Carbon film lithium ion battery anode and production method

A lithium-ion battery and production method technology, applied in the field of lithium-ion batteries, can solve the problems of negative electrode mass-specific capacity improvement, unfavorable lithium-ion batteries, high mass ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

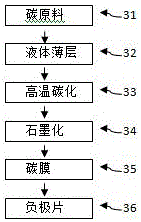

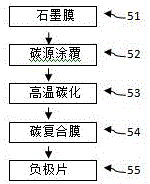

[0012] Add the petroleum asphalt to the melting tank, and the petroleum asphalt forms a thin layer of asphalt on the surface of the molten tin in the melting tank; the thin layer of asphalt is carbonized at about 1000 °C to form a mesophase carbon film; the mesophase carbon film is further heated, at 2000 °C The graphite film formed by the above high-temperature graphitization; the graphite film is processed into a lithium-ion battery negative electrode according to a certain shape and size.

Embodiment 2

[0014] Add coal tar pitch to the melting tank, and the coal tar pitch forms a thin layer of pitch on the surface of the molten lead in the melting tank; the thin layer of pitch is carbonized at about 1000 °C to form a mesophase carbon film; the mesophase carbon film is further heated, at 2000 °C The graphite film formed by the above high-temperature graphitization; the graphite film is processed into a lithium-ion battery negative electrode according to a certain shape and size.

Embodiment 3

[0016] Add petroleum asphalt to the melting tank, and the petroleum asphalt forms a thin layer of asphalt on the surface of the molten tin in the melting tank; the thin layer of asphalt is heated at about 2000°C to carbonize to form a carbon film; the carbon film is processed into a lithium-ion battery according to a certain shape and size negative electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com