Steel skeleton of greenhouse shed

A technology for greenhouses and steel skeletons, applied in greenhouse cultivation, horticulture, climate change adaptation, etc., can solve the problems of poor bending resistance, high cost, poor corrosion resistance, etc., to overcome poor corrosion resistance, short life, increase snow resistance, The effect of corrosion resistance for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

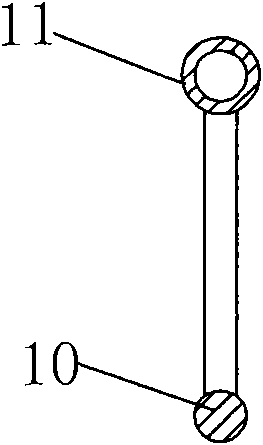

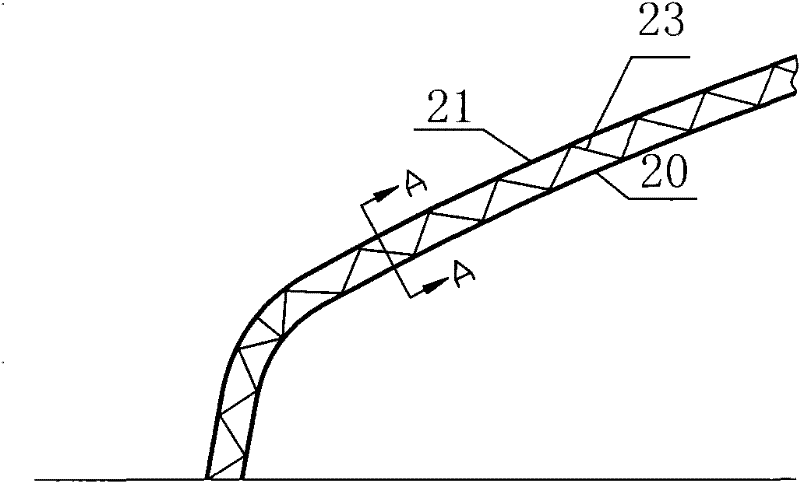

[0038] refer to image 3 , a steel frame for a greenhouse, including an inner chord 20 and an outer chord 21 that are generally arc-shaped, and the inner chord 20 and the outer chord 21 are connected by a zigzag connecting rib 23 in the middle. refer to Figure 4 , Figure 4a , Figure 4b , Figure 4c , Figure 4d , the outer chord 21 is made of "I"-shaped profile, the I-shaped profile includes a wide surface and a narrow surface, the surface connected to the "Zigzag" rib 23 is the narrow surface, and the other surface is the wide surface to hold up the shed film , the outer edge of the wide face in the cross-section of the "I" shape is in the shape of a convex arc to the outside of the profile, and the outer edge of the narr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com