Patents

Literature

36results about How to "Improve mass to energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal management system of electric automobile

ActiveCN101885313AGuaranteed output currentGuaranteed output voltageAir-treating devicesElectric propulsion mountingControl signalThermal management system

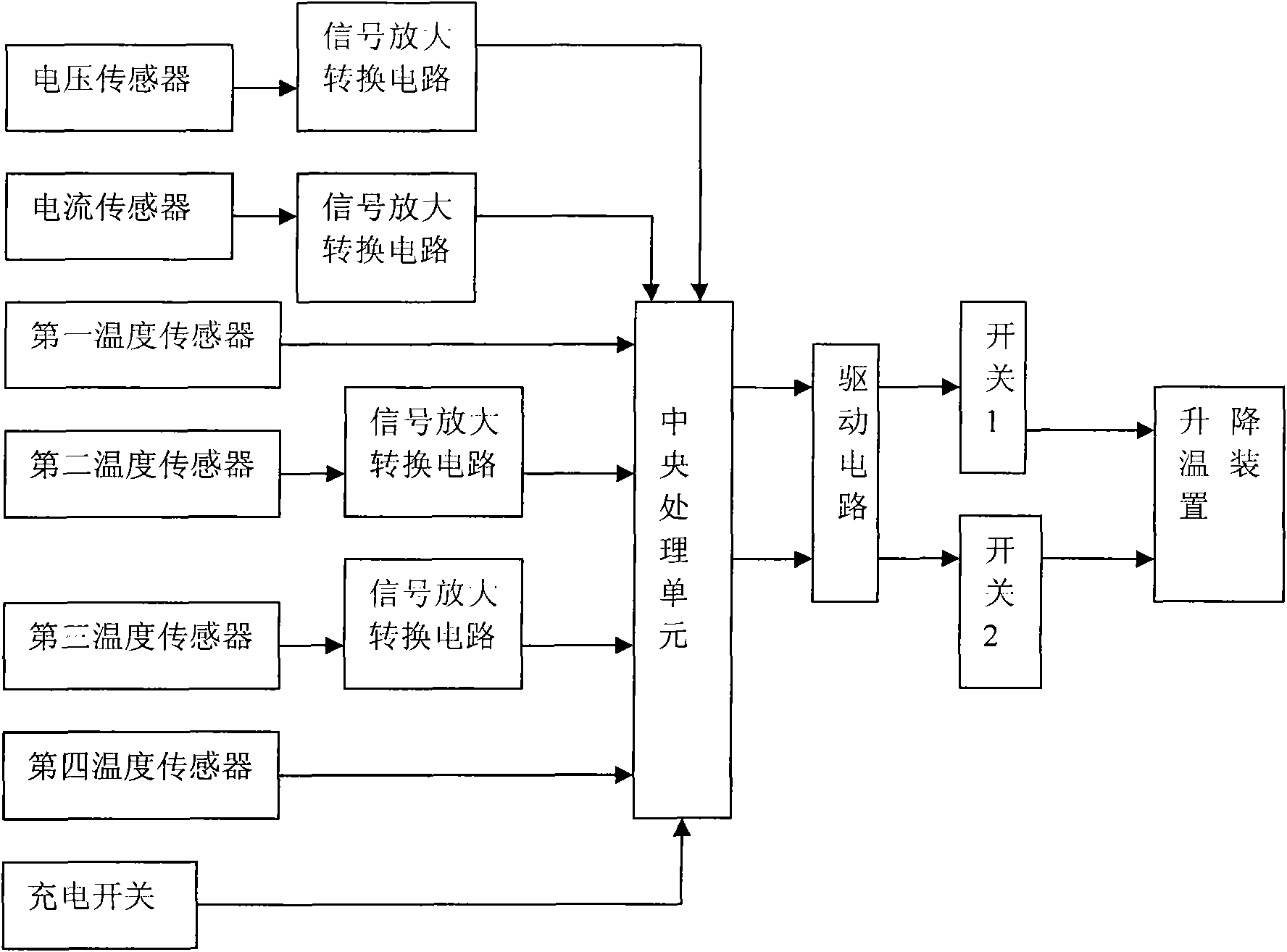

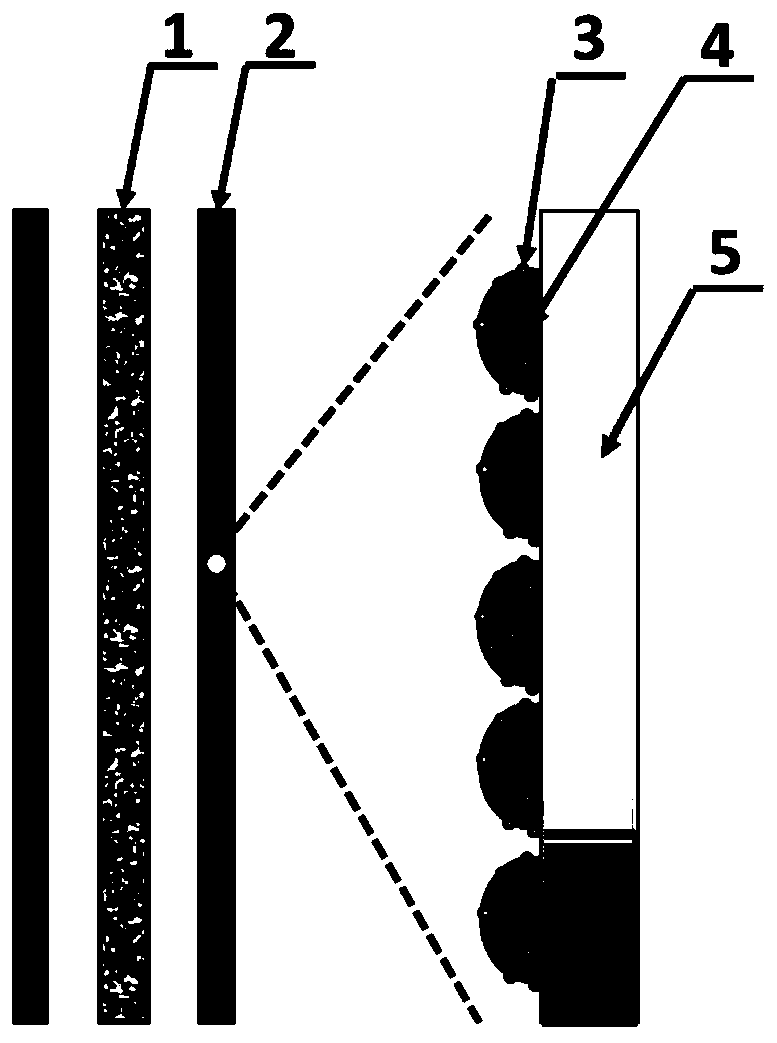

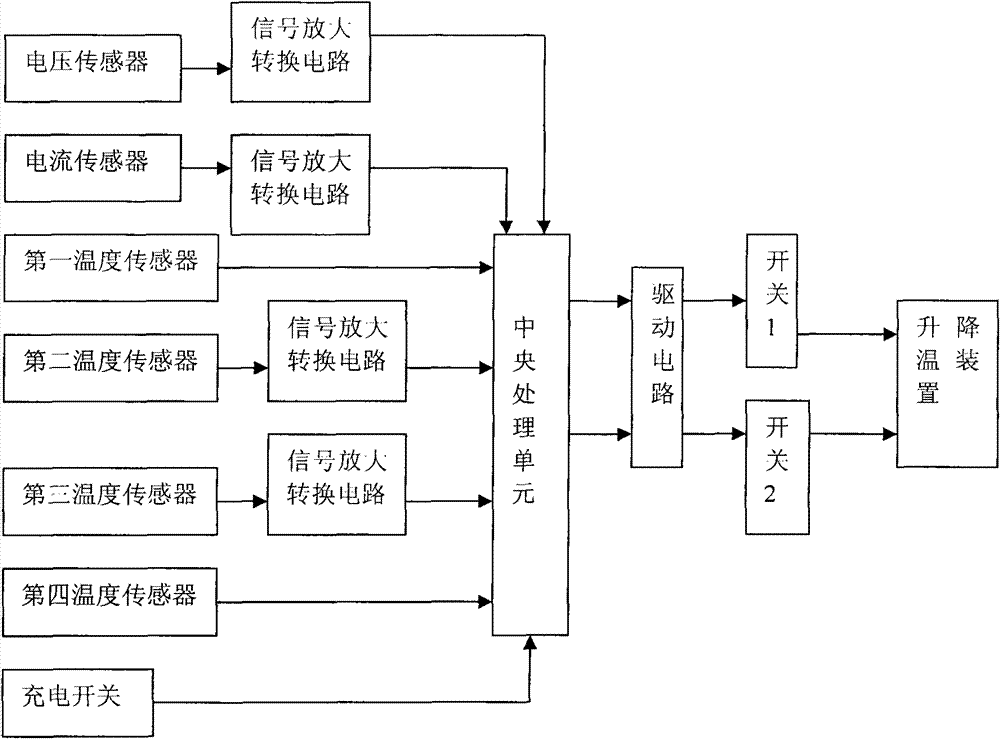

The invention discloses a thermal management system of an electric automobile, comprising a temperature sensor, a heating and cooling device and a central processing unit, wherein the temperature sensor is used for acquiring the temperature of components generating the raising and the drop of temperature in the electric automobile; the heating and cooling device is used for generating a heat source and a cold source which are transmitted to components needing heating and cooling and is connected with the signal output end of the central processing unit through a control switch; and the central processing unit is used for receiving a signal of the temperature sensor and calculating and outputting the control signal to the heating and cooling device. In the invention, the temperature conditions of various components can be detected by using the temperature sensor and are transmitted to the central processing unit which controls the temperature in time so as to ensure that the temperatures of various components are in a proper range. The system not only can be used for monitoring the temperature of batteries, but also can be used for monitoring the temperature of a motor and a motor controller, thereby avoiding the motor and the motor controller from being damaged due to overhigh temperature. The system can also be used for monitoring the temperature in a carriage and ensures thecomfort degree of the moving space of people.

Owner:李辉 +1

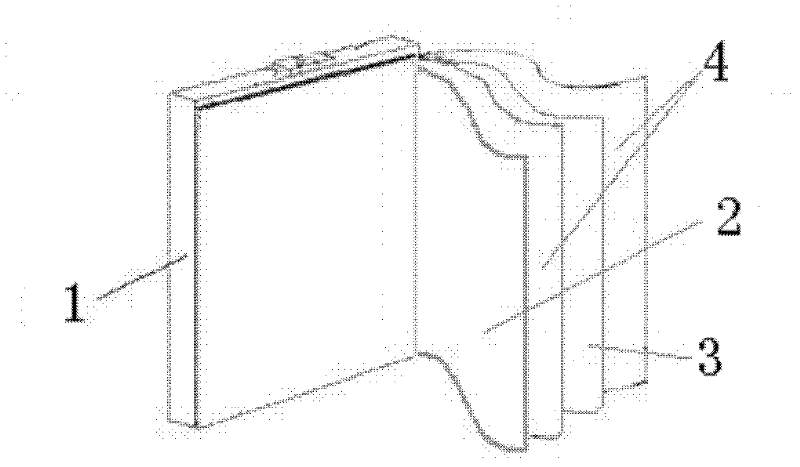

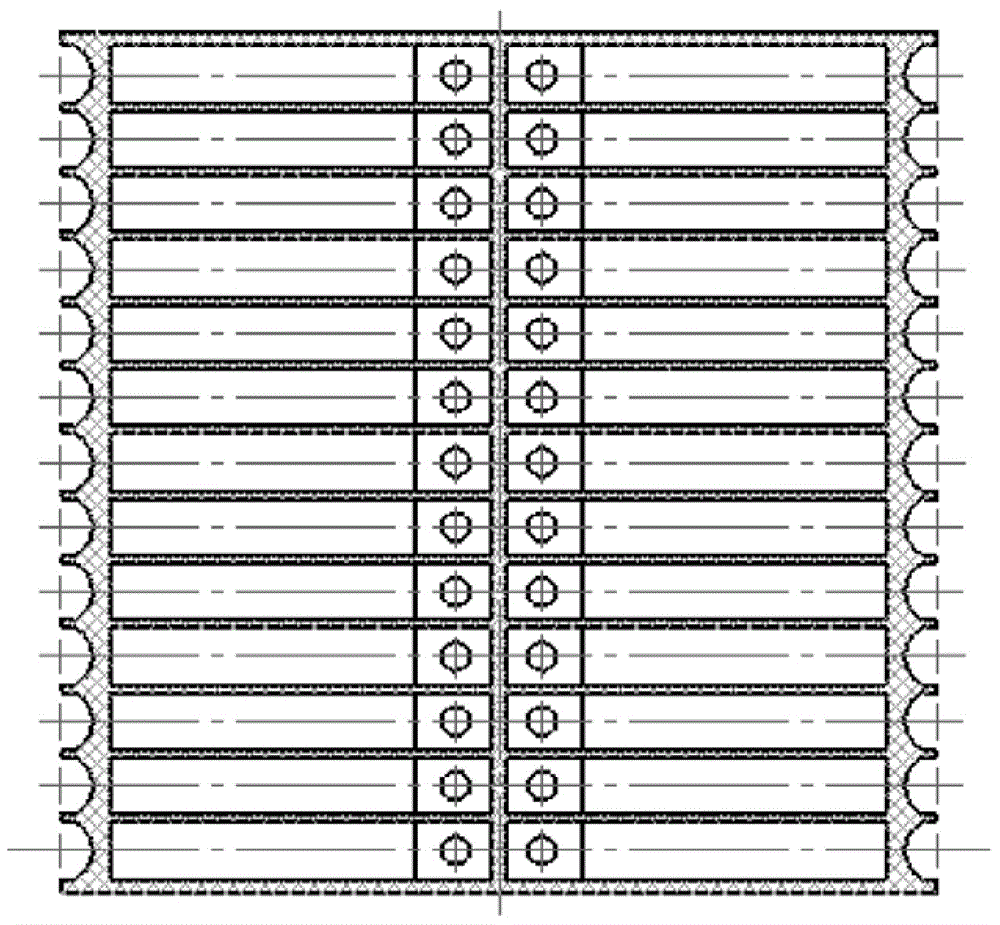

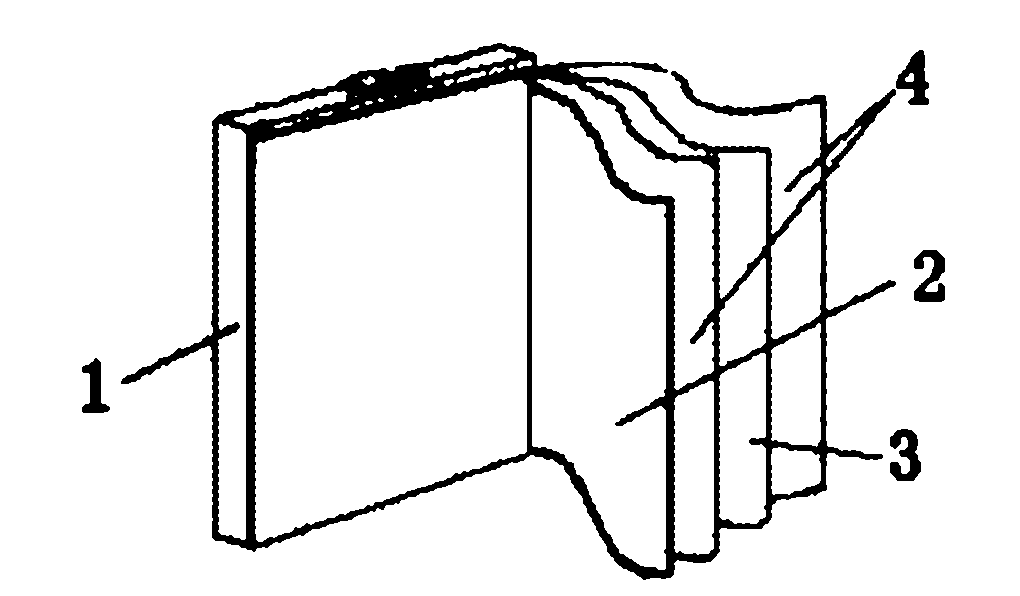

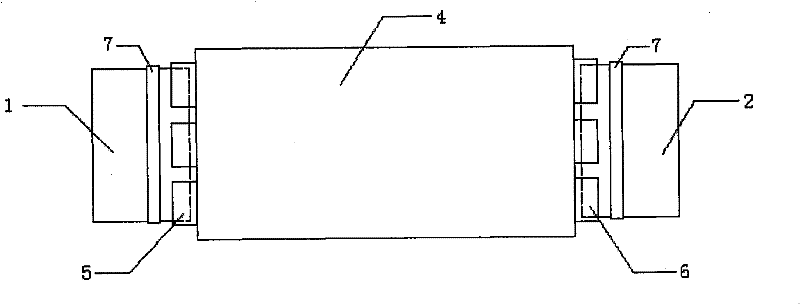

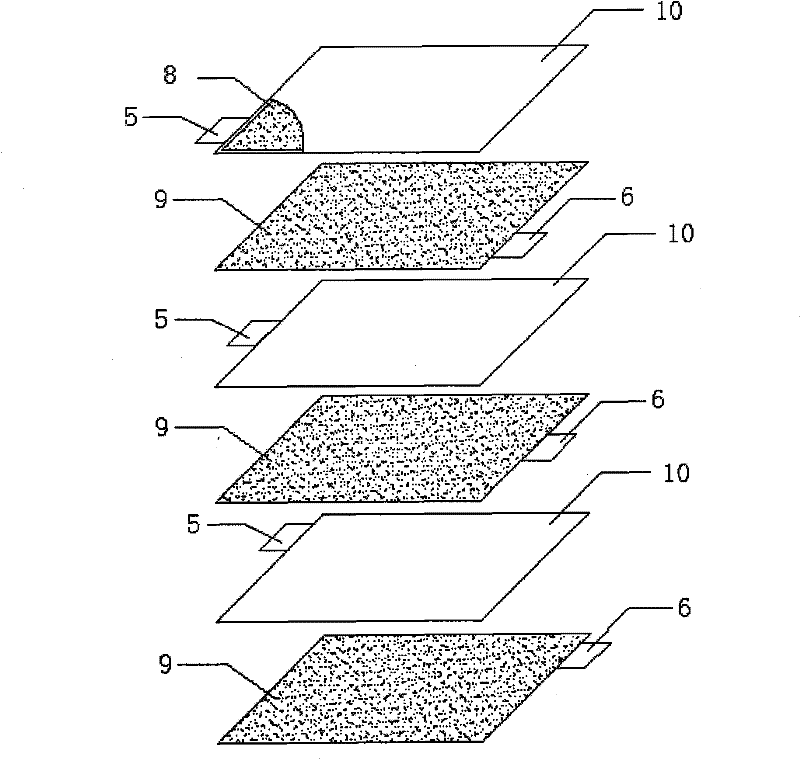

Cylinder type lithium ion battery cell and making method thereof

InactiveCN101640284AReduce leak rateReduce product scrap rateFinal product manufactureSecondary cellsWork in processLithium-ion battery

The invention discloses a cylinder type lithium ion battery cell and making method thereof; wherein the making method of the cylinder type lithium ion battery cell includes the following steps: (1) making an aluminium lug and a nickel lug; (2) making a positive plate and a negative plate by respectively welding the aluminium lug and the nickel lug with a positive substrate and a negative substratefirmly; (3) obtaining an aluminium plastic composite membrane with dual circular arc structure by adopting a mould with circular structure to punch the aluminium plastic composite membrane; (4) winding the positive plate, the negative plate and a diaphragm in to a winding core; (5) placing the winding core into the aluminium plastic membrane for sealing the two end faces, so as to obtain sealed semi-finished product cell; (6) baking the semi-finished product cell and then injecting electrolyte containing Li<+>, and carrying out precharge after the semi-finished product cell is laid for a period of time; (7) vacuumizing and sealing the side of the cell after precharge, and then cutting excessive aluminium plastic composite membrane, so as to the obtain finished product cell.

Owner:珠海汉格能源科技有限公司

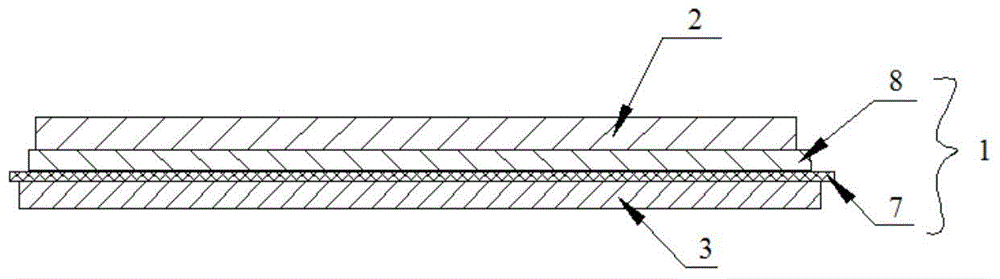

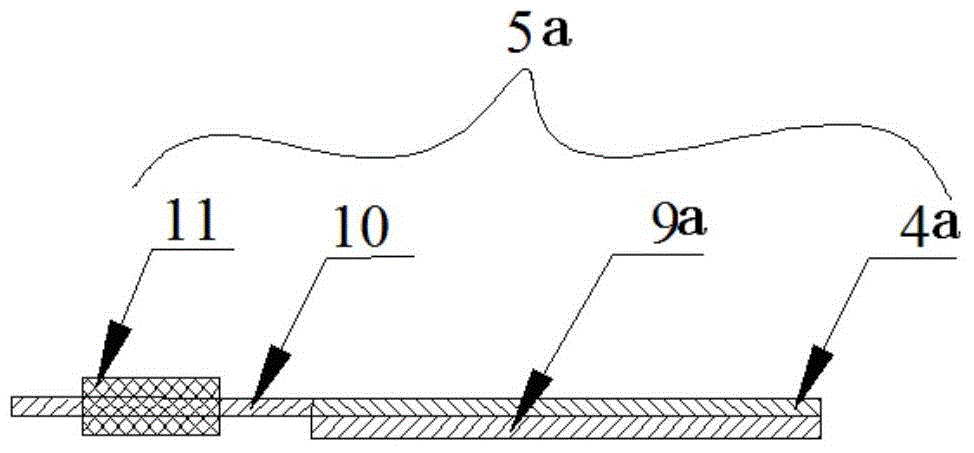

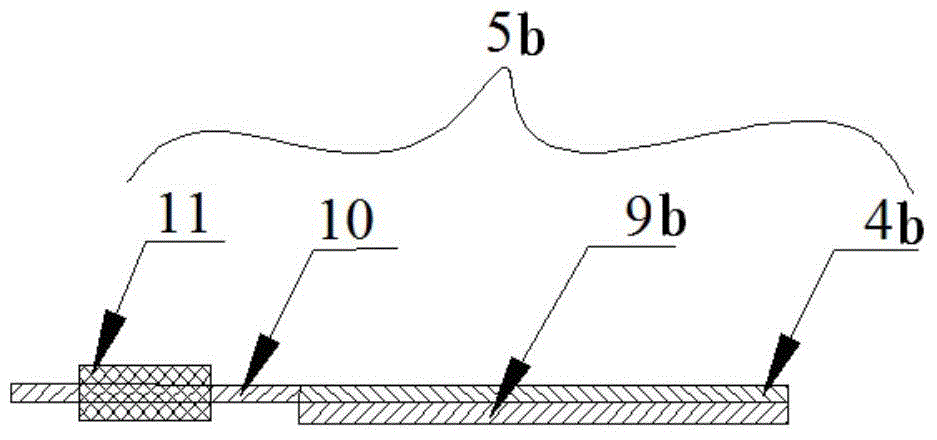

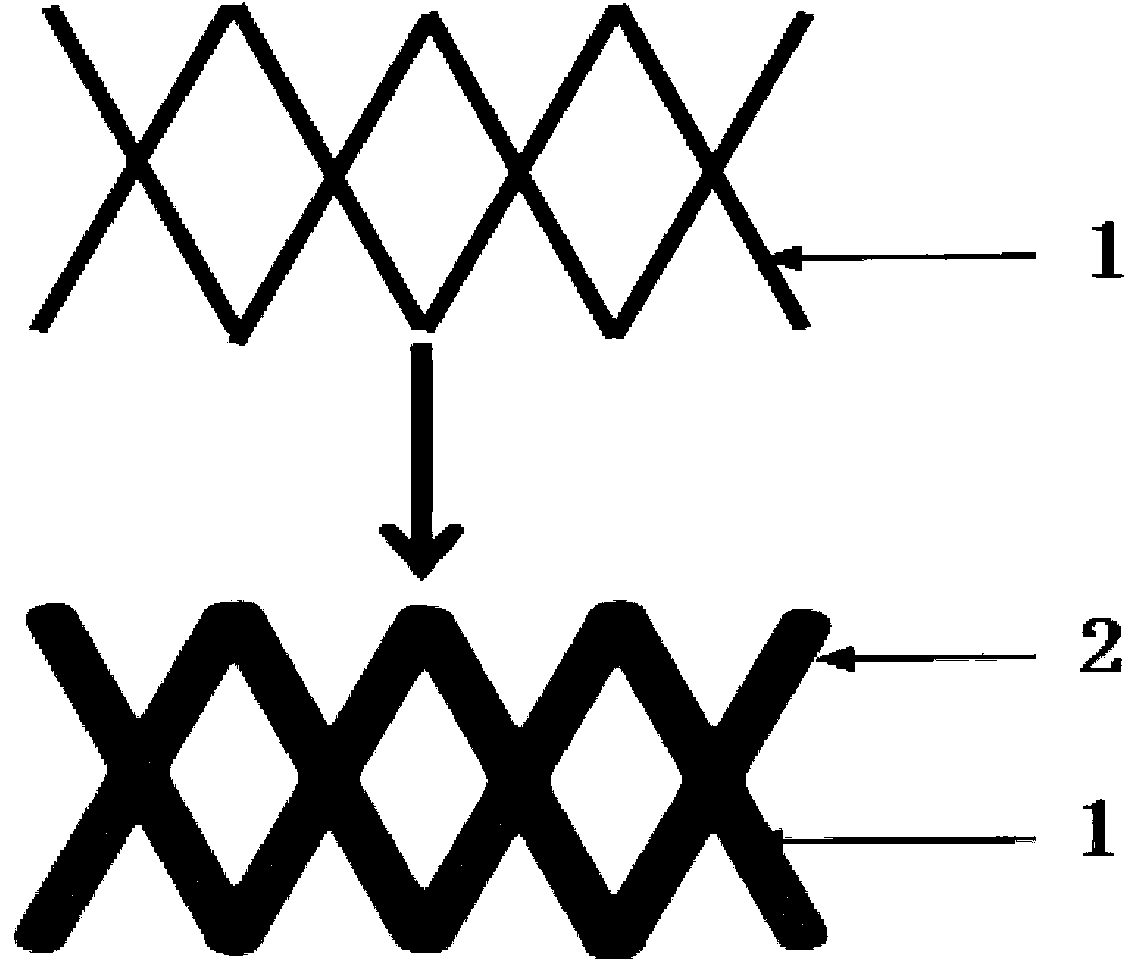

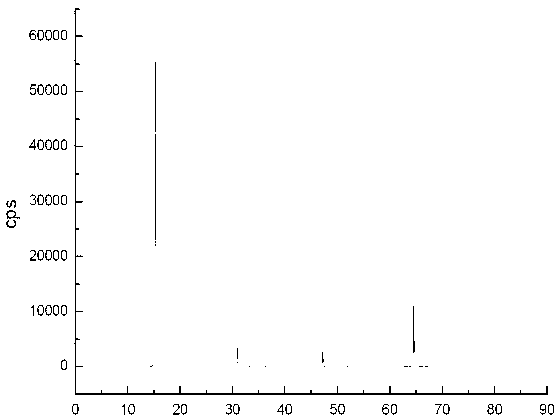

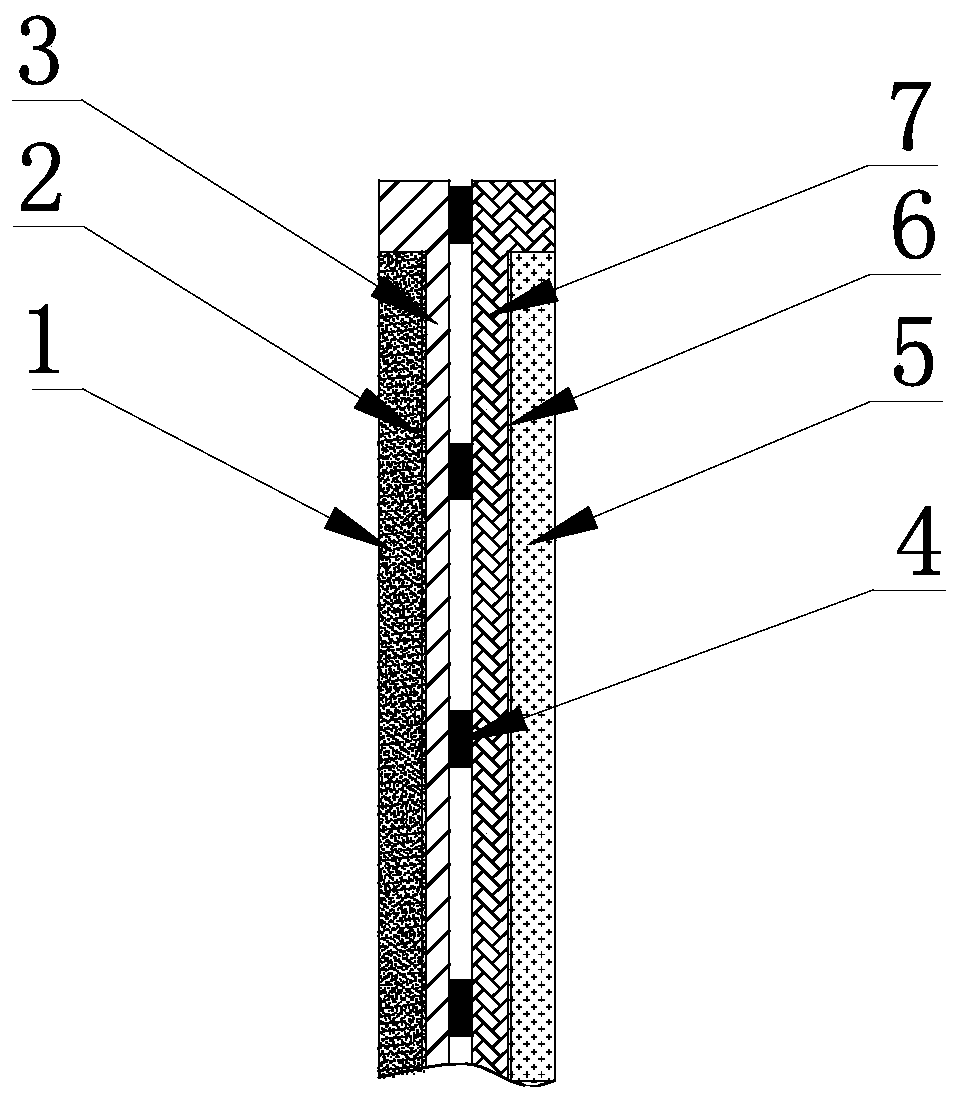

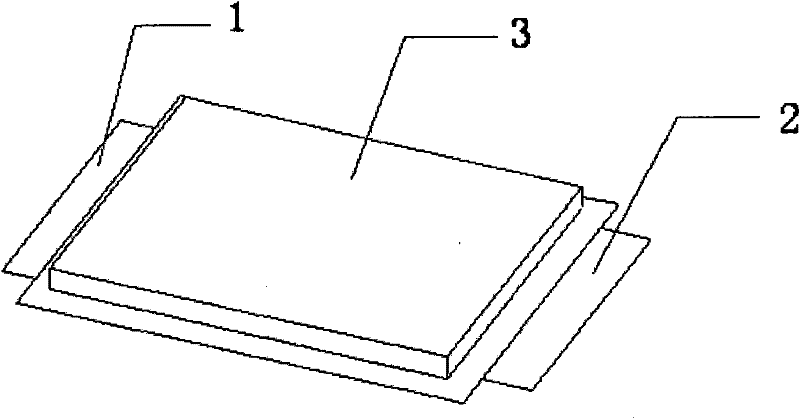

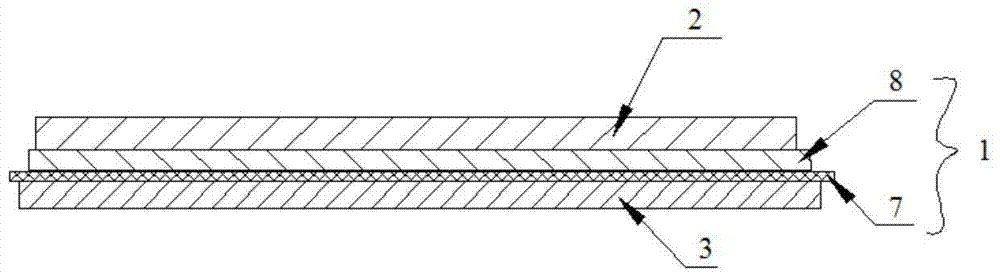

Ultrathin secondary battery and preparation method thereof

ActiveCN104638213ASmall spacingControl shapeFinal product manufactureCell component detailsEngineeringSlurry

The invention relates to an ultrathin secondary battery and a preparation method thereof, and belongs to the field of electrochemistry. The thickness of the ultrathin secondary battery is 0.3-1.0mm. The ultrathin secondary battery comprises a diaphragm, a positive electrode membrane and a negative electrode membrane, wherein the positive electrode membrane and the negative electrode membrane are respectively adhered to two sides of the diaphragm and directly contact the diaphragm; the diaphragm consists of a substrate and a conductive layer; the conductive layer is positioned on one side of the substrate and directly contacts the positive electrode membrane. The preparation method comprises the following steps: firstly, respectively coating the front and back sides of the diaphragm with positive electrode slurry and negative electrode slurry according to set sizes, drying and rolling, thereby obtaining the diaphragm with the positive electrode membrane and the negative electrode membrane; secondly, pressing, thereby enabling a positive electrode current collector and a negative electrode current collector to respectively tightly contact the positive electrode membrane and the negative electrode membrane; finally, packaging by using a package membrane according to design size, performing vacuum dewatering and electrolyte injection in sequence, subsequently sealing, activating, forming, packaging for the second time, and performing volume division, thereby obtaining the ultrathin secondary battery.

Owner:HUNAN GAOYUAN BATTERY

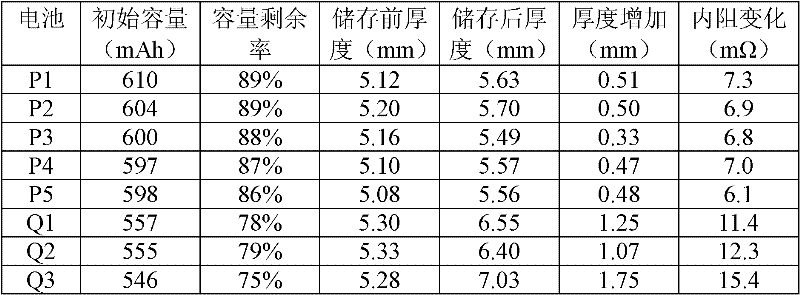

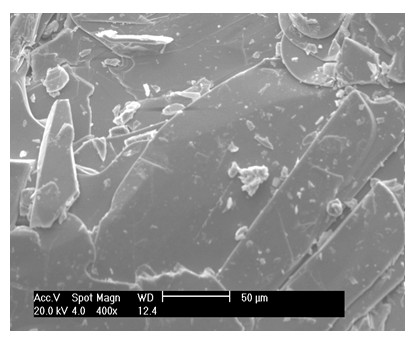

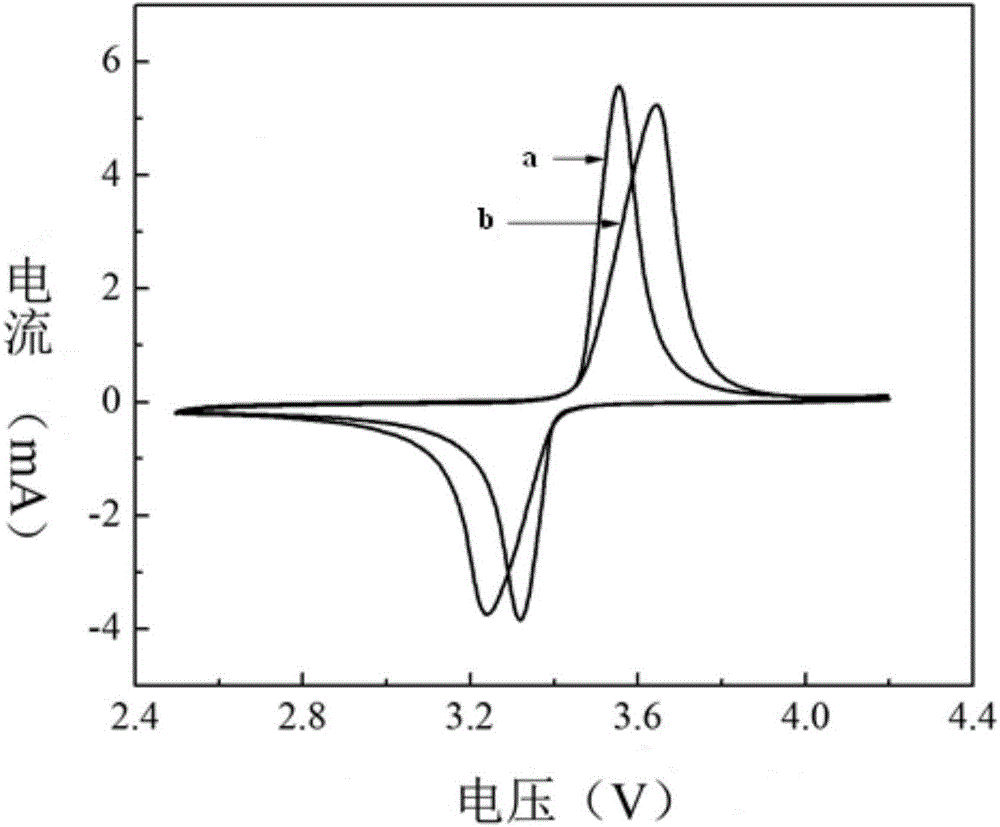

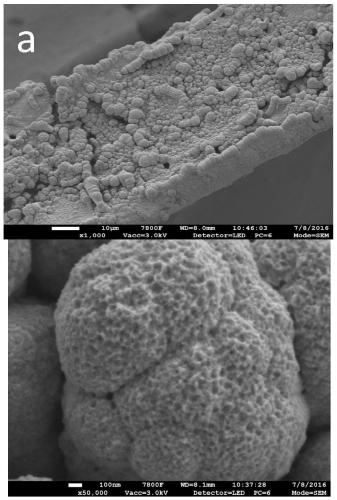

Negative electrode active material, preparation method thereof, and lithium ion secondary battery prepared using the negative electrode active material

InactiveCN102299311AEasy to coverReduce irreversible capacityCell electrodesSecondary cellsLithiumMixed oxide

The invention provides a cathode active material and a preparation method thereof and a lithium ion secondary battery prepared by the cathode active material. The preparation method comprises the following steps: mixing spherical oxides and rod-like oxides to obtain mixed oxides, performing ball milling and mixing of the mixed oxides in an N-methyl pyrrolidone solution of polyvinylidene fluoride with a mass fraction of 4% for 1 hour, adding lithium titanate and performing ball milling and mixing for 3 hours to obtain slurry, heating the slurry, stirring at 170 DEG C till the slurry is dried to obtain a titanium composite material, roasting the titanium composite material at 600 DEG C for 24-72 hours in Ar or N2 atmosphere or under vacuum, cooling to room temperature to obtain the cathode active material; the obtained cathode active material has the characteristic of dense and uniform coating layer, can effectively reduce the contact of lithium titanate and water; because of the nano-scale particle sizes of the oxides, the oxides can effectively coat lithium titanate, and thus avoid the generation of swollen phenomenon to the maximum extent, and facilitate the improvement of the cycle life, the storage performance and the security of the lithium ion secondary battery.

Owner:IRICO

Preparation method of positive pole material of thermal battery

ActiveCN102157722AHigh tap densityImprove electrical and thermal conductivityPrimary cell electrodesThermal conductivityTemperature treatment

The invention relates to a preparation method of a positive pole material of a thermal battery, which comprises the following steps: (1) performing forced air drying; (2) performing vacuum drying in a vacuum drying box; (3) containing in a quartz tube, and placing in a crucible resistance furnace for high-temperature treatment; (4) taking out the material which becomes a pole billet out of the quartz tube, and smashing; and (5) weighing nickel chloride treatment powder prepared in (4) according to the proportion, stirring a conductive agent after drying with a molten salt after drying, and preparing the positive pole material of the thermal battery. Commercially available nickel chloride hexahydrate is adopted as a raw material, the forced air drying and the vacuum drying are performed, and the high-temperature treatment is performed on the dried material after smashing and screening; the loose density and the tap density of the material after treatment are improved, the electrical conductivity and the thermal conductivity of the material are improved, and the electrochemical activity of the material is improved; and the weight of water contained in the material is reduced to 1000PPM from 5% before drying. The process is simplified and stabilized, the equipment investment cost is low, and conditions are created for realizing the industrialization of the positive pole material of the thermal batteries.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Electrolyte used for ion state mixed crystal salt storage battery

ActiveCN102881949AAvoid pollutionAvoid polluting emissionsLead-acid accumulatorsStrong acidsDistilled water

The invention discloses an electrolyte used for an ion state mixed crystal salt storage battery. The electrolyte comprises the following components in percentage by weight: 52-80% of hydrosulphate, 0.1-8% of corrosion inhibitor, 0.4-3% of antiager, 3-12% of strong acid salt agent, 0.1-10% of ester ion concentration control agent, 1-13% of lead-acid storage battery activating agent, 1-10% of chemically pure sulfuric acid of which the concentration is larger than or equal to 98%, and the balance of distilled water. The electrolyte disclosed by the invention has the advantages that the environment pollution caused by sulfuric acid in the electrolyte of the existing lead-acid storage battery is effectively avoided, a system is enabled to have stable and mild reactivity, the stable electrochemical performance of the storage battery is improved, the high and low ambient temperature adaptability is strong, the effective discharge capacity and the self discharge rate are small, and the service life of the battery can be effectively prolonged.

Owner:北京艾塔文商贸有限责任公司

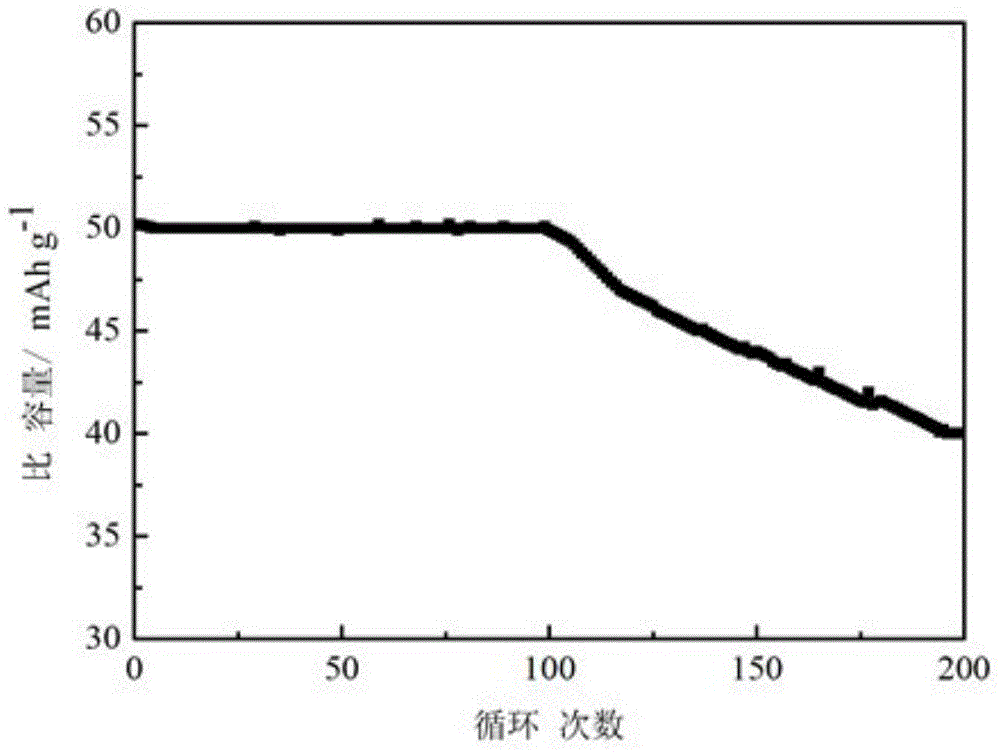

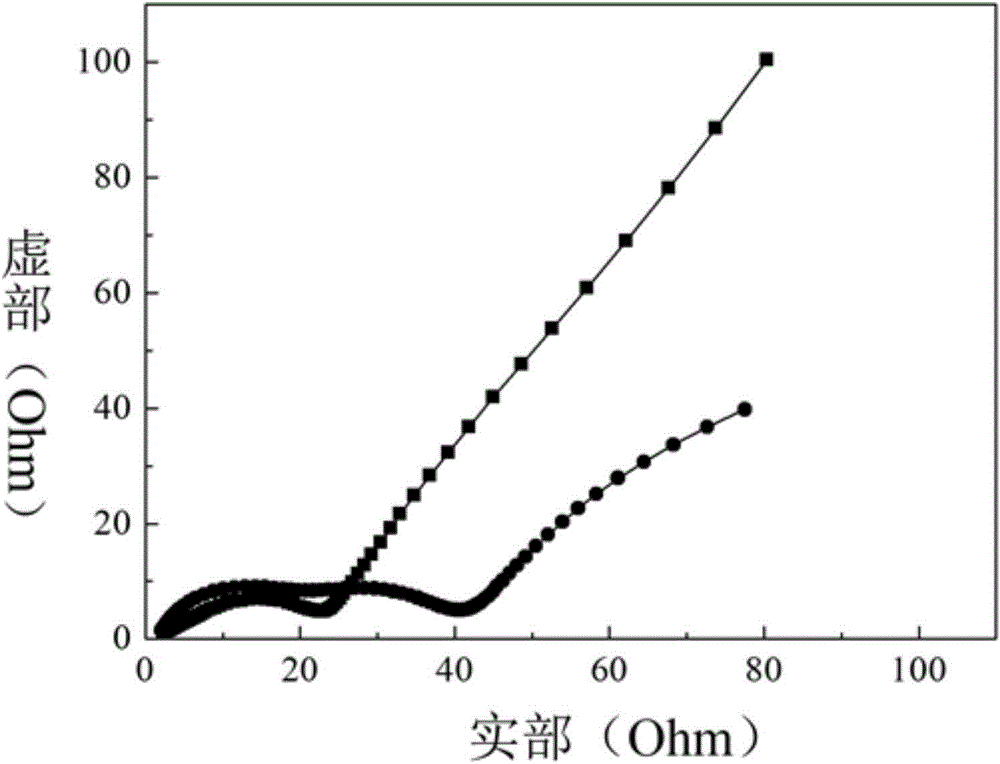

Method for improving electrode stability of aqueous electrolyte battery and aqueous electrolyte capacitor

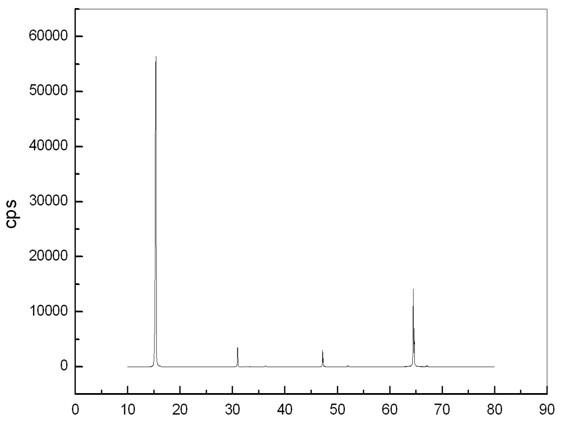

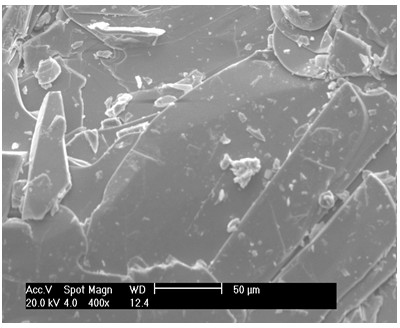

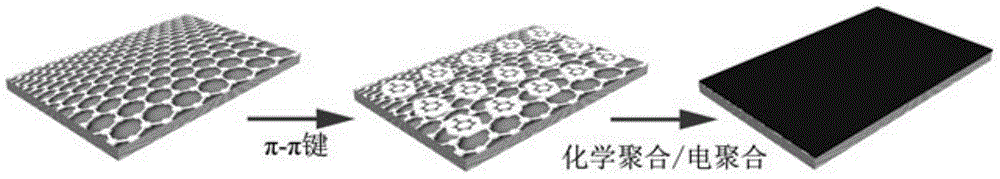

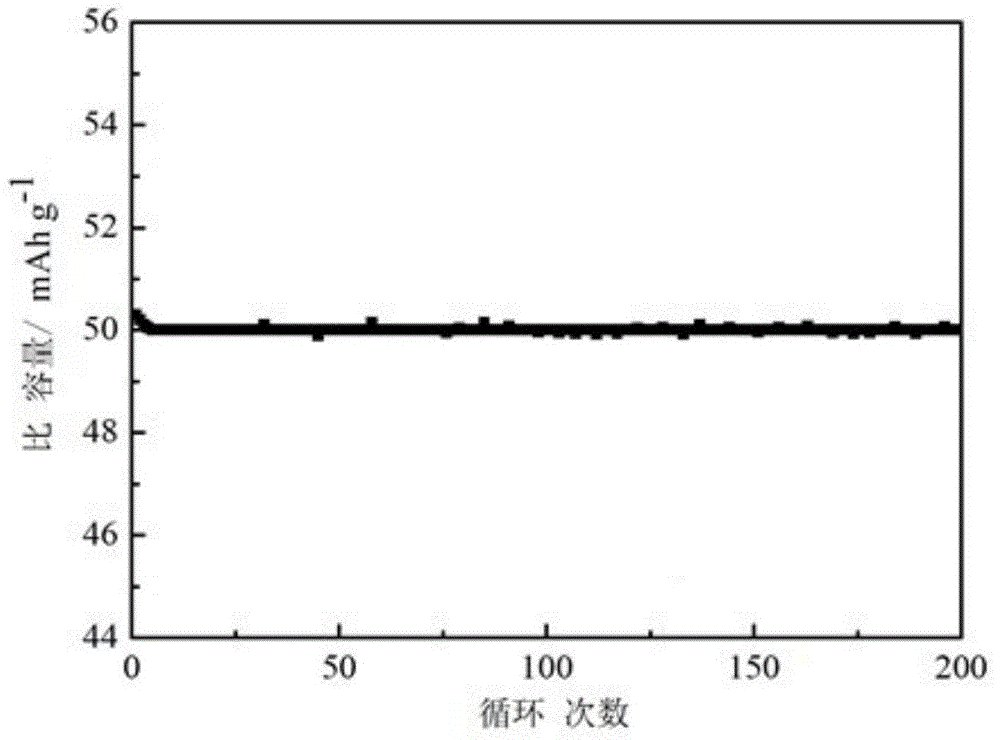

InactiveCN104882615AImprove mass to energyImprove machinabilityHybrid capacitor electrodesElectrode carriers/collectorsPolymer modifiedConductive polymer

The invention provides a method for improving the electrode stability of an aqueous electrolyte battery and an aqueous electrolyte capacitor, relates to methods for stability of batteries and capacitors, and aims at solving the problem that an existing electrode current collector is poor in stability and short in service life. According to the method, ultrathin flexible graphite paper or a conducting polymer modified graphite material is used as a positive and negative electrode current collector material of the aqueous electrolyte battery and the aqueous electrolyte capacitor; on one hand, an ultrathin flexible graphite paper coiled material is used for preparing the current collector, so that the continuous production of electrode plates can be realized; on the other hand, a conducting polymer on the surface of the ultrathin flexible graphite paper is modified, so that the problem that the electrode material is in uniform coating caused by the fact that the hydrophilia of the graphite paper is poor is solved. The method can be used in the fields of the aqueous electrolyte batteries and the aqueous electrolyte capacitors.

Owner:哈尔滨天宝石墨科技发展有限公司

Carbon coated titanium-based lead dioxide positive plate for lead-acid storage battery

InactiveCN104362301ALight in massImprove binding tightnessElectrode carriers/collectorsLead-acid accumulator electrodesCarbon layerLead dioxide

The invention discloses a preparation method of a carbon coated titanium-based lead dioxide positive plate which is obtained by coating a carbon material on the surface of a metallic titanium mesh with a vapor deposition method. The thickness of a carbon layer of a carbon coated titanium-based grid is 5-20 mu m. Compared with a traditional lead-acid battery positive plate, the carbon coated titanium-based lead dioxide positive plate has the characteristics of light grid mass and high mass specific energy; and further, with adoption of the carbon coated titanium-based lead dioxide positive plate, the metallic titanium-based surface layer is prevented from forming a passivation layer, contact resistance of active substances and the titanium-based grid is reduced, and the metallic titanium-based grid can be practically applied to a positive pole of the lead-acid battery.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

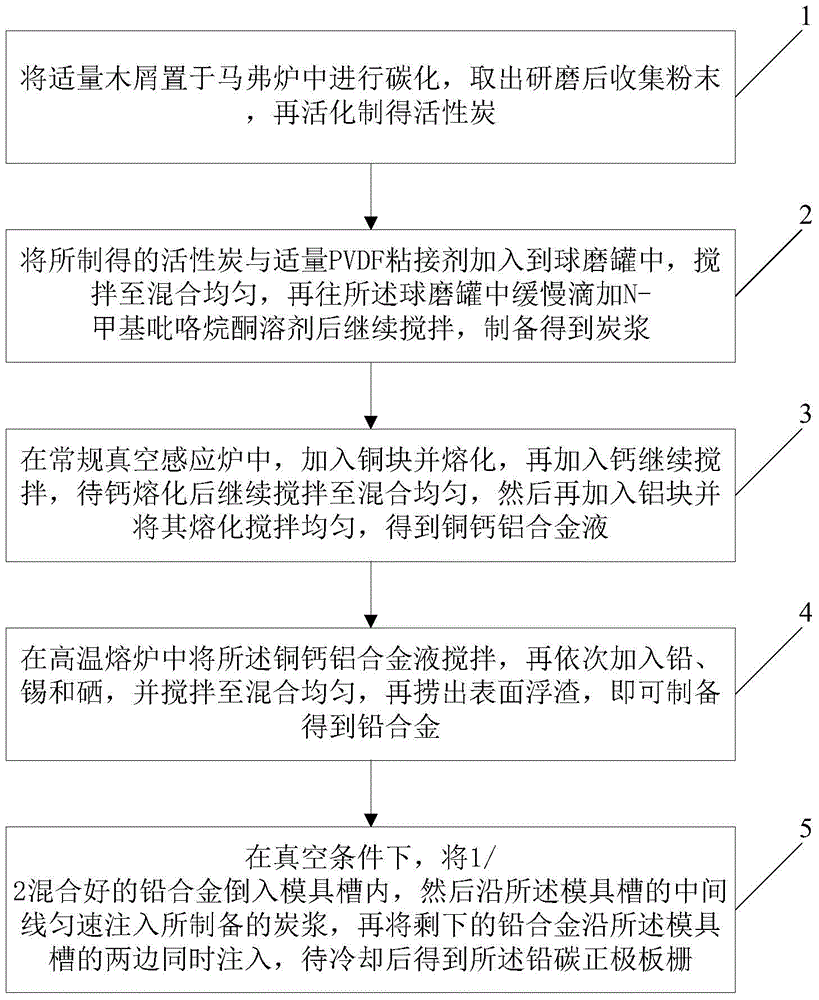

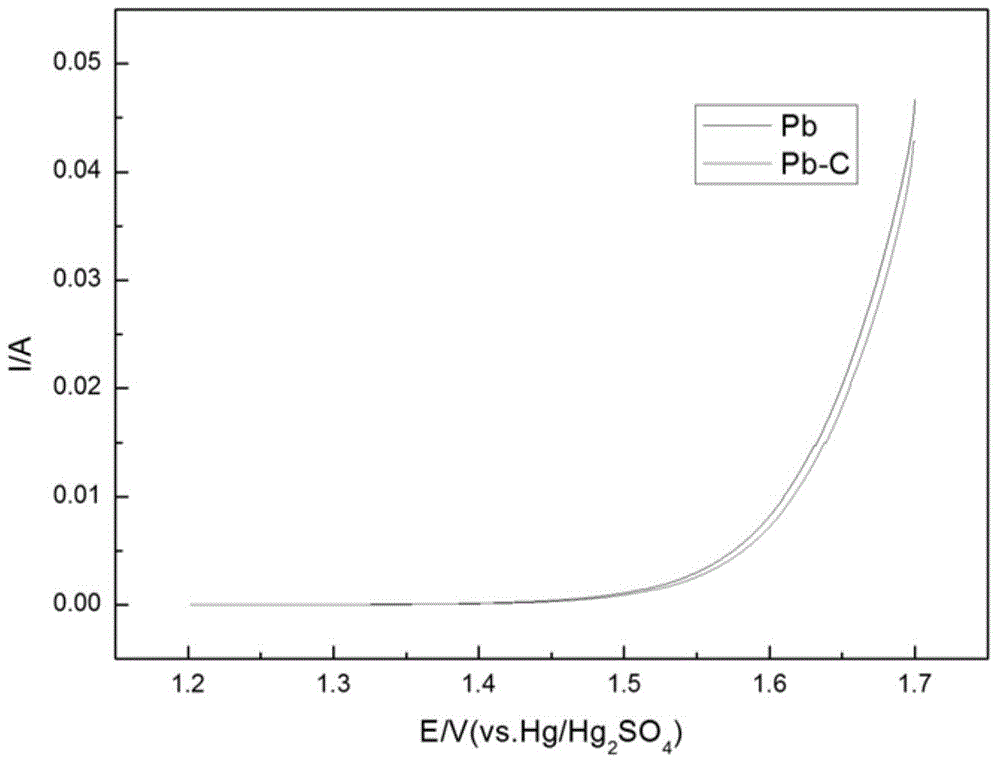

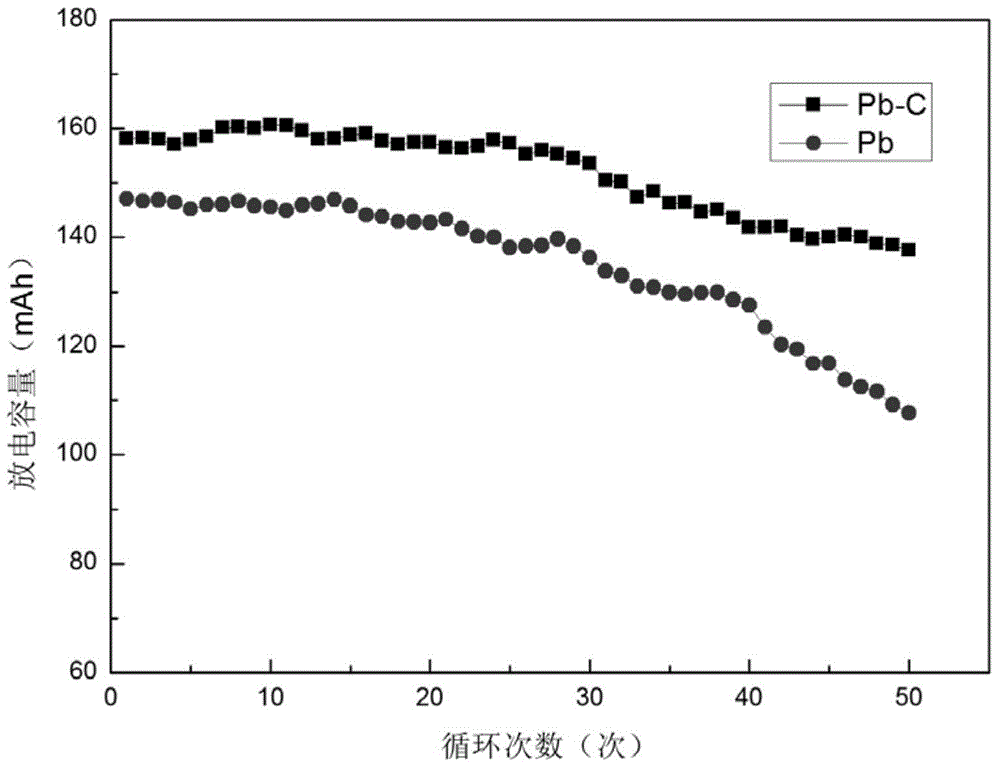

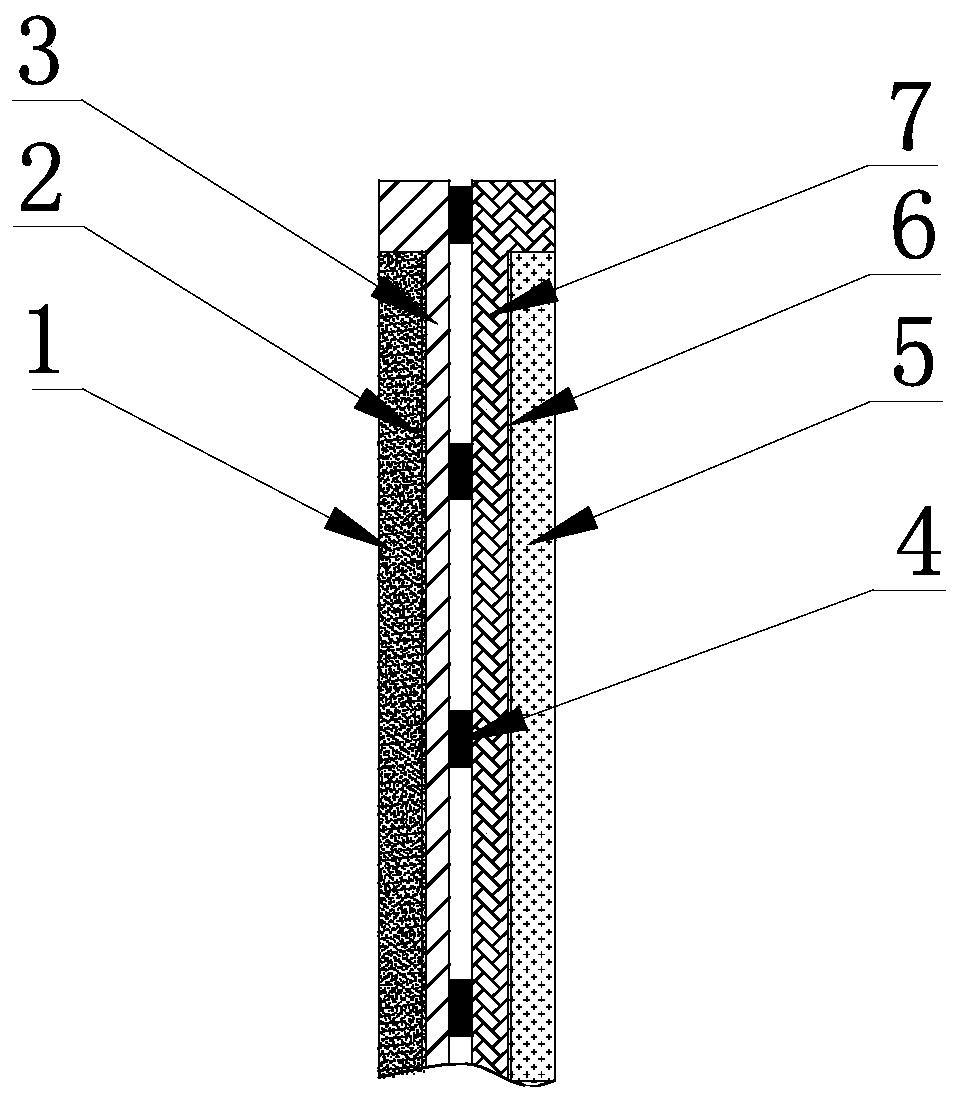

Manufacturing method of lead-carbon positive grid for lead-acid storage battery

ActiveCN105024083ALight in massImprove mass to energyElectrode carriers/collectorsOver potentialEngineering

The invention discloses a manufacturing method of a lead-carbon positive grid for a lead-acid storage battery. The manufacturing method comprises the following steps: putting a proper amount of saw dust into a muffle furnace to carbonize, taking the carbonized saw dust out, and grinding the saw dust to obtain active carbon; adding the obtained active carbon and a proper quantity of PVDF (Polyvinylidene Fluoride) bonding agent into a ball milling tank to prepare carbon slurry; adding copper blocks, calcium and aluminum blocks into a conventional vacuum induction furnace, and stirring the copper blocks, calcium and aluminum blocks uniformly to obtain copper-calcium-aluminum alloy liquid; stirring the copper-calcium-aluminum alloy liquid in a high-temperature smelting furnace, adding lead, tin and selenium in sequence, and stirring the materials till the materials are mixed uniformly to obtain a lead alloy; and pouring a half of the mixed lead alloy into a mold groove, injecting the obtained carbon slurry at a uniform speed along the middle line of the mold groove, injecting the remaining lead alloy along both sides of the mold groove at the same time, and performing cooling to obtain the lead-carbon positive grid. The obtained grid has the advantages of light mass, high weight specific energy, low production cost, high corrosion resistance and high oxygen evolution over-potential, so that the cycle life of the lead-acid storage battery is long.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Bipolar battery pole plate and preparation method thereof

ActiveCN110336038AImprove corrosion resistanceLight in massFinal product manufactureElectrode carriers/collectorsEngineeringCopper

The invention belongs to the technical field of a lead-acid storage battery and specifically relates to a bipolar battery pole plate and a preparation method thereof. The bipolar battery pole plate comprises a bipolar plate grid, a positive electrode active material and a negative electrode active material. The bipolar plate grid is composed of a titanium foil and a copper plate. The bipolar battery pole plate prepared by electroplating a lead layer on positive and negative poles of the bipolar plate grid simultaneously, and then, coating the positive electrode active material and the negativeelectrode active material is high in power, high in mass specific energy and small in gas evolution amount, and has better mechanical strength and corrosion resistance, and pole plate current and potential are evenly distributed. The preparation method can reduce production cost, reduce environmental protection pressure and improve battery performance.

Owner:ZIBO TORCH ENERGY

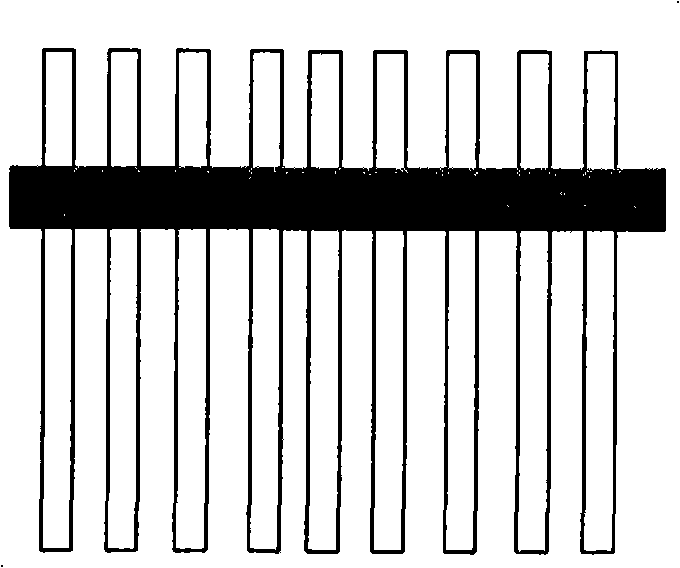

Method for improving uniform heat dispersion performance of lithium ion battery electrode piece

InactiveCN104882631AOvercome flatulenceOvercome longevityElectrode carriers/collectorsSecondary cellsHeat conductingCopper foil

The invention discloses a method for improving a uniform heat dispersion performance of a lithium ion battery electrode piece, relates to methods for uniform heat dispersion performances of battery electrode pieces and solves the problem that a heat-conducting performance of the plane of a conventional metal current collector adopted in a lithium ion battery is poor, so that the local overheating of an electrode in the charging and discharging processes occurs, and further battery bloating is caused and the service life of the battery is shortened in the prior art. The method has the characteristics that flexible graphite paper is used for replacing an aluminum foil and a copper foil in the lithium ion battery to be used as an electrode material active substance-loaded current collector; and heat at heat points of the electrode piece can be fast and uniformly dispersed by using the high heat-conducting performance of the flexible graphite paper, so that the heat points can be removed, the temperature of a battery cell is uniformly distributed, and further electrolyte decomposing, battery service life shortening and battery damage caused by the local overheating of the battery core can be avoided. The electrochemistry unreactiveness of the flexible graphite paper and the condition that the flexible graphite paper can not react with lithium ions and the electrolyte during over-charging and over-discharging are used, so that the service life of the battery is prolonged, and the safety of the battery is improved; and the method is used in the field of the batteries.

Owner:哈尔滨天宝石墨科技发展有限公司

Preparation method of positive pole material of thermal battery

ActiveCN102157722BHigh bulk densityHigh tap densityPrimary cell electrodesAfter treatmentMolten salt

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

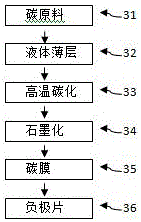

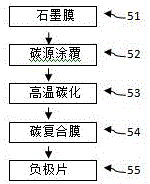

Carbon film lithium ion battery anode and production method

InactiveCN105826517AImprove mass to energyHigher quality than capacityElectrode carriers/collectorsSecondary cellsCarbon filmPhysical chemistry

Provided are a carbon film lithium ion battery anode and a production method. A carbon film can serve as an anode current collector and can also serve as an anode active substance. The carbon film can be an intermediate phase carbon film, namely the carbon film formed by carbonizing an organic polymer material at the temperature of 800 to 2000 DEG C, and the carbon content is 90% or above. The carbon film can also be a graphite film, the graphite film formed by graphitizing the intermediate phase carbon film at the high temperature of 2000 DEG C, and the content is 99% or above. The carbon film can also be a composite carbon film, a middle layer is graphite, and an outer layer is intermediate phase carbon.

Owner:周虎

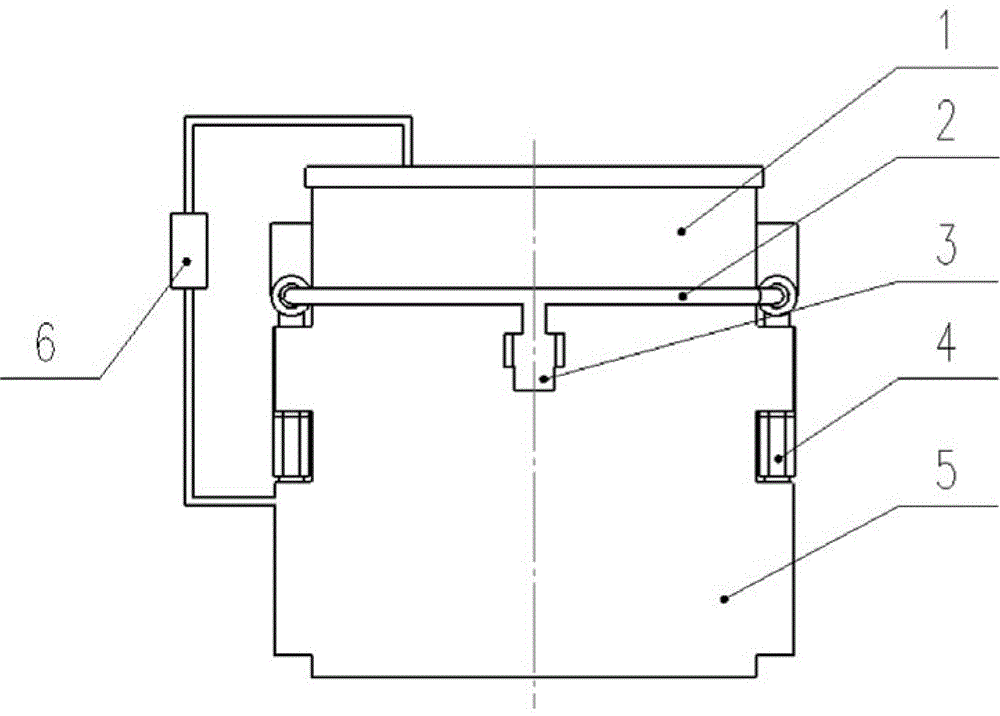

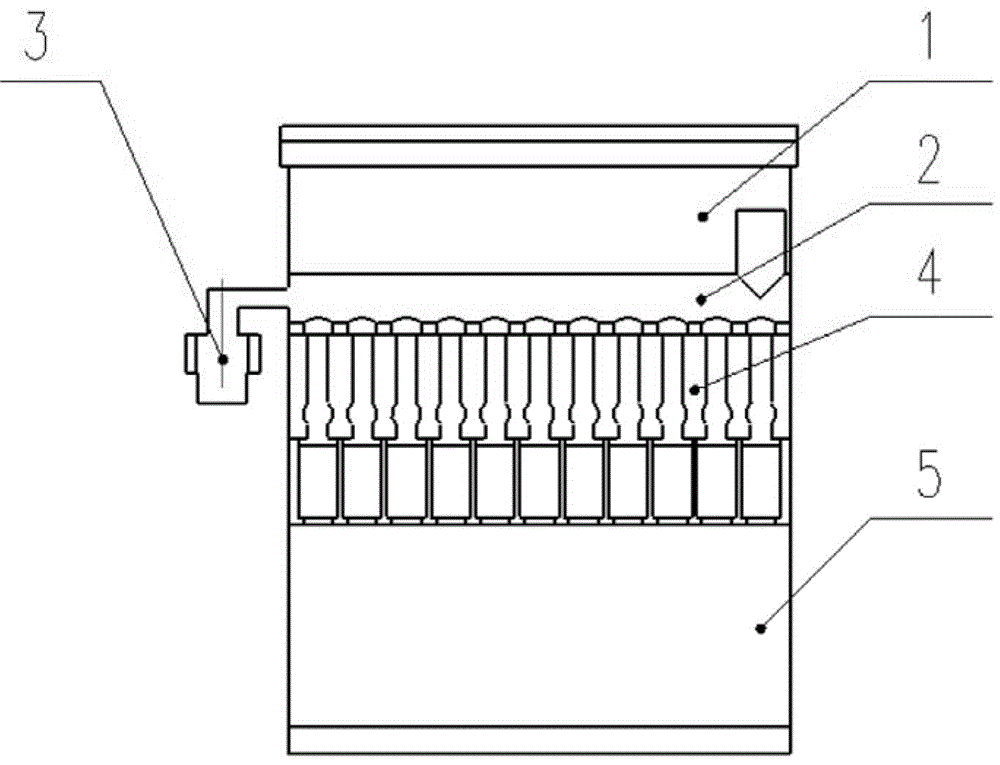

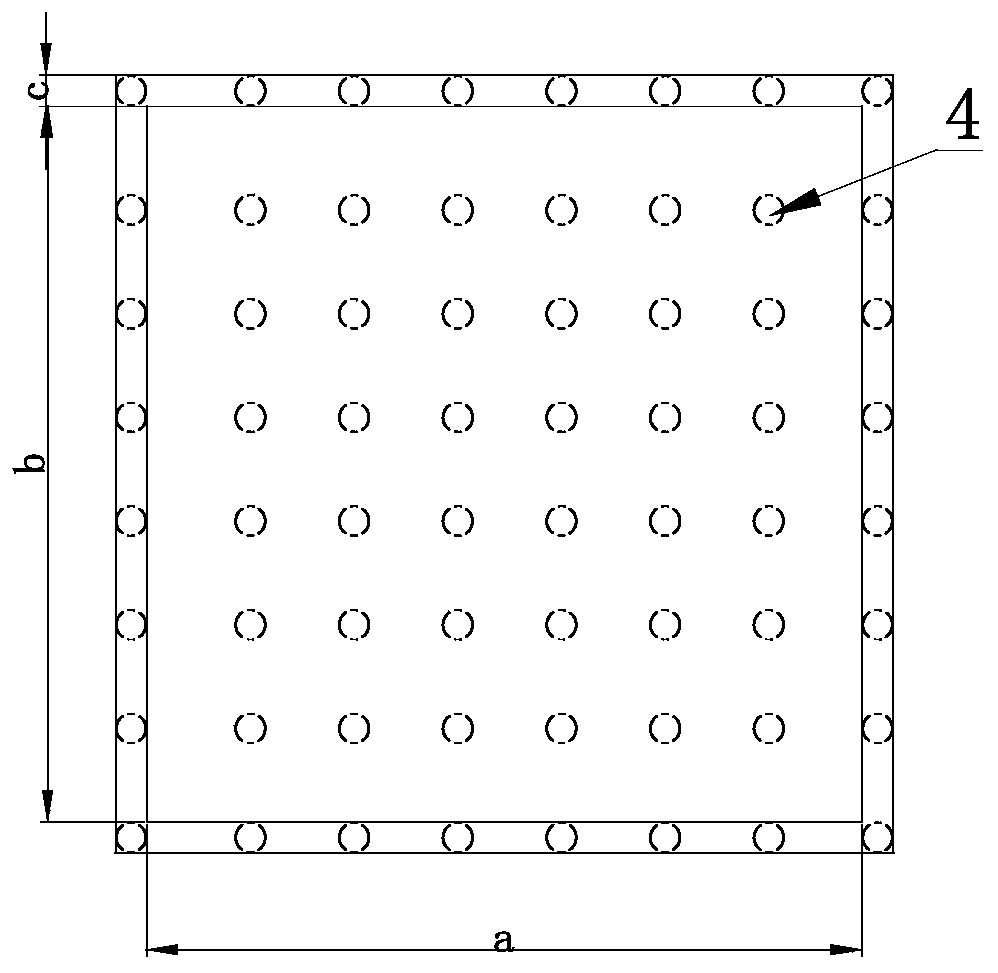

Automatic activation device for reserve battery

ActiveCN106450368ASmall self-dischargeImprove mass to energyPrimary cell maintainance/servicingGas chamberHigh pressure

The invention discloses an automatic activation device for a reserve battery. The automatic activation device comprises a battery pack and a liquid reservoir arranged above the battery pack, wherein a common gas chamber is communicated between the battery pack and the liquid reservoir; cavities are arranged in the liquid reservoir, the cavities are internally filled with electrolyte, liquid outlet holes are formed in the cavities, and valves are respectively connected with the liquid outlet holes; outlet ends of the valves are communicated with the battery pack, and inlet ends of the valves are communicated with a high-pressure gas source by a pipeline. According to the automatic activation device, each single battery corresponds to one valve and is separately provided with an electrolyte flow channel, so that the uniform distribution of the electrolyte can be realized, the phenomenon of electric leakage of a common flow channel is avoided, and the mass specific energy of the battery is improved.

Owner:中船重工黄冈水中装备动力有限公司

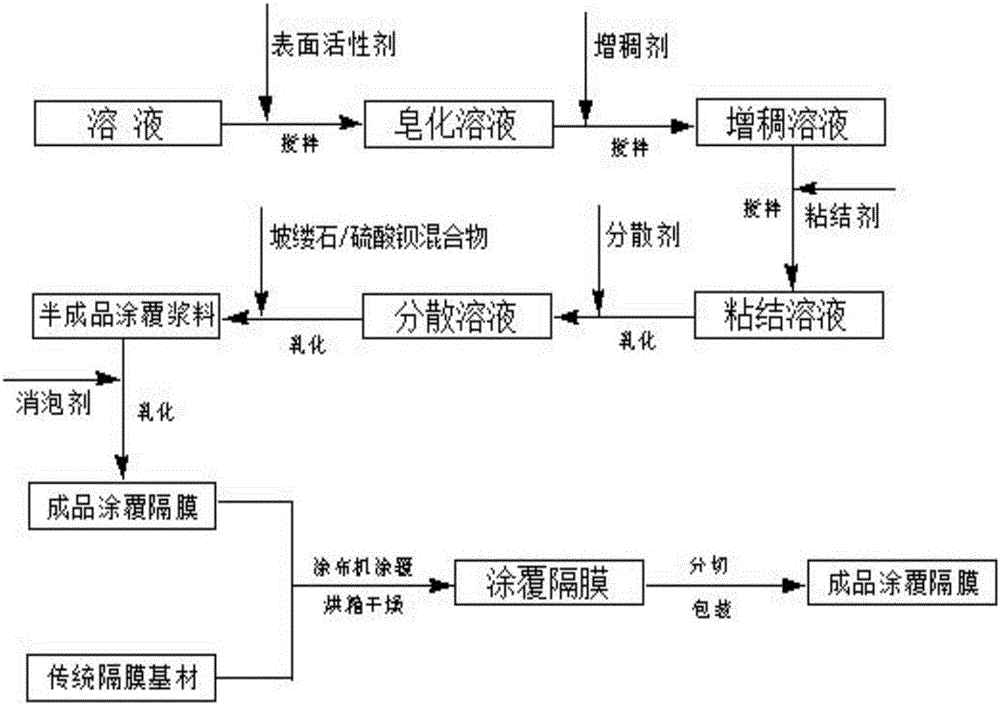

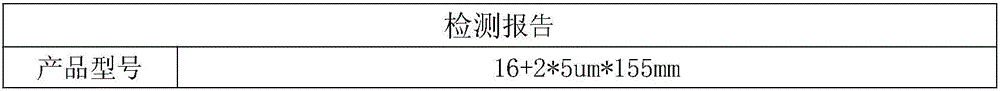

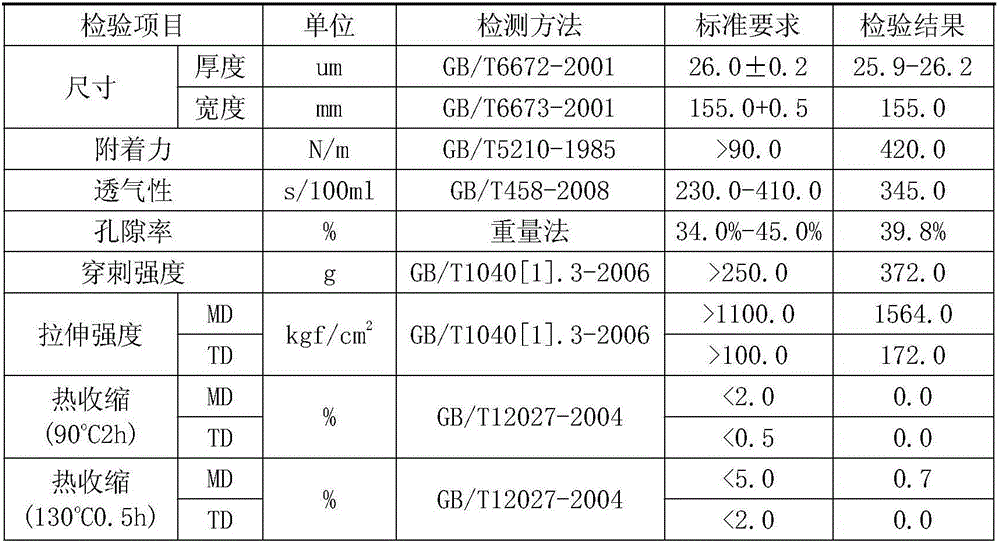

Palygorskite/aluminum oxide composite lithium ion battery coating diaphragm and preparation method thereof

InactiveCN105914326ALow costImprove market competitive advantageCell seperators/membranes/diaphragms/spacersSecondary cellsPalygorskiteAttapulgus clay

The invention discloses a palygorskite / aluminum oxide composite lithium ion battery coating diaphragm and a preparation method thereof. The surface of a lithium ion battery diaphragm substrate of the palygorskite / barium sulfate composite lithium ion battery coating diaphragm disclosed by the invention is uniformly coated by a layer of palygorskite / barium sulfate slurry; the palygorskite / barium sulfate slurry is prepared from the following raw materials by weight percent: 0.7-1.5% of a surfactant, 0.5-1.0% of a thickening agent, 6.0-12.0% of an adhesive, 0.1-0.5% of a dispersing agent, 20.0-50.0% of a palygorskite / barium sulfate mixture, 3.0-7.0% of a defomaing agent and 40.0-70.0% of a solution, wherein the sum of the percentages of the raw materials is 100.0%. The invention further discloses a preparation method. By adopting the palygorskite / barium sulfate composite lithium ion battery coating diaphragm disclosed by the invention, the electrochemical property of a lithium ion battery can be effectively improved by the related product, the cost is low, and great competitive advantages in market can be achieved.

Owner:湖南锂顺能源科技有限公司

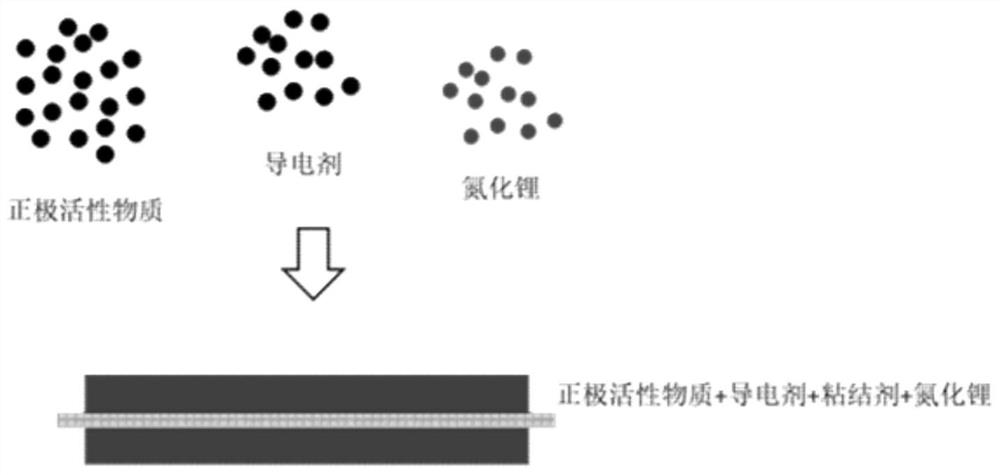

Lithium ion battery pre-lithiated positive pole piece and preparation method of lithium ion battery

InactiveCN112635770AImprove Coulombic efficiencyImprove mass to energyElectrode carriers/collectorsSecondary cellsPhysical chemistryPole piece

The invention provides a lithium ion battery pre-lithiated positive pole piece and a preparation method of a lithium ion battery, the positive pole piece comprises a current collector and a positive pole slurry arranged on the surface of the current collector, and the positive pole slurry comprises lithium nitride. The preparation method of the lithium ion battery pre-lithiated positive pole piece comprises the following steps: coating the surface of the current collector with the positive pole slurry, and carrying out drying and rolling to obtain the positive pole piece. According to the pre-lithiated positive pole piece, the coulombic efficiency of the lithium ion battery in the first week can be improved, and meanwhile, the specific energy of the battery can be kept at a relatively high level.

Owner:EVE ENERGY CO LTD

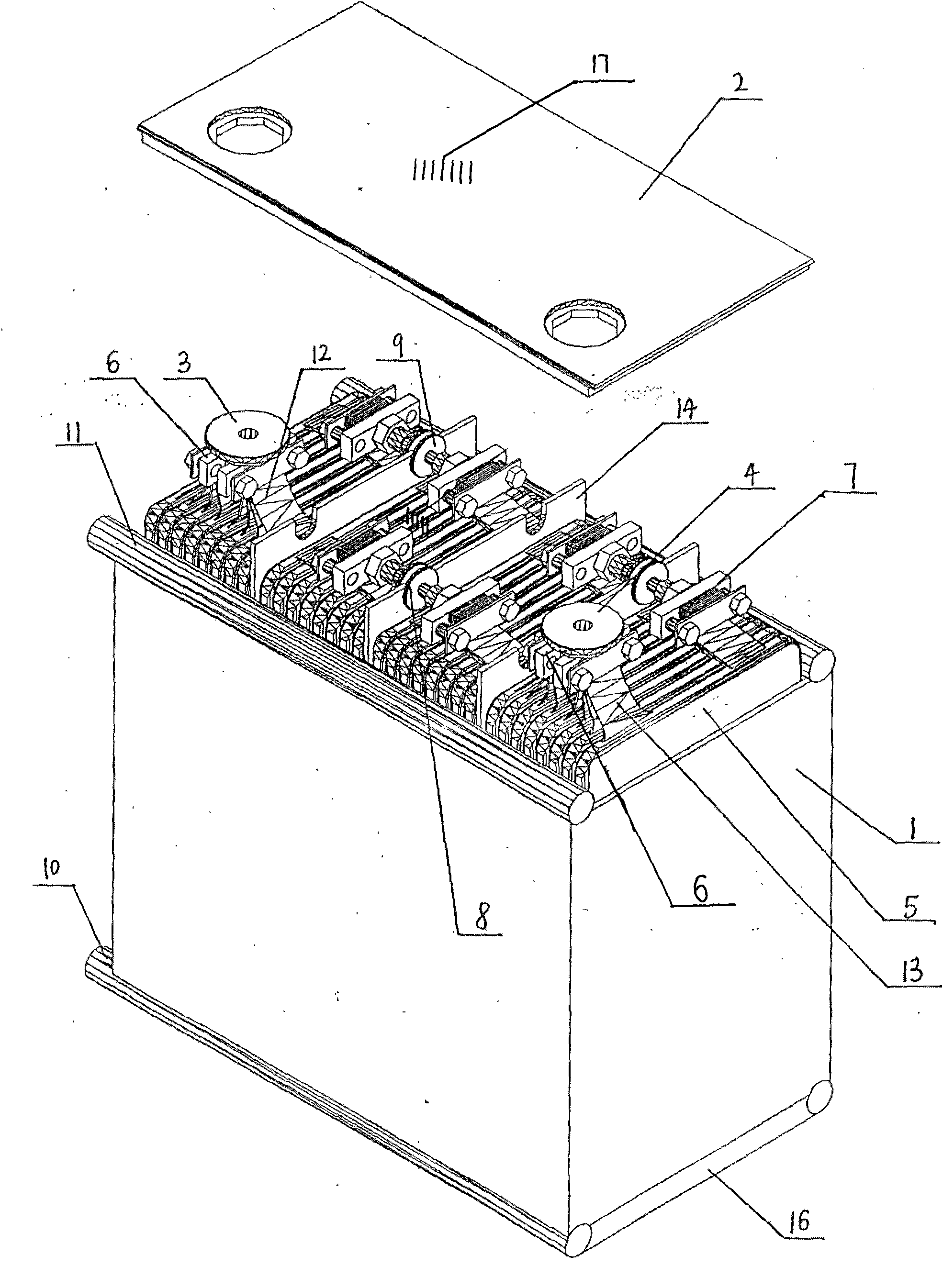

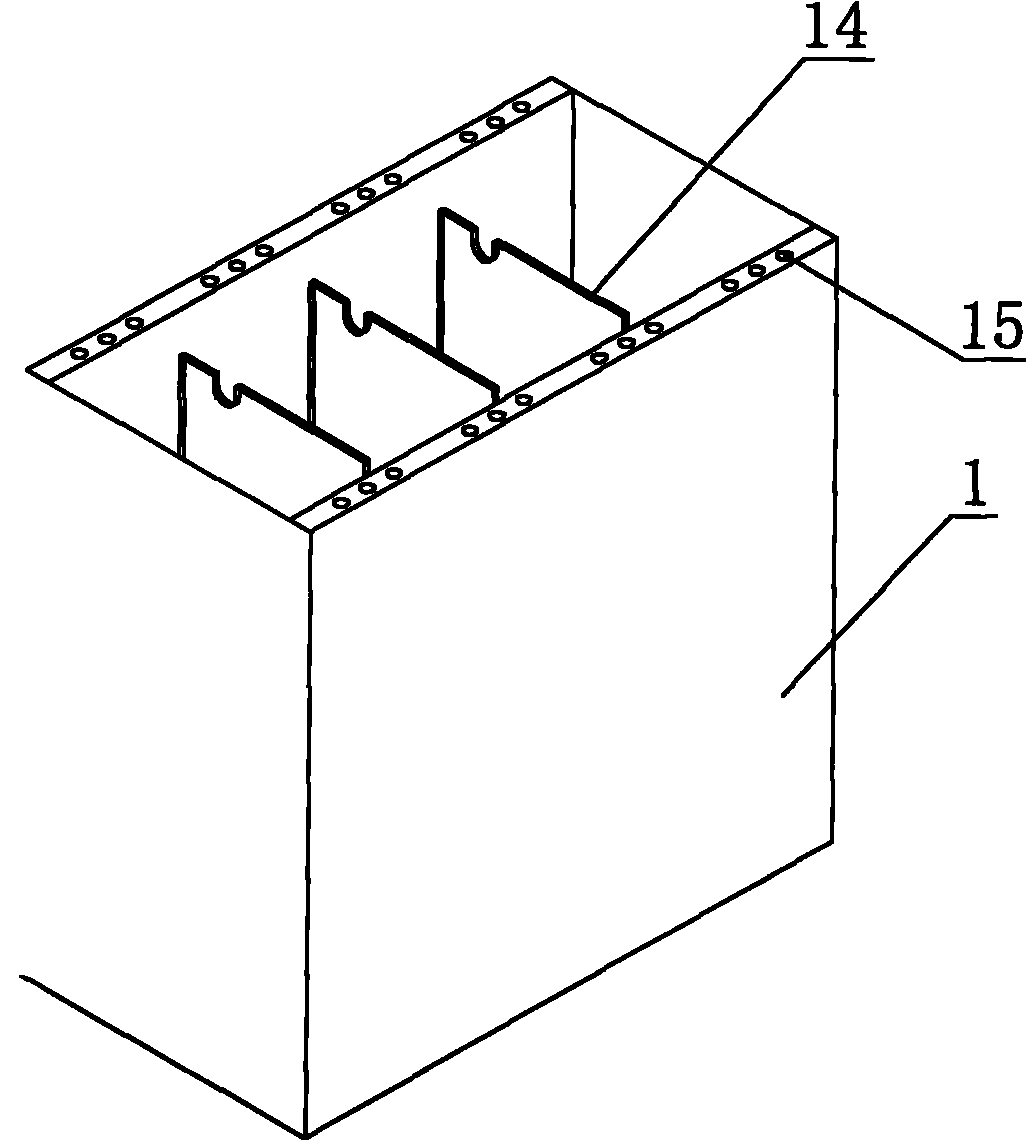

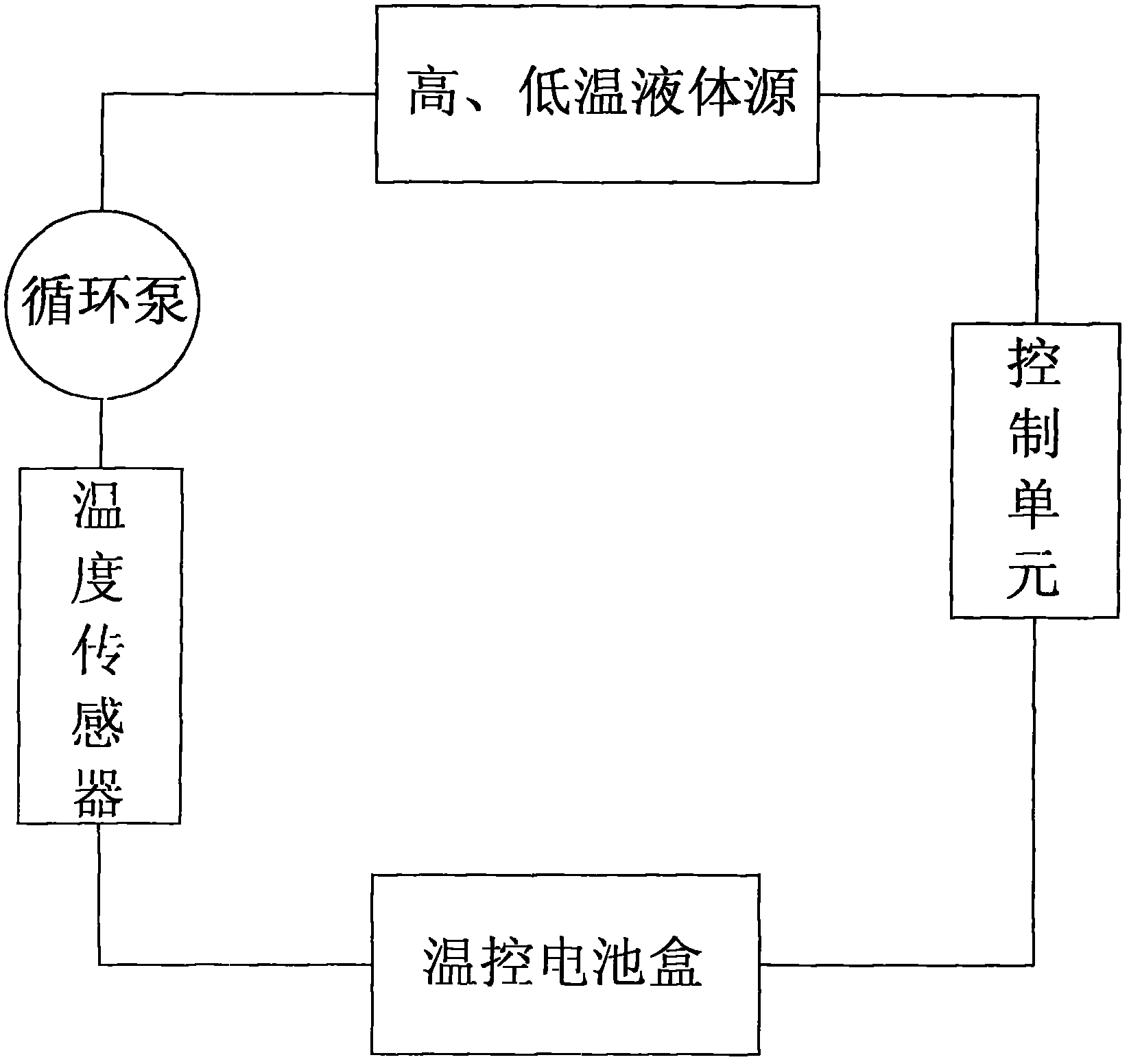

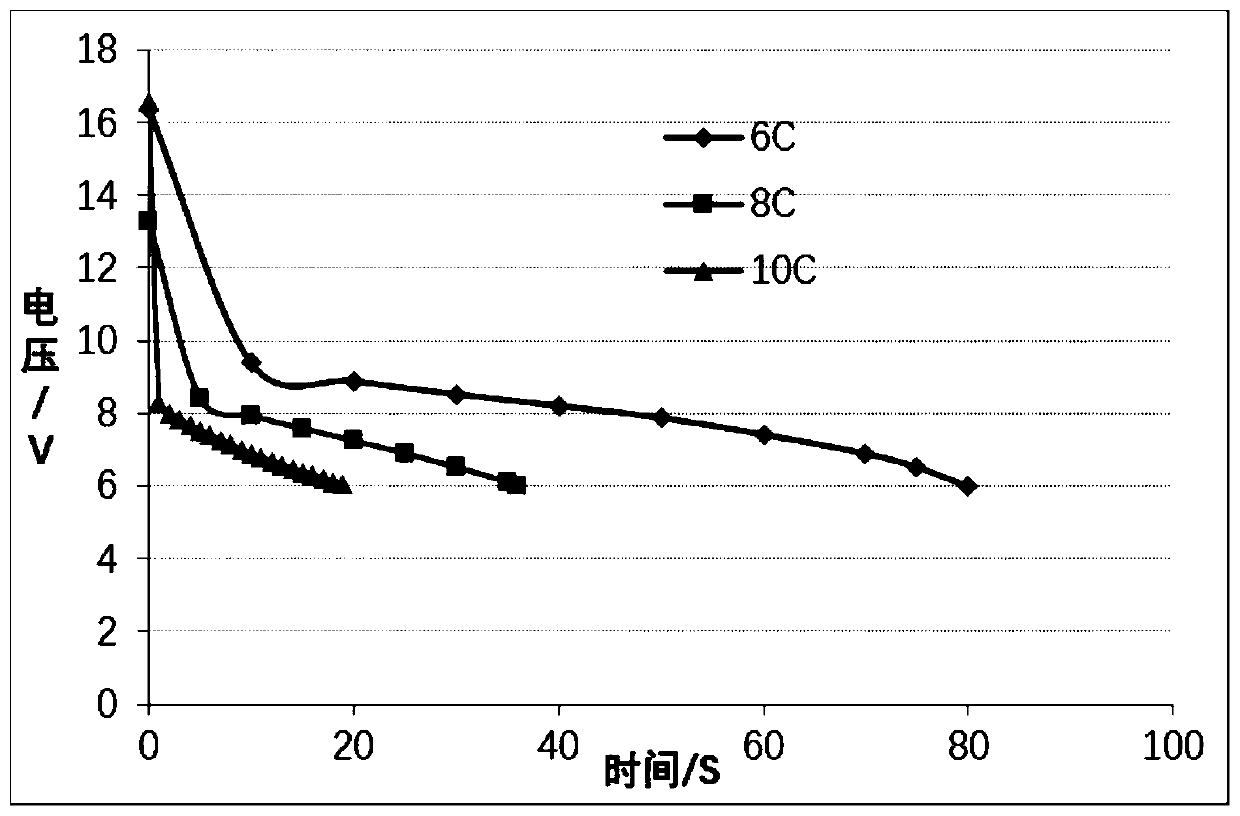

Temperature control device for power lithium battery

InactiveCN102544623ASuitable working environment temperatureGuaranteed output currentSecondary cellsElectrochemical responseEngineering

The invention discloses a temperature control device for a power lithium battery. The temperature control device comprises a temperature controlled battery box communicated with a high-temperature liquid source and a low-temperature liquid source to form a circulation loop via pipelines, wherein a circulating pump is arranged on the circulation loop; a temperature sensor and a control unit are connected between the circulating pump and the temperature controlled battery box; and the high-temperature liquid source, as well as the low-temperature liquid source, comprises a temperature controlled liquid box with both a liquid inlet and a liquid outlet, a radiator is arranged above the temperature controlled liquid box, a metal plate is arranged between the temperature controlled liquid box and the radiator, and semiconductor temperature difference modules are respectively arranged between the metal plate and the temperature controlled liquid box, as well as between the metal plate and the radiator, and are electrically connected with a DC power supply after being coupled with each other. Through real-time detection of the temperature sensor and in-time regulation and control of the control unit, an appropriate work environment temperature can be provided for the lithium battery, the electrochemical reaction speed is increased, and the output current, the output voltage and the discharge capacity of the lithium battery are ensured to enable the lithium battery to play the optimal performance and satisfy the utilization request of the power supply.

Owner:李辉 +1

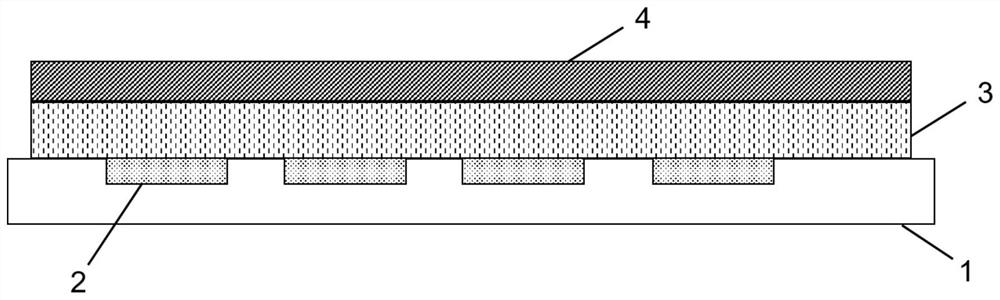

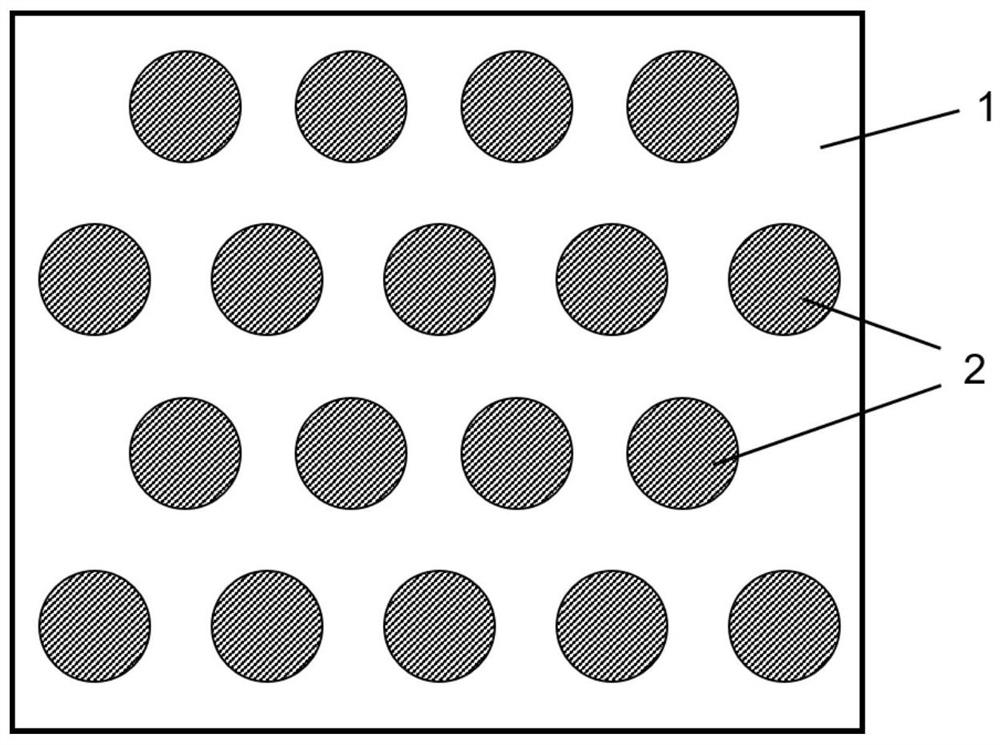

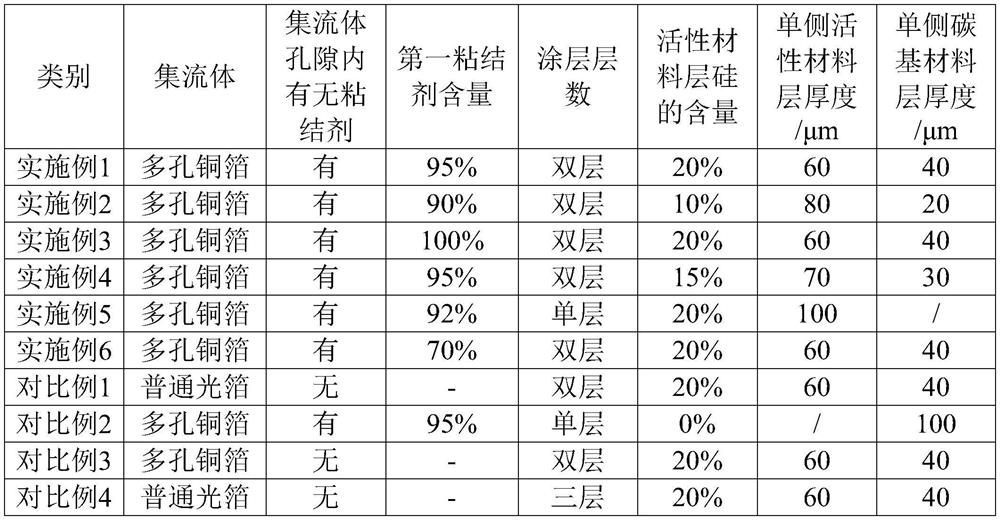

Negative plate and lithium ion battery comprising same

PendingCN111916753AReduce weightImprove mass to energyElectrode carriers/collectorsNegative electrodesCopper foilBattery cell

The invention provides a negative plate and a lithium ion battery comprising the same. The invention discloses a lithium ion battery negative plate. A porous copper foil filled with a binder is adopted as a negative current collector, the liquid retention amount of the negative plate is improved due to the existence of pores in the porous copper foil, the porous copper foil is lighter than commonlight foil, the overall mass specific energy of a battery cell can be improved, and the flexibility of the negative plate is also improved; the binder filled in the pores greatly improves the bindingpower between the active material layer and the negative electrode current collector, avoids stripping of the active material layer from the negative electrode current collector due to large volume expansion of the silicon-based material, and reduces the contact resistance between the silicon-based material and the negative electrode current collector; and the silicon-based material is used, so the overall capacity of the cell can be greatly improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Horizon battery and manufacturing method thereof

ActiveCN103208633BHigh strengthAccelerated corrosionFinal product manufactureElectrode carriers/collectorsGlass fiberHorizon

Owner:CHAOWEI POWER CO LTD

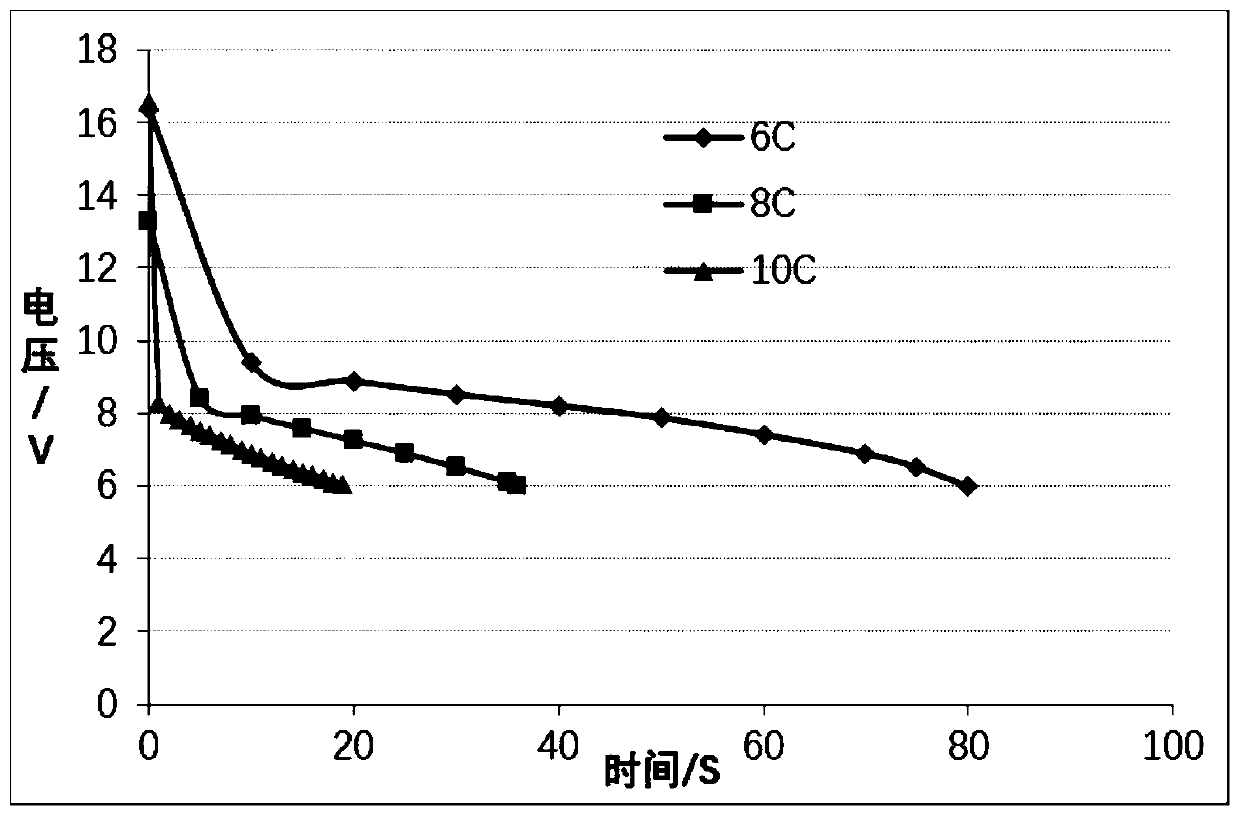

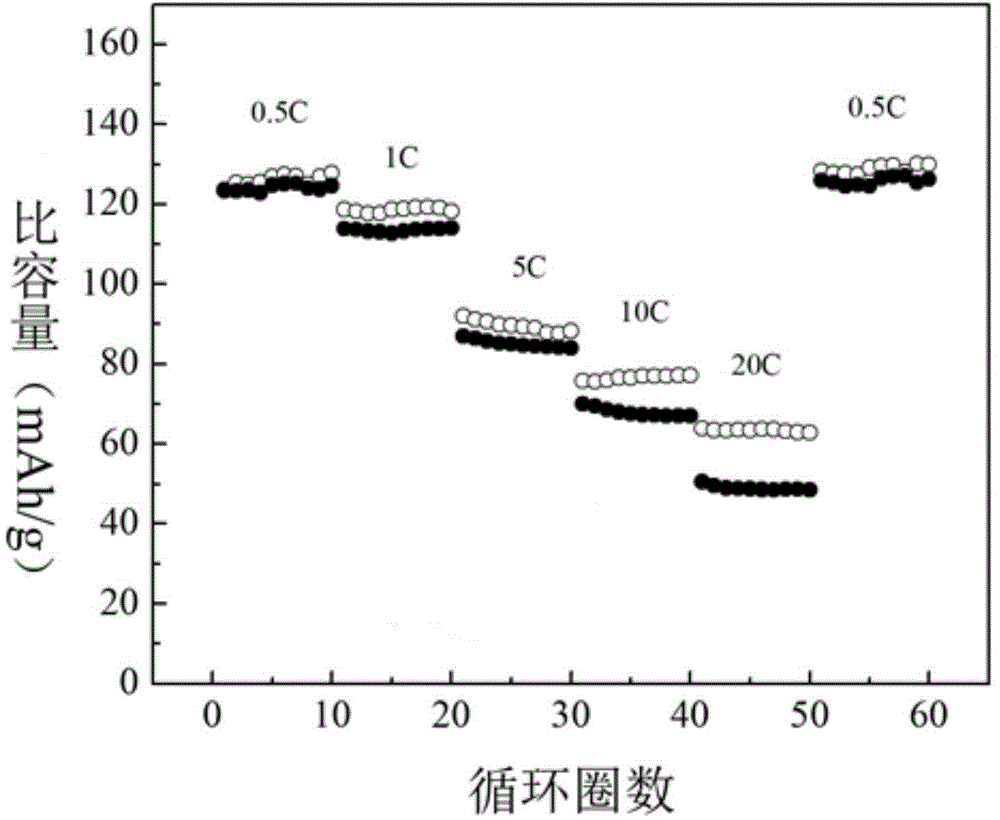

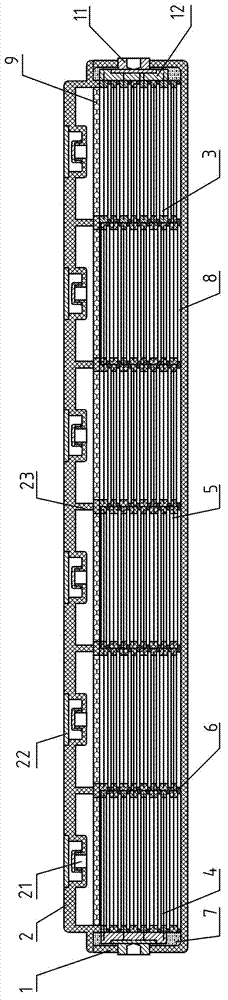

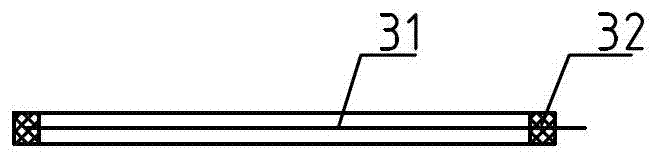

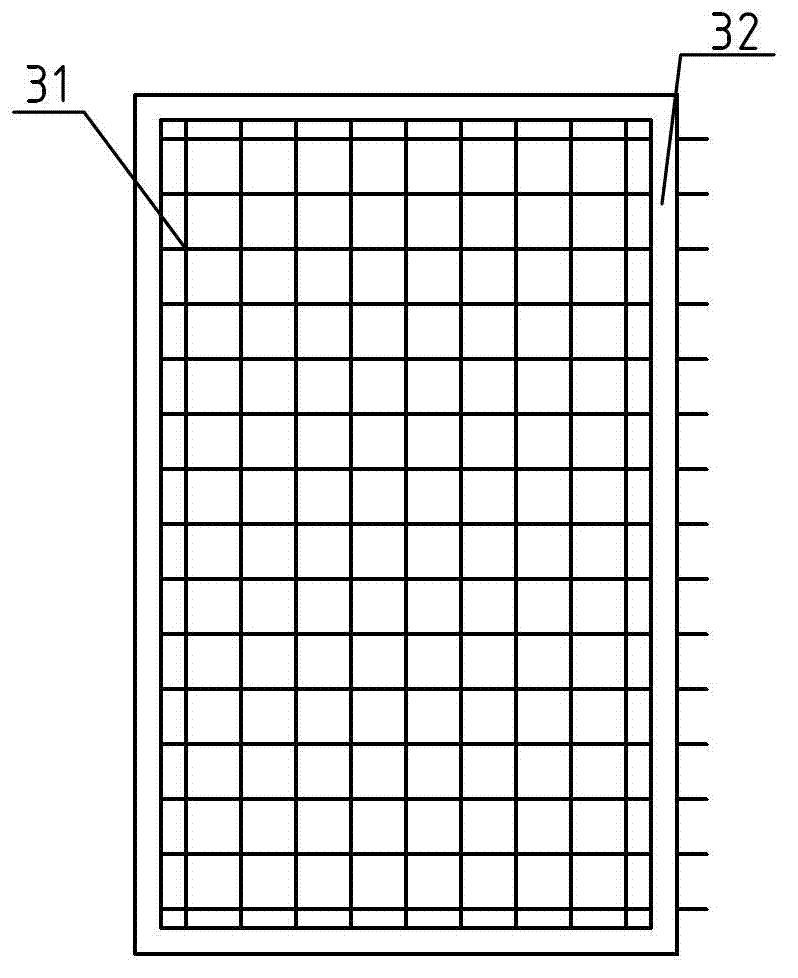

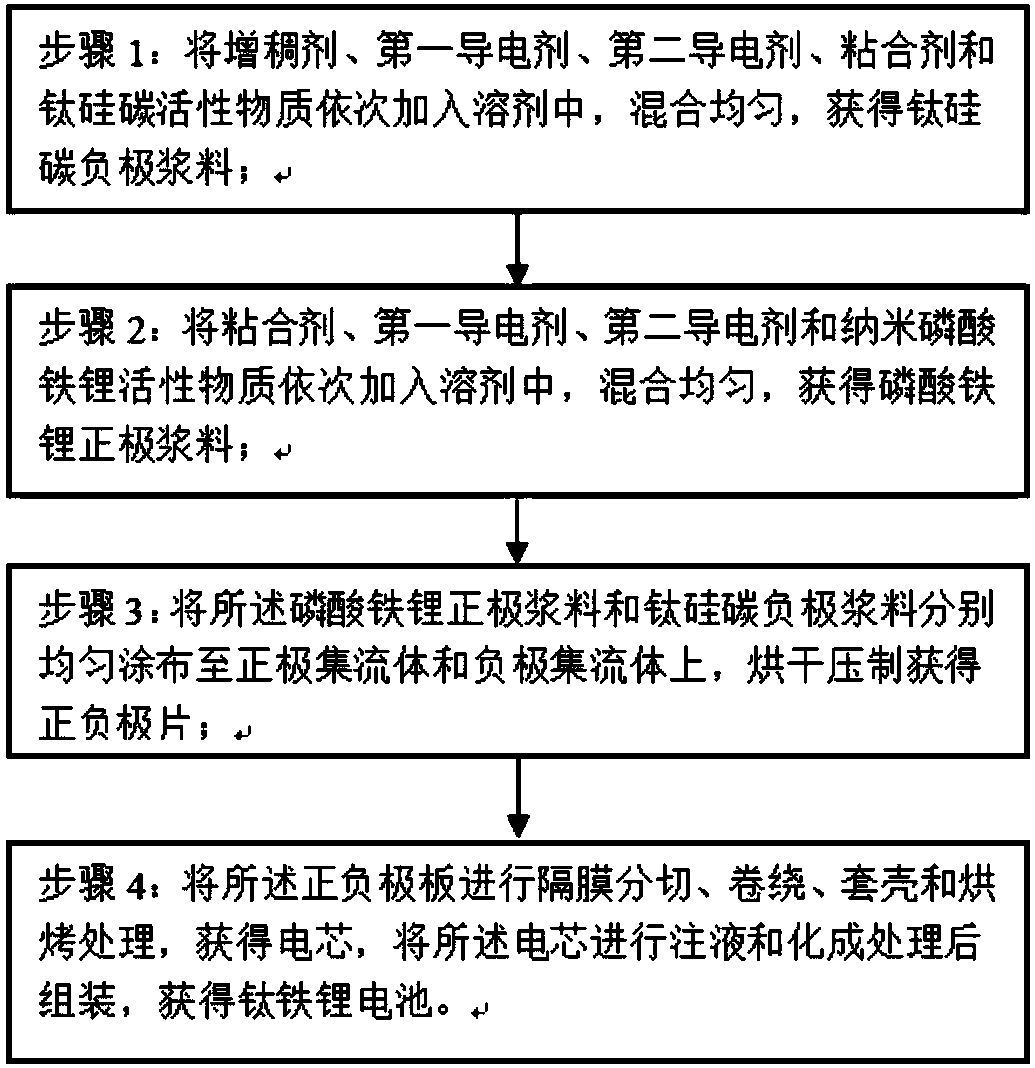

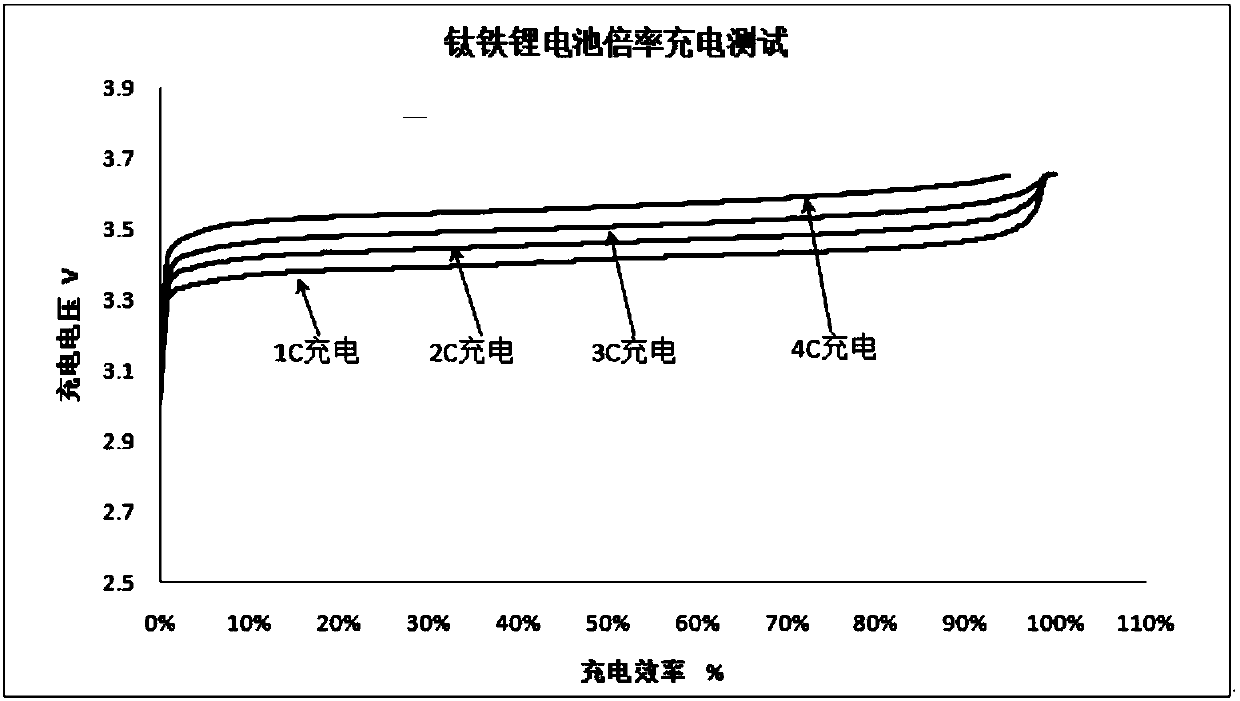

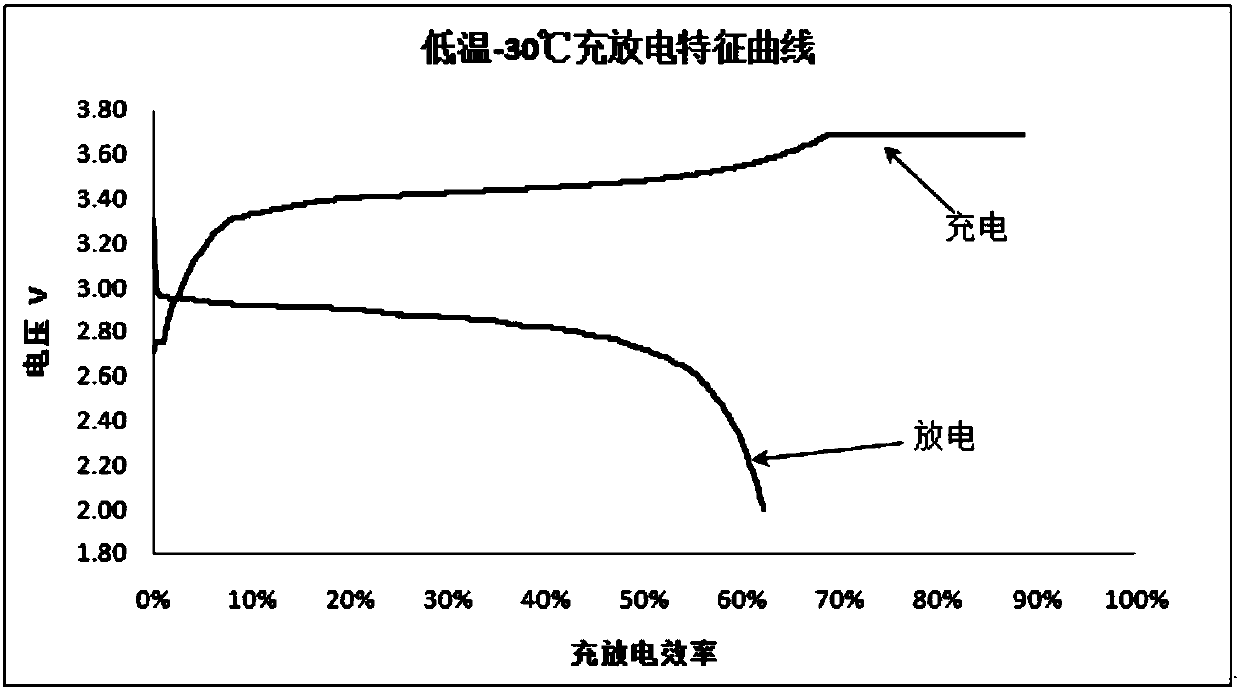

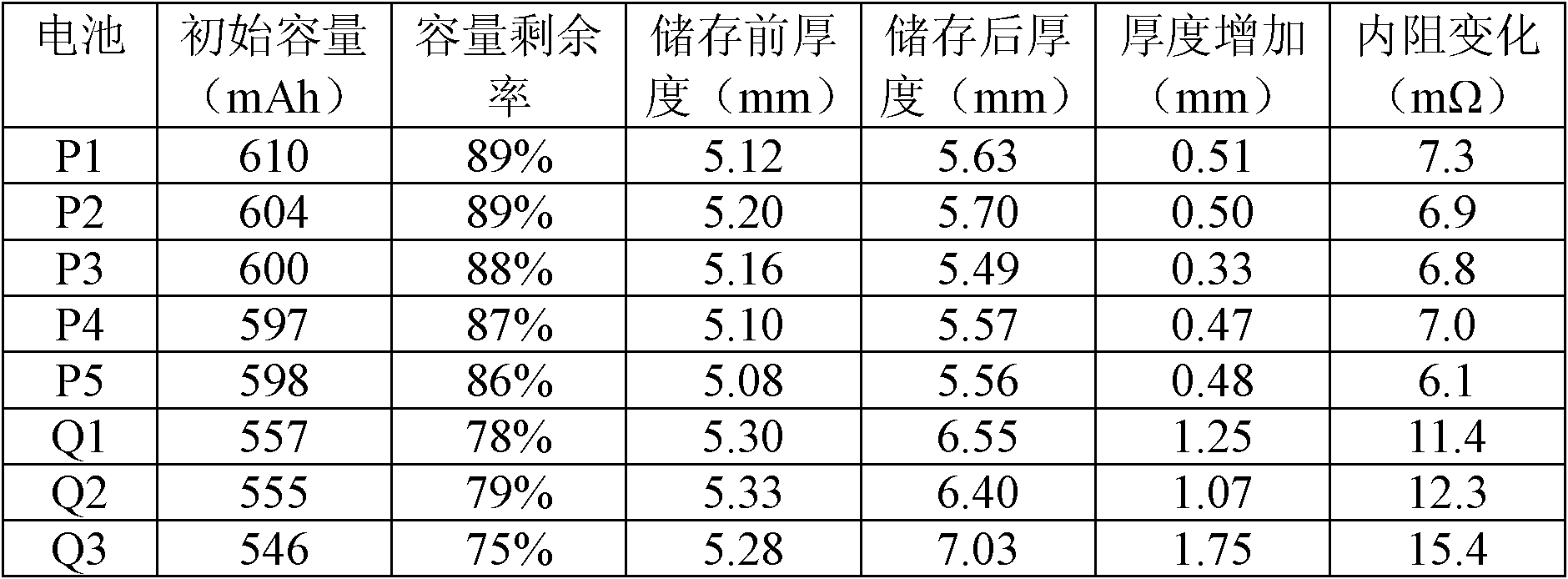

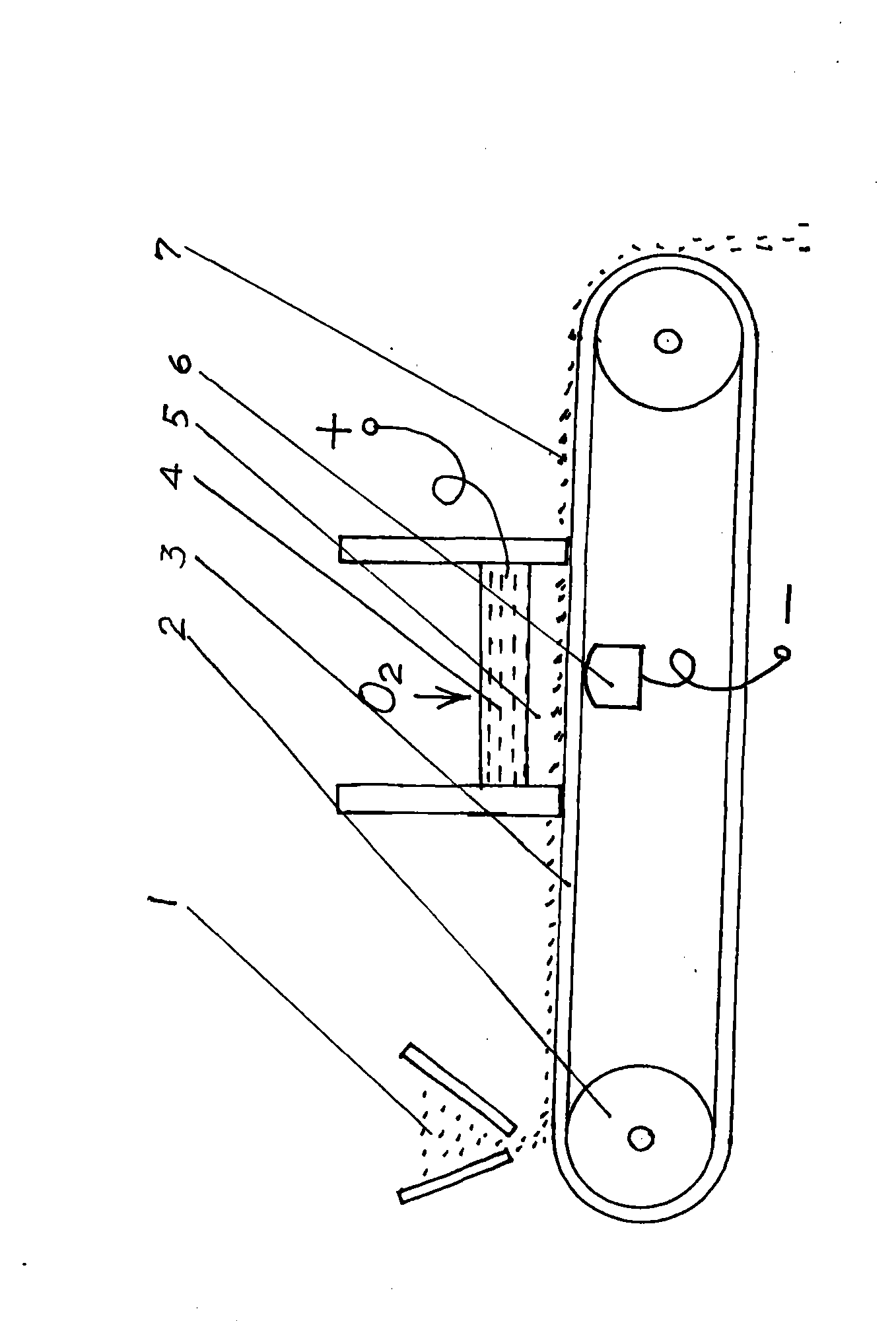

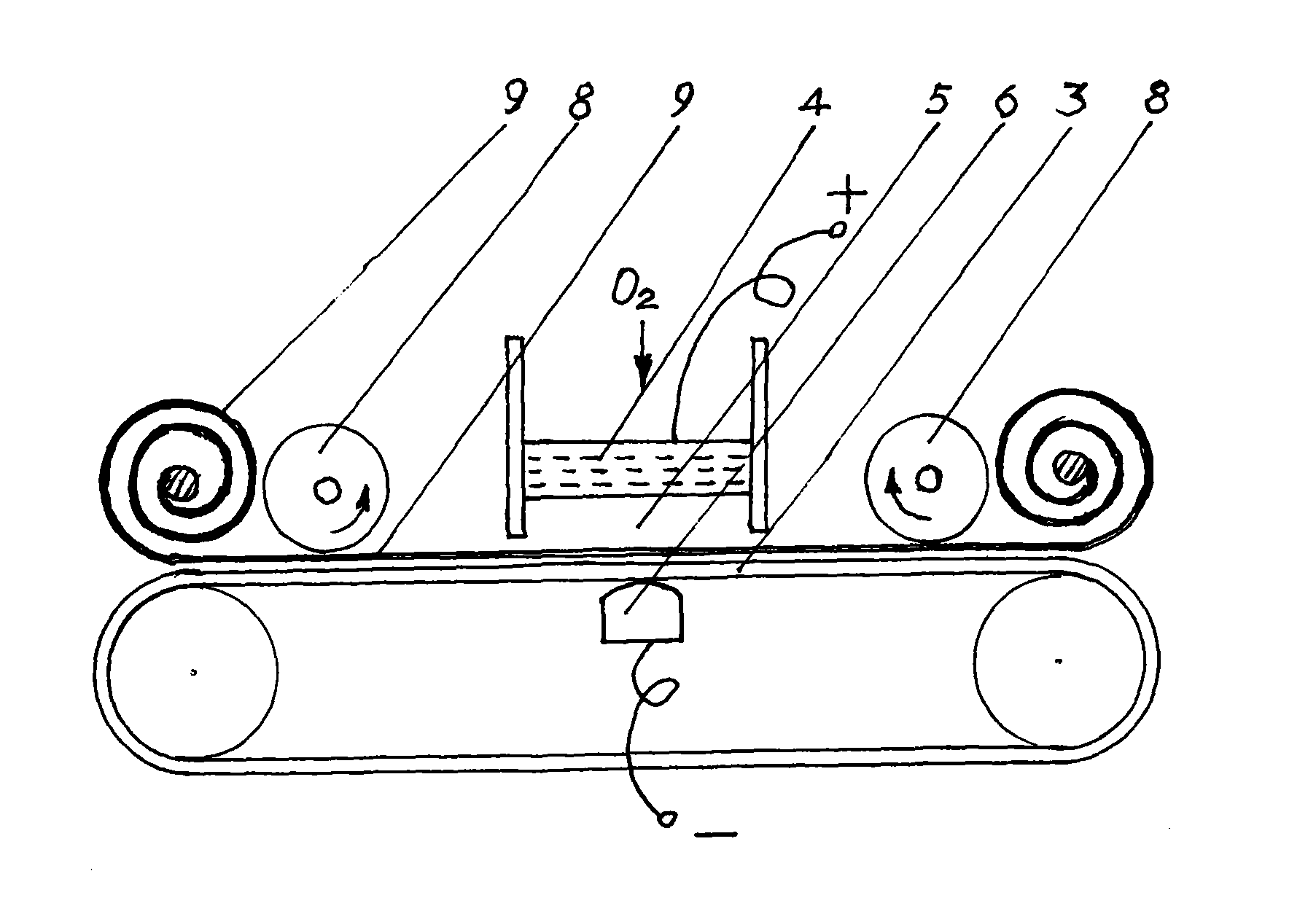

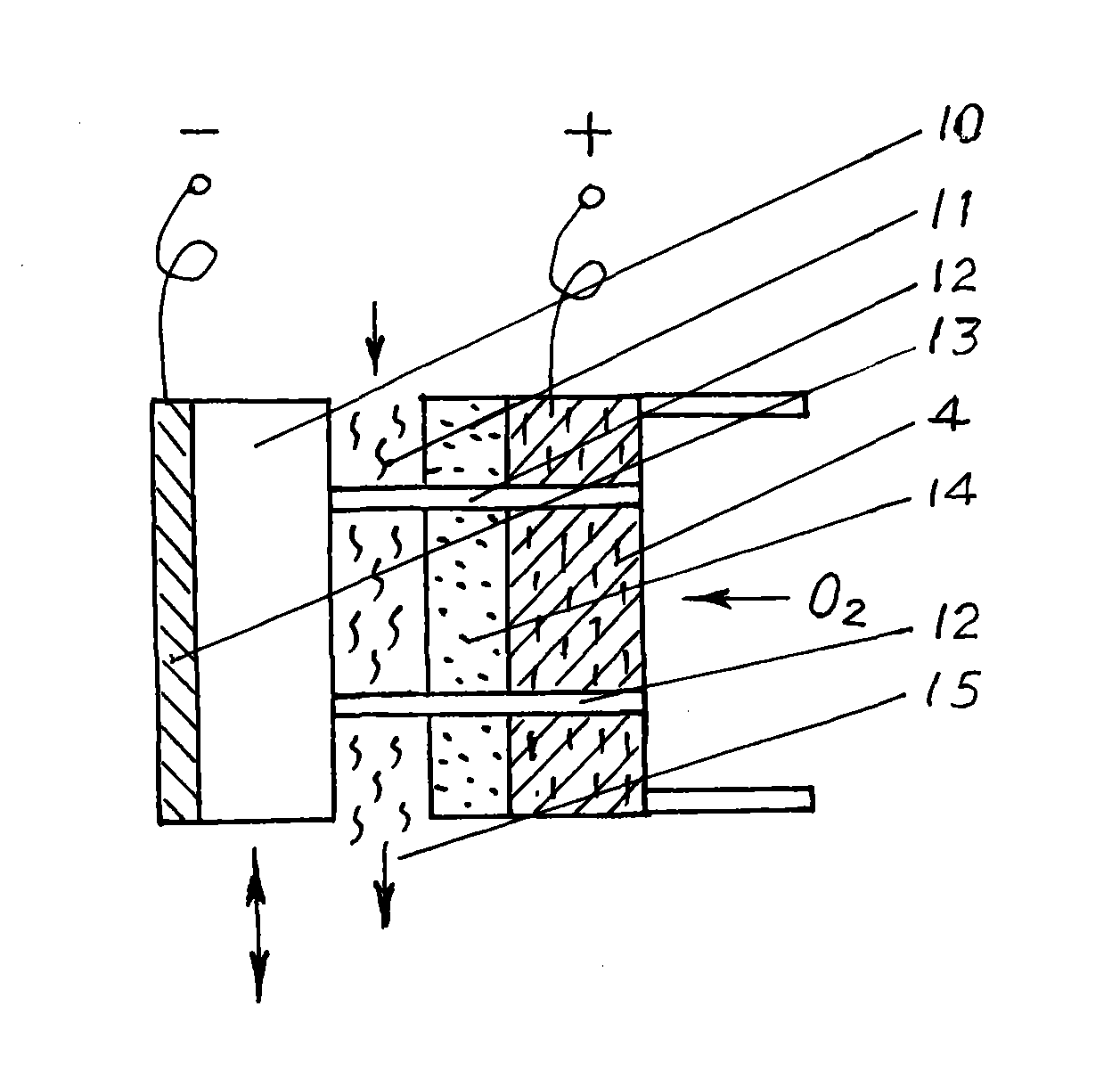

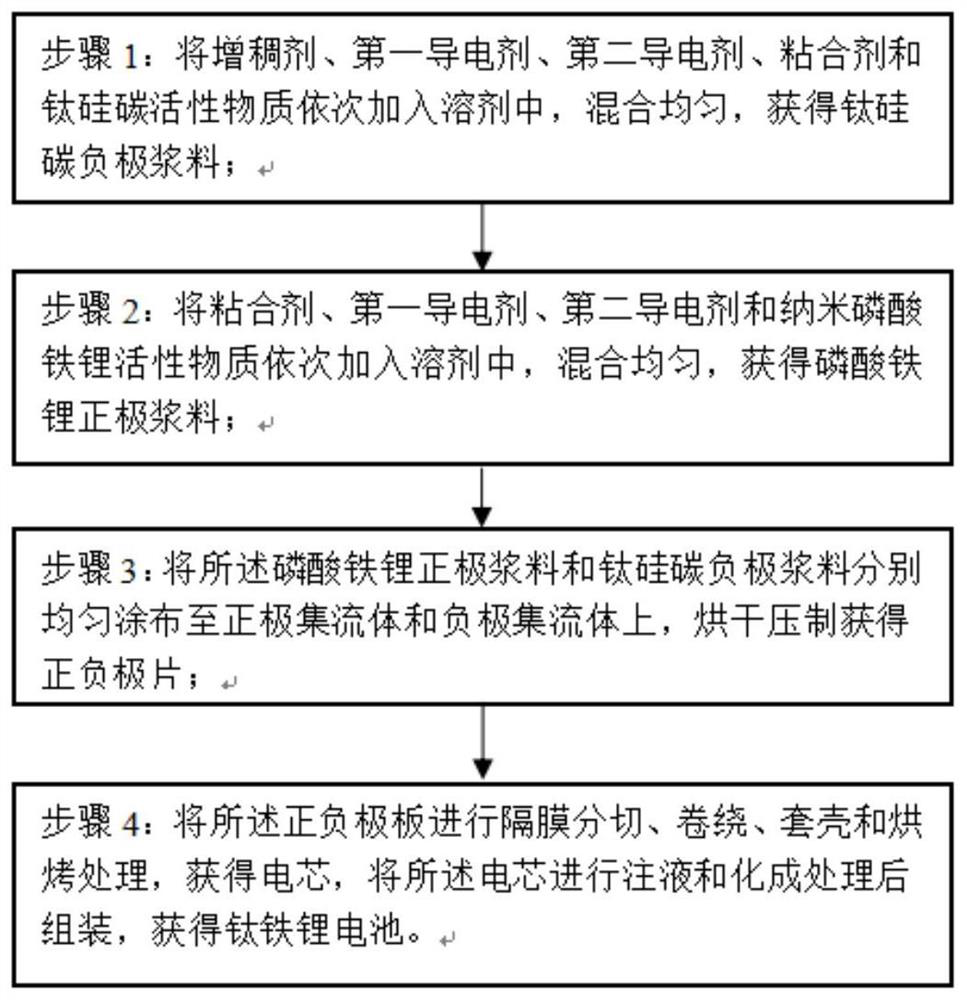

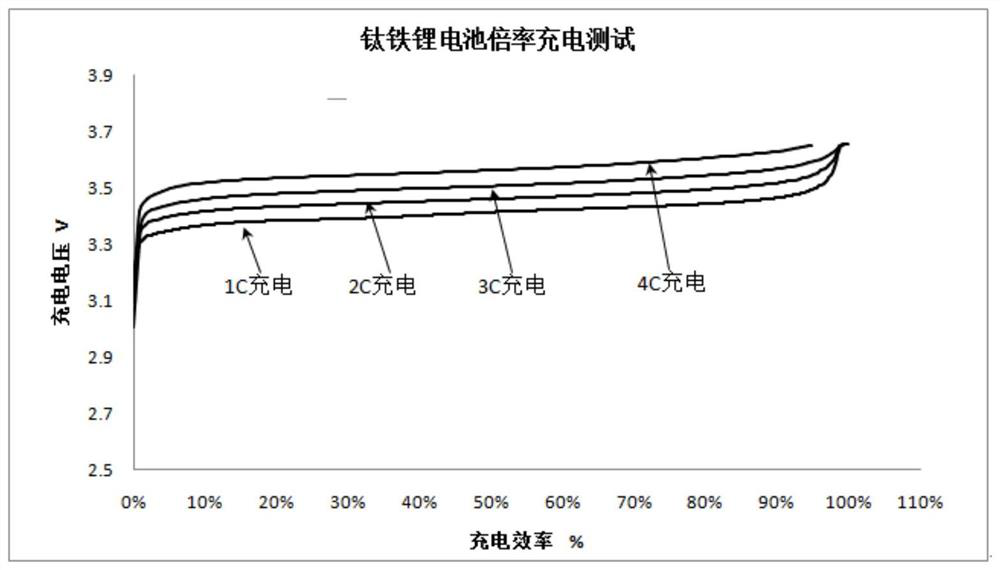

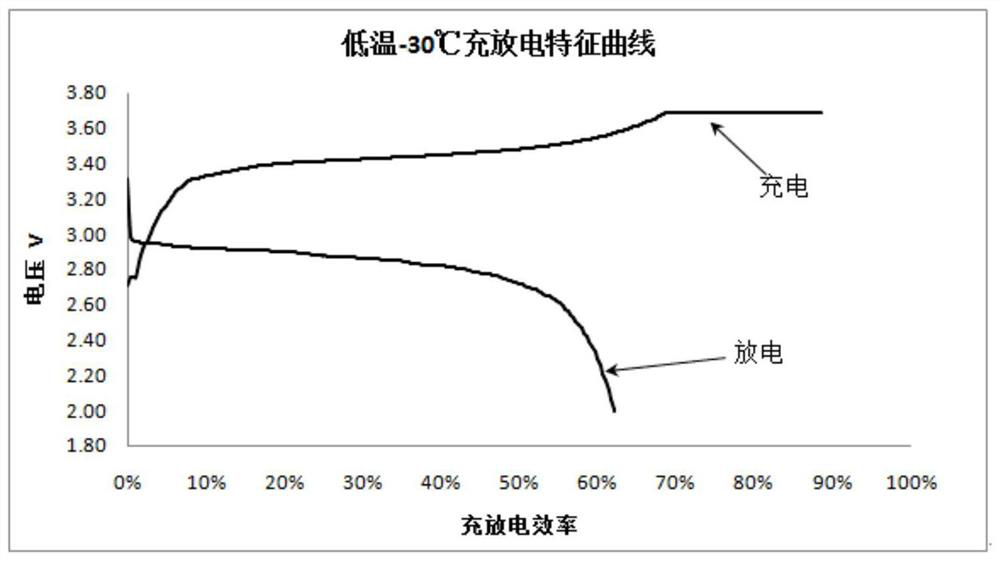

Method for preparing titanium iron lithium battery

ActiveCN109713357AImprove safety and reliabilityImprove cycle lifeElectrode manufacturing processesFinal product manufactureLithium iron phosphateElectrical battery

The invention discloses a method for preparing a titanium iron lithium battery. The method comprises preparing a titanium silicon carbon negative electrode paste and lithium iron phosphate positive electrode paste; then uniformly applying the lithium iron phosphate positive electrode paste and the titanium silicon carbon negative electrode paste to a positive electrode current collector and a negative electrode current collector respectively; obtaining positive and negative electrode sheets by drying and pressing; and finally obtaining the titanium iron lithium battery by assembly. The titanium silicon carbon is used as a negative electrode material. The shell, the core and the pomegranate sheath in a titanium silicon carbon shell-core pomegranate structure can be used for ensuring that atitanium silicon carbon anode material is more stable and reliable than the conventional graphite in a charge and discharge process, thereby further improving the safety and reliability of the battery, extending the cycle life of the battery, and improving the quality and specific energy of the battery.

Owner:YINLONG ENERGY CO LTD

Cathode active material and preparation method thereof and lithium ion secondary battery prepared by cathode active material

InactiveCN102299311BEasy to coverReduce irreversible capacityCell electrodesSecondary cellsSlurryN-Methyl-2-pyrrolidone

Owner:IRICO

Bipolar battery pole plate and preparation method thereof

ActiveCN110336038BImprove corrosion resistanceLight in massFinal product manufactureElectrode carriers/collectorsPhysical chemistryElectrical polarity

The invention belongs to the technical field of lead-acid batteries, and in particular relates to a polar plate of a bipolar battery and a preparation method thereof. The bipolar battery plate includes a bipolar grid, a positive active material and a negative active material, and the bipolar grid is composed of titanium foil and copper plate, and the bipolar grid is positively The lead layer is electroplated on both sides of the negative electrode at the same time, and then the bipolar battery plate prepared by filling the positive active material and the negative active material has high power, high mass specific energy, less gas evolution, strong mechanical strength and corrosion resistance. The current and potential distribution of the plate is uniform; the preparation method of the invention can reduce production costs, reduce environmental protection pressure and improve battery performance.

Owner:ZIBO TORCH ENERGY

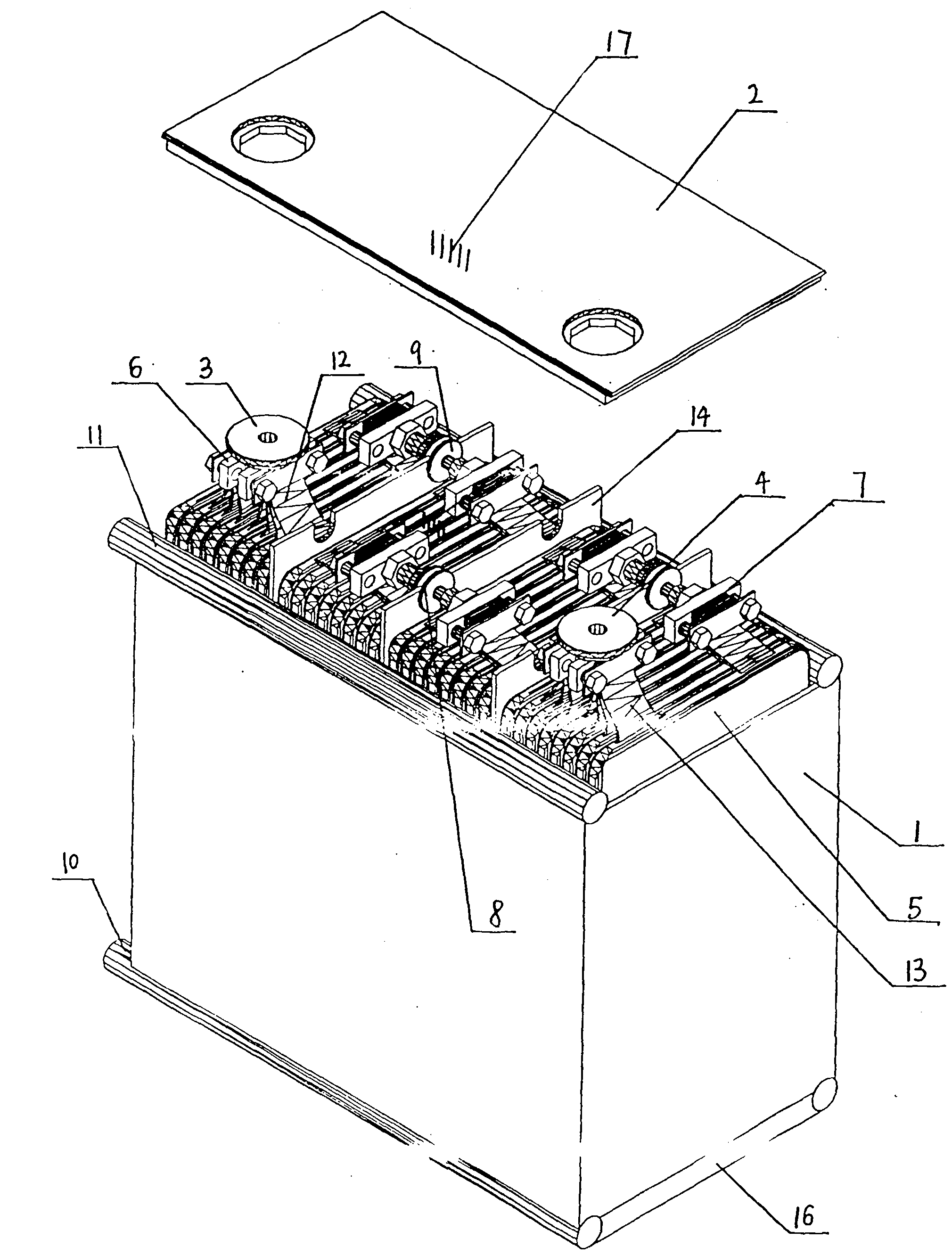

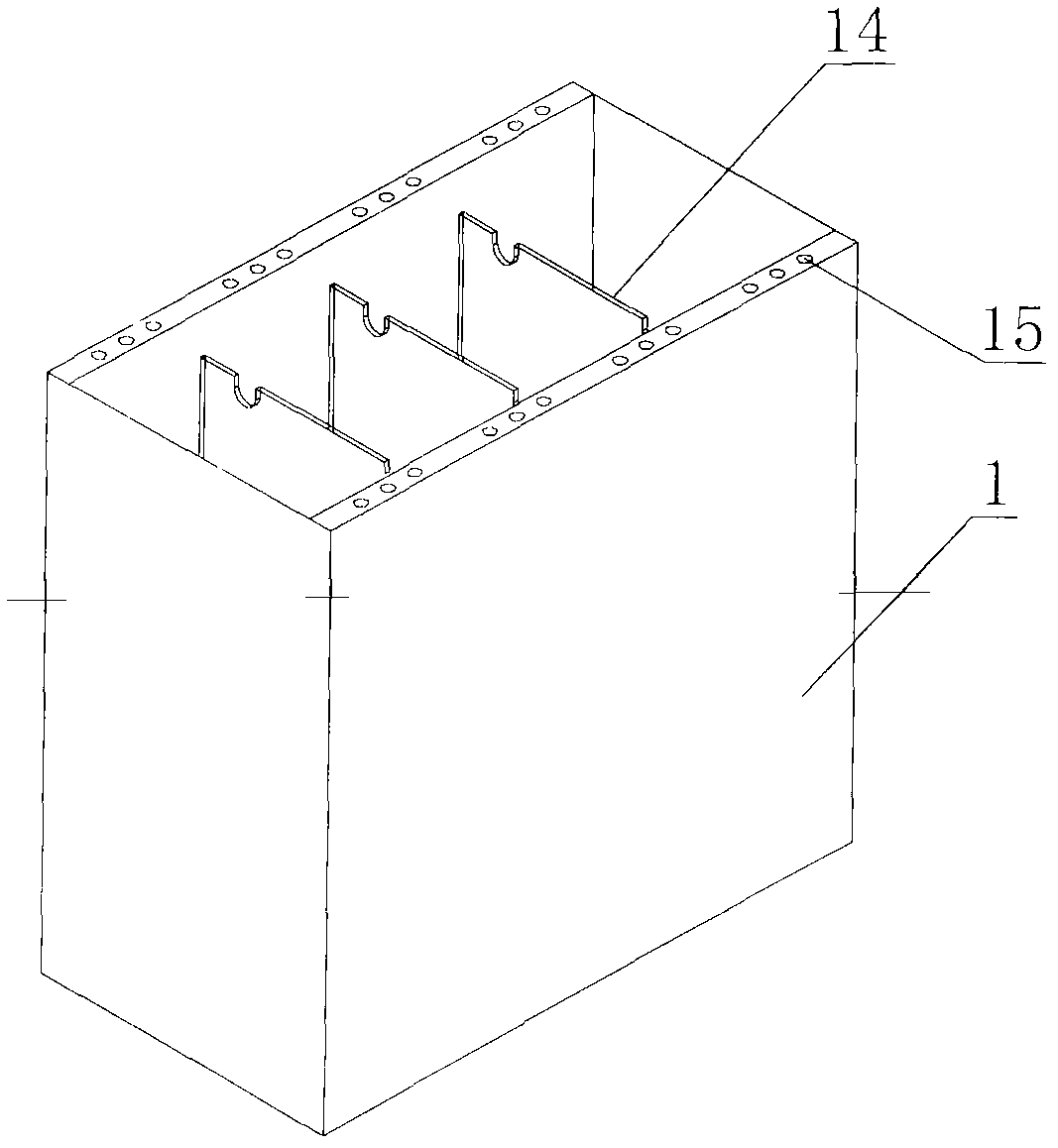

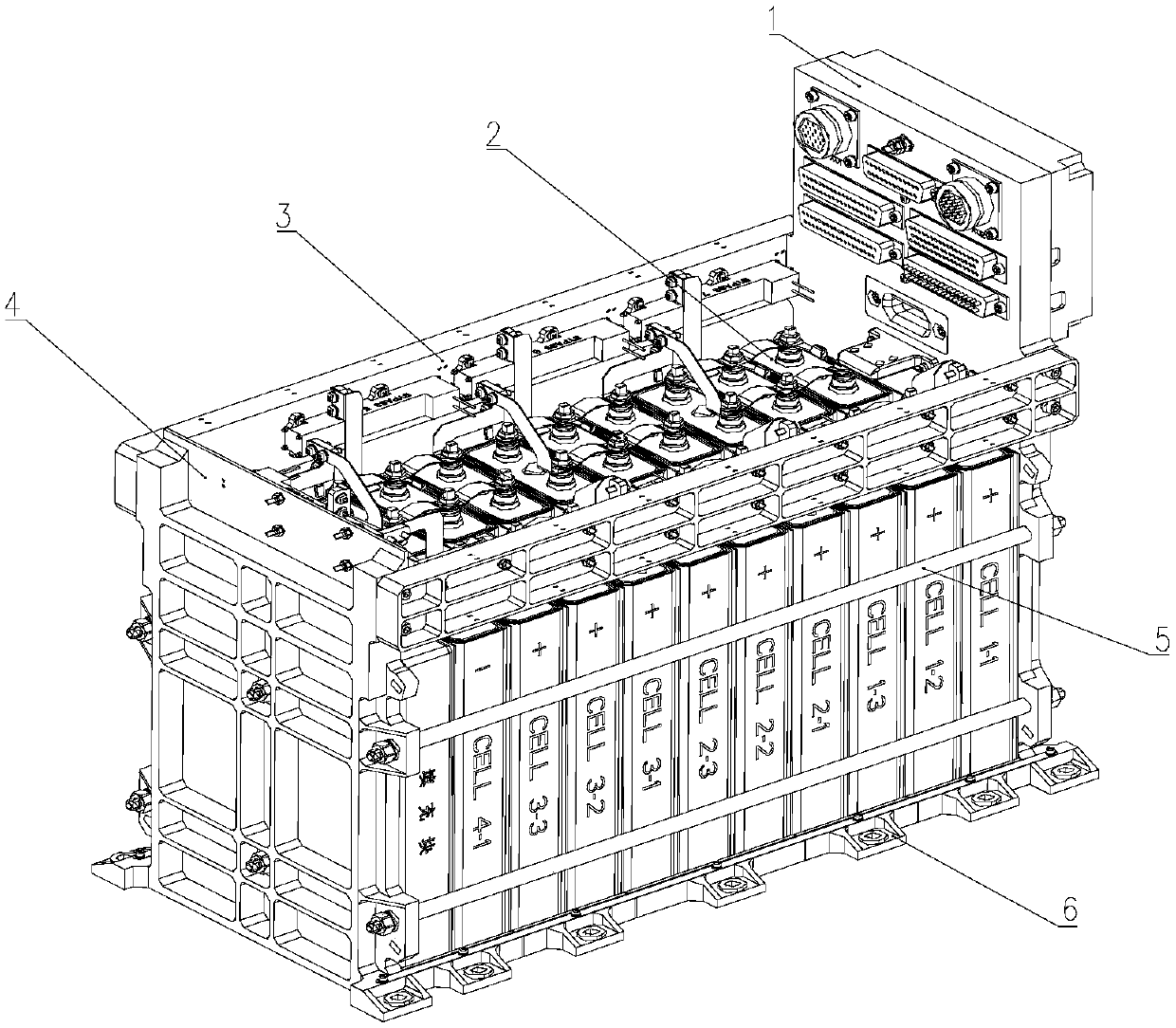

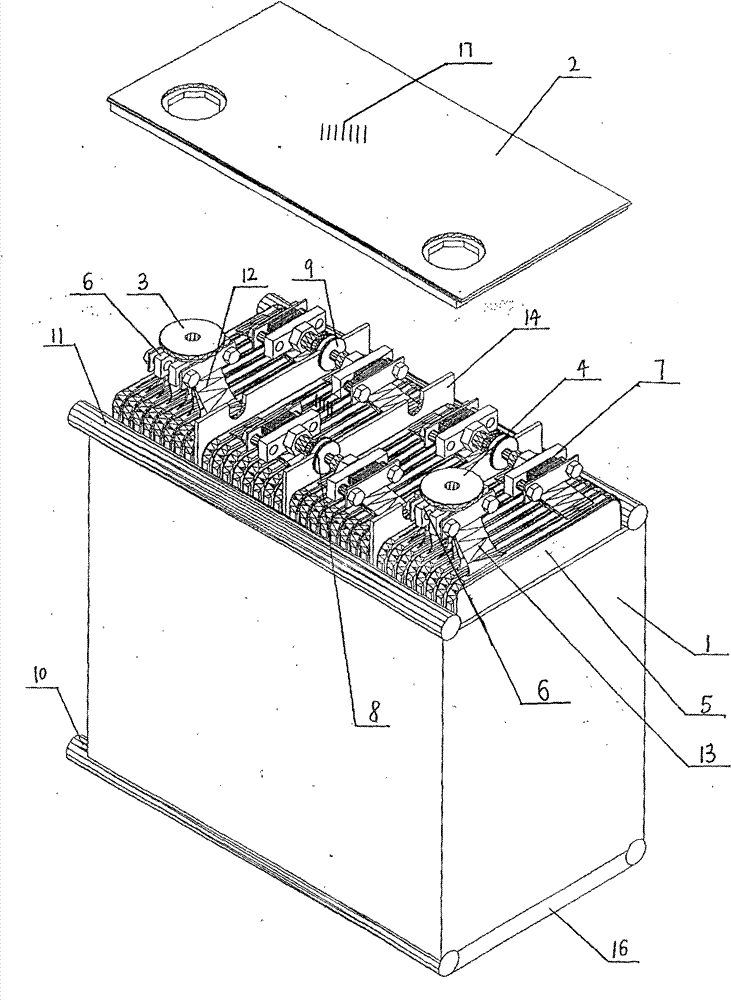

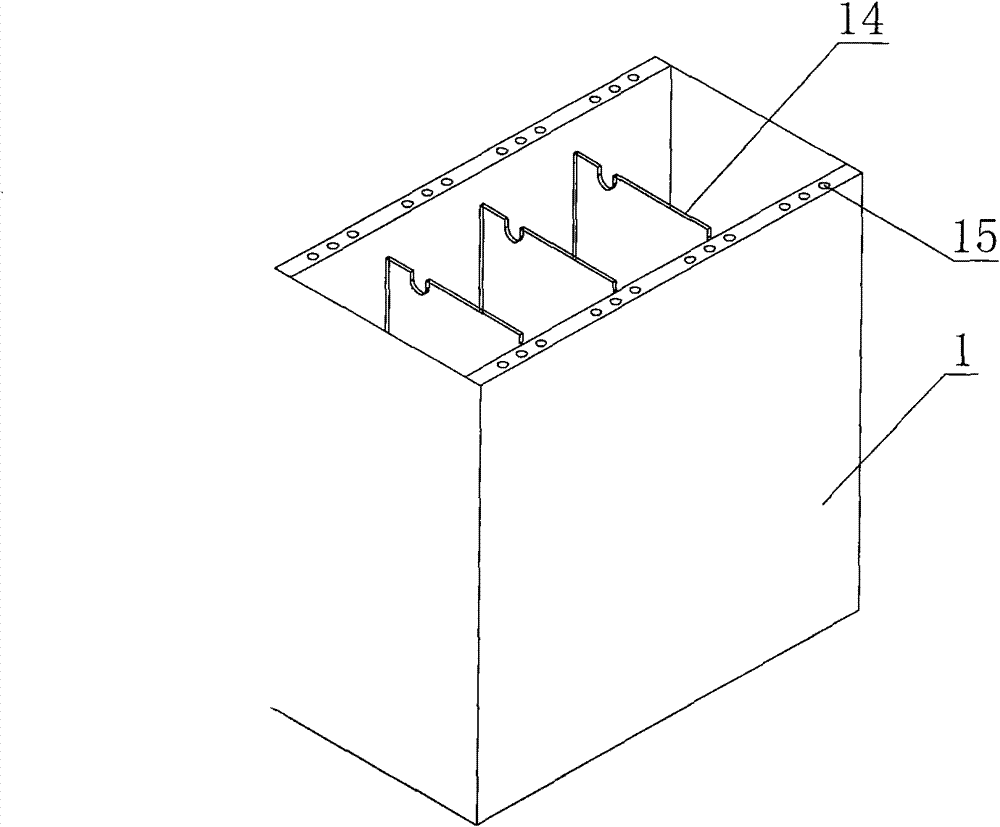

Magnesium lithium alloy lithium-ion battery pack for space

InactiveCN109560231ASimple and efficient structural designImprove mass to energyCell component detailsBatteriesLithiumEngineering

The invention discloses a magnesium lithium alloy lithium-ion battery pack for a space. The battery pack comprises several battery monomers, a left end plate, a right end plate, a pressure strip and abracket; the left end plate and the right end plate are arranged at two ends of the battery pack, and used for fastening the battery monomers; the pressure strip is arranged at the bottom of the battery pack, and used for supporting the battery monomers, and connected with the deck of a spacecraft; the bracket is positioned at the upper part of the battery pack; two ends of the bracket are connected with the left end plate and the right end plate, wherein the left end plate, the right end plate, the pressure strip and the bracket are made of a magnesium lithium alloy material; the battery pack further comprises a pull rod; the pull rod is connected to the left end plate and the right end plate; and the pull rod is made of a titanium alloy material. The magnesium lithium alloy lithium-ionbattery pack for the space disclosed by the invention is simple and high-efficiency in structural design, few in part and high in mass specific energy; most of structures can be made of the magnesiumlithium alloy material; the weight of the battery pack is effectively reduced; furthermore, the structural strength is increased; the launching cost is reduced; and the effective load is increased.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

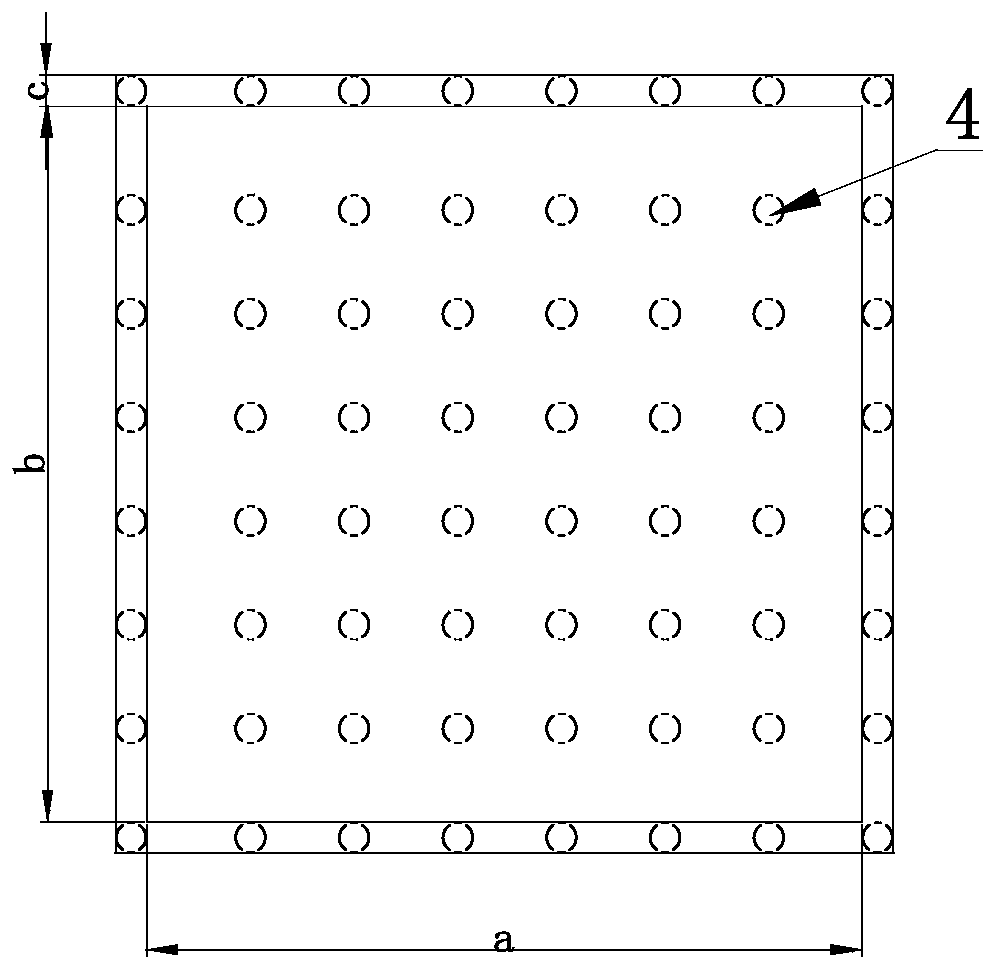

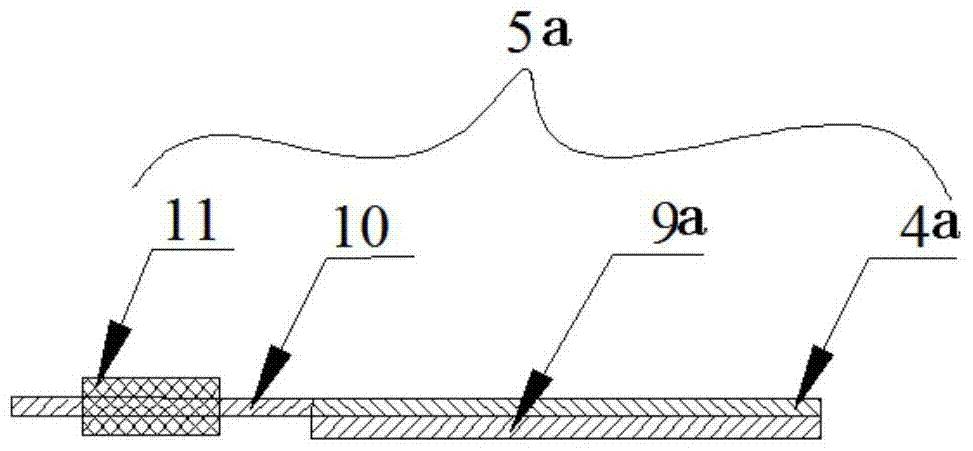

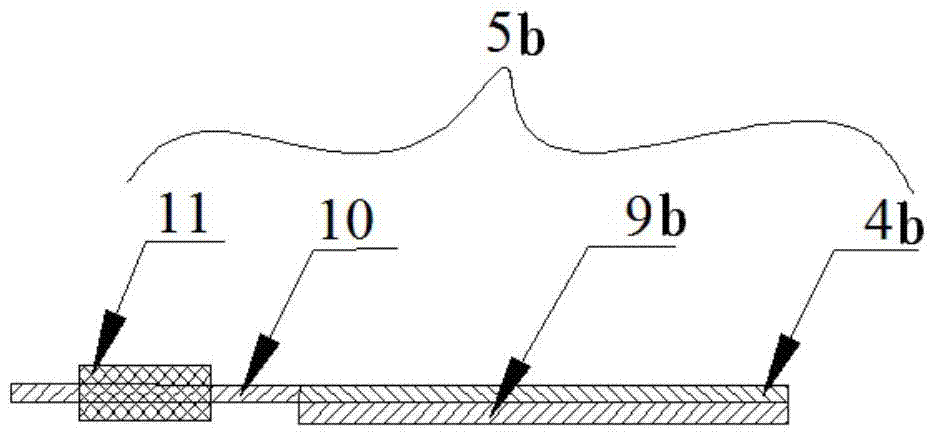

Thin-type soft packaging super capacitor

ActiveCN101694815BAvoid short circuitImprove the safety of useCapacitor housing/encapsulationHybrid capacitor current collectorsPower flowHigh energy

The invention relates to a thin-type soft packaging super capacitor, which comprises a soft packaging thin film, electrolytic solution, a capacitor chip, an anode ear and a cathode ear, wherein the capacitor chip comprises an anode piece, a porous isolation film and a cathode piece which are mutually overlapped together in turn, the end potion of one end of each anode piece is provided with a blank anode current collector, the blank cathode current collector is arranged on the end portion of one end of each cathode piece, and the anode ear and the cathode ear are arranged on two ends of the capacitor chip. The thin-type soft packaging super capacitor effectively increases the thickness and the overall area of the pole ear, reduces heating capacity, avoids short circuit between the anode ear and the cathode ear, and lowers welding thickness. And the super capacitor has the characteristics of high energy density, safe use and convenient welding and processing, and is suitable for big current to charge and discharge.

Owner:中国船舶重工集团公司第七一二研究所

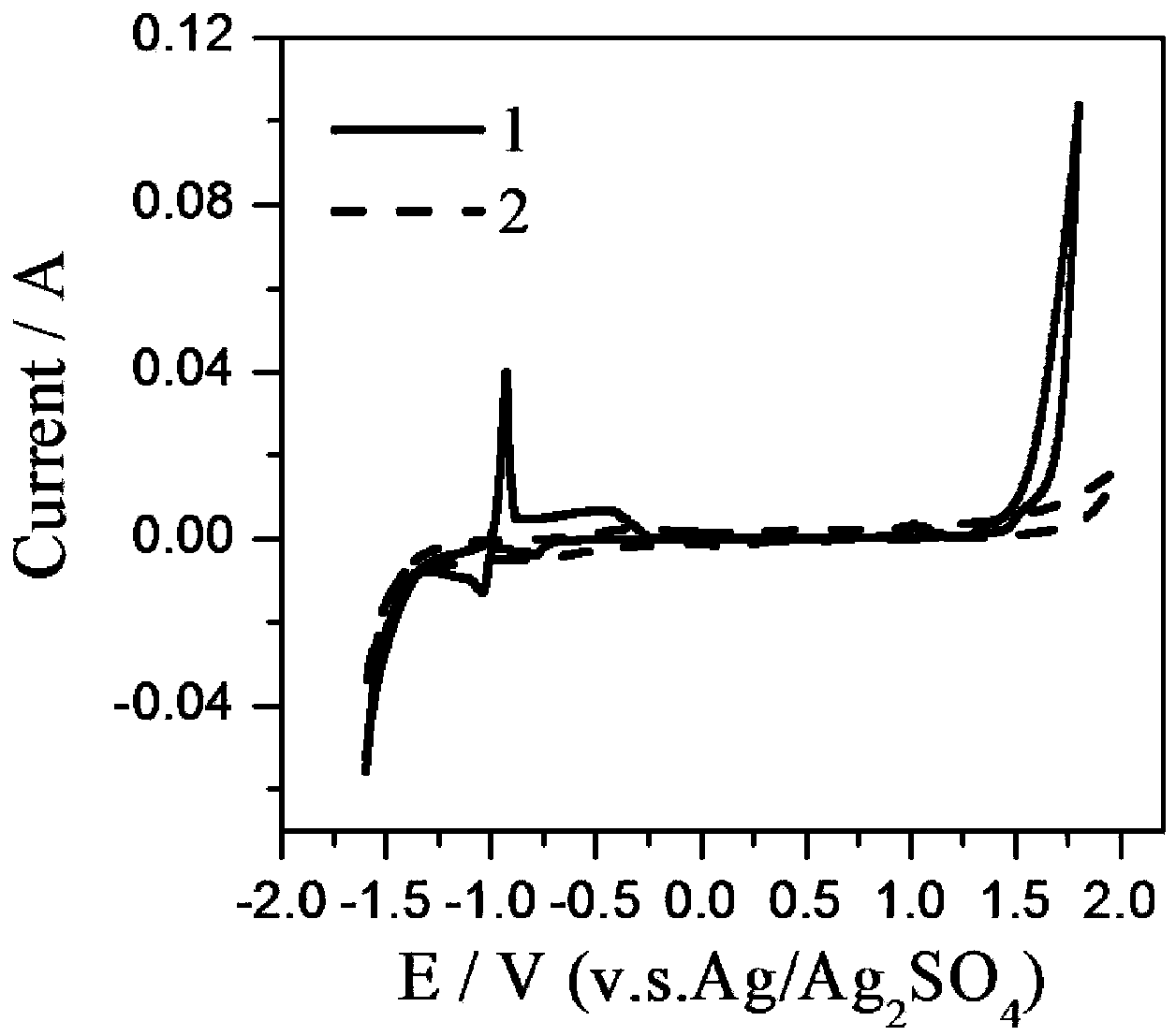

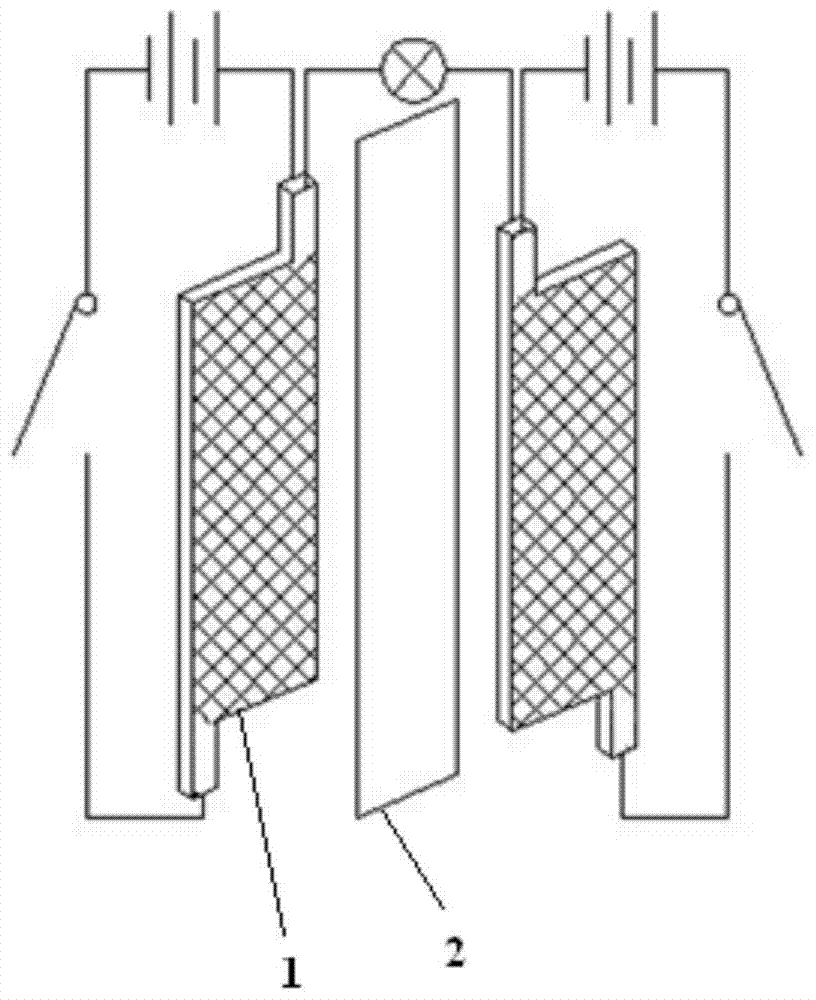

A kind of bifunctional electrode and its preparation and application

ActiveCN108172947BHigh reactivityIncrease the areaFuel and primary cellsCell electrodesPtru catalystElectrical battery

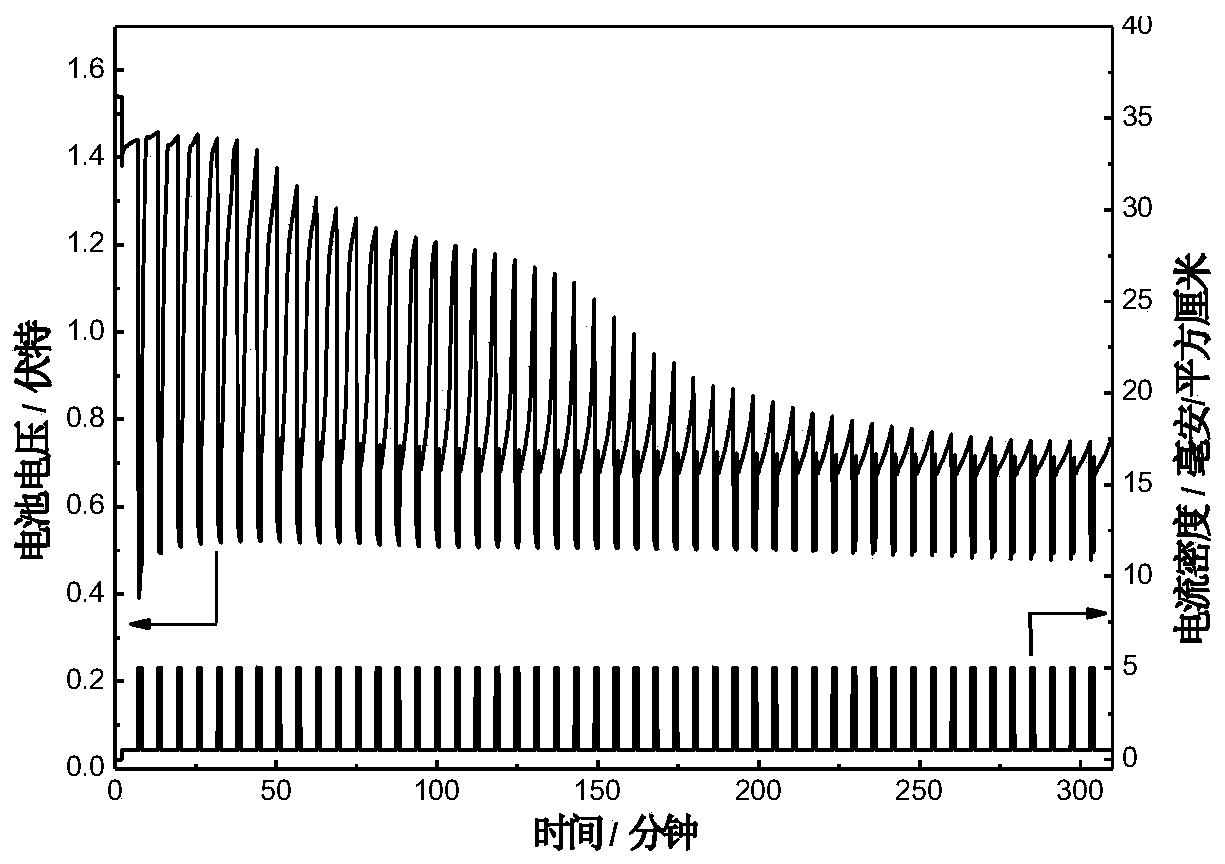

The present invention provides a bifunctional electrode, a preparation method and applications thereof. The bifunctional electrode comprises a current collector and a hydrogen evolution-oxygen reduction bifunctional catalyst, wherein the catalyst is made of one selected from noble metals such as palladium and platinum, and uniformly grows on a hemispherical metal layer, the metal layer grows on anelectric-conduction foam metal through electroplating, the surface of the metal layer is oxidized into a metal-electroplated hydroxide, two cathodes are opposite to an anode in a battery monomer to form a sandwich-like configuration, and the cathodes and the anode are fixed by a battery shell. According to the present invention, the advantages of magnesium-water batteries and magnesium-dissolvedoxygen batteries are effectively combined, wherein the discharging is performed by using the working principle of the magnesium-dissolved oxygen battery during the low-current discharging so as to achieve the high discharging voltage and the high specific energy, and the discharging is performed by using the working principle of the magnesium-seawater battery under the condition of high current orinsufficient dissolved oxygen so as to ensure the normal working of the battery and effectively improve the stability of the battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Thermal management system of electric automobile

ActiveCN101885313BGuaranteed output currentGuaranteed output voltageAir-treating devicesElectric propulsion mountingControl signalEngineering

The invention discloses a thermal management system of an electric automobile, comprising a temperature sensor, a heating and cooling device and a central processing unit, wherein the temperature sensor is used for acquiring the temperature of components generating the raising and the drop of temperature in the electric automobile; the heating and cooling device is used for generating a heat source and a cold source which are transmitted to components needing heating and cooling and is connected with the signal output end of the central processing unit through a control switch; and the central processing unit is used for receiving a signal of the temperature sensor and calculating and outputting the control signal to the heating and cooling device. In the invention, the temperature conditions of various components can be detected by using the temperature sensor and are transmitted to the central processing unit which controls the temperature in time so as to ensure that the temperatures of various components are in a proper range. The system not only can be used for monitoring the temperature of batteries, but also can be used for monitoring the temperature of a motor and a motor controller, thereby avoiding the motor and the motor controller from being damaged due to overhigh temperature. The system can also be used for monitoring the temperature in a carriage and ensures thecomfort degree of the moving space of people.

Owner:李辉 +1

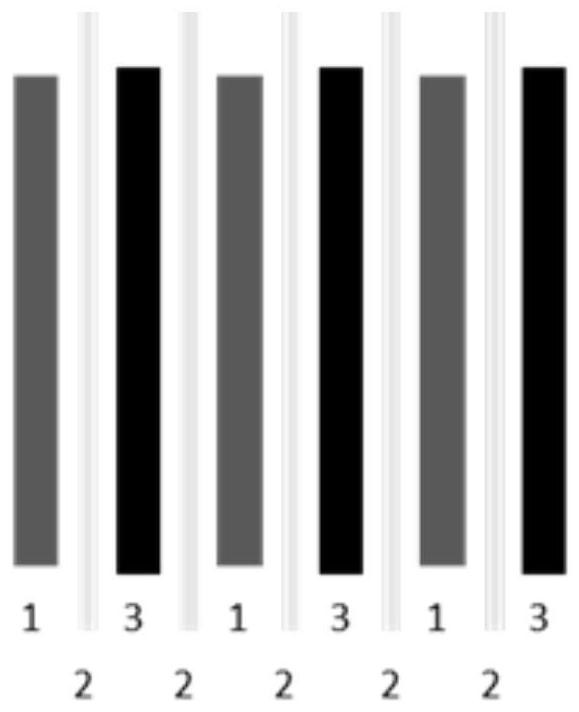

A kind of ultra-thin secondary battery and preparation method thereof

ActiveCN104638213BSmall spacingControl shapeFinal product manufactureCell component detailsSlurryElectrolyte

The invention relates to an ultra-thin secondary battery and a preparation method thereof, belonging to the field of electrochemistry. The thickness of the ultra-thin secondary battery designed by the present invention is 0.3-1.0mm; It comprises separator, positive electrode diaphragm, negative electrode diaphragm; direct contact; the diaphragm is composed of a substrate and a conductive layer); the conductive layer is located on one side of the substrate, and the conductive layer is in direct contact with the positive electrode diaphragm. The preparation method is as follows: first, according to the set size, respectively coat the positive electrode slurry and the negative electrode slurry on the front and back surfaces of the separator, dry and roll to obtain the separator with the positive electrode diaphragm and the negative electrode diaphragm; Pressing, so that the positive electrode current collector and the negative electrode current collector are in close contact with the positive electrode diaphragm and the negative electrode diaphragm respectively. Finally, the packaging film is used for packaging according to the designed size, followed by vacuum dehydration, electrolyte injection, sealing, activation, shaping, secondary packaging, and volume separation to obtain an ultra-thin secondary battery.

Owner:HUNAN GAOYUAN BATTERY

Back-oxygen lithium-air battery technology

InactiveCN103022527ASolve the problem of blocking the pores of the catalytic layerGood health status does not changeDeferred-action cellsLithium–air batteryOxygen ions

The invention relates to a back-oxygen lithium-air battery technology. According to the technology, the battery chemical reaction for combining lithium ions with oxygen ions is retained, but the position of the reaction is moved outside a catalyst layer, and an electrolyte is not used, so that reactants can be discharged conveniently. By the back-oxygen lithium-air battery technology, a lithium-air battery can work stably.

Owner:胡小华

Preparation method of titanium iron lithium battery

ActiveCN109713357BImprove safety and reliabilityImprove cycle lifeElectrode manufacturing processesFinal product manufactureLithium iron phosphateElectrical battery

The invention discloses a method for preparing a titanium-iron-lithium battery, a method for preparing a titanium-iron-lithium battery. The method prepares a titanium-silicon-carbon negative electrode slurry and a lithium iron phosphate positive electrode slurry, and then prepares the lithium iron phosphate positive electrode The slurry and the titanium-silicon-carbon negative electrode slurry are uniformly coated on the positive electrode current collector and the negative electrode current collector respectively, dried and pressed to obtain positive and negative electrode sheets, and finally assembled to obtain a titanium-iron-lithium battery; thus, the present invention uses titanium-silicon carbon as the negative electrode The material can use the "shell", "core" and "pomegranate coat" in the "shell core pomegranate structure" of titanium silicon carbon to ensure that the titanium silicon carbon negative electrode material is more stable and reliable than conventional graphite during charge and discharge, thereby further Improve the safety and reliability of the battery, prolong the cycle life of the battery, and improve the mass specific energy of the battery.

Owner:YINLONG ENERGY CO LTD

Method for Improving Low-temperature Starting Performance of Batteries

ActiveCN104916848BImprove mass to energyImprove machinabilityElectrode carriers/collectorsSecondary cellsLow voltageElectrical battery

The invention discloses a method for improving battery low-temperature starting performance, and relates to the method for improving the battery starting performance in a low temperature environment. The invention aims to solve problems that a conventional battery has low voltage and discharge capacity and poor use performance during low-temperature starting. Under conditions without changing a battery material and an electrolyte solution and without significantly changing an internal structure and preparation processes, flexible graphite paper entirely or partly replaces a metal to be used as an electrode current collector, or the graphite paper is directly placed between a positive electrode and a negative electrode to be used as an electrical heating element, an external-connection power source is applied to the graphite paper to make the graphite paper rapidly heated, so that the electrode material and the electrolyte solution are rapidly heated, the battery internal temperature rises rapidly, the battery discharge voltage and the battery discharge capacity can be close to room temperature values in a short period of time, and the problem of substantial attenuation of the performance during the battery low-temperature starting is effectively solved. The method is used in the field of secondary batteries.

Owner:哈尔滨天宝石墨科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com