Patents

Literature

39results about How to "Extend corrosion resistance time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

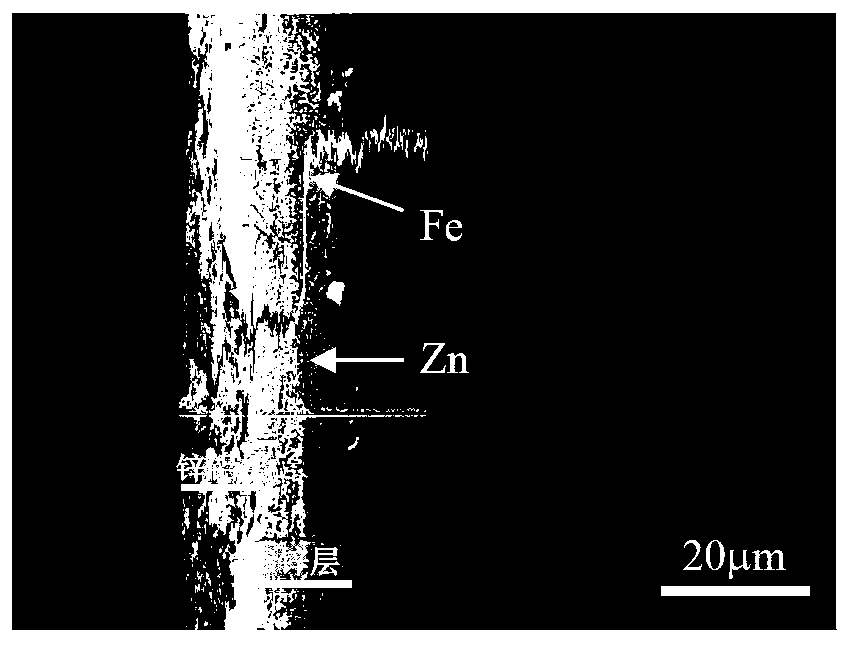

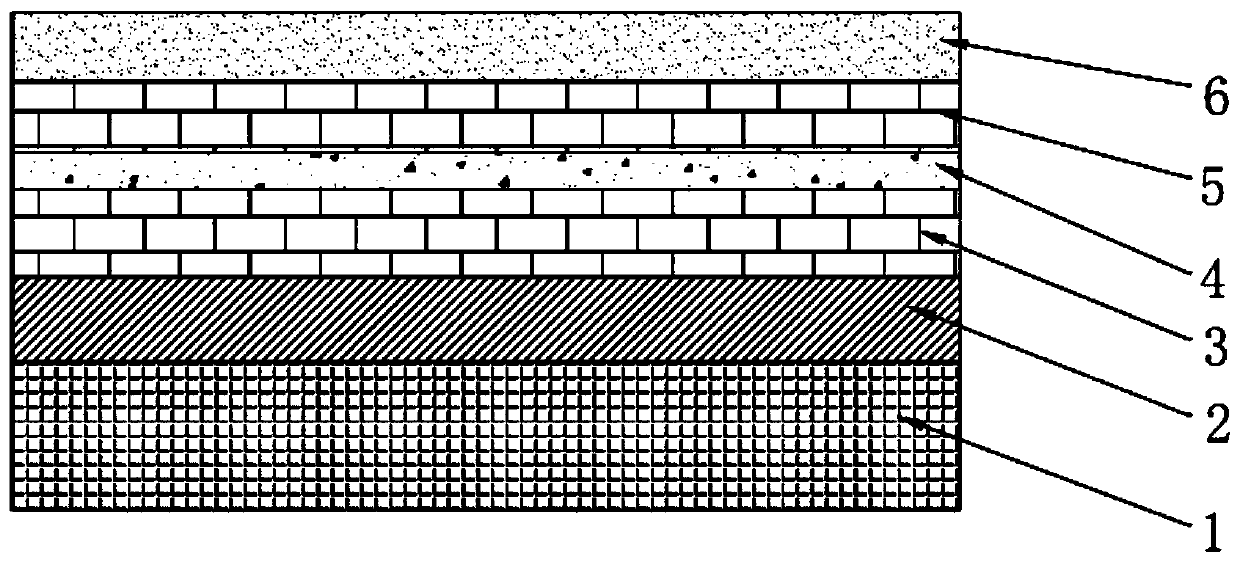

Production method for ship fastener complex coating

ActiveCN103316828AIncrease the effective thicknessSmall effective thicknessPretreated surfacesSpecial surfacesMetallic materialsDip-coating

The invention belongs to the technical field of metal material surface processing and relates to a production method for a ship fastener complex coating. A zinc impregnation coating, a zinc-aluminum coating and an epoxy coating are arranged on the fastener surface from internal to external and zinc impregnation, washing, zinc-aluminum coating liquid dip-coating, zinc-aluminum coating solidification, epoxy coating liquid dip-coating and epoxy coating solidification are performed on the faster after sequentially being performed on oil removing and rust removing to form into a protective layer. The production method for the ship fastener complex coating has the advantages of being simple in production technology and reasonable in principle. The complex coating has the advantages of being good in corrosion resistance, being capable of effectively solving the problem that the faster is corroded in the seawater environment and being environmentally friendly.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

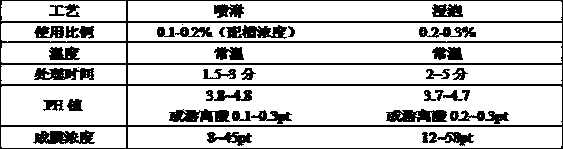

Phosphorus-free nano vitrification agent, and preparation method and application thereof

ActiveCN103938198AEasy to handleReduce environmental problemsMetallic material coating processesWaste treatmentZirconium oxychloride

The invention relates to the field of metal surface treatment agents, and relates to a phosphorus-free nano vitrification agent, and a preparation method and application thereof. The phosphorus-free nano vitrification agent is prepared from the following raw materials in percentage by mass: 3-6% of fluorozirconic acid, 3-7% of zirconium oxychloride, 0.1-0.6% of ammonium fluozirconate, 0.8-2% of tartaric acid, 0.5-1% of sodium nitrate and the balance of water. The phosphorus-free nano vitrification agent provided by the invention can be operated at normal temperature, and is short in treatment time and simple in process; almost no deposit exists, and nozzle blocking is avoided; the waste treatment cost is reduced; and the adhesive force between paint and metal can be obviously improved, and the corrosion resistance time of the metal can be prolonged.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Hard anode oxidation process

InactiveCN109183114AAchieve hard anodizingExtend corrosion resistance timeAnodisationAcid etchingCooking & baking

The invention relates to a hard anode oxidation process. The hard anode oxidation process comprises the following specific steps of A, hanging up; B, degreasing; C, first-time water washing; D, alkalietching; E, second-time water washing; F, acid etching; G, third-time water washing; H, ash removing; I, fourth-time water washing; J, first-time oxidizing; K, second-time oxidizing; L, fifth-time water washing; M, hole sealing with pure water; N, sixth-time water washing; O, seventh-time water washing; P, blow-dry; Q, hanging down; R, hot water washing; S, blow-dry with nitrogen; T, baking; andU, packaging. The process has the advantages of being simple and convenient and capable of effectively improving the corrosion resistance time.

Owner:TORRANCE SEMICON EQUIP QIDONG CO LTD

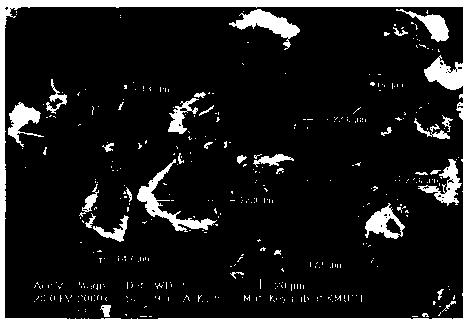

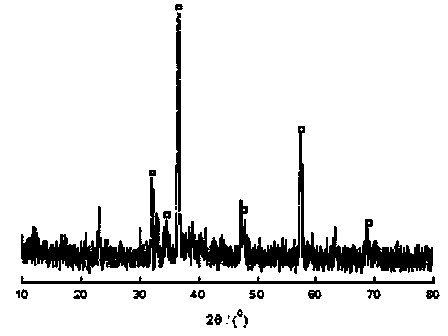

Method for manufacturing superfine flaky zinc powder with high corrosion resistance

The invention provides a method for manufacturing superfine flaky zinc powder with high corrosion resistance, and belongs to the technology of metallurgical waste utilization and metal powder material manufacturing. Raw zinc powder is commercially available waste sieved out in a battery zinc powder process, the raw zinc powder, industrial auxiliary agents and grinding media are placed into a horizontal type blade high-powered stirring grinder to be ground, the mass ratio of the grinding media to the raw zinc powder is 10:1-20:1, the mass of the industrial auxiliary agents is 1.0-3.0% of the mass of the raw zinc powder, the industrial auxiliary agents are one or two of hexadecanoic acid, dodecyl alcohol, ethyl stearate and silane coupling agents, the grinding media are bearing steel balls with the diameters being 5-7 millimeters, vacuum pumping is conducted firstly, and then inert gas is fed two times for protection; the ground flaky zinc powder is placed in a mixer, and mixing and passivation are conducted in air; the mixed flaky zinc powder is placed in a cyclone classifier and classified so as to obtain the superfine flaky zinc powder. The metallurgical waste can be used; the superfine flaky zinc powder has the high corrosion resistance, and production cost is reduced.

Owner:昆明海创兴科技有限公司

Graphene oxide-carbon quantum dot complex modified anticorrosive coating and preparation method thereof

PendingCN109971323AImprove uniformity and stabilityStrong environmental protectionAnti-corrosive paintsPolyester coatingsCorrosionBarium sulfate

The invention provides a graphene oxide-carbon quantum dot complex modified anticorrosive coating and a preparation method thereof, and belongs to the technical field of coatings. The coating comprises the following raw materials: a graphene oxide-carbon quantum dot nano complex, water-based alkyd resin, titanium dioxide, barium sulfate, a dispersant, a defoaming agent, a thickening agent, an auxiliary agent and a curing agent; and the preparation method comprises the steps of preparing the graphene oxide-carbon quantum dot nano complex, preparing graphene oxide-carbon quantum dot slurry, preparing a pre-prepared coating, and adding the curing agent and performing mixing to obtain the anticorrosive coating. The anticorrosive coating provided by the invention has good corrosion resistance,high mechanical strength and strong environmental protection; and the preparation method has a simple process and is easy to operate.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Corrosion-resistant long-acting antirust liquid

InactiveCN106086851AStop the spreadInhibit migrationMetallic material coating processesPolyethylene glycolPhytic acid

The invention discloses corrosion-resistant long-acting antirust liquid. Raw materials of the corrosion-resistant long-acting antirust liquid comprise, by weight, 35-45 parts of compound corrosion inhibitor, 0.1-0.3 parts of a surface active agent, 0.2-0.4 part of hydroxy propyl cellulose, 0.3-0.5 part of polyethylene glycol, 0.1-0.3 part of a defoaming agent, 1-3 parts of sodium gluconate, 0.2-0.3 part of benzisothiazolones and 50-54 parts of water, wherein raw materials of the compound corrosion inhibitor comprise phytic acid, sodium molybdate, diethanol amine, monoethanolamine borate and 2-methyl benzimidazoline. According to the corrosion-resistant long-acting antirust liquid, by means of cooperation of the phytic acid, the sodium molybdate, the diethanol amine, the monoethanolamine borate and the 2-methyl benzimidazoline, the film forming speed of a protective film is increased, the corrosion speed is decreased, the thickness of the protective film is increased, corrosion media are prevented from making contact with metal, and the corrosion-resistant long-acting antirust liquid is made to have good corrosion-resistant performance and long-acting antirust performance.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Surface rust preventing treatment process for iron art products

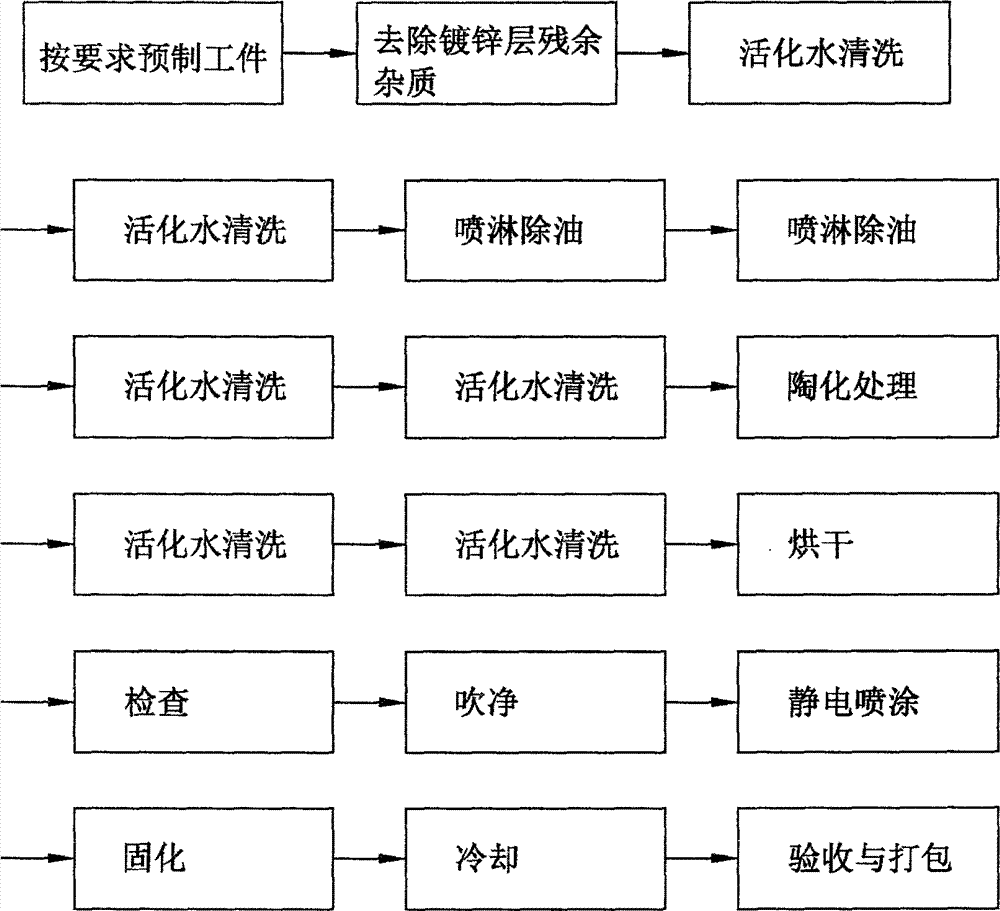

ActiveCN103205751AImprove coating qualityImprove water saving performanceLiquid surface applicatorsSuperimposed coating processProduction lineWater based

The invention relates to a surface rust preventing treatment process for iron art products and provides a novel spraying line production technique. The surface rust preventing treatment process is characterized in that traditional phosphating is replaced by ceramic treatment on a spraying flow production line, common urban tap water is replaced by small cluster water with activity in each washing link during spraying, and common water base degreasing fluid is replaced by small cluster water base degreasing fluid. Compared with traditional phosphating, the method uses non-phosphorus ceramic treatment for pretreatment in prior to nano spaying, and accordingly adhesive force between coating and metal can be increased evidently, and corrosion-resistant time of metal can be prolonged.

Owner:广东鸿图新材料科技有限公司

High-salt-fog-resistance aluminum product passivator and preparation method thereof

InactiveCN102965654AImprove corrosion resistanceImprove adhesionMetallic material coating processesNickel saltNitrite

The invention relates to a high-salt-fog-resistance aluminum product passivator which is an environment-friendly passivator having excellent adhesive force and high corrosion resistance, remarkably prolonging the corrosion resistance time and containing no phosphate, nitrite or other toxic heavy metal ions. The aluminum product passivator mainly comprises the following components: fluozirconate, chromic sulfate, sodium hydroxide, fluoride salt, nitrate, nickel salt and water. A preparation method of the aluminum product passivator comprises the following steps: mixing the fluozirconate and the fluoride salt, dissolving in water; fully dissolving the chromic sulfate in water of 70-75 DEG C, then adding into the former solution, and evenly mixing; and then, sequentially adding the sodium hydroxide, the nitrate and the nickel salt into the mixed solution, evenly stirring, and adding water to a specified volume, thus obtaining the aluminum product passivator. The method is simple to operate and short in processing time; and the aluminum product passivator can be repeatedly used. Thus, the cost can be saved.

Owner:况金权 +2

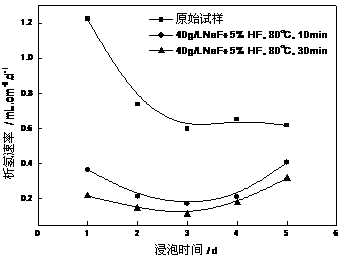

Biological magnesium alloy with surface coated with sodium magnesium fluoride film and preparation method thereof

ActiveCN103451643AReduce the rate of hydrogen evolutionExtend corrosion resistance timeMetallic material coating processesMetal layered productsFluorhydric AcidSurface modification

The invention relates to a biological magnesium alloy with a surface coated with a sodium magnesium fluoride film and a preparation method thereof. The surface of the biological magnesium alloy is coated with the sodium magnesium fluoride film. The preparation method of the biological magnesium alloy comprises the following steps: carrying out alkaline oil removal; washing; preparing the sodium magnesium fluoride film; washing; washing by using alcohol; air-drying. The method for preparing the sodium magnesium fluoride film particularly comprises the following steps: immersing the biological magnesium alloy into a treatment solution with the temperature of 75-90 DEG C and the molar concentration of sodium fluoride and hydrofluoric acid respectively equal to 1.6 mol / L and 4.8 mol / L; performing heat preservation for 10-90 minutes, and then taking out the biological magnesium alloy. According to the biological magnesium alloy with the surface coated with the sodium magnesium fluoride film, the sodium magnesium fluoride film has the characteristics of simple preparation process, convenience for operation, suitability for industrial production, and the like, and can be used for the surface modification coating of a magnesium alloy; the biological magnesium alloy disclosed by the invention can be used for preparing a biological magnesium alloy device.

Owner:江苏凯晞投资有限公司

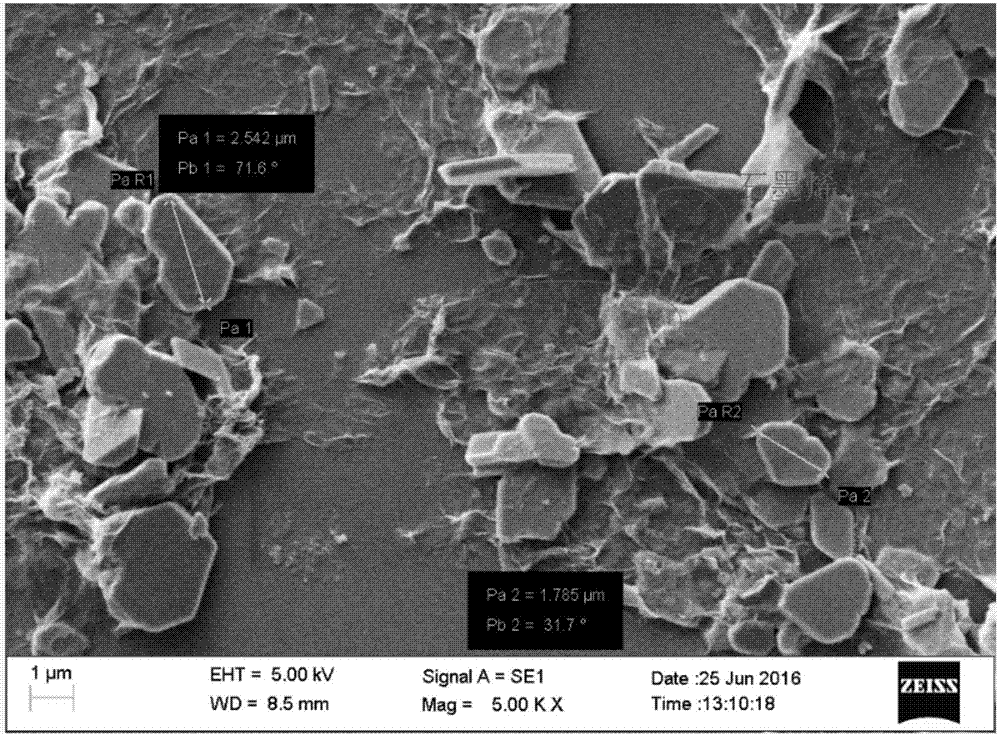

Preparation method of high anti-corrosion coating on surface of sintered Nd-Fe-B magnet

InactiveCN108364780AImprove anti-aging propertiesExtend corrosion resistance timeMagnetic materialsPermanent magnet manufacturePorosityAging resistance

The invention discloses a preparation method of a high anti-corrosion coating on the surface of a sintered Nd-Fe-B magnet. The method comprises the steps that a machined and shaped Nd-Fe-B magnet is preprocessed, the preprocessed Nd-Fe-B product is soaked with a pre-processing solution, and the pre-processing solution is prepared by mixing distilled water, a coating agent and an accelerator; priming coating of a ZnAl coating solution is performed on the surface of the soaked Nd-Fe-B magnet, and the Nd-Fe-B magnet with the ZnAl coating obtained after priming coating is obtained; top coating ofa Al-enriched coating solution is performed on the surface of the Nd-Fe-B magnet obtained after priming coating, and the high anti-corrosion Nd-Fe-B magnet is obtained. Due to two times of coating processing, the porosity between the magnet and a corrosive medium is effectively lowered, the binding force between the coating and the magnet is improved, and the sintered Nd-Fe-B magnet has the good corrosion resistance. Due to the ZnAl coating obtained after priming coating, the quantity of a medium entering the deeper layer of the coating is greatly reduced, and therefore the high temperature and high pressure resistance and the ageing resistance of the magnet are greatly improved.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

One-step method non-phosphorus skin film agent

ActiveCN103046039AGood degreasingSolve the problem of insufficient spaceMetallic material coating processesSodium molybdatePotassium

The invention discloses a one-step method non-phosphorus skin film agent which comprises the ingredients by mass percent: 2-4% of fluorine zirconic acid, 0-1% of sodium molybdate, 0-0.8% of potassium fluotitanate, 2-3.5% of polyethylene glycol, 0.1-0.6% of sodium fluoride, 0.5-1.5% of acrylic acid, 0-1% of citric acid, 0-1.5% of oxalic acid, 0.1-0.5% of emulsifier and the balance of water. Unoiling and skin film coating are accomplished in one process, and a whole pretreatment process is accomplished through twice washing, so that the conventional six processes are greatly simplified, and the equipment investment is reduced.

Owner:南京金环生物技术有限公司

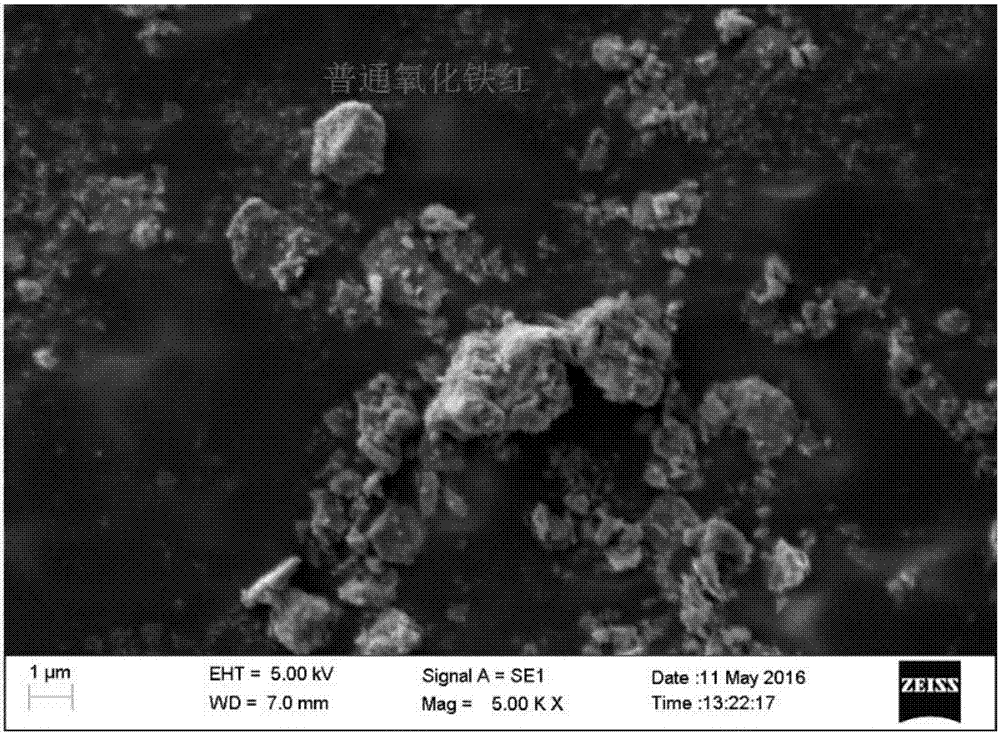

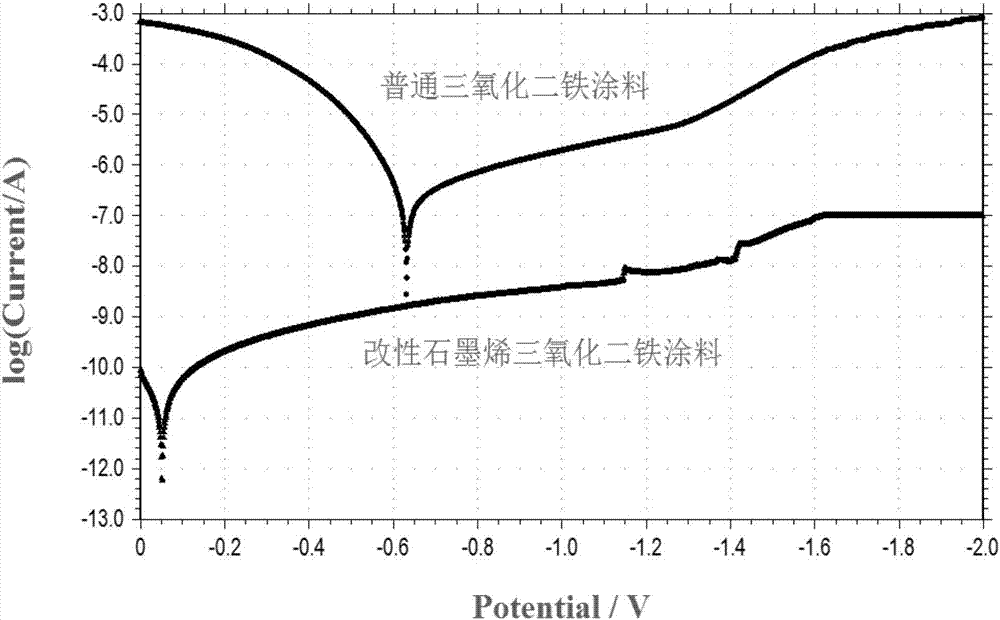

Graphene/ferric oxide composite material-containing resin anticorrosive coating and preparation method thereof

InactiveCN107163775ALow costReduced impact resistanceAnti-corrosive paintsEpoxy resin coatingsCoating systemOxide composite

The invention provides a resin anticorrosive coating which is prepared from resin, a graphene and ferric oxide composite material, an auxiliary and a solvent. According to the resin anticorrosive coating, the adding mode of a graphene material is changed; firstly, graphene is compounded with ferric acid in the coating, thus obtaining the graphene and ferric oxide composite material, and then the treated graphene and ferric oxide composite material is combined with other components, thus obtaining the resin anticorrosive coating; the problem on dispersion of the graphene can be well solved, and perfect exertion of high performance of the resin anticorrosive coating is guaranteed; furthermore, no other auxiliaries are needed, so that introduction of impurities is reduced, and the shortcoming of non-uniform mixing of the graphene material in a coating system is overcome; the graphene can be uniformly dispersed; and in addition, the graphene and ferric oxide composite material can guarantee less folds of the graphene in a horizontal spreading state, os as to better exert the performance of the graphene.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

Plasma coating surface treatment method

InactiveCN108977756AAccelerated corrosionImprove antioxidant capacityMolten spray coatingOxidation resistantSilicon dioxide

The invention discloses a plasma coating surface treatment method. The plasma coating surface treatment method comprises the following steps: I, initially cleaning a plasma coating part needing to becoated, and roughly grinding the surface of the plasma coating part; II, removing oil from the part to be coated which is ground in the step I through an oil remover, and performing decontamination, water washing, deionized water washing and dehydration-drying in sequence; III, introducing aluminum oxide, steel, copper, titanium, chromium and tungsten into an airflow mill for grinding, adding a reducing agent in the grinding process, and collecting with a bag collector at the end of grinding to obtain metal powder; IV, conveying the metal powder obtained in the step III into a plasma coating device, placing the part to be coated which is treated in the step II on a coating table, and performing high-temperature coating on the part to be coated with the plasma coating device. The surface ofthe cooled metal coated part is subjected to hole-sealing treatment by using silicon dioxide sol, so that the corrosion resistance and oxidation resistance of the surface of the metal coated part areimproved effectively.

Owner:叶婉芳

Roller plating process of trivalent yellow zinc

InactiveCN110184594AReach colorMeet anti-corrosion requirementsMetallic material coating processesElectrolysisAcid washing

The invention discloses a roller plating process of trivalent yellow zinc. The roller plating process comprises the following steps of raw material purchasing, feeding, chemical oil removal, water washing, electrolysis oil removal, water washing, acid washing, water washing, electrolysis oil removal, water washing, activation, water washing, alkali soaking, electroplating, water washing, film thickness inspection, transferring, light emitting, water washing, passivation, water washing, spin drying, sealing, drying, discharging, final inspection, packaging and storage, wherein in the passivation step, the raw materials subjected to the light-out water washing are added into a passivating agent aqueous solution for passivating, the pH value is controlled to be 1.6-2.0, the temperature is 24-35 DEG C, the soaking time of the passivating agent is 45-100 s, and the air stirring pressure is 0.4 MPa; and the passivating agent comprises the following components in parts by weight: 5-8 parts ofchromium chloride and 18-22 parts of sodium nitrate, 8-12 parts of sodium fluoride, and 35-45 parts of nickel sulfate. The process has the beneficial effects that hexavalent chromium in the passivating agent can be replaced with trivalent chromium to produce the yellow zinc, so that the characteristics of environmental friendliness and low toxicity are achieved.

Owner:NINGBO YADA METAL SURFACE TREATMENT

Steel surface rust conversion emulsion

InactiveCN104651847AStrong penetrating powerAvoid electrochemical reactionsPhosphoric acidDissolution

The invention discloses a steel surface rust conversion emulsion. The steel surface rust conversion emulsion is prepared from 48-55wt% of deionized water, 8-15wt% of aqueous emulsion, 20-28wt% of industrial phosphoric acid, 0.5-1wt% of triethanolamine borate, 2-5wt% of alumina, 4-7wt% of sulfamic acid, 1-3wt% of oxalic acid, 1.5-2.5wt% of citric acid, 1-2wt% of zinc chloride, 0.5-1.5wt% of manganese chloride, 2.5-5wt% of hexamethylene tetramine and 0.5-1.5wt% of sodium carboxymethyl cellulose. The steel surface rust conversion emulsion has the characteristic that 1, rust removal and prevention functions are obtained and adaptability is good, 2, a bonding force is good, the steel surface rust conversion emulsion can be combined with various types of paint, coatings and paste ash and does not produce dissolution problems such as wrinkling and bubbling and an antirust capability is improved by 30-50%, 3, energy saving, environmental protection, no pollution and no blind angle in construction, and labor and time saving are realized, and 4, the steel surface rust conversion emulsion is suitable for conversion of rust on the surfaces of various labeled steel and cast iron and realizes conversion of harmful rust into a film beneficial for steel surface corrosion resistance.

Owner:陈克华

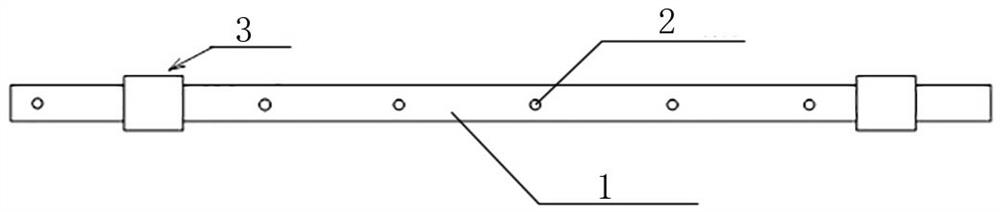

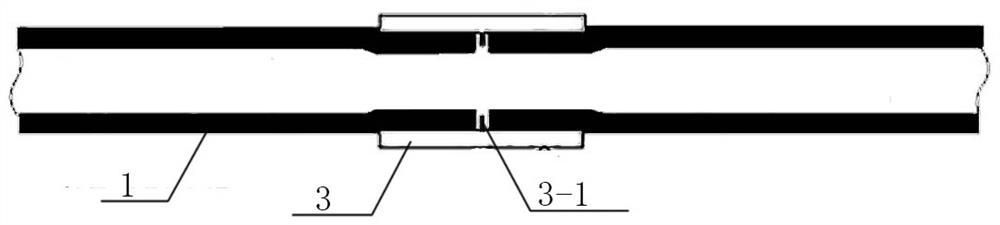

Environment-friendly anti-corrosion large grounding grid with adjustable grounding impedance and construction method

PendingCN112582810AExtend safe operating lifeLower impedanceLine/current collector detailsConnection contact member materialGrounding gridHazardous substance

The invention relates to an environment-friendly anti-corrosion large grounding grid with adjustable grounding impedance. A voltage-sharing bus is made of a seamless steel tube of which the inner walland the outer wall are subjected to conductive and antiseptic treatment, and release holes are uniformly distributed in the tube; the grounding grid comprises a circle of outer edge voltage-sharing bus buried at the outermost edge of a whole area and a grounding grid main body buried in an device area, the grounding grid main body comprises a tubular voltage-sharing bus and a grounding wire whichare buried in the device area, and an outer edge voltage-sharing bus and a grounding grid main body voltage-sharing bus are communicated with each other; a steel pipe vertically communicated with thevoltage-sharing buses is mounted above the ground of each device area to serve as an injection hole, the top end of each injection hole is of a sealed structure, and a grounding electrode which is vertically communicated with the tubular voltage-sharing bus and is downwards inserted into the ground is arranged on the tubular voltage-sharing bus of the grounding grid. According to the invention, the problems of oxidation and disconnection of the grounding grid caused by electrochemical erosion of harmful substances in soil can be effectively prevented, and the safe operation period of the large grounding grid can be prolonged exponentially.

Owner:高政

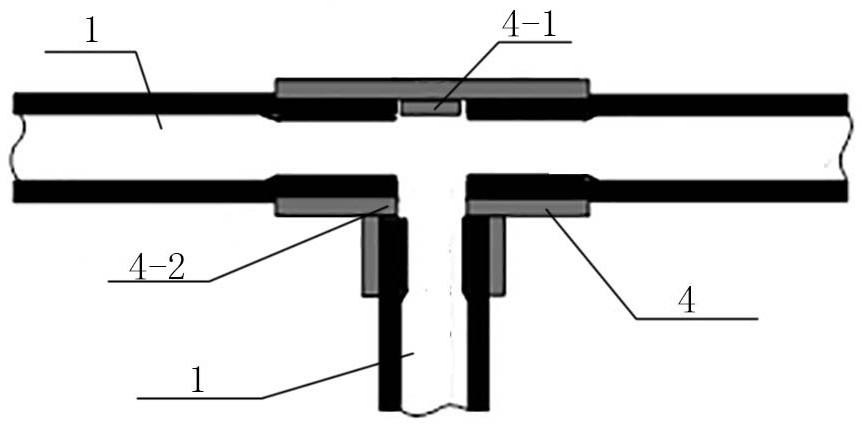

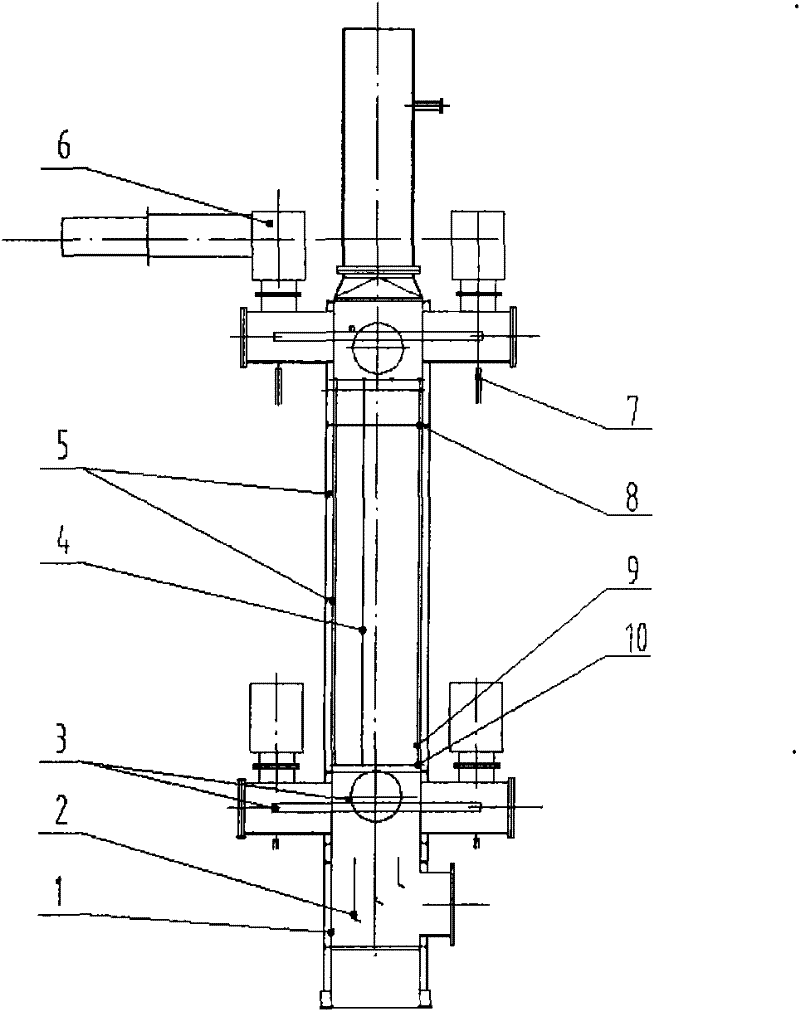

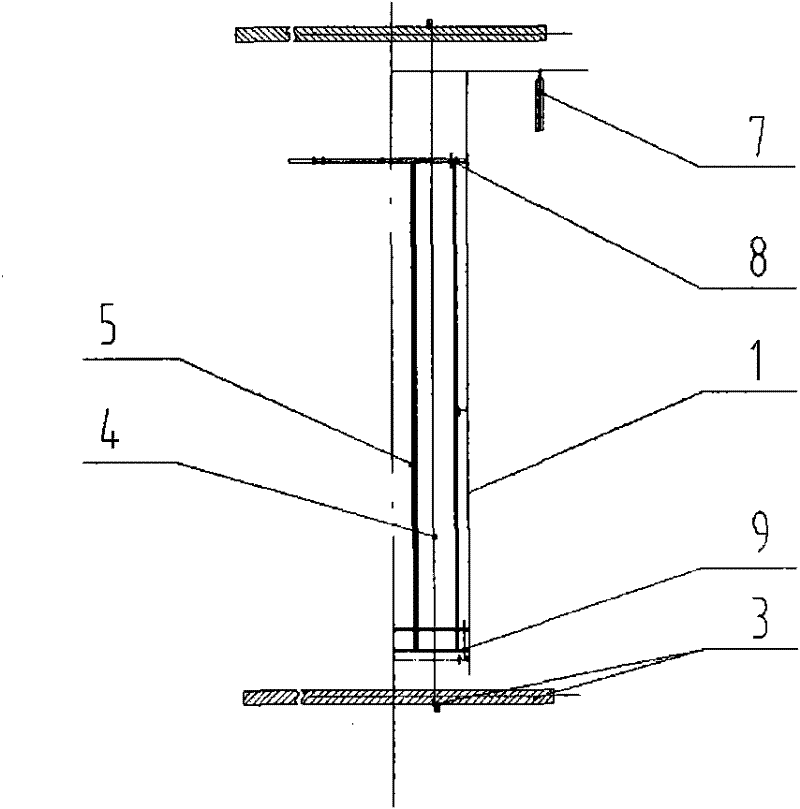

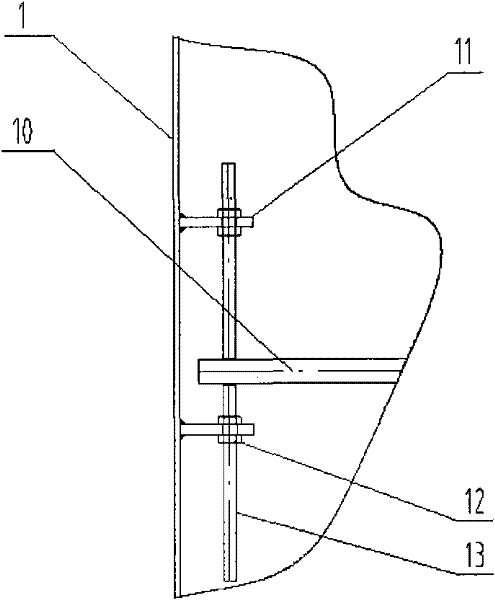

Device and process for homogenizing fabric dust collecting electrode surface water film

ActiveCN101670313BUniform thicknessLow flushing water requirementDispersed particle filtrationExternal electric electrostatic seperatorFiberEngineering

The invention relates to a device and a process for homogenizing a fabric dust collecting electrode surface water film for a wet electrostatic dust collector / demister. The device comprises a shell, a guide vane, a discharge electrode fixing device, a discharge electrode, a dust collecting electrode square tube, an insulated case, a support device, a film distributing device, a dust collecting electrode length adjusting device and a homogenizing rod; the water distribution amount is adjusted by an adjusting valve, the thickness of the collecting electrode surface water film is controlled by a PLC; water flows into the upper part of a fabric collecting electrode through a water distribution hole to form an initial water film and then downwards spreads to the bottom in a corrugated shape; a wall-cooling wall surface formed by the water film contacts with a flue gas counterflow to generate friction lift force to be mutually coupled with flue gas condensed water and capillary characteristics of fiber fabrics, thereby promoting the rapid formation of the water film with uniform thickness; in the process of precipitating water condensation nuclei in the flue gas, micro fine particulate matters are condensed and the particle size is increased; and a grey cake layer formed by the micro fine particulate matters on the surface of the fabrics is fractured and shed in a flaky shape. The device has the outstanding effects of dust removal, demisting, energy saving and consumption reduction.

Owner:SHANDONG UNIV

Long-acting anti-rust solution

ActiveCN106086850AStop the spreadImprove film forming speedMetallic material coating processesPhytic acidRust

The invention discloses a long-acting anti-rust solution. The long-acting anti-rust solution comprises, by weight, 30-40 parts of a compound corrosion inhibitor, 0.5-0.7 part of sodium carboxymethylcellulose, 3-5 parts of polyethylene glycol 400, 0.1-0.3 part of an antifoaming agent, 2-3 parts of sodium molybdate, 1-3 parts of disodium ethylene dinitrilotetra-acetic acid, 0.1-0.2 part of isothiazolinone and 38-45 parts of water, wherein phytic acid, CeNO3, diethanol amine boric acid ester, N-methyldiethanolamine and benzimidazole are adopted as the raw materials of the compound corrosion inhibitor. According to the long-acting anti-rust solution, through cooperation of the phytic acid, CeNO3, diethanolamine boric acid ester, N-methyldiethanolamine and benzimidazole, the long-acting anti-rust solution has the long-acting anti-rust performance.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Corrosion resistant coating of silver combined coating

The invention relates to the technical field of electroplating, in particular to a corrosion resistant coating of a silver combined coating. The corrosion resistant coating comprises a base coating, afirst silver coating, a first gold coating and a rhodium ruthenium coating which are sequentially electroplated on the surface of a base material, the base coating is used for adjusting the surface flatness of the base material, the first silver coating is used for improving the conductivity of the base material, the first gold coating is used for improving the adhesion of the adjacent coating, and the rhodium ruthenium coating is used for improving the corrosion resistance and wear resistance of the base material. The coating structure prepared from the coating has good wear resistance, oxidation resistance, conductivity and corrosion resistance, and the adhesiveness between the electroplating coating and the base material is good.

Owner:东莞市合航精密科技有限公司

Corrosion-resistant coating for interface of electronic device

InactiveCN110401056AImprove wear resistanceImprove antioxidant capacityCoupling contact membersSolderabilityWear resistance

The invention relates to the technical field of electroplating, in particular to a corrosion-resistant coating for an interface of an electronic device. The corrosion-resistant coating comprises a substrate plating layer plated on a surface of a substrate, the substrate plating layer is a nickel-plated tungsten layer for improving corrosion resistance of the substrate, the surface of the nickel-plated tungsten layer is plated with a pre-plating layer for improving the adhesion of adjacent plating layers, a first silver plating layer for improving corrosion resistance and the electrical conductivity of the substrate, and a second gold plating layer for improving adhesion of adjacent plating layers. a third rhodium layer for improving corrosion resistance and wear resistance of the substrateand a fourth gold plating layer for improving the solderability of the substrate. The coating structure combined by the above plating layers has the better wear resistance, oxidation resistance, electrical conductivity and corrosion, and the adhesion between the plating layer and the substrate material is good, and the welding property of the substrate is also improved.

Owner:东莞市合航精密科技有限公司

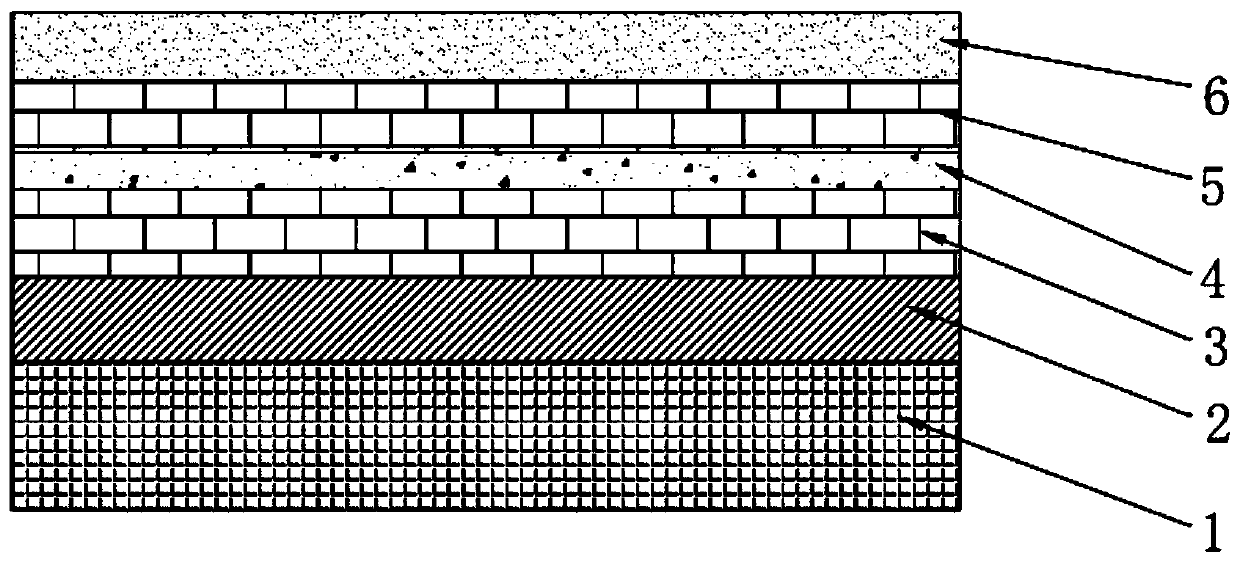

Steel skeleton of greenhouse shed

InactiveCN101569276BImprove wind resistanceImprove insulation effectClimate change adaptationGreenhouse cultivationThermal insulationGreenhouse

A steel skeleton of a greenhouse shed comprises an inner chord and an outer chord which take a circular arc shape as a whole and are connected by a 'zigzag' connecting rib in the middle. The steel skeleton is characterized in that the outer chord is made from an 'I'-shaped sectional material which comprises a wide surface and a narrow surface, the surface of the outer chord connected with the 'zigzag' connecting rib is the narrow surface, and the other surface is the wide surface for uplifting a shed film. The 'I'-shaped sectional material of the greenhouse shed integrates the advantages of strong bending resistance of a steel pipe and long corrosion resistance time of reinforcing steel bar overcomes the disadvantages of poor corrosion resistance and short service life of the steel pipe and poor bending resistance of the reinforcing steel bar, and has functions for unique innovation of laying a double-layer shed film and internally providing an insulating layer so that the greenhouse shed constructed by the sectional material improve snow resistance, wind resistance and internal thermal insulation, thus filling a gap for facility agriculture.

Owner:刘国兴

Vitrification agent and preparation method and using method thereof

InactiveCN108047939AEasy to handleReduce environmental problemsAnti-corrosive paintsVitrificationHigh energy

The invention provides a vitrification agent and a preparation method and a using method thereof. The preparation method of the vitrification agent mainly comprises the following steps: under the condition of continuous stirring, adding low-molecular-weight water-soluble silane, citric acid, a complexing agent, sodium nitrate and zirconium propyl oxide in water of a reaction kettle; and finally, adding water to regulate density. The vitrification agent is prepared from the following raw materials according to the formula: the low-molecular-weight water-soluble silane, the citric acid, the zirconium propyl oxide, the complexing agent, the sodium nitrate and the water. The using method of the vitrification agent comprises the step of only needing to dilute the vitrification agent with water.By the vitrification agent and the preparation method and the using method thereof, the technical problems of environmental pollution, complicated process, high energy consumption and high cost in the prior art are solved.

Owner:湖南德莱恩新材料科技有限公司

Vitrification agent and preparation method and application method thereof

InactiveCN108796483AEasy to handleReduce environmental problemsMetallic material coating processesSilanesVinylsilane

The invention provides a vitrification agent and a preparation method and an application method thereof. The vitrification agent contains the following raw materials of, by weight, 1%-5% of ammonium fluorozirconate, 0.2-1.5% of acetic acid, 0.5-0.8% of citric acid, 0.5-3% of vinyl silane, 0.1-3% of sodium chloride, 0.2-1% of zinc oxide and the balance water. The preparation method of the vitrification agent mainly comprises the following steps of 1, under normal temperature and normal pressure, water which accounts for two thirds of a formula amount is added into a reaction container, and thewater is slowly and non-stopping stirred; 2, the ammonium fluorozirconate, the acetic acid, the citric acid, the vinyl silane, the sodium chloride and the zinc oxide are sequentially and slowly addedinto the reaction container according to the formula amount while the stirring is kept; and 3, after a liquid stirring tool is continuously stirred for a certain time, the residual water is added andthe density is adjusted until 1.01-1.03 g / ml. The application method of the vitrification agent mainly comprises the following steps of degreasing treatment, two water washing, surface treatment on the vitrification agent prepared by the method, washing with pure water, drying, spraying and solidifying.

Owner:深圳市华世纪联合企业管理有限公司

High-adhesion zinc powder anticorrosive paint and preparation method thereof

PendingCN114574067AImprove adhesionExtend corrosion resistance timeAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

The invention belongs to the technical field of coatings, and particularly relates to a high-adhesion zinc powder anticorrosive coating, a preparation method thereof and application of the high-adhesion zinc powder anticorrosive coating in the field of corrosion resistance. The zinc powder anticorrosive paint is prepared by mixing a component A and a component B according to a mass ratio of (24.2-36.3): 1, the component A comprises epoxy resin, a solvent A, mica powder, talcum powder, an anti-settling agent, a corrosion inhibitor and zinc powder, and the component B comprises a curing agent and a solvent B; the corrosion inhibitor is one or a mixture of more of a silane coupling agent, acetylacetone and an organic-inorganic hybrid modified silane coupling agent. The high-adhesive-force zinc powder anticorrosive paint provided by the invention has the characteristics of high adhesive force to a base material, small adhesive force loss in a service process, long corrosion-resistant time and the like.

Owner:SHENYANG RES INST OF CHEM IND

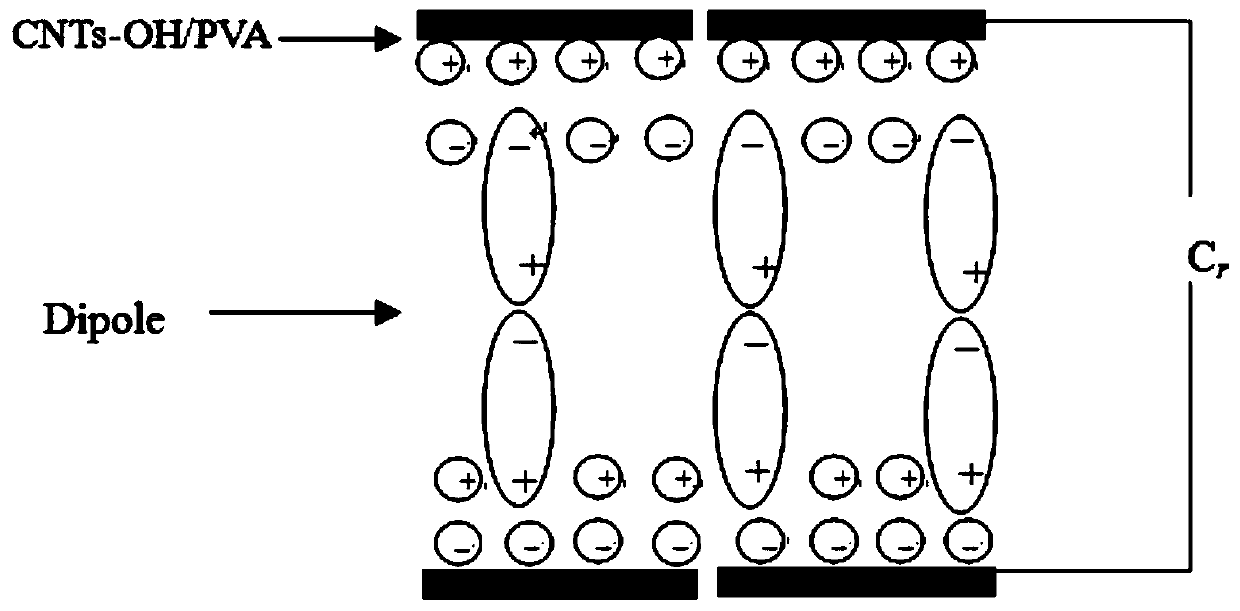

A kind of chlorine salt corrosion resistant carbon nanotube modified reinforced concrete and preparation method thereof

Owner:惠州市华灏混凝土有限公司

Steel surface fluoroferrite conversion plating solution and preparation method thereof

InactiveCN105862020AFilm color depthExtend corrosion resistance timeMetallic material coating processesPotassiumCopper nitrate

The invention discloses a fluoroferrate conversion plating solution for iron and steel surfaces and a preparation method thereof, which is prepared by mixing the following components in parts by weight: 12-26 parts of sulfuric acid, 13-22 parts of nitric acid, and 7-19 parts of citric acid 7-21 parts of sodium silicate, 8-17 parts of zinc nitrate, 9-22 parts of copper nitrate, 11-32 parts of hydrogen peroxide, 9-23 parts of sodium fluoride, 9-21 parts of ammonium persulfate, 9 parts of potassium molybdate ~26 parts, 12~31 parts of nano-potassium bromate, 9-17 parts of nano-potassium chlorate, 12-36 parts of ethanol, 23-48 parts of water. (1) The iron and steel surface fluoroferrate conversion plating solution of the present invention can form a complete conversion film, the film color is deeper, the film surface is smooth and uniform, and the color is not yellow; (2) The transformation formed by the plating solution of the present invention It is found that the corrosion resistance time of the film becomes longer through the neutral salt spray test; (3) the plating solution of the present invention will not cause harm to the environment.

Owner:WUXI EPIC TECH

High-salt-fog-resistance aluminum product passivator and preparation method thereof

InactiveCN102965654BImprove corrosion resistanceImprove adhesionMetallic material coating processesNickel saltNitrite

The invention relates to a high-salt-fog-resistance aluminum product passivator which is an environment-friendly passivator having excellent adhesive force and high corrosion resistance, remarkably prolonging the corrosion resistance time and containing no phosphate, nitrite or other toxic heavy metal ions. The aluminum product passivator mainly comprises the following components: fluozirconate, chromic sulfate, sodium hydroxide, fluoride salt, nitrate, nickel salt and water. A preparation method of the aluminum product passivator comprises the following steps: mixing the fluozirconate and the fluoride salt, dissolving in water; fully dissolving the chromic sulfate in water of 70-75 DEG C, then adding into the former solution, and evenly mixing; and then, sequentially adding the sodium hydroxide, the nitrate and the nickel salt into the mixed solution, evenly stirring, and adding water to a specified volume, thus obtaining the aluminum product passivator. The method is simple to operate and short in processing time; and the aluminum product passivator can be repeatedly used. Thus, the cost can be saved.

Owner:况金权 +2

A kind of anticorrosion and antirust paint and preparation method thereof

ActiveCN109021782BEasy curingImprove adhesionAnti-corrosive paintsEpoxy resin coatingsTriethoxysilaneTitanium powder

Owner:福建省艺邦新材料科技有限公司

One-step phosphorus-free coating agent

ActiveCN103046039BGood degreasingSolve the problem of insufficient spaceMetallic material coating processesPolyethylene glycolPotassium

The invention discloses a one-step method non-phosphorus skin film agent which comprises the ingredients by mass percent: 2-4% of fluorine zirconic acid, 0-1% of sodium molybdate, 0-0.8% of potassium fluotitanate, 2-3.5% of polyethylene glycol, 0.1-0.6% of sodium fluoride, 0.5-1.5% of acrylic acid, 0-1% of citric acid, 0-1.5% of oxalic acid, 0.1-0.5% of emulsifier and the balance of water. Unoiling and skin film coating are accomplished in one process, and a whole pretreatment process is accomplished through twice washing, so that the conventional six processes are greatly simplified, and the equipment investment is reduced.

Owner:南京金环生物技术有限公司

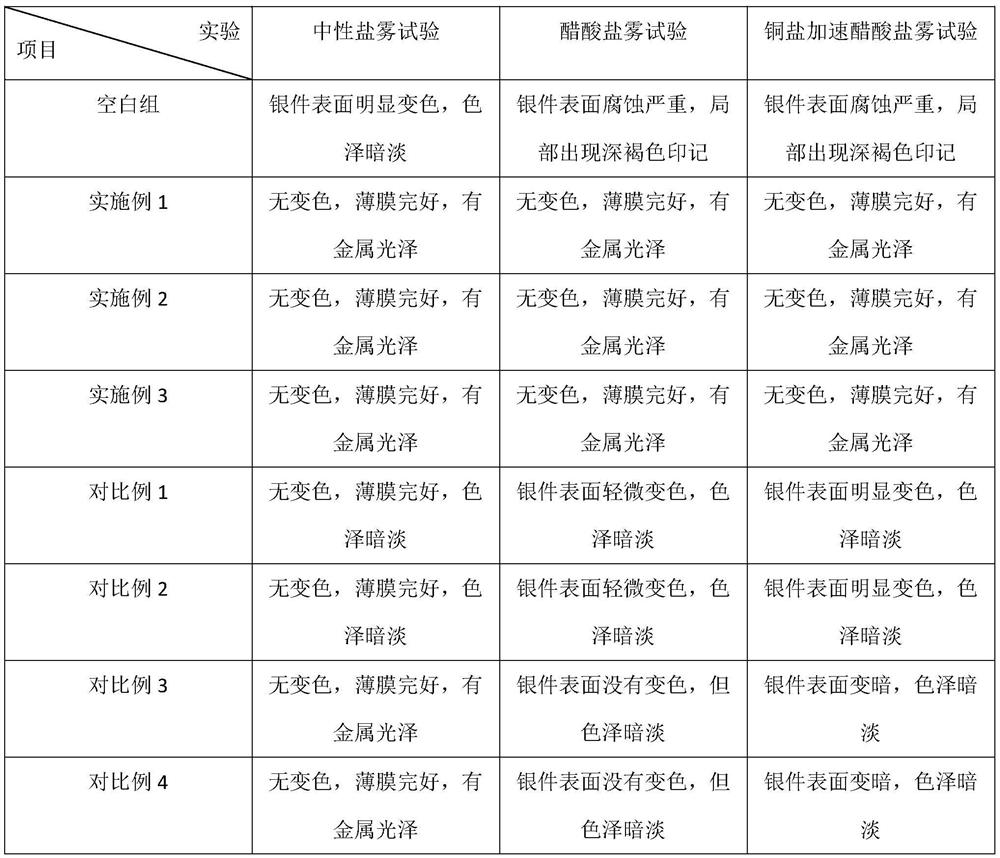

A kind of intermediate, composition, anti-discoloration silver and preparation method for preventing silver discoloration

ActiveCN109338340BSmall impact on structureReduce energy consumptionLiquid/solution decomposition chemical coatingOrganic solventSilicic acid

The invention discloses a silver discoloring preventive intermediate, a composition and discoloring preventive silver and a preparation method. The intermediate is a mixed solution comprising tetraethoxysilane, boric acid, bismuth nitrate and an organic solvent, wherein the weight ratio of tetraethoxysilane to boric acid to bismuth nitrate is 10-13: 1.5-3: 7-10. The composition is a glass body andcomprises silicon dioxide, diboron trioxide and bismuth trioxide based on the weight ratio of 30-35: 10-15: 50-55. The discoloring preventive silver is synthesized by the following steps: (1) mixingboric acid and tetraethoxysilane organic solutions to obtain a solution A; (2) mixing the solution A and bismuth nitrate to obtain the silver discoloring preventive intermediate; (3) soaking silver inthe silver discoloring preventive intermediate; moving out; and forming an intermediate layer on the surface of silver; and (4) thermally processing the intermediate layer; heating; and then decreasing the temperature to obtain the discoloring preventive silver. With the adoption of the silver discoloring preventive intermediate, the color remaining time of the discoloring preventive silver can be prolonged, and meanwhile, the corrosion resisting effect of the discoloring preventive silver can be improved.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com