Method for manufacturing superfine flaky zinc powder with high corrosion resistance

A technology of high corrosion resistance, flake zinc powder, applied in the fields of metallurgical waste utilization and metal powder material manufacturing, can solve the problem of high production cost, and achieve the effect of improving corrosion resistance time, improving coating quality and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

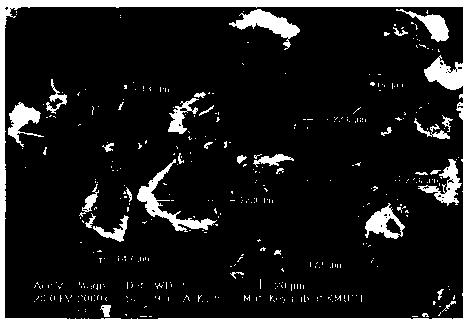

[0021] Example 1: Put 2 kilograms of zinc powder raw materials with an average particle size of 22.5 microns, 20 kilograms of steel balls with a diameter of 5 millimeters, and 40 grams of 16 alkanoic acid into the grinding machine, first vacuumize the grinding chamber and then feed nitrogen twice Then start grinding, the linear speed of the grinder blade is 12 m / s, and the grinding time is 150 minutes. The flake zinc powder after grinding enters the mixer for mixing and passivation treatment for 2 hours, and then classifies to obtain ultra-fine flake zinc powder. Zinc powder, the median diameter D of ultrafine flaky zinc powder 50 They are 5.5, 10.4 and 17.3 microns, and the bulk densities are 1.25, 1.18 and 1.13 g / ml, respectively.

Embodiment 2

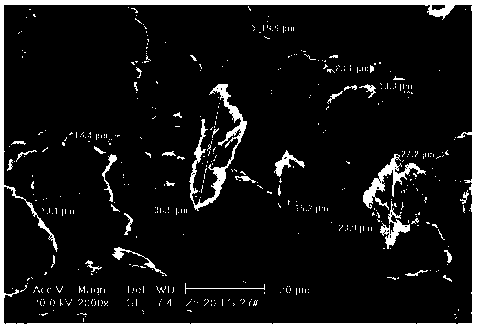

[0022] Example 2: Add 10 kg of zinc powder raw material with an average particle size of 78.90 microns, 200 kg of steel balls with a diameter of 7 mm, 200 grams of silane coupling agent and 100 grams of 12 alkanol into the grinding machine, and first pump the grinding chamber Start grinding after the vacuum feeds nitrogen for 2 times again. The linear speed of the grinder blade is 15 m / s, and the grinding time is 100 minutes. The flake zinc powder after grinding enters the mixer for mixing and passivation treatment for 3 hours. Perform cyclone classification to obtain ultrafine flaky zinc powder, and the median diameter of the ultrafine flaky zinc powder is D 50 They are 9.5, 14.5 and 19.5 microns, respectively, and the bulk densities are 1.28, 1.22 and 1.15 g / ml, respectively.

Embodiment 3

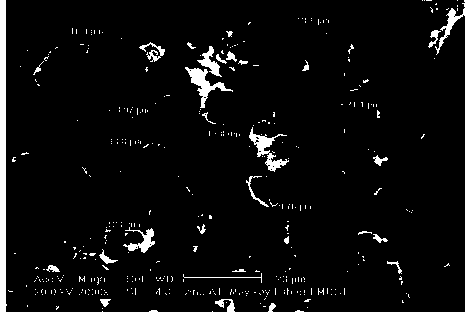

[0023] Example 3: Add 5 kg of zinc powder raw material with an average particle size of 48.60 microns, 75 kg of steel balls with a diameter of 6 mm, and 50 g of ethyl stearate into the grinding machine, and then vacuumize the grinding chamber twice and pass through Start grinding after entering nitrogen gas, the linear speed of the grinding machine blade is 8 m / s, and the grinding time is 200 minutes. The flake zinc powder after grinding enters the mixer for mixing and passivation treatment for 1 hour, and then cyclone classification treatment to obtain Ultrafine flaky zinc powder, median diameter D of ultrafine flaky zinc powder 50 They are 7.5, 12.5 and 17.50 microns, and the bulk densities are 1.24, 1.05 and 1.1 g / ml, respectively.

[0024] In the above examples, the zinc powder raw materials are commercially available, specifically purchased from Huludao Yongxing Energy Storage Materials Co., Ltd., which is the company’s battery zinc powder sieved waste, which is a by-prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com