A kind of chlorine salt corrosion resistant carbon nanotube modified reinforced concrete and preparation method thereof

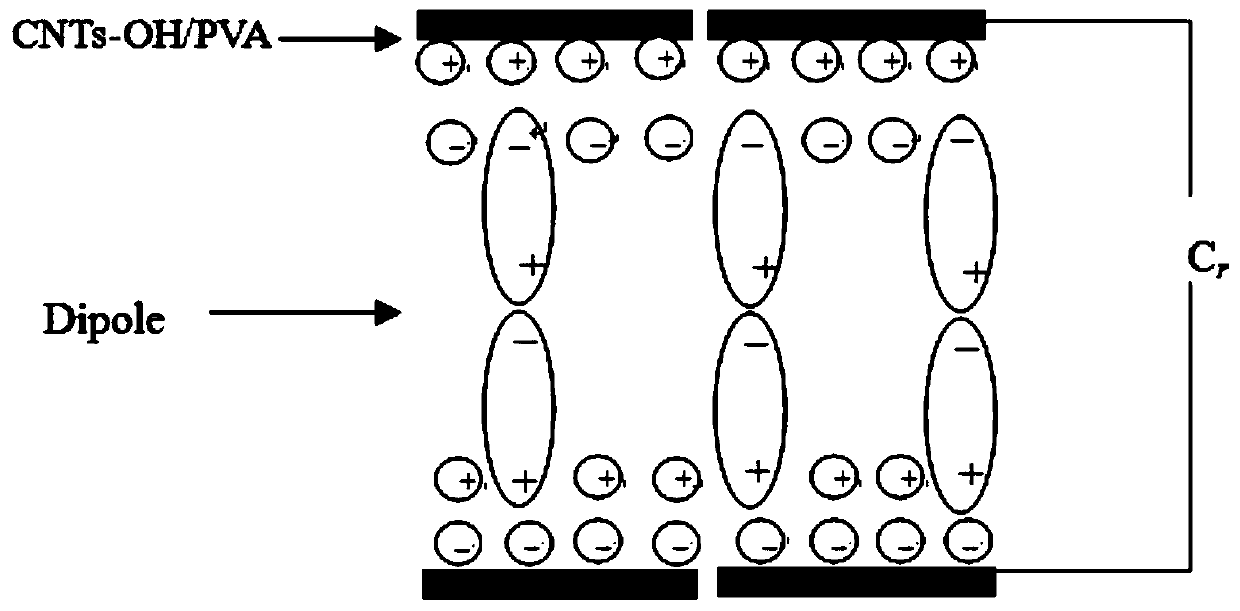

A carbon nanotube modification, reinforced concrete technology, applied in the field of reinforced concrete, can solve the problems of accelerated corrosion of steel bars, less than 50 years / 100 years, etc., to enhance the interface performance, improve the dispersion performance, prevent electrochemical corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]A carbon nanotube / polyvinyl alcohol highly resistant to chlorine salt corrosion reinforced concrete, comprising the following components and parts by weight: 0.5 part of hydroxyl carbon nanotube (Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences), polyvinyl alcohol (Xilong Chemical Institute Purchase, alcoholysis degree is 97%) 1.0 parts, 100 parts of Portland cement, 200 parts of silica sand, 350 parts of coarse aggregate, 30 parts of water, polycarboxylate superplasticizer (CR-P811 powder polycarboxylate high-performance water reducing agent agent) 0.2 part, defoamer (8868 type defoamer produced by Defeng Company) 0.1 part.

[0038] A preparation method of carbon nanotube / polyvinyl alcohol highly resistant to chlorine salt corrosion reinforced concrete, mainly comprising the following steps:

[0039] (1) Preparation of polyvinyl alcohol colloidal solution: Add 1 part of polyvinyl alcohol powder to 14 parts of water and stir evenly at room temperature for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com