A kind of ultra-thin secondary battery and preparation method thereof

A secondary battery, ultra-thin technology, applied in the field of electrochemistry, can solve the problems of low product yield, difficult to roll, difficult to thin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Preparation of conductive layer slurry: Super-P and PVDF were dissolved in NMP (N,N-dimethylpyrrolidone) at a mass ratio of 90:10 to form a stable conductive layer slurry.

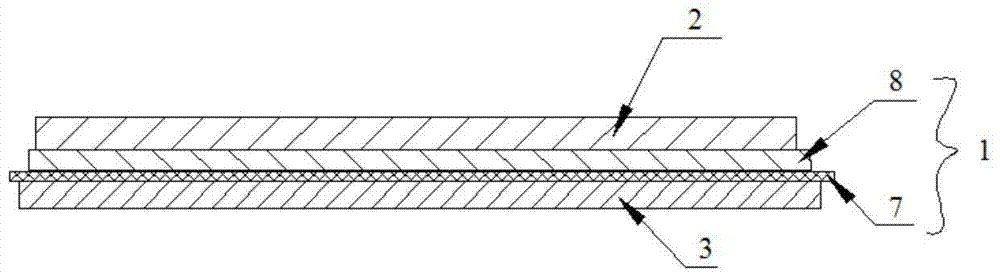

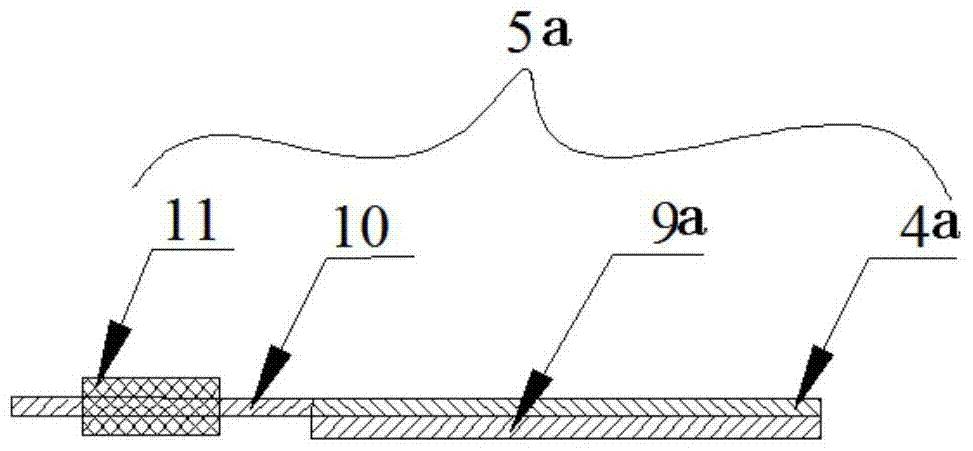

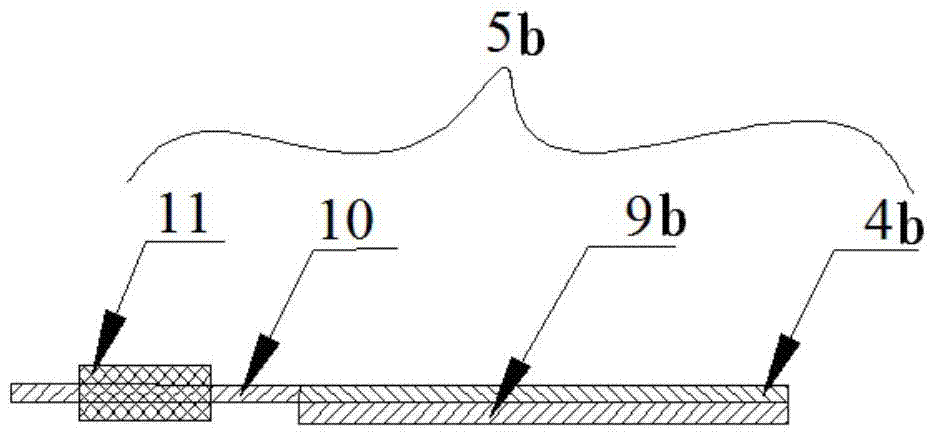

[0090] Preparation of the separator: use PP as the substrate (7), coat the prepared conductive layer slurry on one side of the substrate, and dry in an oven to obtain a functional separator. The thickness of the conductive layer after drying is 10 μm. For the convenience of expression, the side coated with the functional coating is represented as A side (that is, the side with the conductive layer (8) is A side), and the other side is B side.

[0091] Preparation of positive electrode membrane: LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2(nickel cobalt lithium manganese oxide), Super-P (conductive carbon black), PVDF (polyvinylidene fluoride) mixed with NMP (N,N-dimethylpyrrolidone) at a mass ratio of 94:2:4 and stirred evenly to obtain a positive electrode The slurry coated on the pole piece has a solid content ...

Embodiment 2

[0101] Preparation of conductive layer slurry: carbon nanotubes and PVDF were dissolved in NMP (N,N-dimethylpyrrolidone) at a mass ratio of 90:10 to form a stable conductive layer slurry.

[0102] Preparation of the separator: use non-woven fabric as the substrate (7), coat the prepared conductive layer slurry on one side of the substrate, and dry it in an oven to obtain a functional separator. The thickness of the conductive layer after drying is 10 μm, for the convenience of expression, the side coated with the functional coating is represented as the A side (that is, the side with the conductive layer (8) is the A side), and the other side is the B side.

[0103] Preparation of cathode diaphragm: LiCoO 2 (Lithium cobaltate), CNT (carbon nanotube), PVDF (polyvinylidene fluoride) are mixed with NMP (N,N-dimethylpyrrolidone) according to the mass ratio of 98:1:1, and stirred evenly to obtain the positive electrode sheet coating Cloth slurry, the slurry viscosity is 72%. Then...

Embodiment 3

[0113] Preparation of conductive layer slurry: carbon nanotubes and PVDF were dissolved in NMP (N,N-dimethylpyrrolidone) at a mass ratio of 90:10 to form a stable conductive layer slurry.

[0114] Preparation of diaphragm: use PE as the substrate (7), coat the prepared conductive layer slurry on one side of the substrate, and dry in an oven to obtain a functional diaphragm. The thickness of the conductive layer after drying is 10 μm. For the convenience of expression, the side coated with the functional coating is represented as A side (that is, the side with the conductive layer (8) is A side), and the other side is B side.

[0115] Preparation of positive electrode membrane: LiFePO 4 (lithium iron phosphate), Super-P (conductive carbon black), PVDF (polyvinylidene fluoride) are mixed with NMP (N,N-dimethylpyrrolidone) at a mass ratio of 91:3:6, and stirred evenly to obtain a positive electrode Sheet-coated slurry with a solids content of 45%. Then the slurry is evenly coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com