Thermal management system of electric automobile

A thermal management system and technology for electric vehicles, applied in the field of thermal management systems for electric vehicles, can solve the problems of high technical difficulty in manufacturing charge and discharge protection circuits, increased labor intensity for installation workers, and difficulty in solving safety problems thoroughly, thereby improving electrochemical performance. The effect of response speed, elimination of safety hazards, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

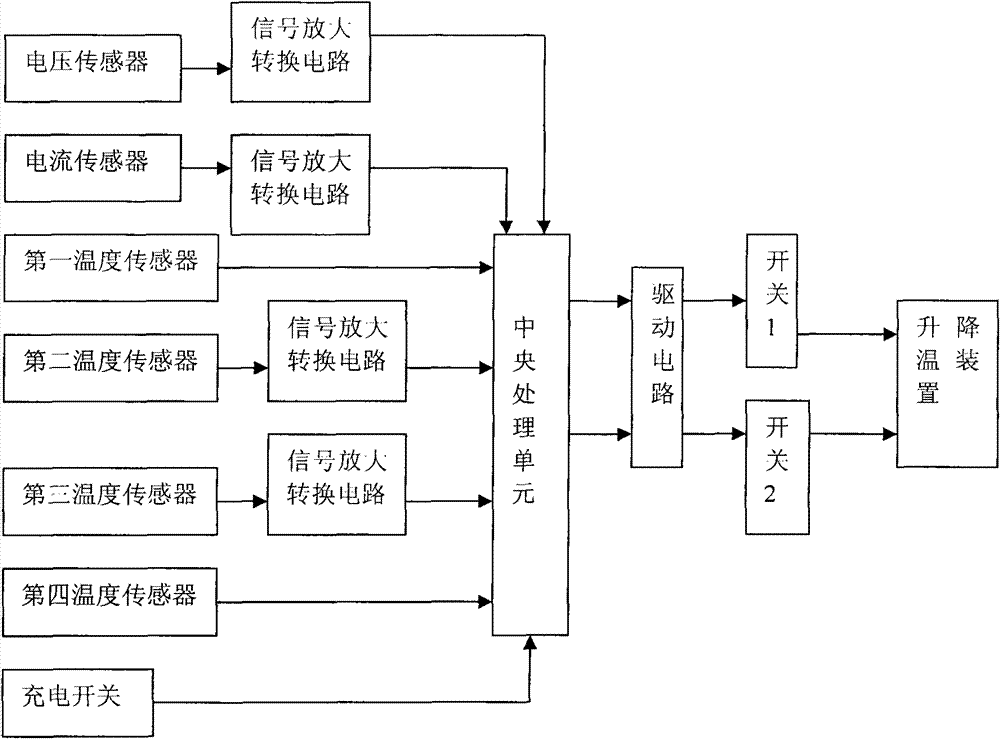

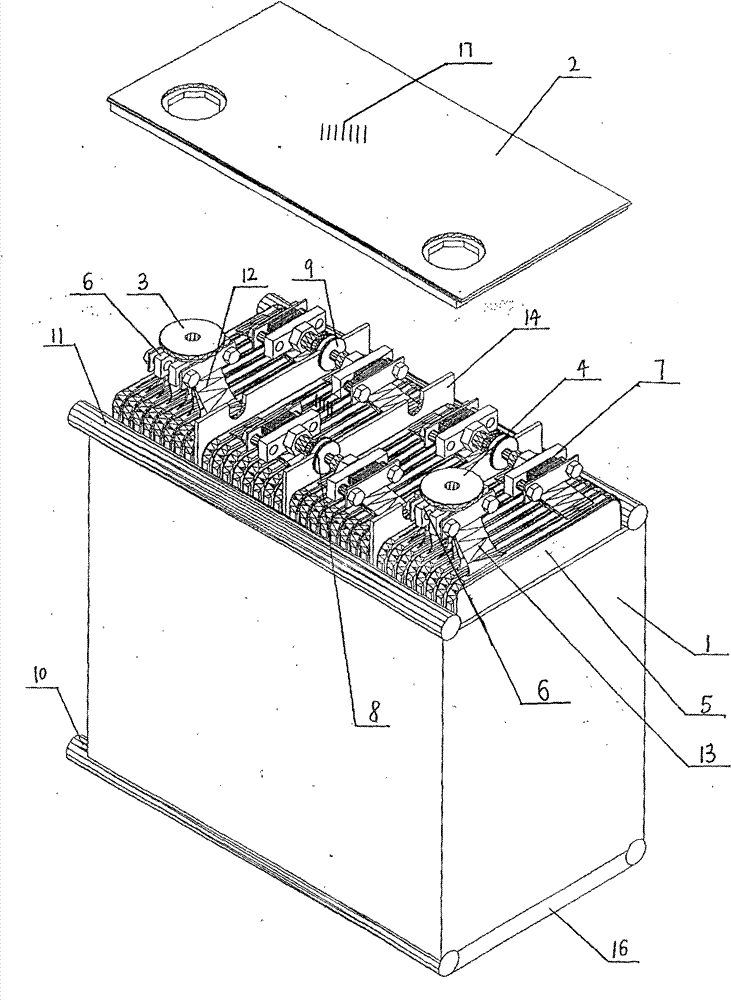

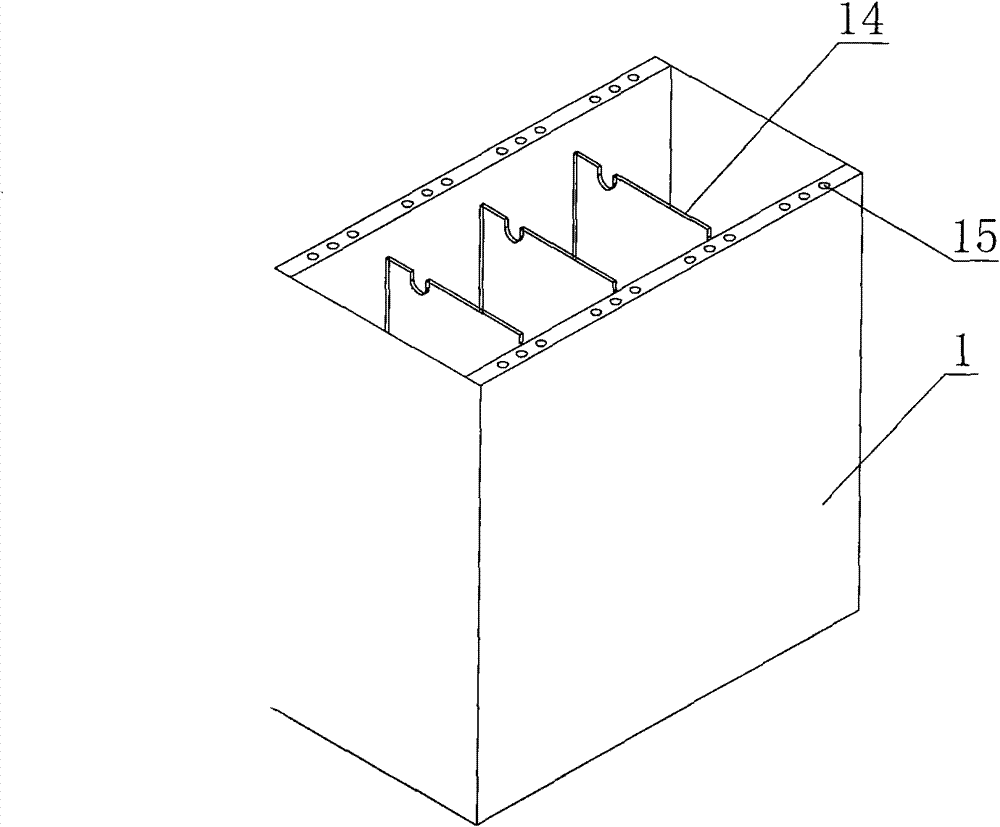

[0026] Such as figure 1 As shown, the electric vehicle thermal management system of the present invention includes a first temperature sensor, a second temperature sensor, a third temperature sensor and a fourth temperature sensor, a central processing unit, and a heating and cooling device, and the first temperature sensor is used to be placed in the battery pack , the second temperature sensor is used to be set inside the motor; the third temperature sensor is used to be set at the motor controller, and the fourth temperature sensor is used to be set in the electric vehicle compartment, and the electric compartment is also provided with a refrigerator and a heater ; The first temperature sensor and the fourth temperature sensor adopt DS18B20, the second temperature sensor and the third temperature sensor adopt PT100, the signal output ends of the second temperature sensor and the third temperature sensor are respectively connected with the input ends of the signal amplificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com