Multi-arc-ion vacuum coating machine

A vacuum coating machine and multi-arc ion technology, applied in ion implantation coating, vacuum evaporation coating, sputtering coating, etc., can solve problems affecting service life, rough coating surface, large friction, etc., to achieve durability Corrosion and lubricating properties are improved, the coating is dense and bright, and the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

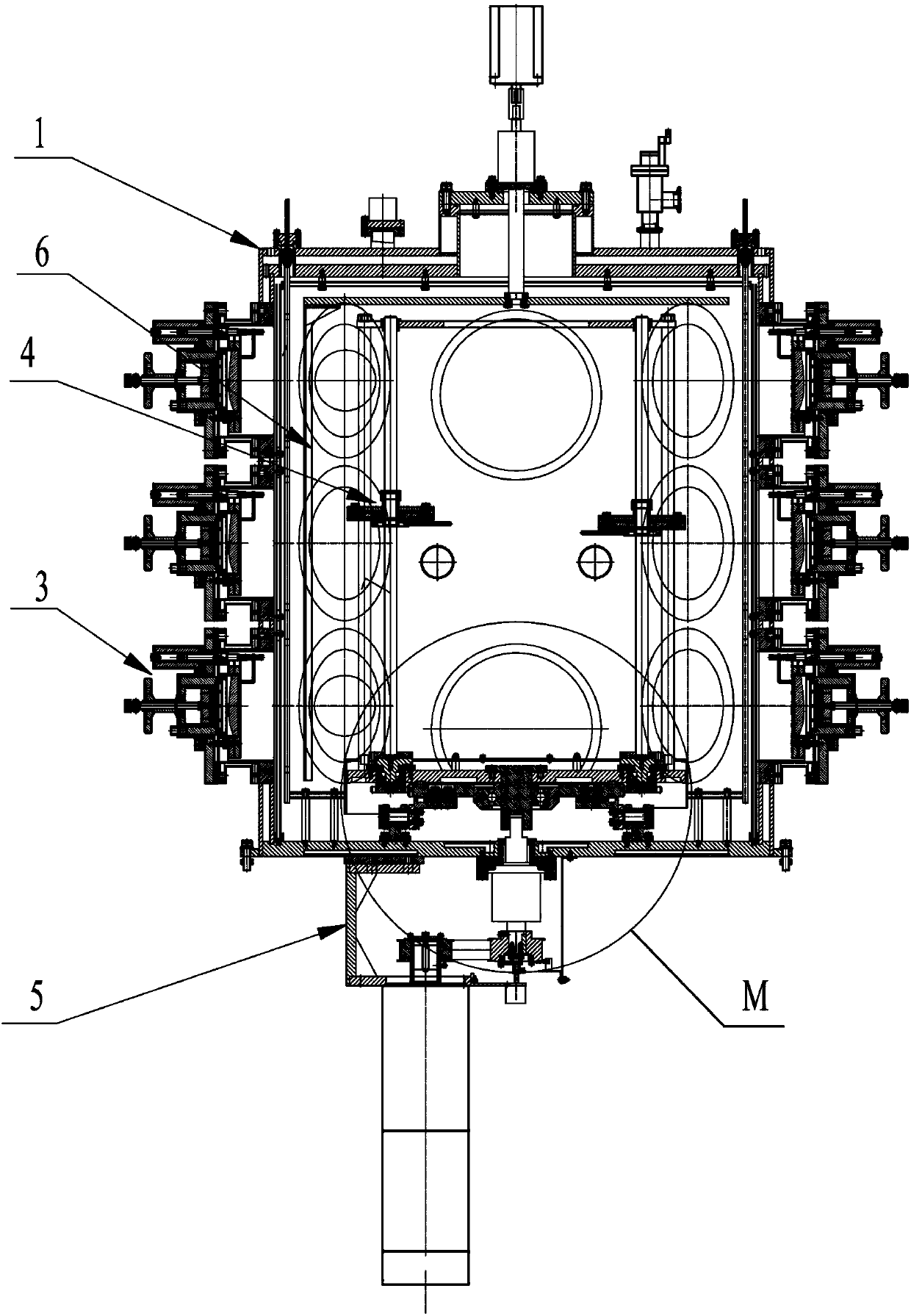

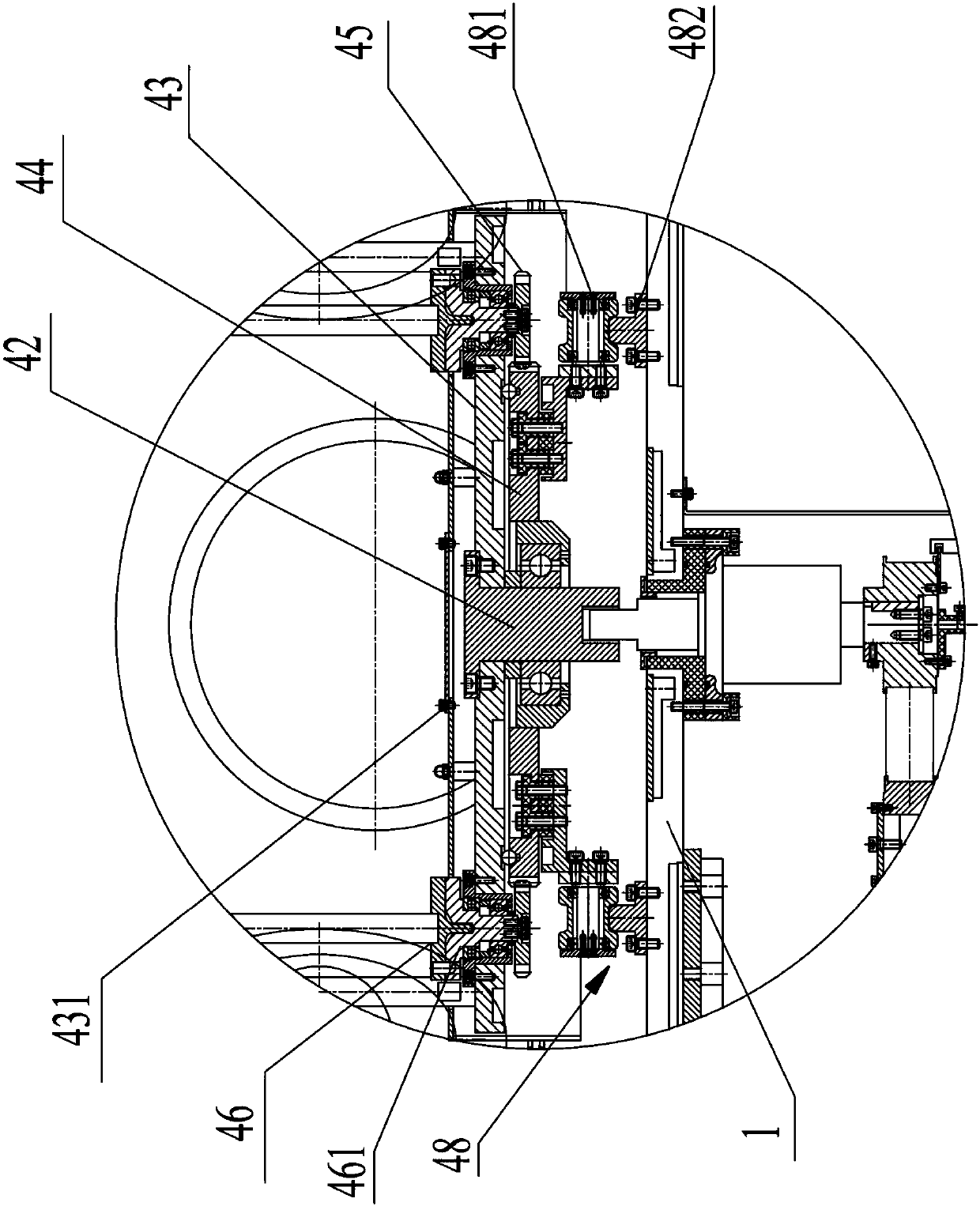

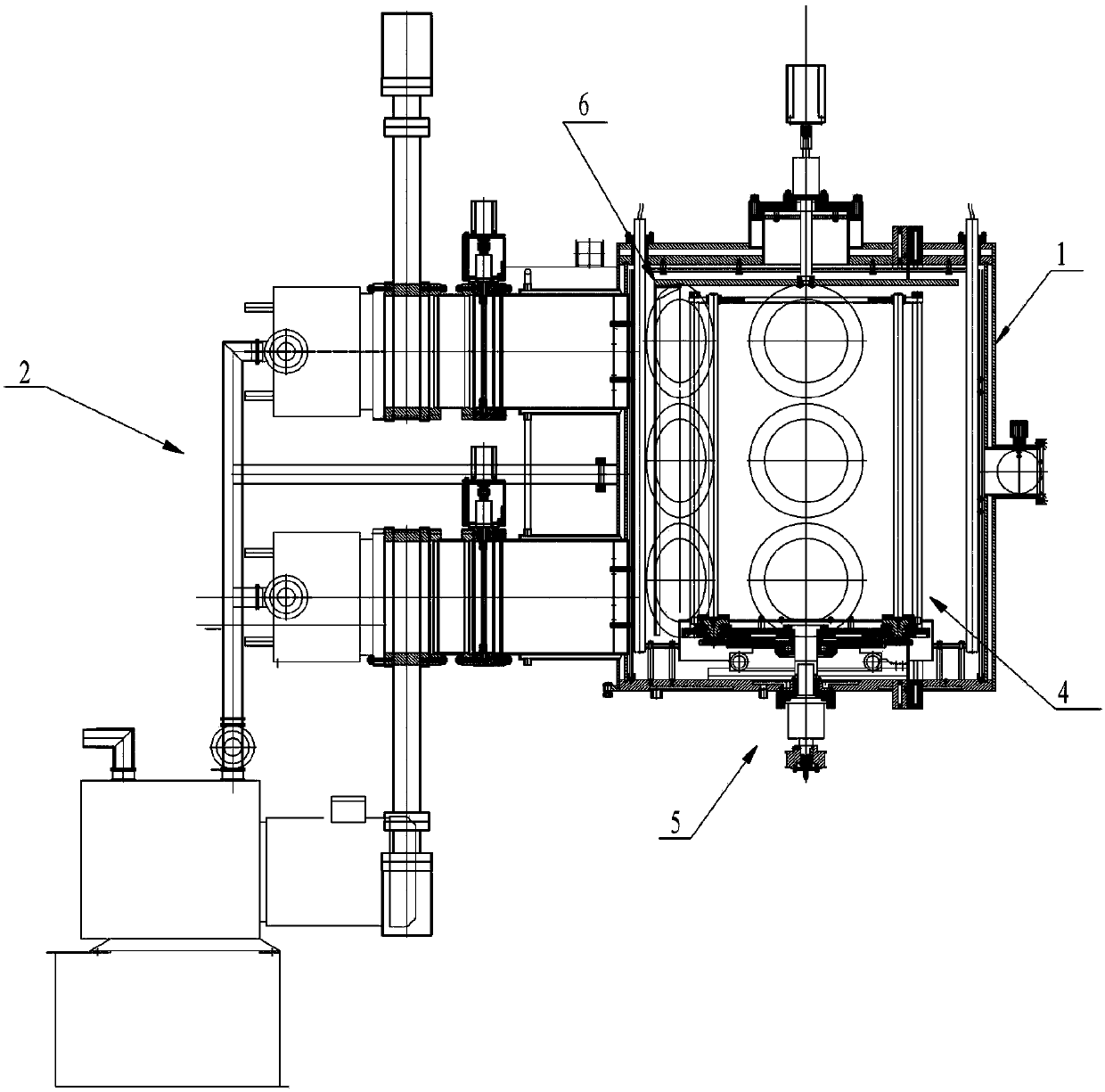

[0038] This embodiment provides a multi-arc ion vacuum coating machine, such as Figure 1-12 As shown, it includes a chamber 1, a vacuum system 2 and a multi-arc target assembly 3. The chamber 1 is provided with a rotating frame assembly 4, and a worktable 41 is installed on the rotating frame assembly 4. The rotating frame assembly 4 is used to drive the workbench 4 rotates in the chamber 1, and the workbench 41 is used to install the workpiece; the vacuum system 2 is connected to the chamber 1 to vacuumize the chamber 1; the multi-arc target assembly 3 includes several cathode multi-arc target seats 31, Each cathode multi-arc target base 31 is provided with a permanent magnet 32. In this embodiment, the outer end of the cathode multi-arc target base 31 is bolted to a carbon steel fixture 33, and one end of the carbon steel fixture 33 is adsorbed with a permanent magnet. 32, and the permanent magnet 32 is fixed on the cathode multi-arc target seat 31; the inner end of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com