Biological magnesium alloy with surface coated with sodium magnesium fluoride film and preparation method thereof

A sodium magnesium fluoride film and surface coating technology, which is applied to chemical instruments and methods, metal layered products, metal material coating processes, etc., can solve the problem of long process time and insufficient corrosion resistance of thicker magnesium fluoride films and other problems, to achieve the effect of short preparation time, prolonging the corrosion resistance time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a bio-magnesium alloy whose surface is coated with a magnesium-sodium-fluoride film, firstly immersing a degreasing and water-washed Mg-Nd-Zn-Zr magnesium alloy sample in a solution of 80°C, sodium fluoride and hydrofluoric acid After reacting for 30 minutes in the treatment solutions with molar concentrations of 1.6mol / L and 4.8mol / L, the samples were taken out, washed with water and alcohol, and dried in the air.

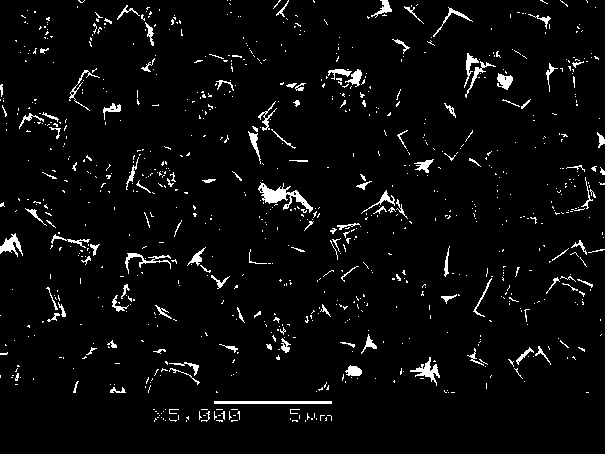

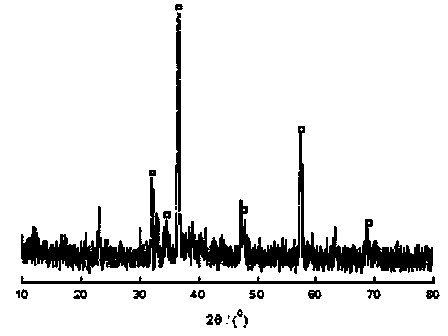

[0024] as attached figure 1 As shown, the morphology observation of the sodium magnesium fluoride film on the surface of the biological magnesium alloy sample with a scanning electron microscope shows that the sodium magnesium fluoride film is composed of approximately cubic sodium magnesium fluoride particles, and the sodium magnesium fluoride particles have a two-dimensional shape. There are two growth mechanisms of nuclear step growth and helical growth. The average edge length of sodium magnesium fluoride particles is about 2 μm,...

Embodiment 2

[0029] A method for preparing a bio-magnesium alloy whose surface is coated with a magnesium-sodium-fluoride film, firstly immersing a degreasing and water-washed Mg-Nd-Zn-Zr magnesium alloy sample in a solution of 80°C, sodium fluoride and hydrofluoric acid After reacting for 10 minutes in the treatment solutions with molar concentrations of 1.6mol / L and 4.8mol / L, the samples were taken out, washed with water and alcohol, and then dried in the air.

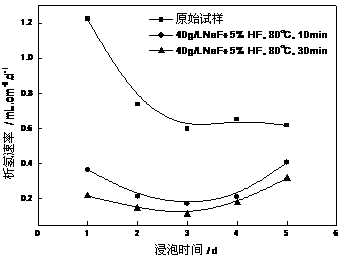

[0030] as attached image 3 As shown, the immersion test in SBF solution shows that the sodium magnesium fluoride film can significantly reduce the hydrogen evolution rate of the matrix magnesium alloy.

[0031] The observation of the sodium magnesium fluoride film on the surface of the biological magnesium alloy sample with a scanning electron microscope shows that the sodium magnesium fluoride film is composed of sodium magnesium fluoride particles that are approximately cubic, and the average edge length of the sodium magnesiu...

Embodiment 3

[0033] A method for preparing a bio-magnesium alloy whose surface is coated with a magnesium-sodium-fluoride film, firstly immersing a degreasing and water-washed Mg-Nd-Zn-Zr magnesium alloy sample in a solution of 80°C, sodium fluoride and hydrofluoric acid After reacting for 60 minutes in the treatment solutions with molar concentrations of 1.6mol / L and 4.8mol / L, the samples were taken out, washed with water and alcohol, and dried in the air.

[0034] Observation of the morphology of the sodium magnesium fluoride film on the surface of the biological magnesium alloy sample with a scanning electron microscope shows that the sodium magnesium fluoride film is composed of approximately cubic sodium magnesium fluoride particles. Potassium permanganate (0.5 g / L) and Nitric acid (30 ml / L) solution titration shows that its discoloration time is 5.3 times that of the matrix magnesium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Self-corrosion potential | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com