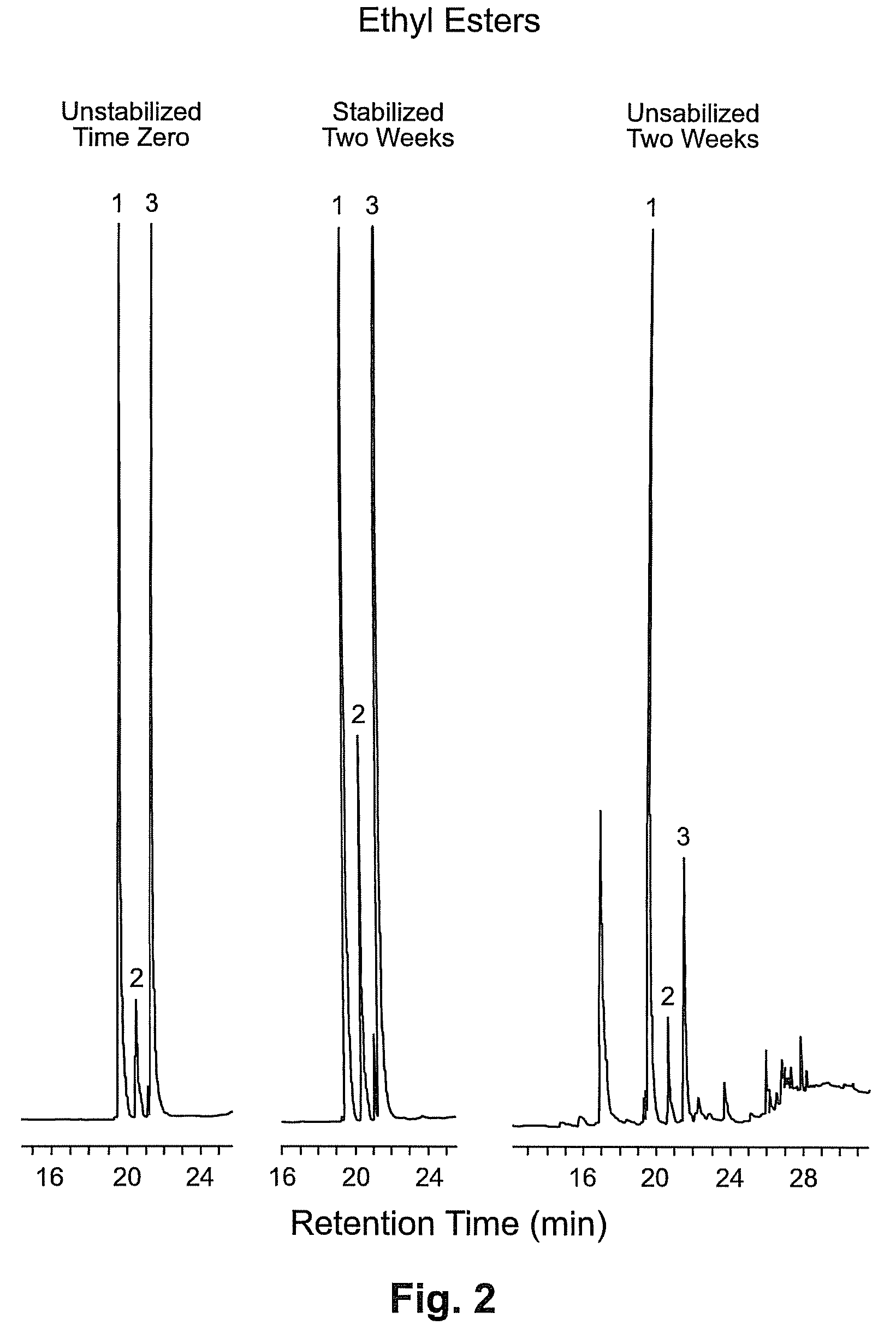

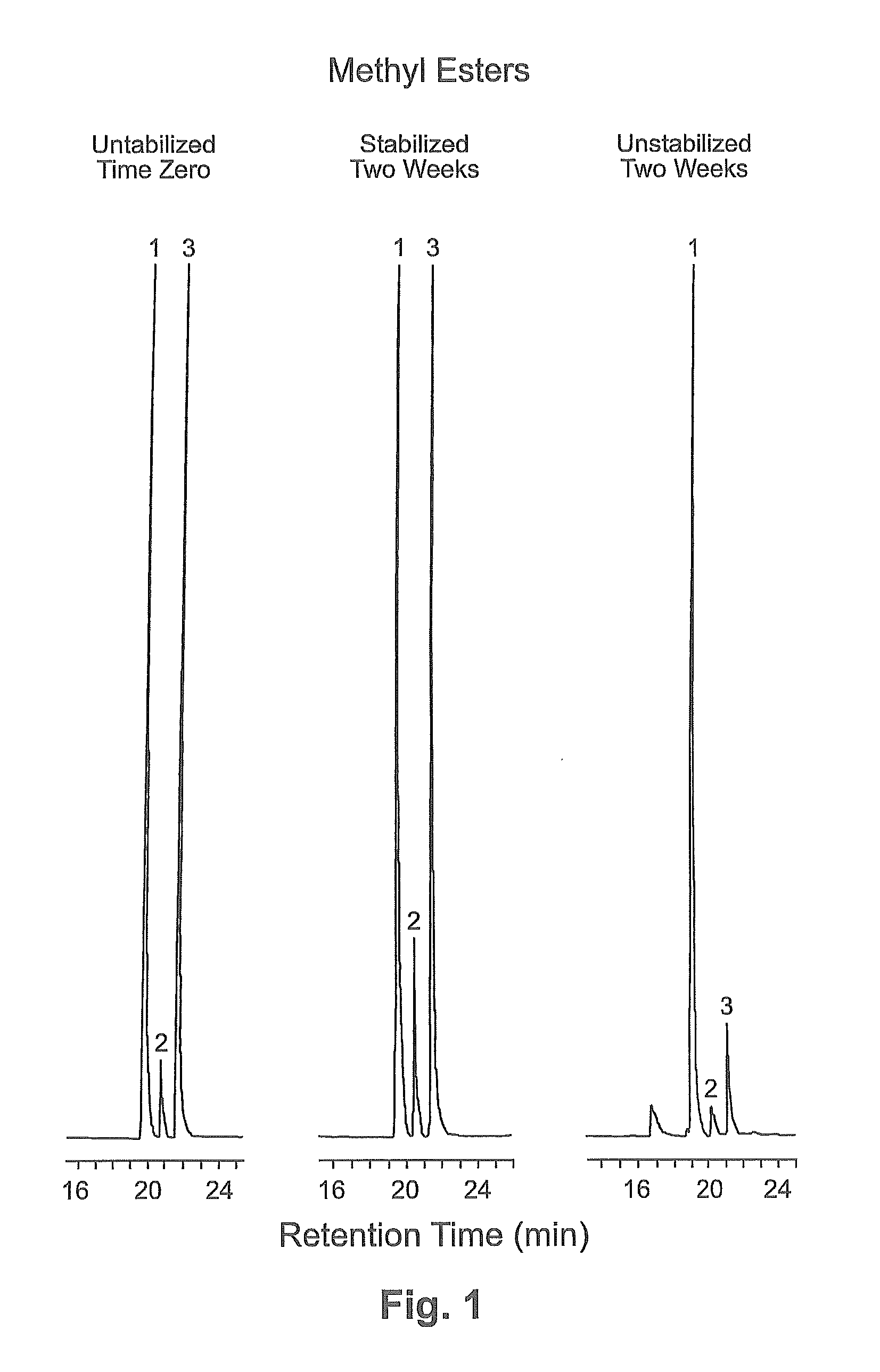

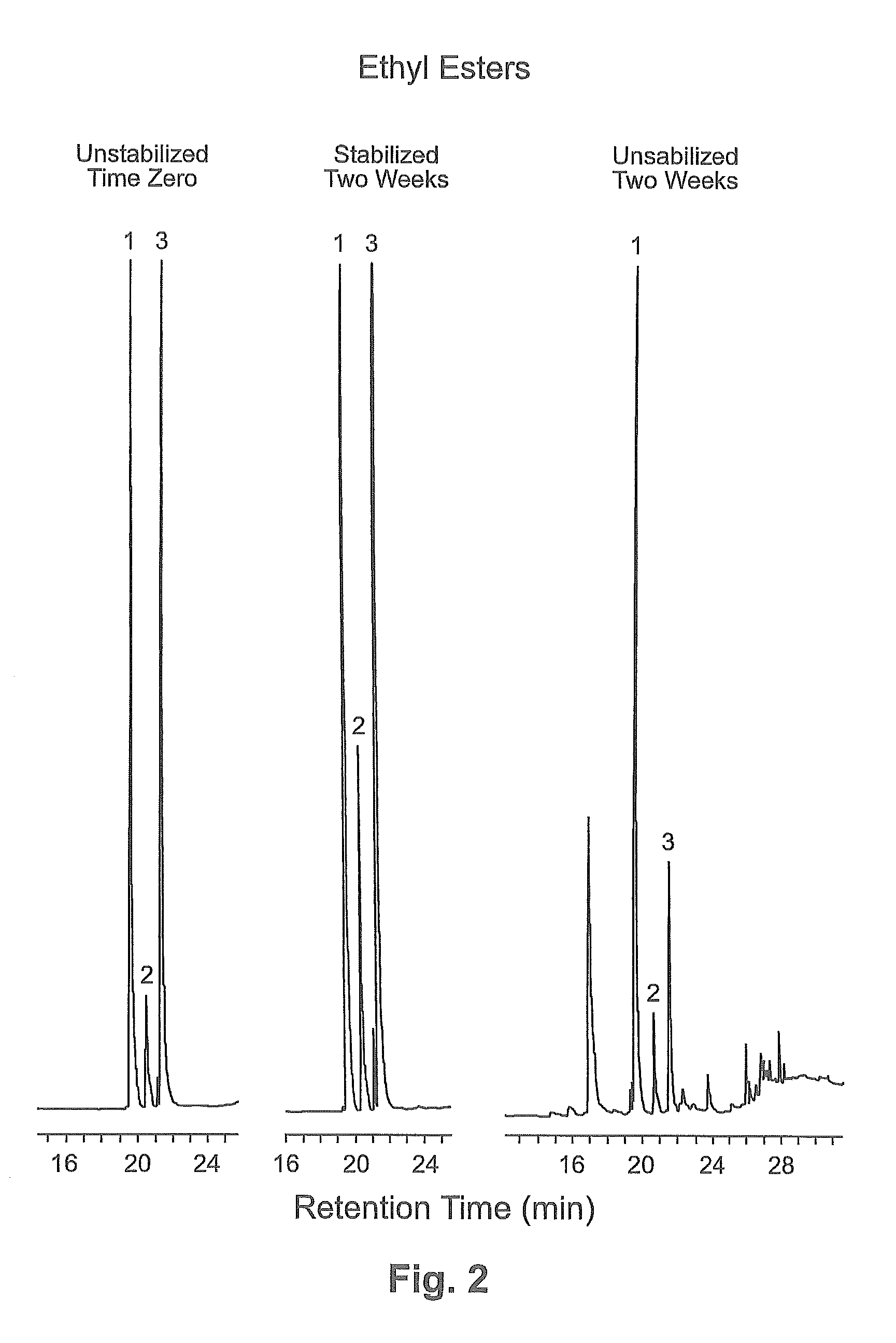

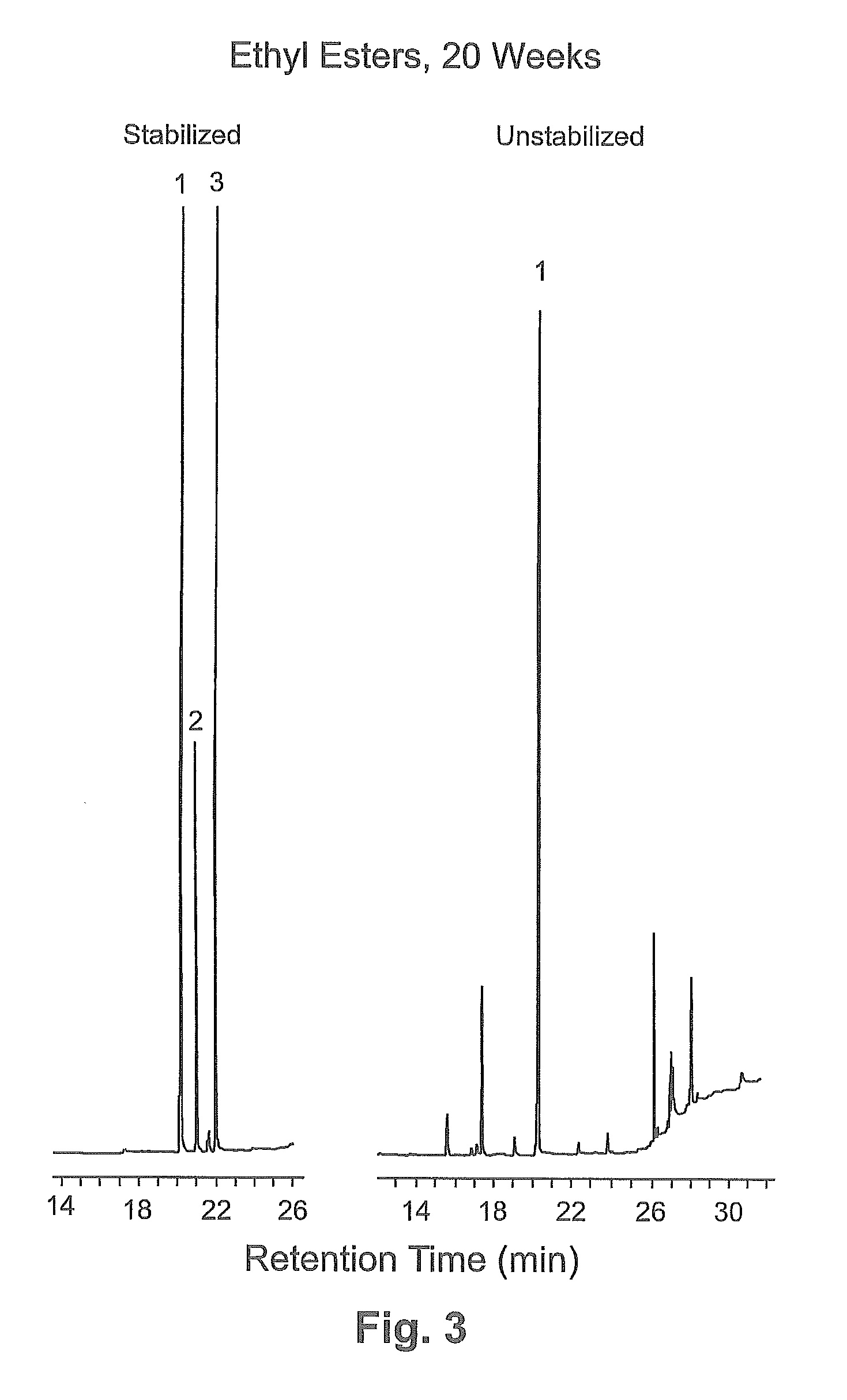

ActiveUS7727517B2Raise the ratioLower latencyBiocideHydroxy compound active ingredientsMethyl linoleateEthyl stearate

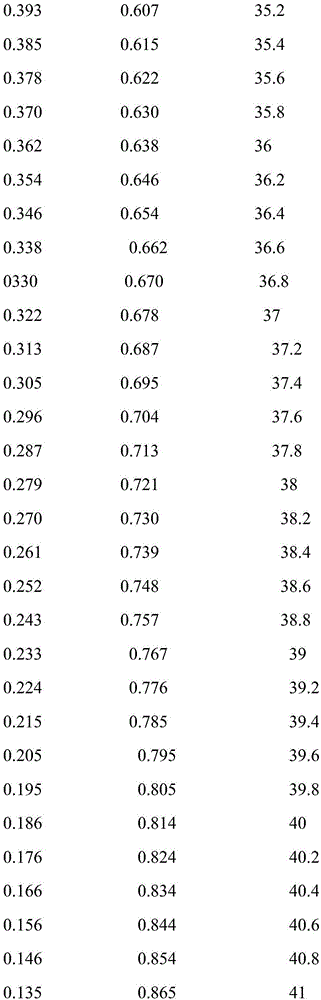

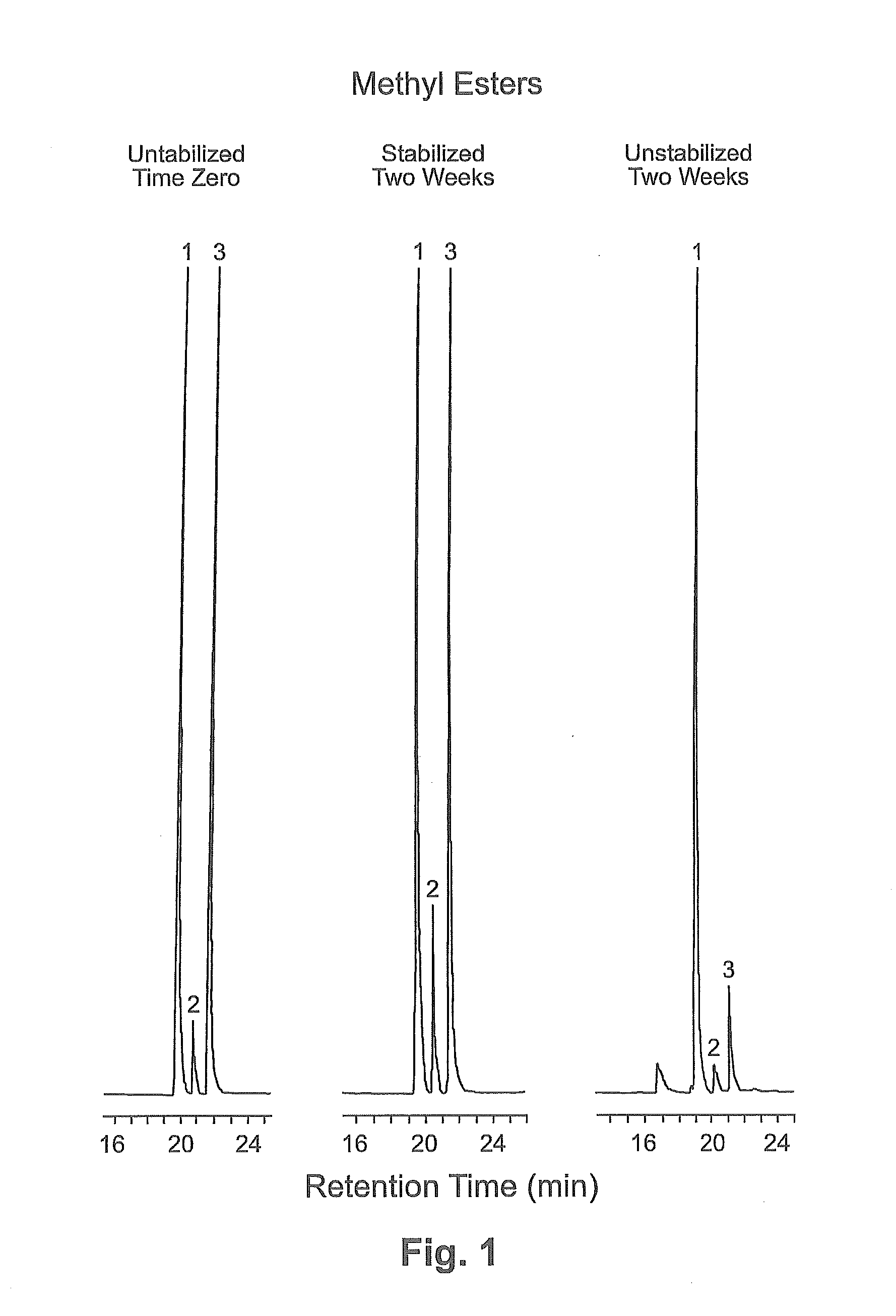

This invention relates to a stabilized honey bee pheromone and methods of stabilizing the honey bee brood pheromone, thereby enabling the production and sustained use of commercial products based on that pheromone. The stabilized pheromone can be used to manipulate the behavior and improve the performance of worker honey bees, resulting in overall increased vigor of the hive. The pheromone composition comprises two or more of ethyl linoleate, ethyl linolenate, ethyl oleate, ethyl palmitate, ethyl stearate, methyl linoleate, methyl linolenate, methyl oleate, methyl palmitate and methyl stearate and an antioxidant.

Owner:OMS INVESTMENTS INC +1

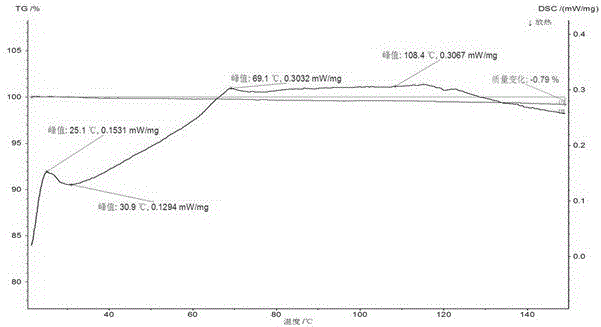

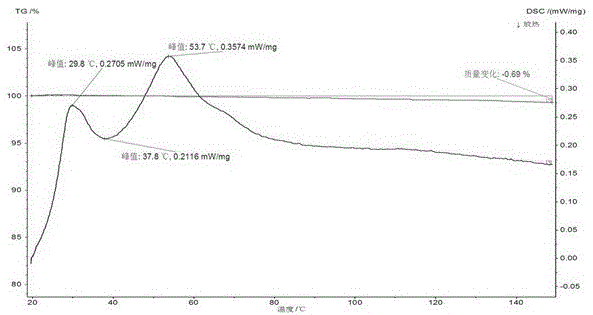

Heat insulation material and preparation method thereof

InactiveCN105567175ALarge latent heat of phase changeStable formHeat-exchange elementsEthyl stearateRoom temperature

The invention discloses a material having phase change and energy storage functions and especially being used as an exterior wall heat insulation material, and a preparation method and a use method thereof. The above phase change and energy storage composite material contains stearate and a carrier, and the heat insulation material concretely comprises methyl stearate, ethyl stearate, stearate and a lightweight hollow inorganic material used as the carrier, wherein the methyl stearate, the ethyl stearate and the stearate are supported in pores of the porous carrier. The phase change material has the advantages of low cost, room temperature approaching phase change point, large phase change latent heat, excellent heat insulation effect, and simple and easy practical operation.

Owner:SHANDONG HAIRONG ENERGY SAVING NEW MATERIAL CO LTD

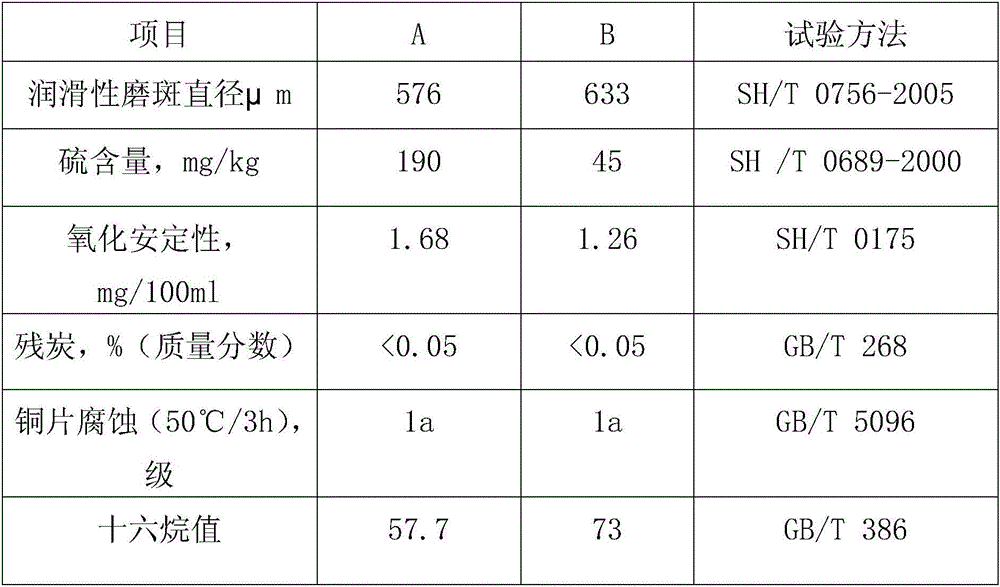

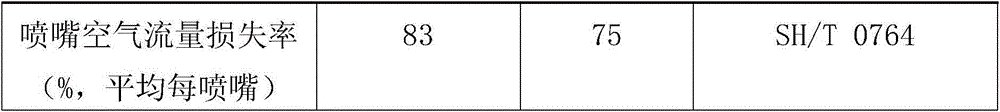

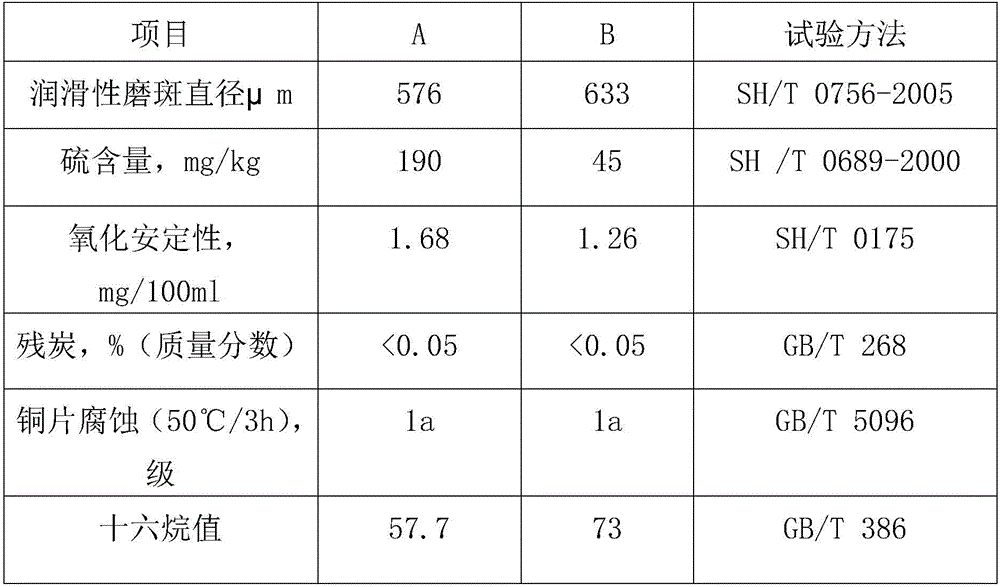

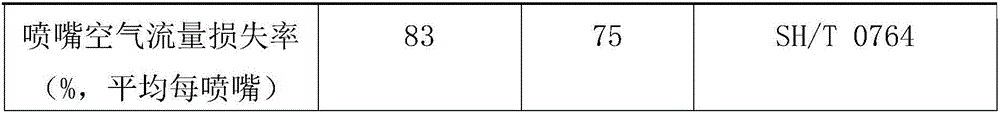

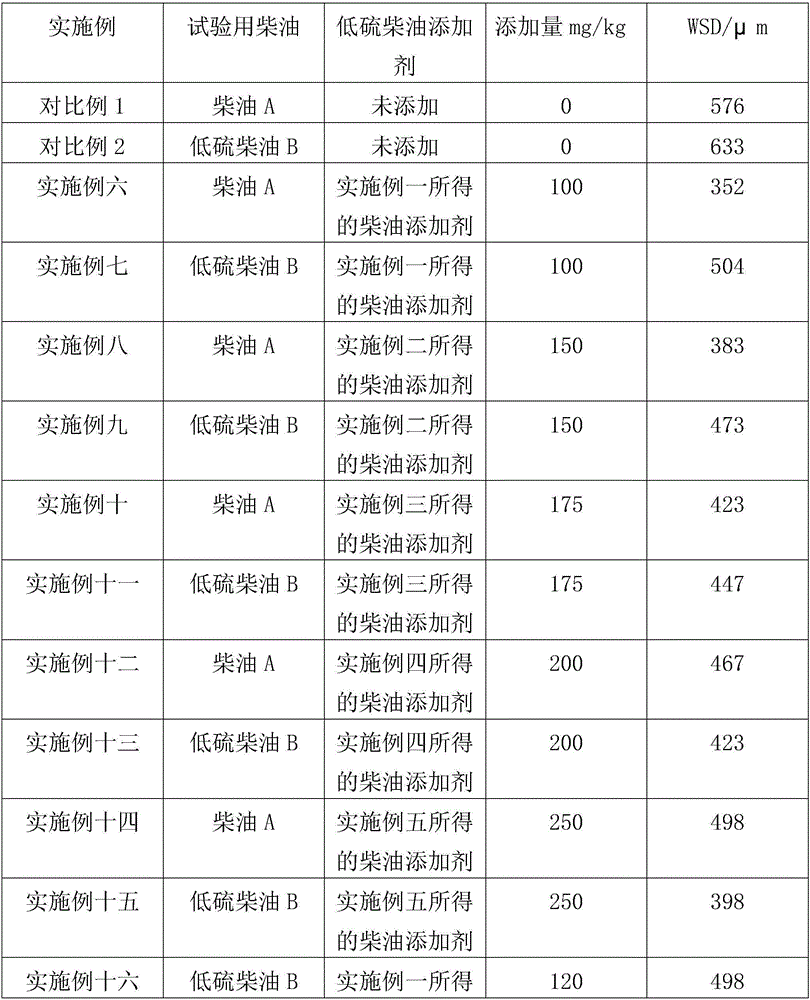

Low-sulfur diesel additive and preparation technology thereof

ActiveCN105462636AImprove the lubrication effectIncrease burn rateLiquid carbonaceous fuelsFuel additivesBiodieselAntioxidant

The invention relates to a low-sulfur diesel additive and a preparation technology thereof. The low-sulfur diesel additive comprises the following components in parts by weight: 40-45 parts of biodiesel, 3-8 parts of glyceryl stearate, 2-5 parts of ethyl stearate, 9-15 parts of oleamide, 20-24 parts of solubilizer, 6-10 parts of detergent and 5-8 parts of antioxidant. A preparation method of the low-sulfur diesel additive comprises the following steps: adding the biodiesel and solubilizer into a reaction container; heating and stirring and adding the glyceryl stearate, ethyl stearate and oleamide; adding the detergent and the antioxidant and stirring and mixing; and after that, filtering to obtain the low-sulfur diesel additive. The advantages of the invention are as follows: the low-sulfur diesel additive can be dissolved well with diesel, and the lubricating property of the diesel can be obviously improved; and the low-sulfur diesel additive also has oxidation resistance as well as detergency and dispersibility.

Owner:丁以钿

Disposable thermometer

ActiveCN105784186ALow costDisinfection safetyThermometers using physical/chemical changesHeat-exchange elementsEthyl stearateN-Octadecanoic acid

The invention discloses a disposable thermometer, which is mainly used for measuring body temperature. The thermometer is totally made of organic matters, and can be disposed through incineration after use. Phase-change material powders are placed in a container made of plastics, and body temperature is represented through the feature that different phase-change materials have phase change under different temperatures. The phase-change materials comprise aliphatic hydrocarbons, fatty alcohol, fatty acid and fatty acid ester. The aliphatic hydrocarbons comprise n-nonadecane-n-tetracosane; the fatty alcohol comprises n-tridecanol-n-hexadecanol; the fatty acid comprises n-capric acid-n-octadecanoic acid; and the fatty acid ester comprises methyl stearate, ethyl stearate, methyl nonadecanoate, ethyl nonadecanoate, eicosanoic acid methyl ester and eicosanoic acid ethyl ester. The phase-change materials having different phase-change temperatures are mixture of two or three kinds of different phase-change materials. The disposable thermometer is cheap, does not need disinfection and is easy to dispose.

Owner:DONGHUA UNIV

Ginseng skin cream

InactiveCN107174544AMoisturizingWith whiteningCosmetic preparationsToilet preparationsWrinkle skinEthyl stearate

The invention discloses a ginseng skin cream, which is characterized in that its ingredients are: ethyl stearate, glycerin acetyl tartaric acid fatty acid ester, sea bird feather oil, isopropyl palmitate, butyl acetate, glycerin, Nepal gold Methyl esters, ginseng, witch hazel extract, parfum, diisopropylethylamine, water. The ginseng skin cream of the invention can improve the smoothness of the skin and has the effects of wrinkle removal, wrinkle resistance and skin beautification.

Owner:成都九朗生物科技有限公司

Stabilized Synthetic Brood Pheromone and Race-Specific Ratios of Components for Manipulating the Behavior and Physiology of Honey Bees

ActiveUS20110021622A1Raise the ratioIncrease load weightBiocideDead animal preservationMethyl linoleateEthyl stearate

This invention relates to a 10-component stabilized synthetic honey bee brood pheromone and methods of stabilizing said pheromone by adding one or more antioxidants, thereby enabling the production and sustained use of commercial products based on that pheromone. The 11-component stabilized pheromone composition formed by adding the antioxidant tertiary-butyl hydroquinone to a synthetic blend of ethyl linoleate, ethyl linolenate, ethyl oleate, ethyl palmitate, ethyl stearate, methyl linoleate, methyl linolenate, methyl oleate, methyl palmitate and methyl stearate can be used in generic or race-specific ratios to manipulate the behavior and improve the performance of worker honey bees, resulting in overall increased vigor of the hive.

Owner:TEXAS A&M UNIVERSITY +1

Stabilized brood pheromone for manipulating the behavior and physiology of honey bees

ActiveUS20080124300A1Raise the ratioIncrease load weightBiocideHydroxy compound active ingredientsMethyl linoleateAntioxidant

This invention relates to a stabilized honey bee pheromone and methods of stabilizing the honey bee brood pheromone, thereby enabling the production and sustained use of commercial products based on that pheromone. The stabilized pheromone can be used to manipulate the behavior and improve the performance of worker honey bees, resulting in overall increased vigor of the hive. The pheromone composition comprises two or more of ethyl linoleate, ethyl linolenate, ethyl oleate, ethyl palmitate, ethyl stearate, methyl linoleate, methyl linolenate, methyl oleate, methyl palmitate and methyl stearate and an antioxidant.

Owner:OMS INVESTMENTS INC +1

A kind of low-sulfur diesel oil additive and its preparation process

ActiveCN105462636BImprove the lubrication effectIncrease burn rateLiquid carbonaceous fuelsFuel additivesBiodieselAntioxidant

The invention relates to a low-sulfur diesel additive and a preparation technology thereof. The low-sulfur diesel additive comprises the following components in parts by weight: 40-45 parts of biodiesel, 3-8 parts of glyceryl stearate, 2-5 parts of ethyl stearate, 9-15 parts of oleamide, 20-24 parts of solubilizer, 6-10 parts of detergent and 5-8 parts of antioxidant. A preparation method of the low-sulfur diesel additive comprises the following steps: adding the biodiesel and solubilizer into a reaction container; heating and stirring and adding the glyceryl stearate, ethyl stearate and oleamide; adding the detergent and the antioxidant and stirring and mixing; and after that, filtering to obtain the low-sulfur diesel additive. The advantages of the invention are as follows: the low-sulfur diesel additive can be dissolved well with diesel, and the lubricating property of the diesel can be obviously improved; and the low-sulfur diesel additive also has oxidation resistance as well as detergency and dispersibility.

Owner:丁以钿

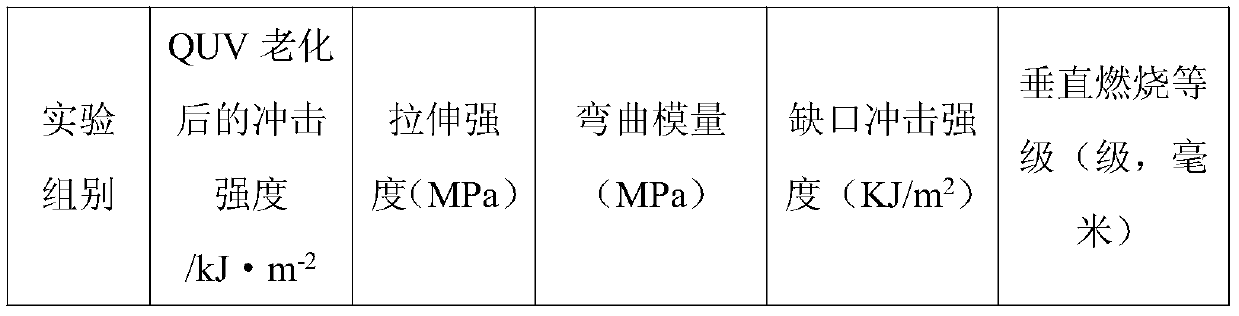

Highly-flame-retardant polypropylene composite material for new energy automobiles, and preparation method thereof

InactiveCN109929208AImprove dispersion stabilityImprove thermal conductivityPolymer scienceCarbon fibers

The invention discloses a highly-flame-retardant polypropylene composite material for new energy automobiles, and a preparation method thereof. The highly-flame-retardant polypropylene composite material for new energy automobiles comprises polypropylene resin, polyacrylamide microspheres, ethyl stearate, paraffin, dodecanoic acid, 1,3:2,4-di-p-methylbenzylidenesorbitol, dimethyl malonate, iron sodium tartrate, melamine, magnesium salt whiskers, lithium porcelain stones, calcium stearate, diethylene glycol monoacrylate, nano-aluminum powder, carbon fibers, hydroxyethyl acrylate, acrylic acid,nano-copper powder, microcrystalline graphite and methyl diphenylene diisocyanate. The preparation method comprises the following steps: preparing a mixture I and a mixture II, feeding the mixture I into the main feed port of a double screw extruder, feeding the mixture II from the side port of the double screw extruder, performing mixing, and carrying out extruding granulation to obtain the highly-flame-retardant polypropylene composite material for new energy automobiles. The sole material of the present invention has excellent aging resistance.

Owner:长沙而道新能源科技有限公司

disposable thermometer

ActiveCN105784186BLow costDisinfection safetyThermometers using physical/chemical changesHeat-exchange elementsN-Octadecanoic acidEthyl stearate

Owner:DONGHUA UNIV

Preparation method and application of energy-saving environment-friendly building material

The invention discloses a preparation method and application of an energy-saving environment-friendly building material. The preparation method comprises the steps of mixing coal ash, feldspar powderand silicon dioxide, adequately grinding in a grinding machine, adding methoxy polyethylene glycol, ethyl stearate and polyamide into deionized water, carrying out ultrasonic treatment, mixing the twomixtures, feeding the mixture into a reaction kettle, heating for reaction, immediately pouring a primary reaction product into a mold, carrying out demolding after the product is solidified and formed, drying, and carrying out packaging and sealing, so as to obtain a finished product. The prepared energy-saving environment-friendly building material has good thermal insulation effect and high strength and further has good application prospect in constructional engineering.

Owner:付主枝

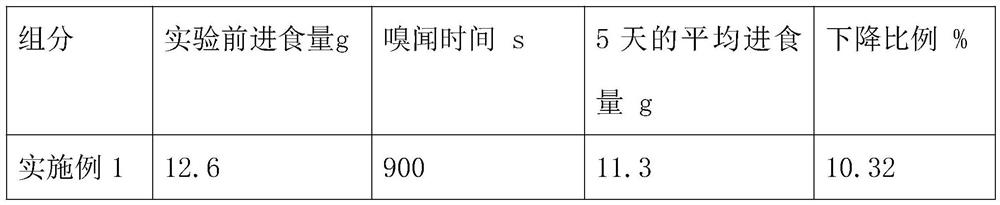

Substance for regulating body satiety hormone and application thereof

PendingCN111838659AIncrease satietyReduce energy intakeHydroxy compound active ingredientsPharmaceutical delivery mechanismEthyl stearateEthyl palmitate

The invention relates to a substance for regulating body satiety hormone and application thereof. The substance is prepared from the following components in parts by weight: 6 to 25 parts of coconut aldehyde, 10 to 39 parts of amyl valerate, 13 to 22 parts of nerol, 2 to 42 parts of hexyl caproate, 8 to 28 parts of ethyl palmitate and 1 to 18 parts of ethyl stearate. The invention provides a substance capable of improving body satiety hormone and reducing body hunger sensation hormone, the substance is utilized by the body in an olfactory manner, the application is convenient, the applicationscene and prospect are wide, and as the substance is zero-energy, the problem of extra energy intake during absorption of traditional weight-reducing food or meal replacement is solved.

Owner:河南思迈尔健康科技有限公司 +2

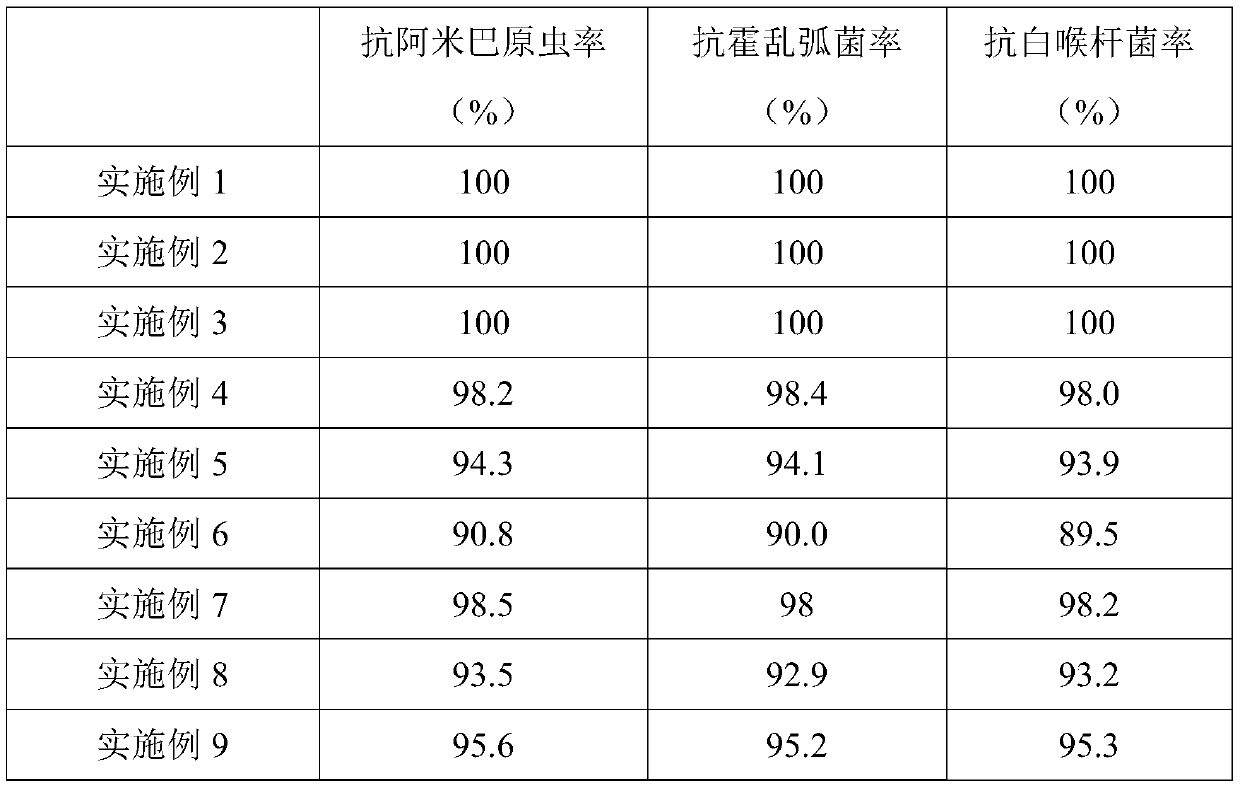

Nano phytoncide composition for bacteriostasis and preparation method thereof

The invention relates to the field of phytoncide compositions, in particular to a nano phytoncide composition for bacteriostasis and a preparation method thereof. The composition provided in the firstaspect comprises the following components in parts by weight: 50-60 parts of nano phytoncide, 25-35 parts of plant extracts and 20-30 parts of water. Under the action of cane sugar, ethyl stearate, potassium aliphatate and sodium ethoxide, the nano phytoncide prepared can be quickly and uniformly mixed in water and other plant extracts, thus reducing production time; meanwhile, a grapefruit extract, a mint extract, a forsythia suspensa extract, a scindapsus aureus extract and the nano phytoncide are adopted to achieve a synergistic bacteriostatic effect, so that the sterilization effect is strong, the effect is remarkable, the 100% sterilization rate can be achieved within a short time, bacteria can be effectively inhibited, and the composition can be widely applied to multiple fields ofdaily chemical products, cosmetics and the like.

Owner:深圳市芬多精纳米生物科技有限公司

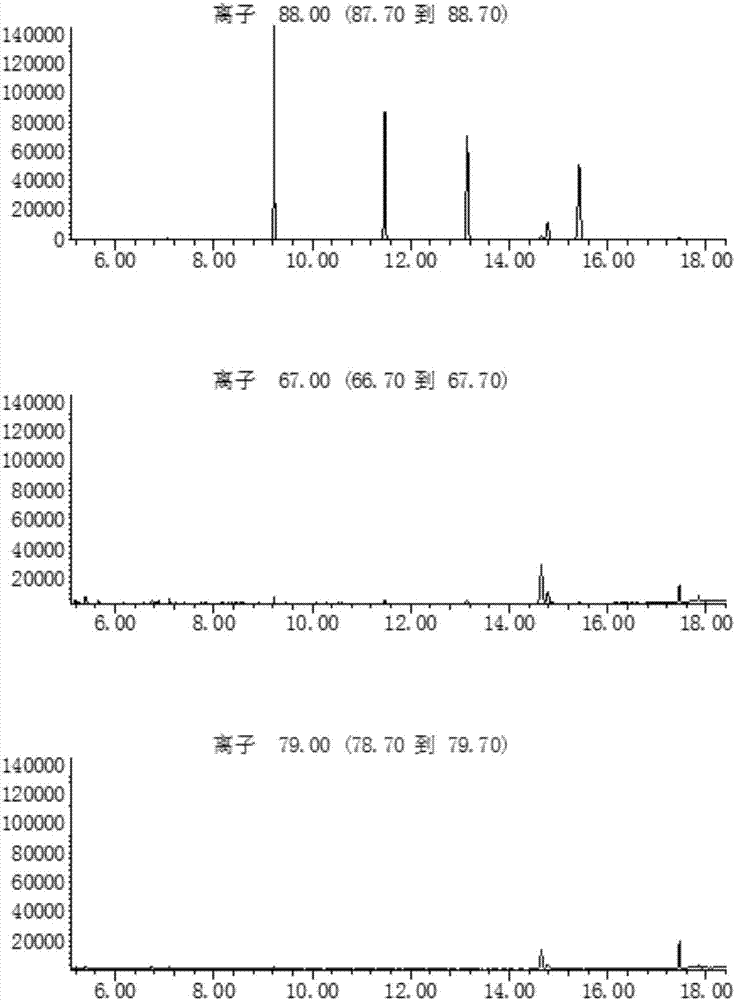

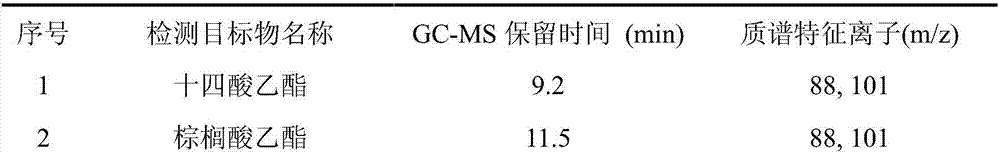

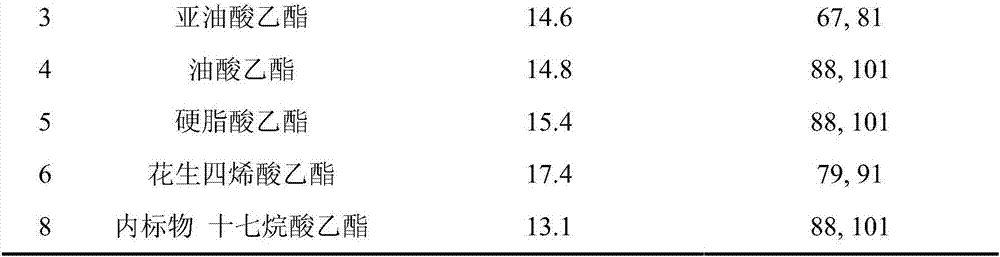

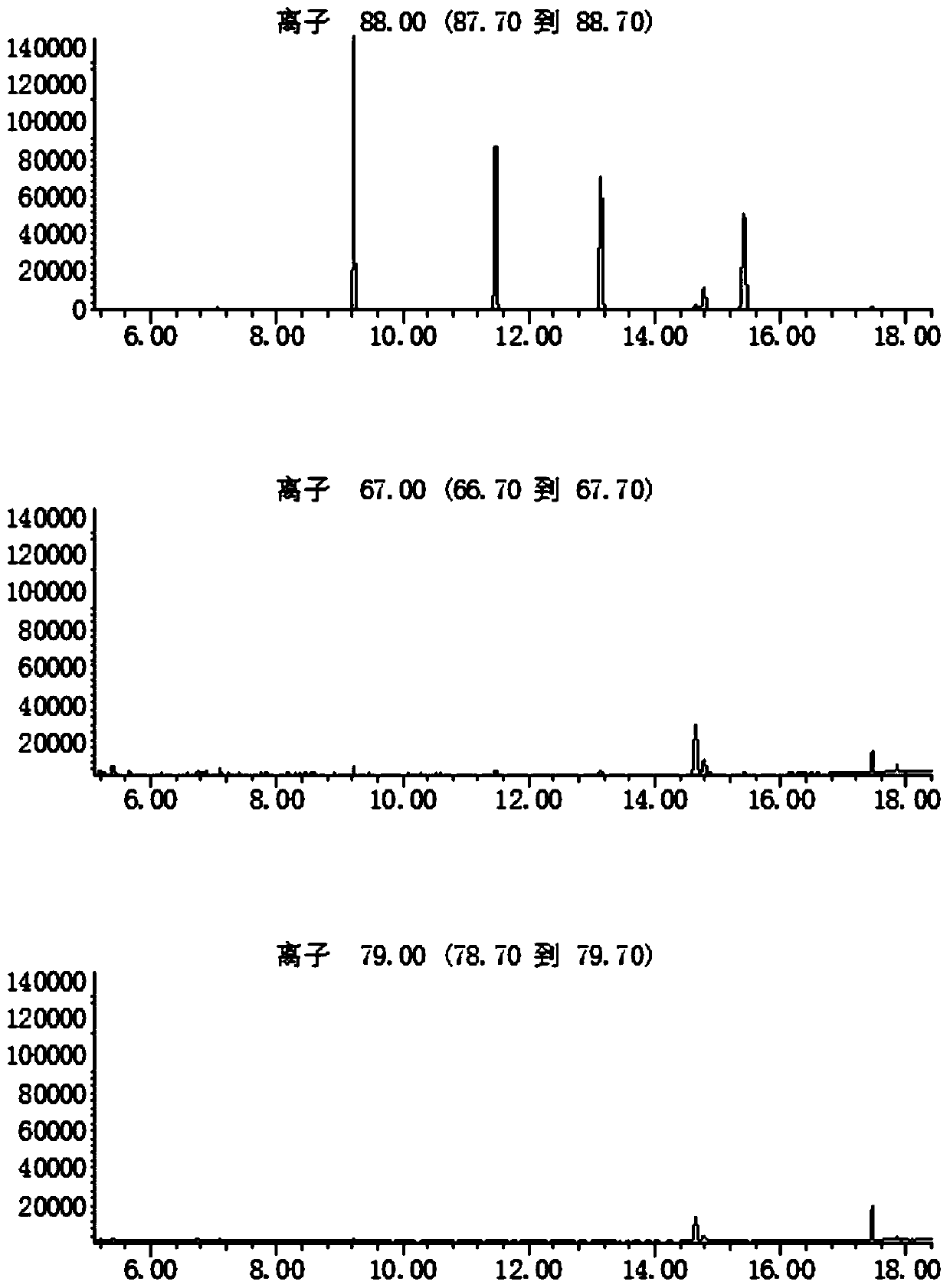

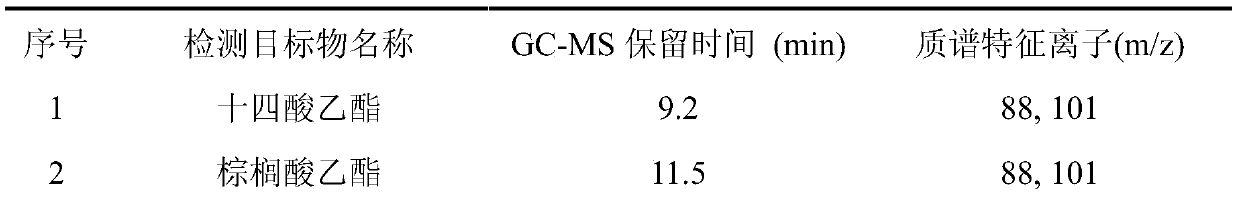

Method for simple and rapid determination of six fatty acid ethyl esters in human whole blood

The invention relates to a method for simple and rapid determination of six fatty acid ethyl esters in human whole blood, belonging to the technical fields of drug detection and forensic identification, wherein the six fatty acid ethyl esters include ethyl myristate, ethyl palmitate, ethyl stearate, ethyl oleate, ethyl linoleate and ethyl arachidonate. The method is low in the usage amount of samples, and as few as 200 [mu]L of samples are examined. The process of pretreatment is simple and fast. A HP-5MS capillary gas chromatographic column and a mass spectrometric detector are employed for determination of the contents of the six fatty acid ethyl esters in human whole blood. The method has the advantages of high sensitivity, good specificity, a wide linear range, simple and fast operation and low usage amount of extraction solvents, and is capable of satisfying high requirements of urgent forensic identification tasks on detection time and easy to operate and promote.

Owner:FUDAN UNIV

A simple and rapid method for the determination of six fatty acid ethyl esters in human whole blood

ActiveCN107543869BReduce dosageIncrease consumptionComponent separationEthyl stearateEthyl arachidonate

The invention relates to a method for simple and rapid determination of six fatty acid ethyl esters in human whole blood, belonging to the technical fields of drug detection and forensic identification, wherein the six fatty acid ethyl esters include ethyl myristate, ethyl palmitate, ethyl stearate, ethyl oleate, ethyl linoleate and ethyl arachidonate. The method is low in the usage amount of samples, and as few as 200 [mu]L of samples are examined. The process of pretreatment is simple and fast. A HP-5MS capillary gas chromatographic column and a mass spectrometric detector are employed for determination of the contents of the six fatty acid ethyl esters in human whole blood. The method has the advantages of high sensitivity, good specificity, a wide linear range, simple and fast operation and low usage amount of extraction solvents, and is capable of satisfying high requirements of urgent forensic identification tasks on detection time and easy to operate and promote.

Owner:FUDAN UNIV

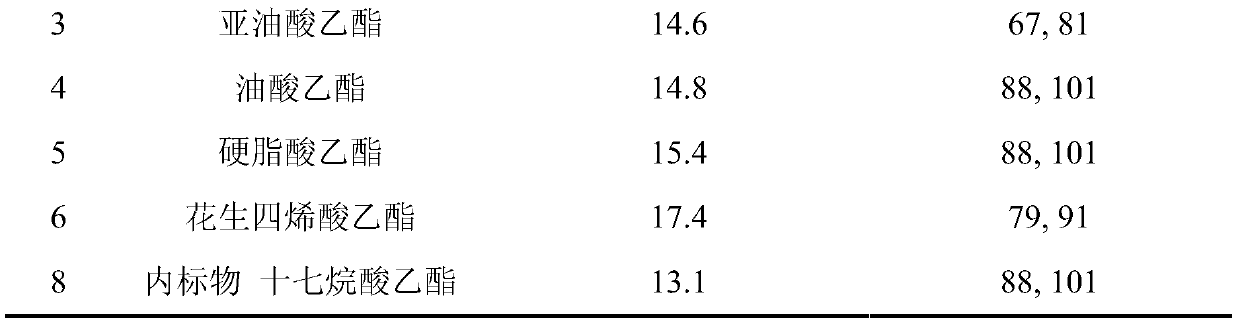

Long glass fiber reinforced nylon composite material, preparation method thereof, and application of composite material in electric cutters

The invention discloses a long glass fiber reinforced nylon composite material, a preparation method thereof, and an application of the composite material in electric cutters. The composite material comprises 1-2 parts of cyclohexane, 5-7 parts of ethyl stearate, 3-4 parts of maleic anhydride, 1-2 parts of bisphenol A type liquid epoxy resin, 50-70 parts of nylon resin, 20-40 parts of glass fibers, 0.2-1 part of an antioxidant, 0.2-1 part of a lubricant and 0.1-1 part of pigment. The long glass fiber reinforced nylon composite material matrix has high impact performance, greatly reduces use ofa toughening agent, and can meet performance requirements of related products.

Owner:南京欣阳新能源科技有限公司

Stabilized synthetic brood pheromone and race-specific ratios of components for manipulating the behavior and physiology of honey bees

ActiveUS9107396B2Solve the lack of lifeRaise the ratioBiocideIn-vivo radioactive preparationsAntioxidantEthyl stearate

Owner:TEXAS A&M UNIVERSITY +1

A kind of preparation method of biodiesel

ActiveCN109294636BHigh calorific valueIncrease cetane numberBiofuelsLiquid carbonaceous fuelsPtru catalystEthyl stearate

The invention discloses a preparation method of biomass diesel. The preparation method comprises the following steps: adding rice husks, walnut shell powder, a catalyst and water into an autoclave, sealing the autoclave, heating the autoclave, adjusting the pressure in the autoclave, carrying out a reaction, and naturally cooling the obtained reaction product to room temperature in order to obtainan oil and water mixture; taking the oil and water mixture, stirring the oil and water mixture and diesel to achieve mixing, carrying out ultrasonic treatment, introducing nano-bubbles to the obtained mixed solution in the ultrasonic process, and carrying out standing layering to separate oil and water; and taking the separated oil, adding the oil into a spherical stainless steel container, thenadding 1,2,3-trimethylcyclopentane, ethyl stearate, nitroethane and diphenyl urea, sealing the spherical stainless steel container, arranging the sealed container on a four-axis grinder, and turning on the four-axis grinder to drive the spherical stainless steel container to rotate randomly in order to obtain the biomass diesel. The biomass diesel oil prepared in the invention has the advantages of high calorific value, high cetane number, small acid value and good stability, and the emission of harmful gases (CO, HC, NO) after combustion is decreased.

Owner:李祥

Production method of highly corrosion-resistant ultrafine flaky zinc powder

The invention provides a method for manufacturing superfine flaky zinc powder with high corrosion resistance, and belongs to the technology of metallurgical waste utilization and metal powder material manufacturing. Raw zinc powder is commercially available waste sieved out in a battery zinc powder process, the raw zinc powder, industrial auxiliary agents and grinding media are placed into a horizontal type blade high-powered stirring grinder to be ground, the mass ratio of the grinding media to the raw zinc powder is 10:1-20:1, the mass of the industrial auxiliary agents is 1.0-3.0% of the mass of the raw zinc powder, the industrial auxiliary agents are one or two of hexadecanoic acid, dodecyl alcohol, ethyl stearate and silane coupling agents, the grinding media are bearing steel balls with the diameters being 5-7 millimeters, vacuum pumping is conducted firstly, and then inert gas is fed two times for protection; the ground flaky zinc powder is placed in a mixer, and mixing and passivation are conducted in air; the mixed flaky zinc powder is placed in a cyclone classifier and classified so as to obtain the superfine flaky zinc powder. The metallurgical waste can be used; the superfine flaky zinc powder has the high corrosion resistance, and production cost is reduced.

Owner:昆明海创兴科技有限公司

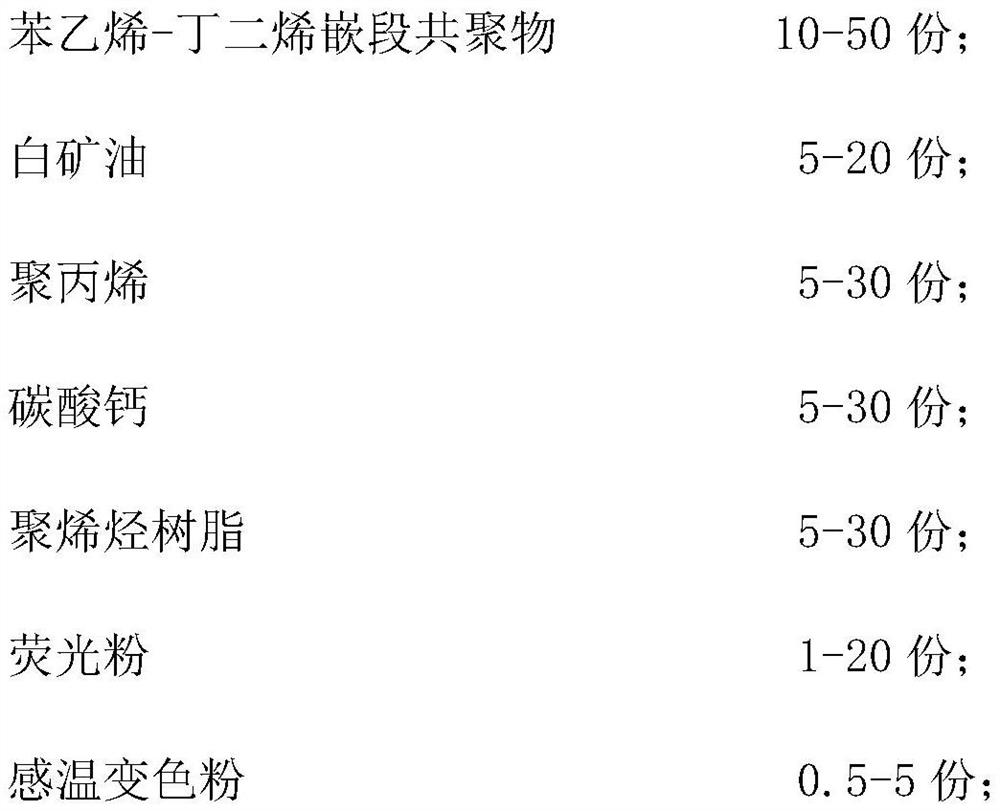

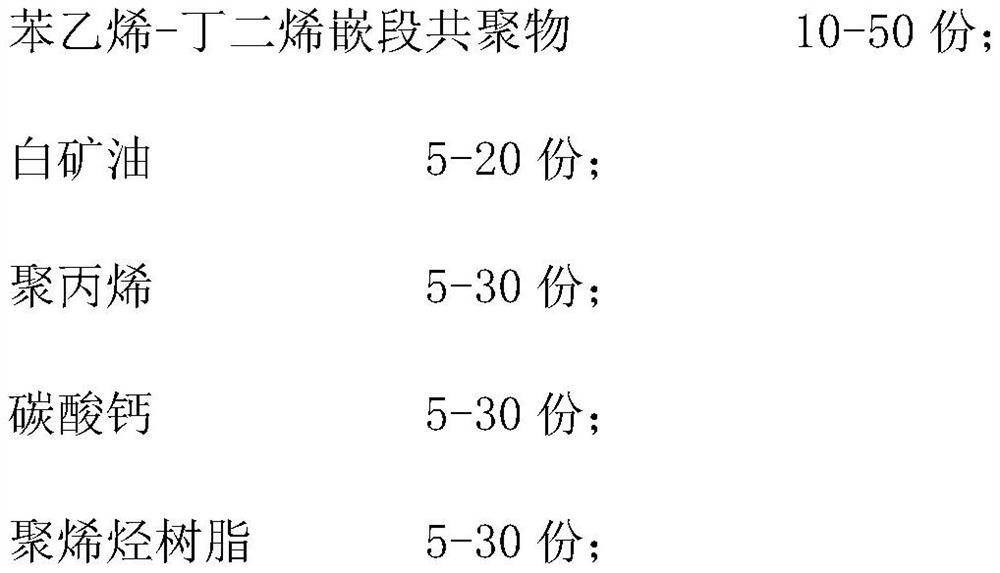

Thermochromic TPE material capable of emitting light at night

InactiveCN111875917AReminder of temperature changesAchieve night glow effectPolyolefinEthyl stearate

The invention discloses a thermochromic TPE material which can be used for a plastic coating layer in a wire and can emit light at night. The TPE material comprises the following raw material components in parts by weight: 10-50 parts of styrene-butadiene segmented copolymer; 5-20 parts of white mineral oil; 5-30 parts of polypropylene; 5-30 parts of calcium carbonate; 5-30 parts of polyolefin resin; 1-20 parts of fluorescent powder; 0.5-5 part of thermochromic powder, wherein the thermochromic powder is prepared from the following raw material components: 10-30 parts of melamino-formaldehyderesin, 3-15 parts of styrene-maleic anhydride copolymer, 30-50 parts of methyl stearate, 5-20 parts of ethyl stearate and 1-8 parts of uranidin-37. The fluorescent powder absorbs light under the irradiation of light in the daytime and emits fluorescence at night, and meanwhile, the color of the thermochromic powder added into the TPE can be changed along with the change of temperature, so that thecolor of the thermochromic powder can be changed after the outdoor temperature is reduced at night, the color of the fluorescence can also be correspondingly changed, and a user is reminded of the temperature change.

Owner:DONGGUAN YINGTONG WIRE +1

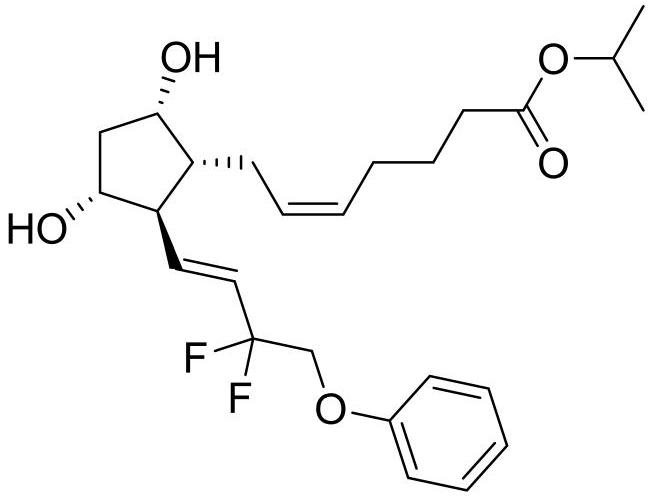

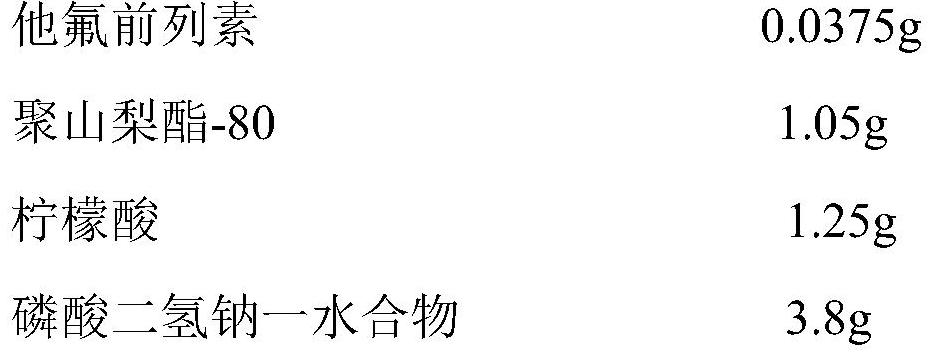

A kind of eye drops for treating glaucoma and preparation method thereof

InactiveCN111840225BHas a buffering effectHydrophobicOrganic active ingredientsSenses disorderEthyl stearateBULK ACTIVE INGREDIENT

The invention belongs to the technical field of medicine, and discloses an eye drop for treating glaucoma and a preparation method thereof. The eye drop contains tafluprost, modified polylysine and a stabilizer, wherein tafluprost The ethyl stearate in the modified polylysine is hydrophobic, can coat tafluprost, play a protective role to tafluprost, improve the stability of the drug, and solve other problems. Fluprostin is unstable in aqueous solution, has poor solubility and is easily absorbed by packaging containers; no additional preservatives are needed; and the modified polylysine can be biodegraded, which is relatively safe for the human body.

Owner:陈丽娜

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com