Nanocrystalline aluminum material, preparation method and application thereof, and aluminum air fuel cell

A fuel cell and nanocrystalline aluminum technology, applied in the field of air fuel cells, can solve the problems of hindering the commercial application of aluminum air fuel cells, increasing the internal electrical loss of the battery, excessive consumption of negative electrode materials, etc., and reducing the hydrogen evolution rate and energy density. Improves and improves the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

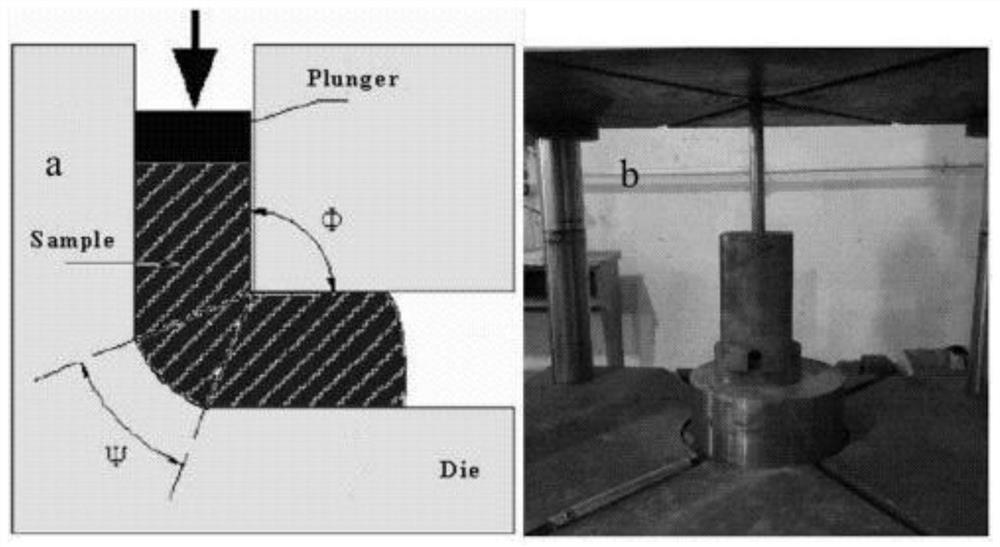

[0021] The invention provides a method for preparing a nanocrystalline aluminum material, comprising the following steps:

[0022] Perform equal-channel angular extrusion on pure aluminum or aluminum alloy samples to obtain nanocrystalline aluminum materials;

[0023] The conditions of the equal-channel angular extrusion include: ψ is 30-70°, Φ is 90°, the number of extrusion passes is 5-10, and the extrusion pressure is 50-90T;

[0024] The diameter of the pure aluminum or aluminum alloy sample is 10-100 mm.

[0025] In the present invention, the ψ of the equal channel angular extrusion is preferably 30°, the number of extrusion passes is preferably 7, and the extrusion pressure is preferably 70T.

[0026] The present invention has no special limitation on the specific method of the equal-channel angular extrusion, and the method of equal-channel angular extrusion well known to those skilled in the art can be used; the present invention has no special limitation on the devic...

Embodiment 1

[0035] High-purity aluminum samples (20 mm in diameter) were subjected to equal-channel angular extrusion, with ψ being 30° and Φ being 90°, and the extrusion passes were 5 to 10 times, and the extrusion pressure was 50T to obtain nanocrystalline aluminum materials.

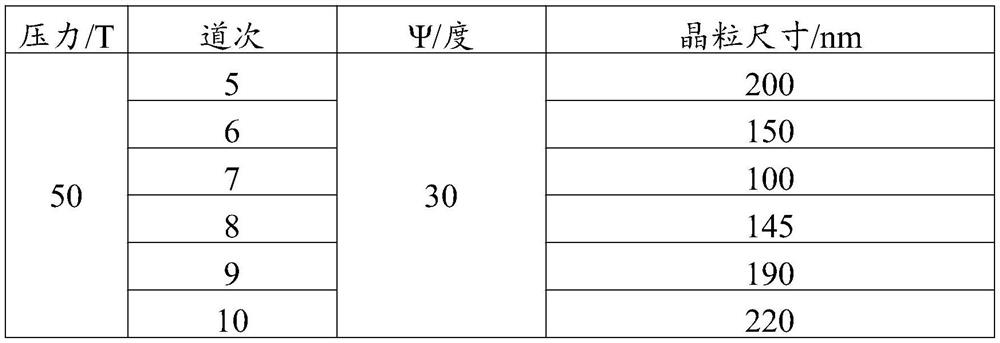

[0036] The grain size of the nanocrystalline aluminum material prepared in Example 1 was tested, and the results are shown in Table 1. It can be seen from Table 1 that the grain size of the prepared nanocrystalline aluminum material is 90-220 nm.

[0037] The grain size of the nanocrystalline aluminum material that table 1 embodiment 1 makes

[0038]

Embodiment 2

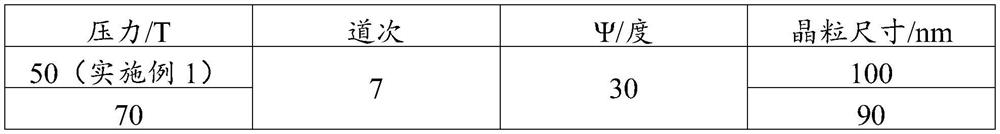

[0040] Same as Example 1, the only difference is that the number of extrusion passes is 7, and the extrusion pressure is 70T and 90T, to obtain nanocrystalline aluminum material.

[0041] The grain size of the nanocrystalline aluminum material prepared in Example 2 was tested, and the results are shown in Table 2. It can be seen from Table 2 that the grain size of the prepared nanocrystalline aluminum material is 90-150 nm.

[0042] The grain size of the nanocrystalline aluminum material that table 2 embodiment 2 makes

[0043]

[0044]

[0045] The nanocrystalline aluminum material prepared in Examples 1-2 is used for the negative electrode of the aluminum-air fuel cell, the positive electrode of the aluminum-air fuel cell is oxygen, and 4M sodium hydroxide aqueous solution is used as the electrolyte. The hydrogen evolution corrosion rate of different nanocrystalline aluminum materials in 4M sodium hydroxide aqueous solution was detected, and the results are shown in Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com