Aluminum-tin-zinc alloy for hydrolysis hydrogen production as well as preparation method and application of aluminum-tin-zinc alloy

A technology for producing hydrogen and zinc alloys by hydrolysis, applied in the field of alloy materials, can solve the problems of low preparation efficiency and unstable hydrogen evolution rate, and achieve the effects of fast hydrogen evolution rate, abundant raw materials, and reduced transportation and storage costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The invention provides a method for preparing an aluminum-tin-zinc alloy for hydrogen production by hydrolysis, comprising the following steps:

[0059] (1) Raw material preparation: Accurately weigh pure Al powder, pure Sn powder and pure Zn powder according to the proportioning method of the above-mentioned mass percentage;

[0060] (2) Powder stirring: the powder weighed in step (1) is placed in a stirring container, and the Al-Sn-Zn powder is obtained after stirring and mixing;

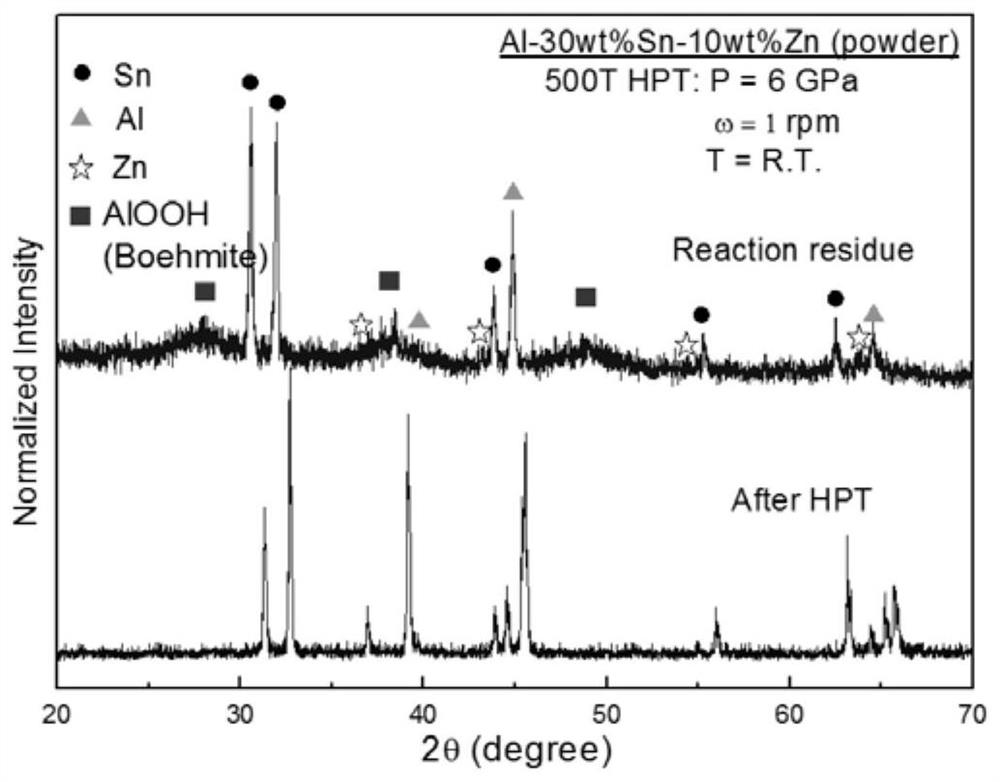

[0061] (3) High-pressure torsion processing: place the Al-Sn-Zn powder obtained in step (2) in the mold of high-pressure torsion processing equipment, set the processing parameters and perform high-pressure torsion processing to obtain formed aluminum-tin-zinc alloy sheets ;

[0062] (4) Shape processing: According to actual needs, aluminum-tin-zinc alloy sheets are processed.

[0063] In one embodiment of the present invention, in step (1), the size of the Al powder is 50-300 μm, the siz...

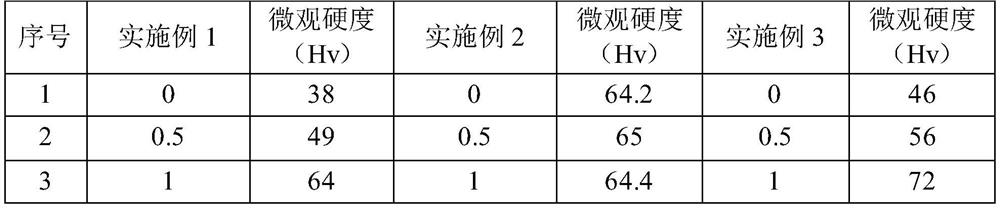

Embodiment 1

[0080] This embodiment provides an aluminum-tin-zinc alloy for hydrogen production by hydrolysis. The raw material of the aluminum-tin-zinc alloy contains 60% of the matrix element Al, 30% of the active element Sn, and 10% of the active element Zn.

[0081] The above-mentioned aluminum-tin-zinc alloy material for hydrogen production by hydrolysis can be prepared by the following method, and the specific steps are as follows:

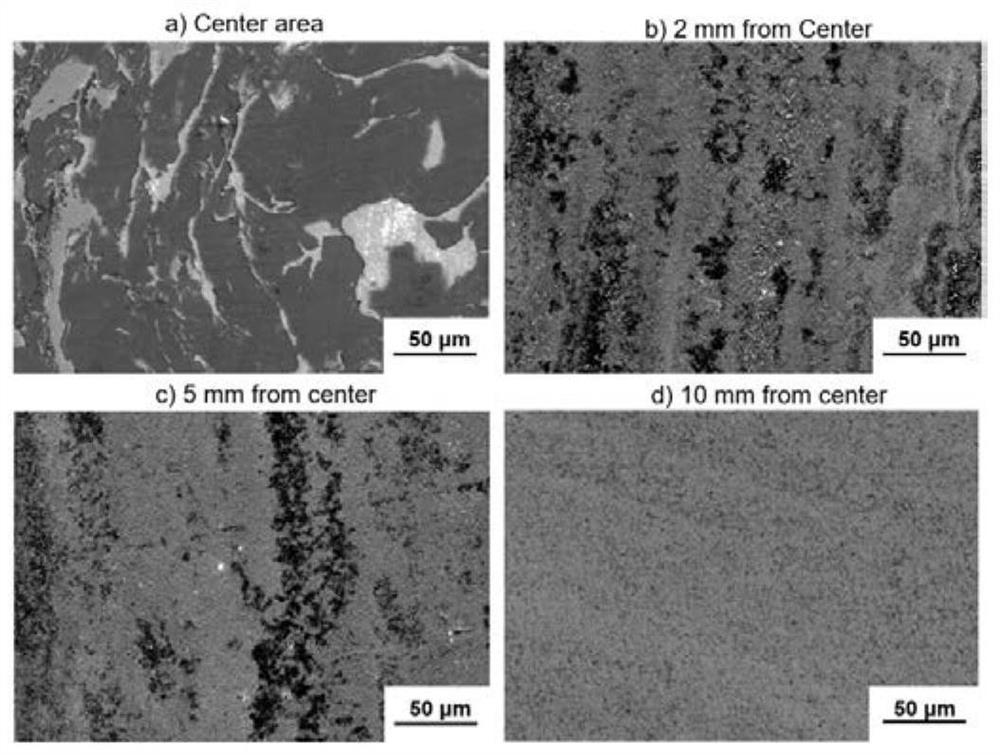

[0082] Weigh the Al powder, Sn powder and powder according to the ratio of Al-30wt%Sn-10wt%Zn, place the Al, Sn and Zn powder weighing Zn in a mechanical stirrer, stir for 5 minutes to make it evenly mixed. Take out the uniformly mixed Al-30wt%Sn-10wt%Zn powder and place it in the mold of the high-pressure torsion processing equipment, set the processing parameters P=6GPa, ω=1RPM, T=25°C, N=20 turns, and start Processing work, take out the formed Al-30wt%Sn-10wt%Zn alloy sheet after the end, its size is as follows: diameter is 30mm and thickness is 0.9mm...

Embodiment 2

[0084] This embodiment provides an aluminum-tin-zinc alloy for hydrogen production by hydrolysis. The raw material of the aluminum-tin-zinc alloy contains 60% of the matrix element Al, 30% of the active element Sn, and 10% of the active element Zn.

[0085] The above-mentioned aluminum-tin-zinc alloy material for hydrogen production by hydrolysis can be prepared by the following method, and the specific steps are as follows:

[0086] Weigh the Al powder, Sn powder and powder according to the ratio of Al-30wt%Sn-10wt%Zn, place the Al, Sn and Zn powder weighing Zn in a mechanical stirrer, stir for 5 minutes to make it evenly mixed. Take out the uniformly mixed Al-30wt%Sn-10wt%Zn powder and place it in the mold of the high-pressure torsion processing equipment, set the processing parameters, P=6GPa, ω=1RPM, T=25°C, N=20 turns, and Start the processing work, take out the formed Al-30wt%Sn-10wt%Zn alloy sheet after the end, its size is as follows: the diameter is 30mm and the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com