Palygorskite/aluminum oxide composite lithium ion battery coating diaphragm and preparation method thereof

A technology of ion battery and alumina, which is applied in the direction of secondary battery, battery pack parts, separator/film/diaphragm/spacer element, etc. It can solve the problems of high price, high price and small specific surface area of coated diaphragm , to achieve the effect of improving market competitiveness and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

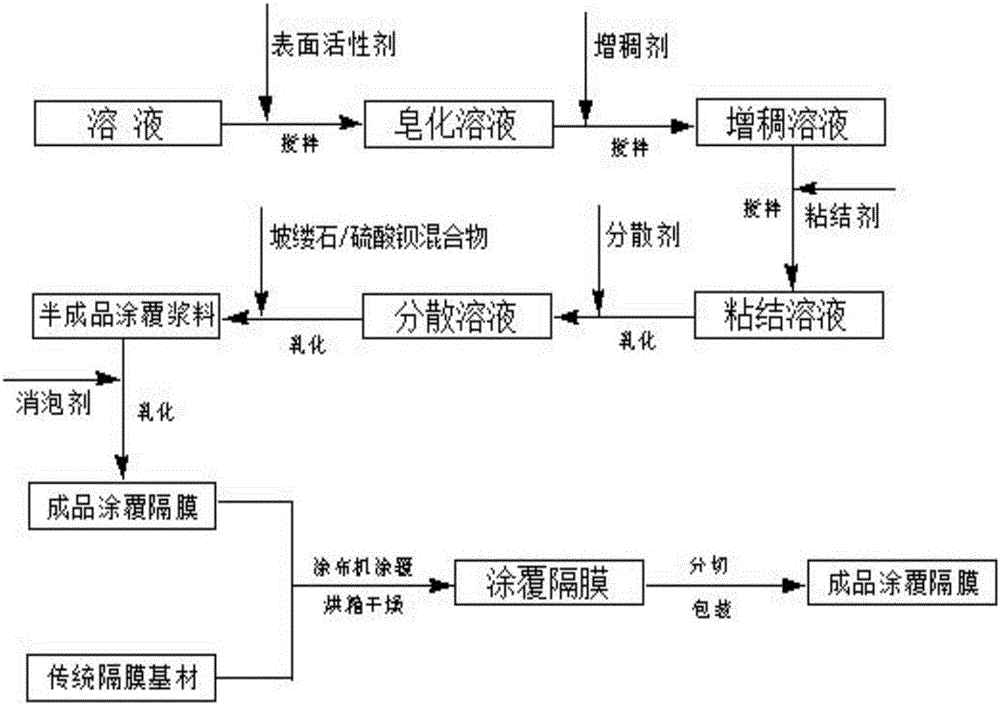

Method used

Image

Examples

Embodiment 1

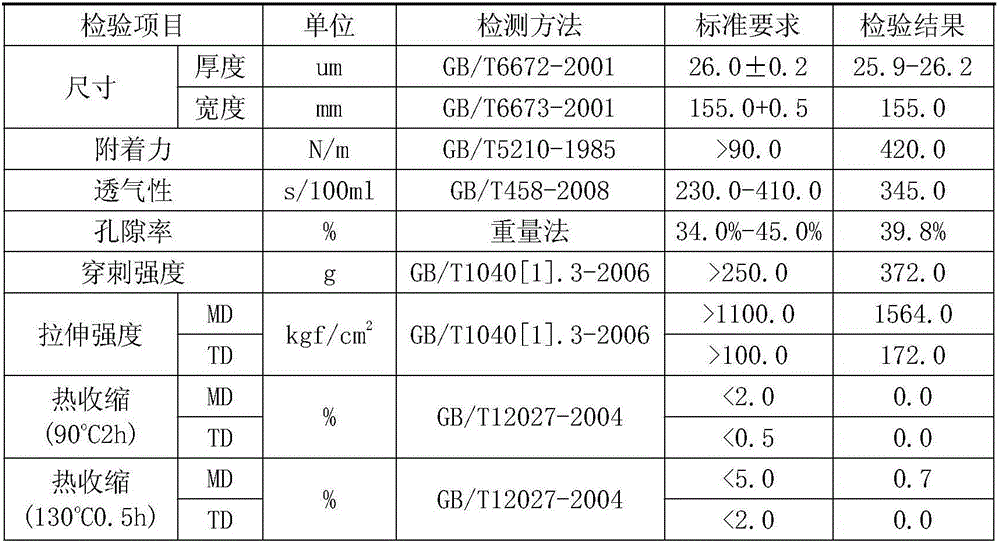

[0029] The palygorskite / alumina composite lithium-ion battery coating diaphragm of the present embodiment uniformly coats a layer of palygorskite / alumina slurry on the surface of the lithium-ion battery separator substrate, and the palygorskite / alumina slurry The material is made of the following raw materials in mass percentage: surfactant 1.2%, thickener 0.8%, binder 10.0%, dispersant 0.4%, β-palygorskite / alumina mixture 35.0%, defoamer 5.6% , solution 47.0%.

[0030] In this embodiment, the mass of palygorskite in the β-palygorskite / alumina mixture is 50.0% of the mass of β-alumina, and the particle diameters of the palygorskite and β-alumina are both 600-700 nm.

[0031] In this embodiment, the surfactant is fatty acid glyceride.

[0032] In this embodiment, the thickener is sodium carboxymethyl cellulose.

[0033] In this embodiment, the binder is battery grade LA133, and the solution is deionized water.

[0034] In this embodiment, the dispersant is TH-904 dispersant....

Embodiment 2

[0046] The palygorskite / alumina composite lithium-ion battery coating separator of the present embodiment is coated with a layer of palygorskite / alumina slurry on the surface of the lithium-ion battery separator substrate, and the palygorskite / alumina slurry is Made from the following raw materials in mass percent: 1.0% surfactant, 0.8% thickener, 10.0% binder, 0.2% dispersant, 40.0% palygorskite / alumina mixture, 5.0% defoamer, solution 43 %.

[0047] In this embodiment, the mass of palygorskite in the α-palygorskite / alumina mixture is 40.0% of the mass of α-alumina, and the particle diameters of the palygorskite and α-alumina are both 500-600 nm.

[0048] In this embodiment, the surfactant is a mixed surfactant of fatty acid glyceride and fatty acid sorbitan.

[0049] In this embodiment, the thickener is xanthan gum.

[0050] In this embodiment, the binder is a mixed binder of battery grade styrene-butadiene rubber emulsion and LA132, and the solution is deionized water.

...

Embodiment 3

[0063] The palygorskite / alumina composite lithium-ion battery coating separator of the present embodiment is coated with a layer of palygorskite / alumina slurry on the surface of the lithium-ion battery separator substrate, and the palygorskite / alumina slurry is Made from the following raw materials in mass percentage: 1.2% surfactant, 0.6% thickener, 7.0% binder, 0.2% dispersant, 27.8% palygorskite / alumina mixture, 3.2% defoamer, 60.0% solution %.

[0064] In this embodiment, the mass of palygorskite in the β-palygorskite / alumina mixture is 30.0% of the mass of β-alumina, and the particle diameters of the palygorskite and β-alumina are both 500-700 nm.

[0065] In this embodiment, the surfactant is polyethylene glycol monooctylphenyl ether.

[0066] In this embodiment, the thickener is a mixed thickener of sodium carboxymethylcellulose and xanthan gum.

[0067] In this embodiment, the binder is battery grade LA132, and the solution is deionized water.

[0068] In this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com