Method for preparing titanium iron lithium battery

A technology of lithium battery and ferro-titanium, which is applied in the field of preparation of titanium-iron-lithium battery, can solve problems such as unfavorable structural stability, impact on discharge capacity, particle pulverization failure, etc., to improve safety and reliability, increase mass specific energy, and prolong cycle The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

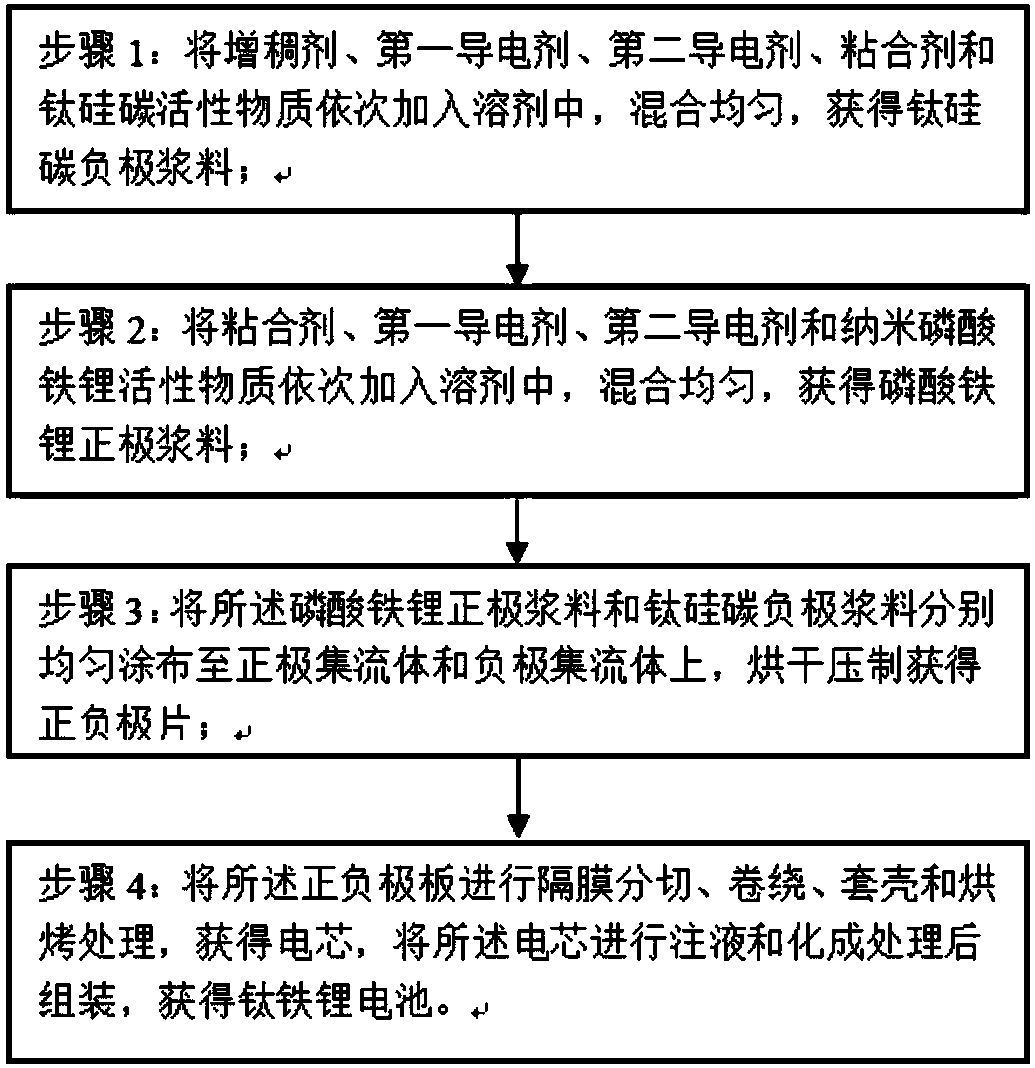

[0034] An embodiment of the present invention provides a method for preparing a titanium-iron-lithium battery, the flow chart of which is as follows figure 1 As shown, the method is implemented through the following steps:

[0035] Step 1: adding the thickener, the first conductive agent, the second conductive agent, the binder and the titanium-silicon-carbon active material into the solvent in sequence, and mixing evenly to obtain the titanium-silicon-carbon negative electrode slurry;

[0036] Wherein, the composition of the titanium-silicon-carbon negative electrode slurry in the step 1 is as follows in parts by weight: titanium-silicon-carbon active material: 86.0-99.0 parts, thickener: 1.0-5.0 parts, first conductive agent: 0.2-6.0 parts, Second conductive agent: 0.5-5.0 parts, binder: 0.2-5.0 parts.

[0037] Step 1 is specifically realized through the following steps: wherein, the ambient humidity during the whole preparation process is 1-20% RH, and the ambient temperat...

Embodiment 1

[0069] Step 1: The composition of the titanium-silicon-carbon negative electrode slurry is as follows in parts by weight: titanium-silicon-carbon active material: 92.0 parts, polytetrafluoroethylene: 3.0 parts, carbon nanotubes: 3.0 parts, graphene: 2.8 parts, epoxy resin: 2.6 parts; polytetrafluoroethylene, carbon nanotubes, graphene, epoxy resin and titanium-silicon-carbon active material are added to the solvent in sequence, and mixed uniformly to obtain titanium-silicon-carbon negative electrode slurry; wherein, the titanium-silicon-carbon active material by D 10 Titanium silicon carbon powder, D 50 Titanium silicon carbon powder and D 90 TiSiC powder composition, the D 10 The particle size of the titanium silicon carbon powder is 0.8-3.0 μm, the D 50 The particle size of the titanium silicon carbon powder is 4.0-18.0 μm, the D 90 The particle size of the titanium silicon carbon powder is less than 25.0 μm; wherein, the solvent is deionized water and N-methylpyrrolidon...

Embodiment 2

[0088] Step 1: The composition of the titanium-silicon-carbon negative electrode slurry is as follows in parts by weight: titanium-silicon-carbon active material: 86.0 parts, polytetrafluoroethylene: 3.0 parts, carbon nanotubes: 6.0 parts, graphene: 2.8 parts, epoxy resin: 2.6 parts; polytetrafluoroethylene, carbon nanotubes, graphene, epoxy resin and titanium-silicon-carbon active material are added to the solvent in sequence, and mixed uniformly to obtain titanium-silicon-carbon negative electrode slurry; wherein, the titanium-silicon-carbon active material by D 10 Titanium silicon carbon powder, D 50 Titanium silicon carbon powder and D 90 TiSiC powder composition, the D 10 The particle size of the titanium silicon carbon powder is 0.8-3.0 μm, the D 50 The particle size of the titanium silicon carbon powder is 4.0-18.0 μm, the D 90 The particle size of the titanium silicon carbon powder is less than 25.0 μm; wherein, the solvent is deionized water and N-methylpyrrolidon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com