Preparation method of positive pole material of thermal battery

A technology of positive electrode material and thermal battery, applied in the field of preparation of positive electrode material of thermal battery, can solve the problems of low monomer voltage, uncertain preparation process, unqualified battery quality, etc., to improve electrical conductivity and thermal conductivity, improve electrochemical Activity, the effect of low equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

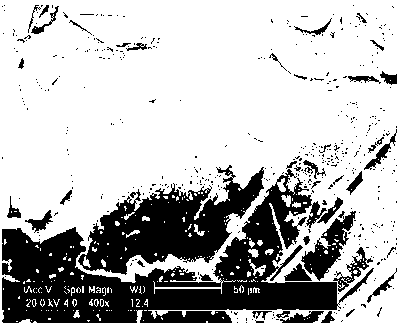

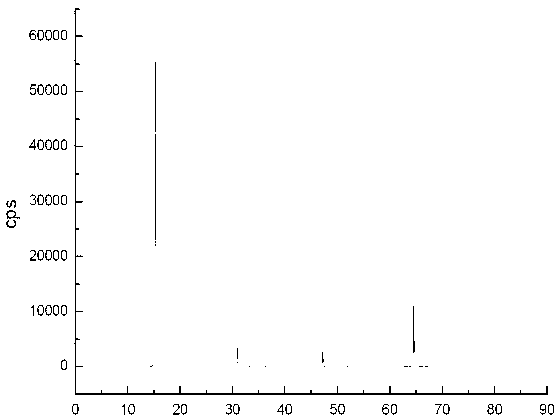

Image

Examples

Embodiment 1

[0038] ⑴ Blast drying:

[0039] Put the commercially available nickel chloride hexahydrate with an analytically pure nickel chloride content of not less than 98% by mass in a blast drying oven for drying at a drying temperature of 140°C and a drying time of 32 hours; naturally cool to below 40°C, In the drying room with a relative humidity of ≤4%, the material is pulverized by a pulverizer and passed through a 80-mesh sieve;

[0040] ⑵ Vacuum drying:

[0041] Put the sieved material in (1) into a vacuum drying oven with a relative vacuum degree ≤ -0.095MPa for vacuum drying at a drying temperature of 140°C for 32 hours;

[0042] ⑶ High temperature treatment:

[0043] Put the vacuum-dried nickel chloride dry powder in a quartz tube with a diameter of 100 mm and a length of 800 mm. Each quartz tube is filled with about 1 kg of material, and placed in a crucible resistance furnace for high-temperature treatment at a temperature of 750 ° C and a time of 8 hours. The nickel mate...

Embodiment 2

[0052] ⑴ Blast drying:

[0053] Put commercially available nickel chloride hexahydrate with an analytically pure nickel chloride content of not less than 98% by mass in a blast drying oven for drying at a drying temperature of 160°C for 24 hours; naturally cool to below 40°C, In the drying room with a relative humidity of ≤4%, the material is pulverized by a pulverizer and passed through a 80-mesh sieve;

[0054] ⑵ Vacuum drying:

[0055] Put the sieved material in (1) into a vacuum drying oven with a relative vacuum degree ≤ -0.095MPa for vacuum drying at a drying temperature of 160°C for 24 hours;

[0056] ⑶ High temperature treatment:

[0057]Put the vacuum-dried nickel chloride dry powder in a quartz tube with a diameter of 100 mm and a length of 800 mm. Each quartz tube is filled with about 1 kg of material, and placed in a crucible resistance furnace for high-temperature treatment at a temperature of 650 ° C and a time of 8 hours. The nickel material removes water and...

Embodiment 3

[0067] ⑴ Blast drying:

[0068] Put the commercially available nickel chloride hexahydrate with an analytically pure nickel chloride content of not less than 98% by mass in a blast drying oven for drying at a drying temperature of 120°C and a drying time of 40 hours; naturally cool to below 40°C, In the drying room with a relative humidity of ≤4%, the material is pulverized by a pulverizer and passed through a 80-mesh sieve;

[0069] ⑵ Vacuum drying:

[0070] Put the sieved material in (1) into a vacuum drying oven with a relative vacuum degree ≤ -0.095MPa for vacuum drying at a drying temperature of 120°C for 40 hours;

[0071] ⑶ High temperature treatment:

[0072] Put the vacuum-dried nickel chloride dry powder in a quartz tube with a diameter of 100 mm and a length of 800 mm. Each quartz tube is filled with about 1 kg of material, and placed in a crucible resistance furnace for high-temperature treatment at a temperature of 850 ° C and a time of 8 hours. The nickel mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com