Surface rust preventing treatment process for iron art products

A technology for anti-rust treatment and iron art products, which is applied in the coating process of metal materials, devices for coating liquid on the surface, and plating of superimposed layers, etc. problems, to achieve strong adhesion, low waste water treatment costs, improve coating quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

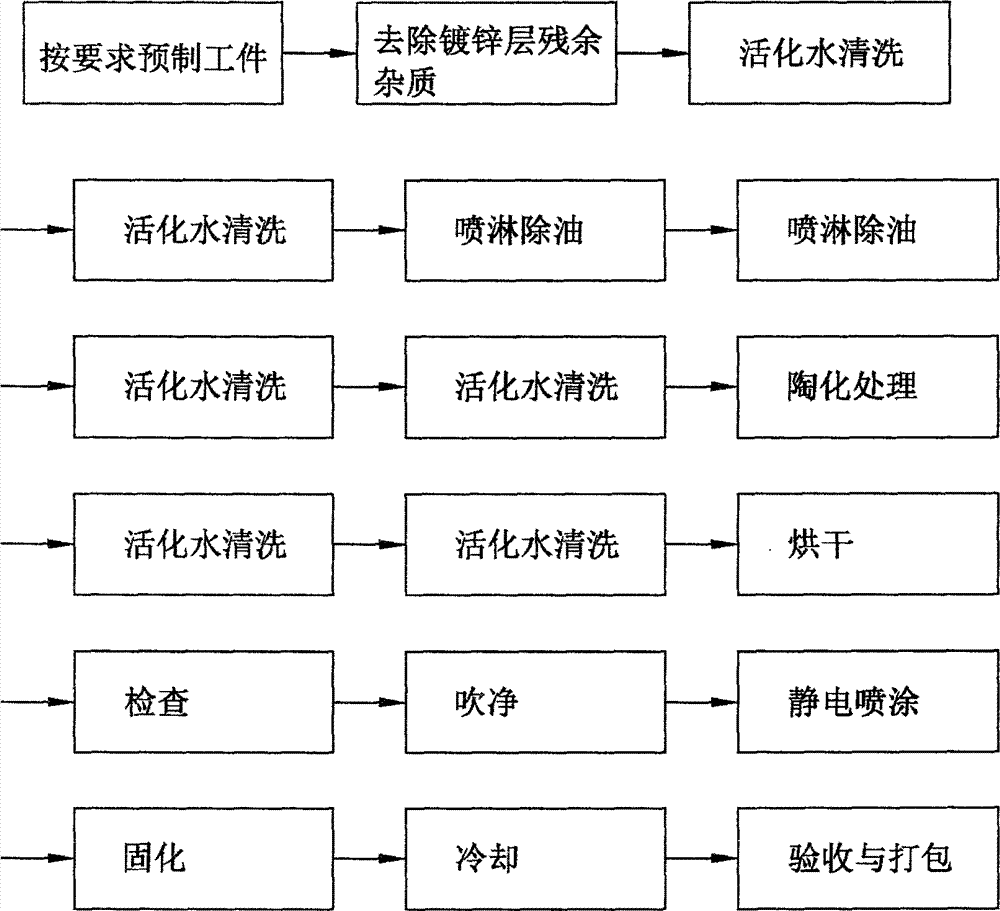

[0028] like figure 1 Shown, a kind of wrought iron product surface antirust treatment process, it comprises following process step:

[0029] (1) According to the design requirements, the pre-fabricated galvanized workpiece;

[0030] (2) Use AL-15 special solution, open the pool to soak the workpiece for 3-5 minutes, remove the impurities on the surface of the workpiece, and ensure that the galvanized layer on the surface of the workpiece does not fall off, and increase the surface bonding force and weather resistance of the workpiece;

[0031] (3) Using the activated water treated by the permalinkite small molecule agglomeration processor provided by Beijing Wanjiaduole Technology Co., Ltd., the workpiece is sprayed and cleaned twice in two pools. The cleaning time is 4 minutes. The HP value is controlled at 7.5-8.5;

[0032] (4) Use the degreasing liquid prepared by activated water and sulfonic acid that has been treated with small molecules, divide the degreasing liquid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com