Carbon coated titanium-based lead dioxide positive plate for lead-acid storage battery

A lead-acid battery, lead dioxide technology, applied in lead-acid battery electrodes, battery electrodes, electrode carriers/current collectors, etc., can solve problems affecting the bonding force of metal lead layers, affecting battery working stability and cycle life, contact resistance Large and other problems, to achieve the effect of high bonding tightness, small contact resistance, and inhibiting passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] (1). Polish the surface of the metal titanium mesh with sandpaper, then immerse it in a NaOH solution with a concentration of 5% to 10% to remove the grease on the surface of the titanium mesh, wash it with water and immerse it in a mixed solution of hydrochloric acid and hydrofluoric acid Pickling to remove surface oxides, wherein the concentration of HCl is 40~50mL / L, and the concentration of HF is 20~40mL / L; then wash with water.

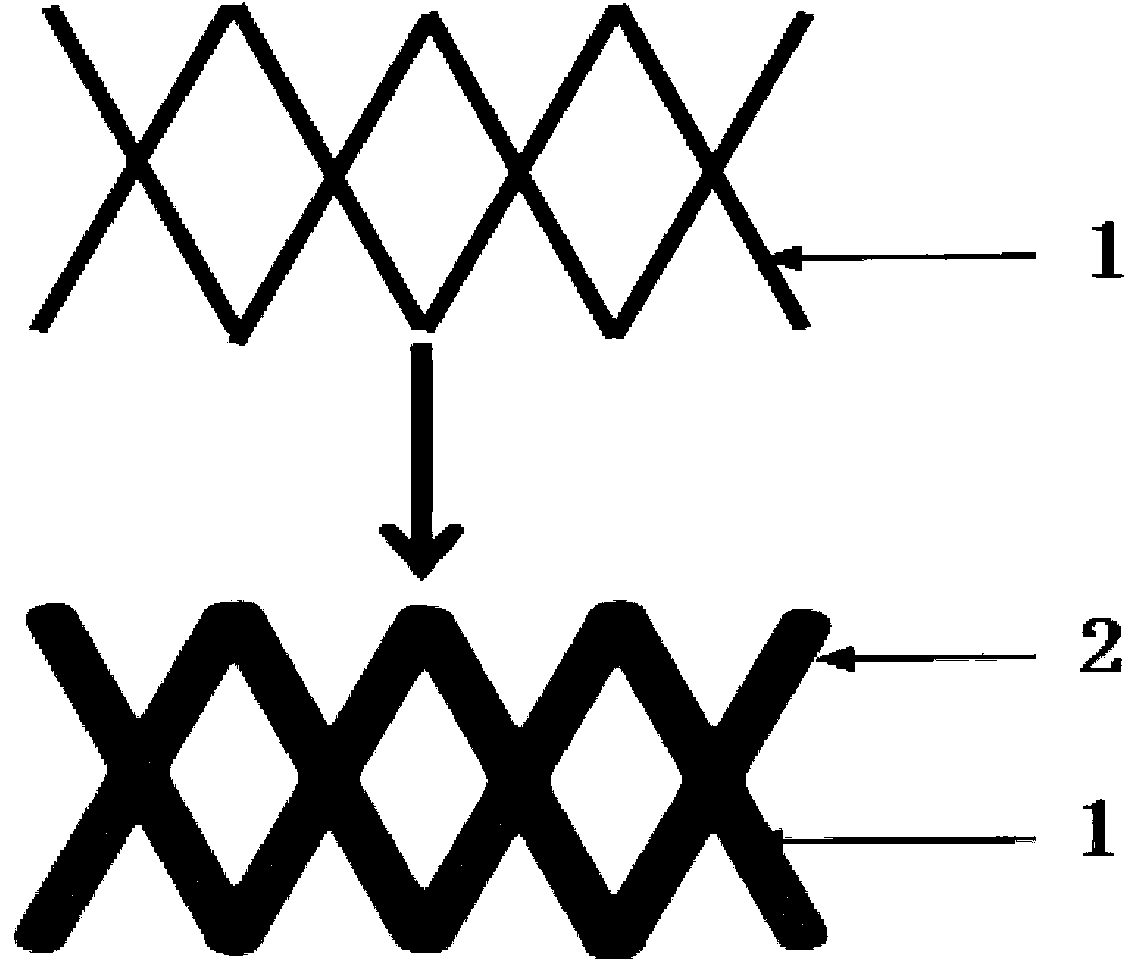

[0028] (2). If figure 1 As shown, the treated titanium grid is vapor-deposited in a high-temperature furnace to obtain a carbon-coated titanium substrate grid. Place the treated titanium mesh in a high-temperature furnace with an inert gas, and raise the temperature at a rate of 5-10°C / min. When a certain temperature is reached, a carbon source gas is introduced, and after a certain period of constant temperature, a carbon-coated titanium substrate grid is obtained. . The carbon source gas can be organic matter such as methane, formaldeh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com