Back-oxygen lithium-air battery technology

A lithium-air battery technology, applied in the direction of delayed action cells, etc., can solve the problem of blocking the discharge of redox products, and achieve the effects of eliminating impact, increasing battery life, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

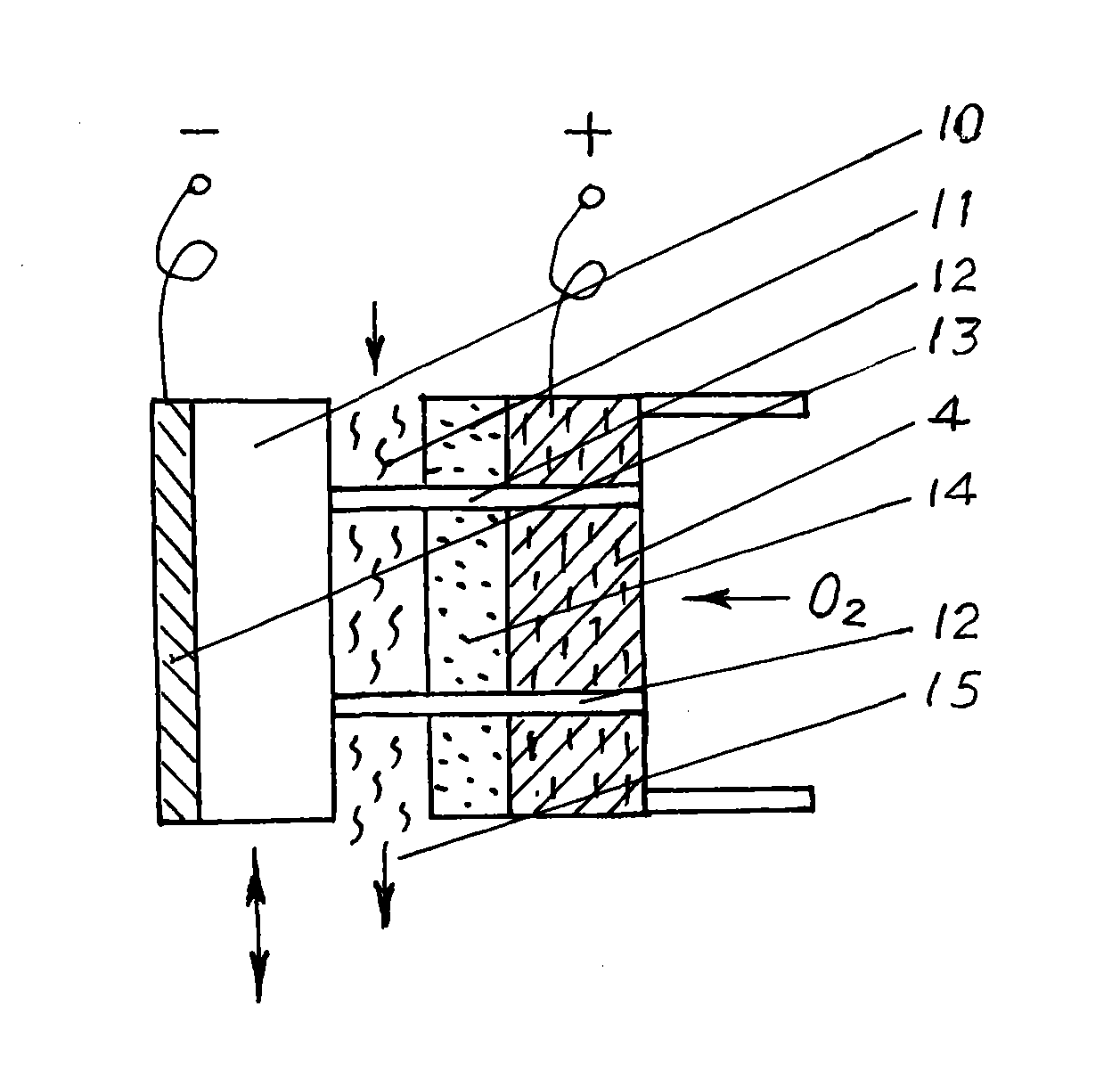

[0028] The present invention can have various implementations, and four implementations thereof are introduced below.

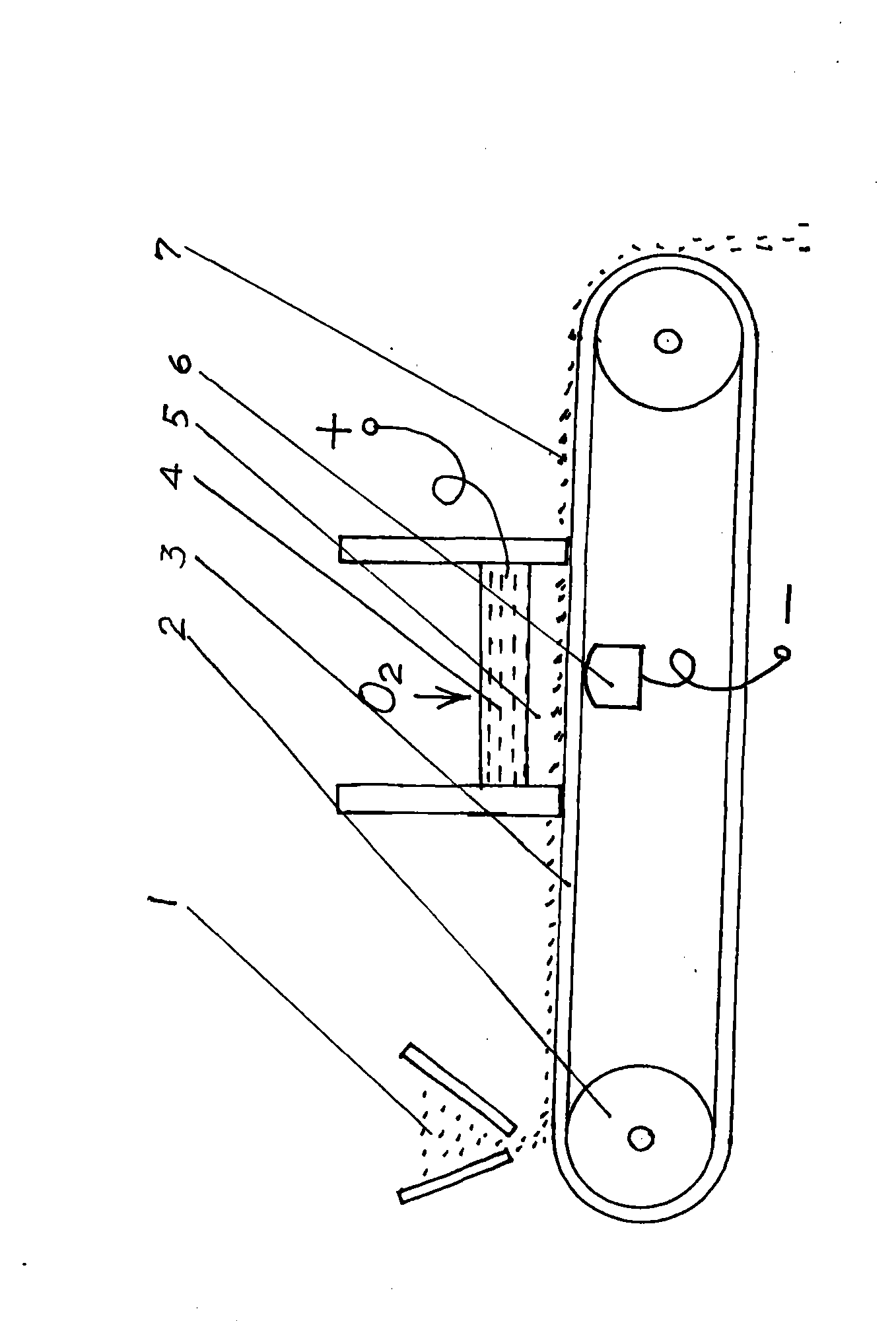

[0029] Option 1: It is a lithium-air battery with powder particles back to oxygen, see figure 1 . The working principle has been introduced in the section of the invention, and the key to its implementation is:

[0030] 1. The diameter of lithium powder is twice that of oxygen ion

[0031] 2. The concentration of oxygen ions in the oxygen ion chamber should be as high as possible.

[0032] 3. The distance between the catalytic layer and lithium powder should be as small as possible.

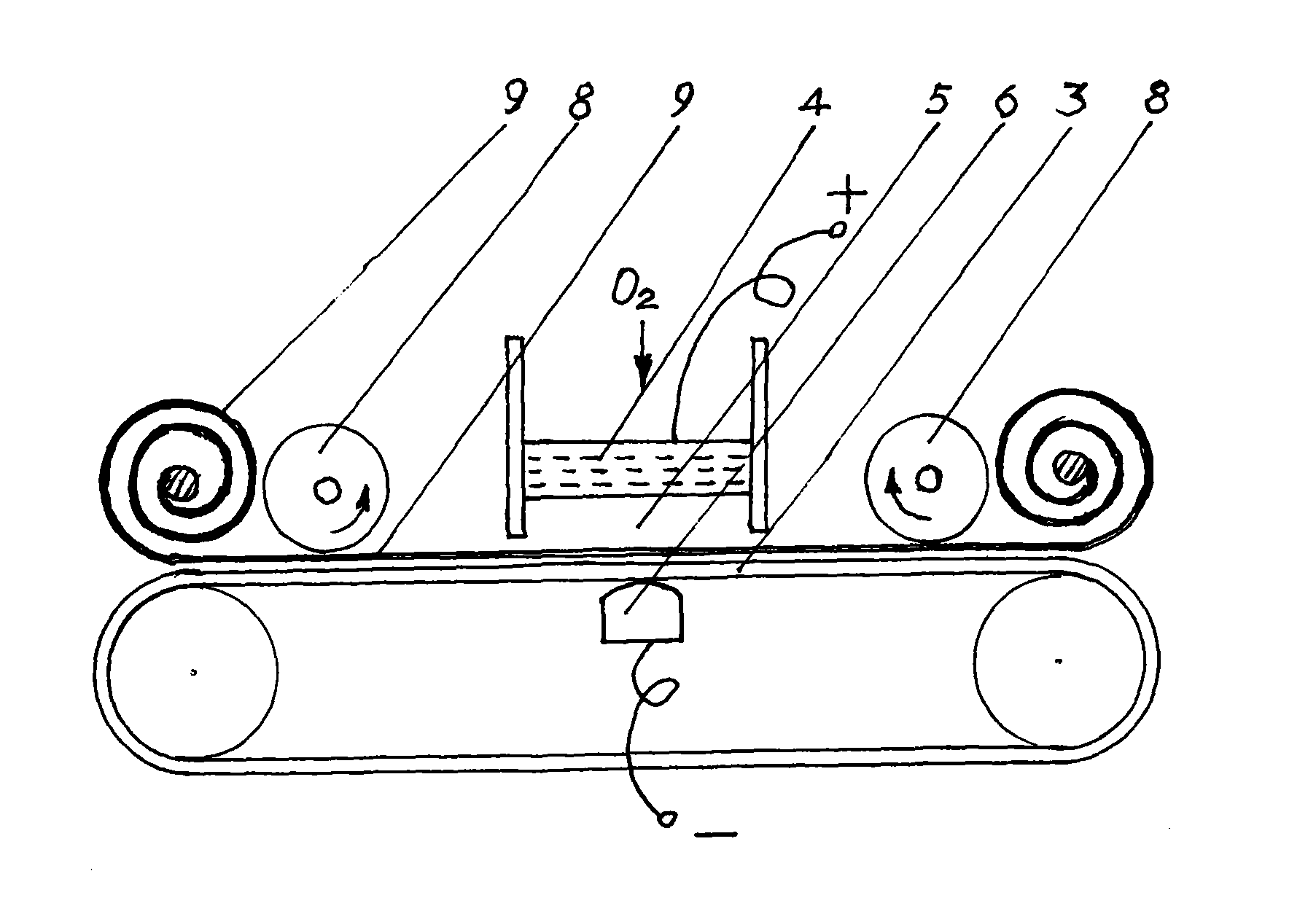

[0033] Option 2: Lithium brings back the oxygen-lithium-air battery, see figure 2 .Its working principle is to press lithium metal into a ribbon (9), enter the oxygen anion chamber (4) like lithium powder, and let the lithium positive ions on the surface of the lithium belt combine with the oxygen anions to form Li 2 O. Li 2 O must be attached to the lithium band surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com