Hollow graphene ball and preparation method and application thereof

A graphene sphere and hollow technology, applied in the field of hollow graphene sphere and its preparation, can solve the problems of low yield, complex preparation process, poor electrochemical performance, etc., and achieve high yield, good controllability, excellent The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A preparation method of hollow graphene spheres, comprising the steps of:

[0056] (1) 0.4g SiO 2 Powder (average particle size 15nm) and 0.1g graphene oxide were dispersed in 200mL deionized water, and ultrasonically dispersed for 30min to obtain a dispersed suspension;

[0057] (2) Spray-dry the dispersed suspension with an inlet temperature of 200°C and an outlet temperature of 110°C to obtain a precursor; the precursor is graphene oxide-wrapped SiO 2 powder compound;

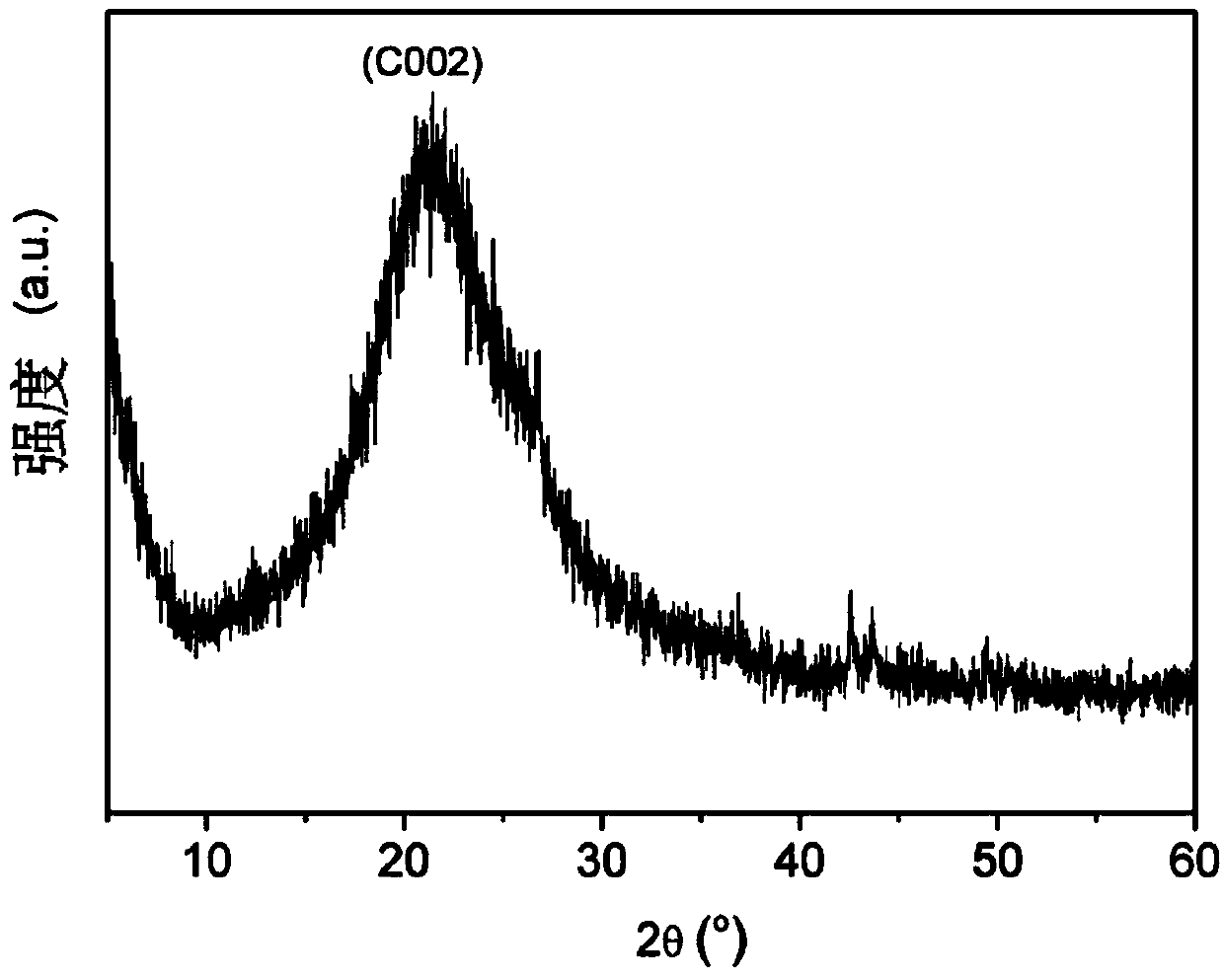

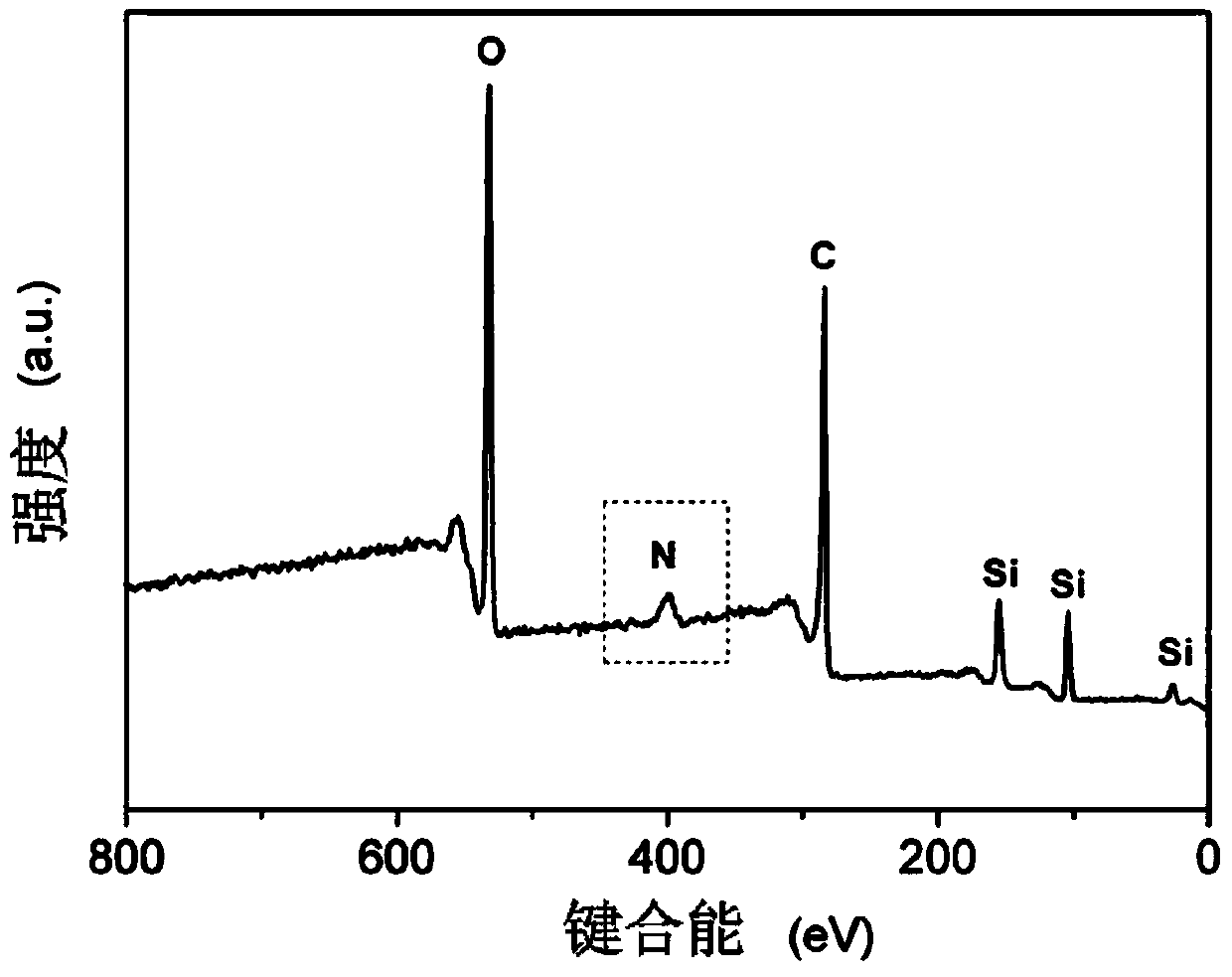

[0058] (3) Place the precursor in a high-temperature furnace, feed a mixed gas of ammonia and argon, the volume content of ammonia in the mixed gas of ammonia and argon is 10%, and the temperature is 10°C min -1 The heating rate is increased to 1100°C for reduction treatment, and then directly cooled to room temperature without heat preservation to obtain the reduced product;

[0059] (4) Mix the reducing substance with hydrofluoric acid to SiO 2 Dissolve completely; collect the solid matter remai...

Embodiment 2

[0065] A preparation method of hollow graphene spheres, comprising the steps of:

[0066] (1) Add 0.1g Fe 2 o 3 Disperse the powder (particle size 50-100nm) and 0.1g graphene oxide in 100mL methanol, and ultrasonically disperse for 60min to obtain a dispersed suspension;

[0067] (2) Spray-dry the dispersed suspension with an inlet temperature of 220°C and an outlet temperature of 140°C to remove methanol to obtain a precursor, which is graphene oxide-wrapped Fe 2 o 3 powder compound;

[0068] (3) Put the precursor in a high-temperature furnace, feed a mixed gas of hydrogen and argon, the volume content of hydrogen in the mixed gas of hydrogen and argon is 5%, raise the temperature to 300° C. for reduction treatment, keep the temperature for 5 hours, and then Cool naturally to room temperature to obtain the reduced product;

[0069] (4) Mix the reducing substance with concentrated hydrochloric acid until Fe 2 o 3 Dissolve completely, collect the solid matter remaining a...

Embodiment 3~ Embodiment 5

[0075] Each step in the preparation method of Examples 3 to 5 is the same as that of Example 1, wherein different process conditions are listed in Table 1, and other conditions not listed are the same as Example 1.

[0076] Process condition in table 1 embodiment 3~5

[0077]

[0078] The hollow graphene spheres obtained in Examples 3 to 5 have similar morphology and electrochemical properties to the samples in Examples 1 and 2.

[0079] It can be seen from the above examples that the present invention uses a simple method of atomization drying combined with etching technology to prepare hollow graphene spheres as the positive electrode material for lithium-air batteries. The surface and interior of the product obtained by this method have different levels of pores, and the pore size ratio can be controlled and adjusted through the particle size and dispersion state of the powder. The porous surface and hollow structure facilitates the entry of oxygen into the air electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com