Method for improving uniform heat dispersion performance of lithium ion battery electrode piece

A lithium-ion battery, uniform heat dissipation technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc. The effect of stable performance, extended service life and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

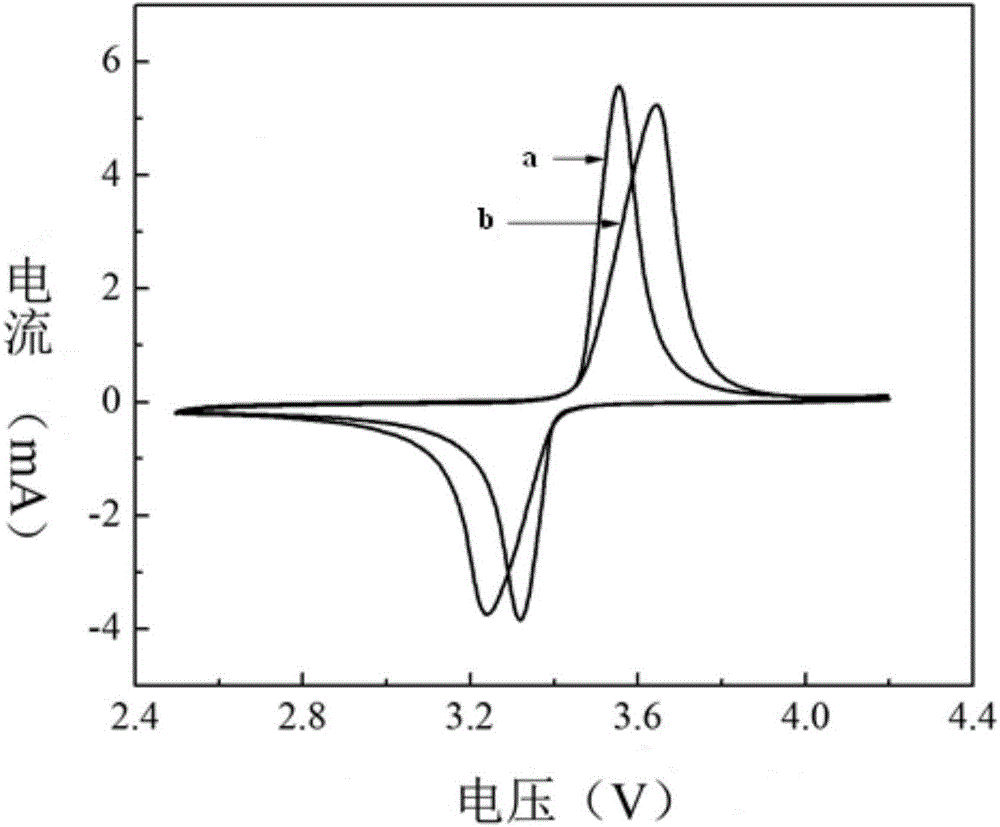

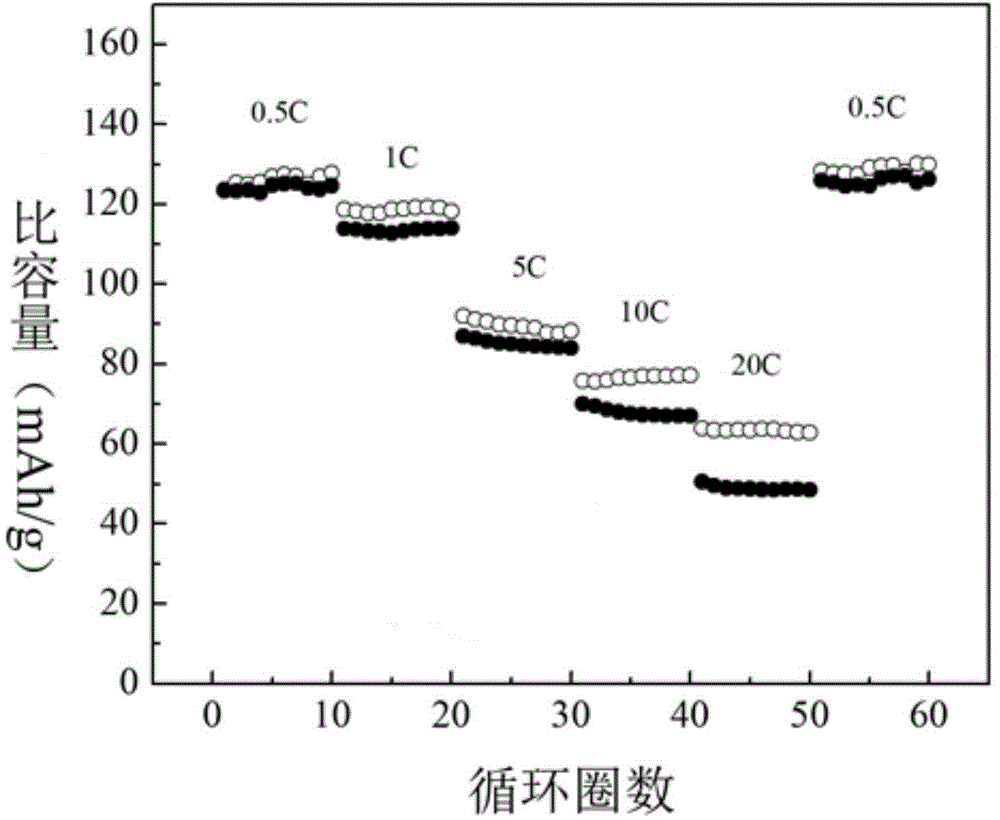

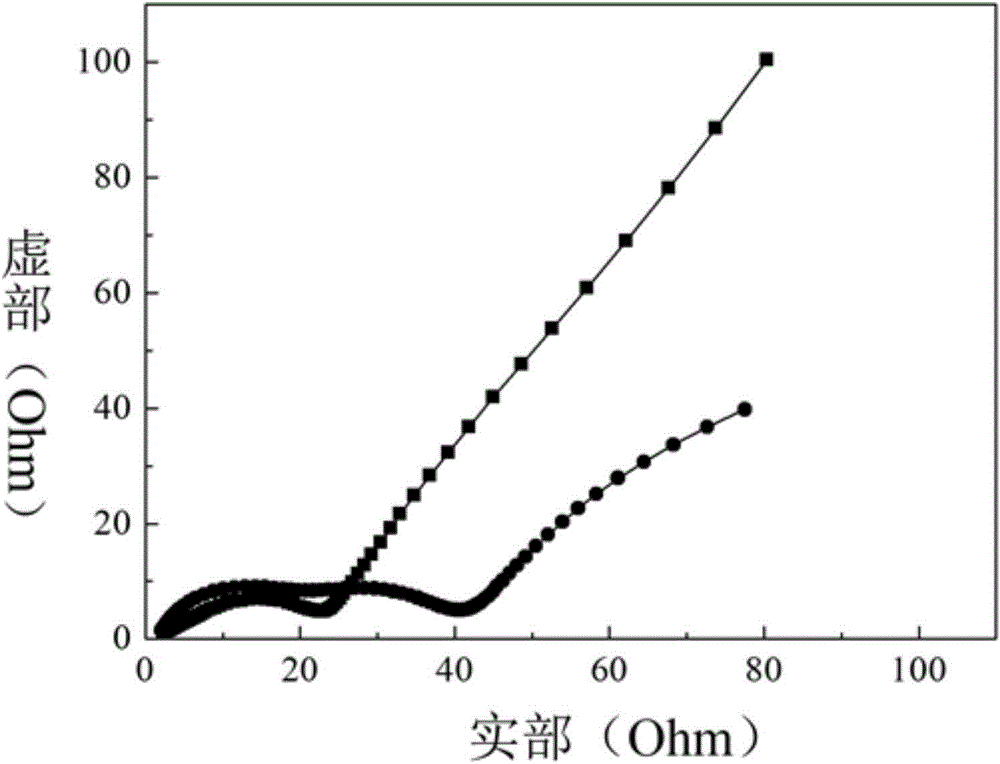

[0020] Embodiment 1: The method of this embodiment to improve the uniform heat dissipation performance of lithium-ion battery pole pieces is specifically to use flexible graphite paper instead of aluminum foil and copper foil in lithium-ion batteries as a current collector for loading active materials of electrode materials.

[0021] In this embodiment, the ultra-thin flexible graphite paper is used as the current collector of the positive and negative electrodes of the lithium-ion battery, so as to completely replace the traditional metal current collectors such as copper foil and aluminum foil. Utilizing the ultra-high thermal conductivity of ultra-thin flexible graphite paper in the xy direction of the plane, the heat at the hot spot of the electrode sheet is quickly and evenly dispersed during charging and discharging, thereby eliminating the hot spot and achieving the purpose of uniform temperature distribution of the battery core, thereby avoiding Local overheating leads ...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment is different from Embodiment 1 in that: the thickness of the flexible graphite paper is 0.01-1.0 mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment is different from Embodiment 1 in that: the thickness of the flexible graphite paper is 0.015-0.025 mm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com