Bipolar battery pole plate and preparation method thereof

A bipolar battery, bipolar plate technology, applied in the direction of lead-acid battery electrodes, lead-acid batteries, lead-acid battery construction, etc. high power characteristics of non-polar batteries, corrosive perforation of bipolar grids, etc., to achieve the effect of light weight, high mechanical strength, and high charge and discharge power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

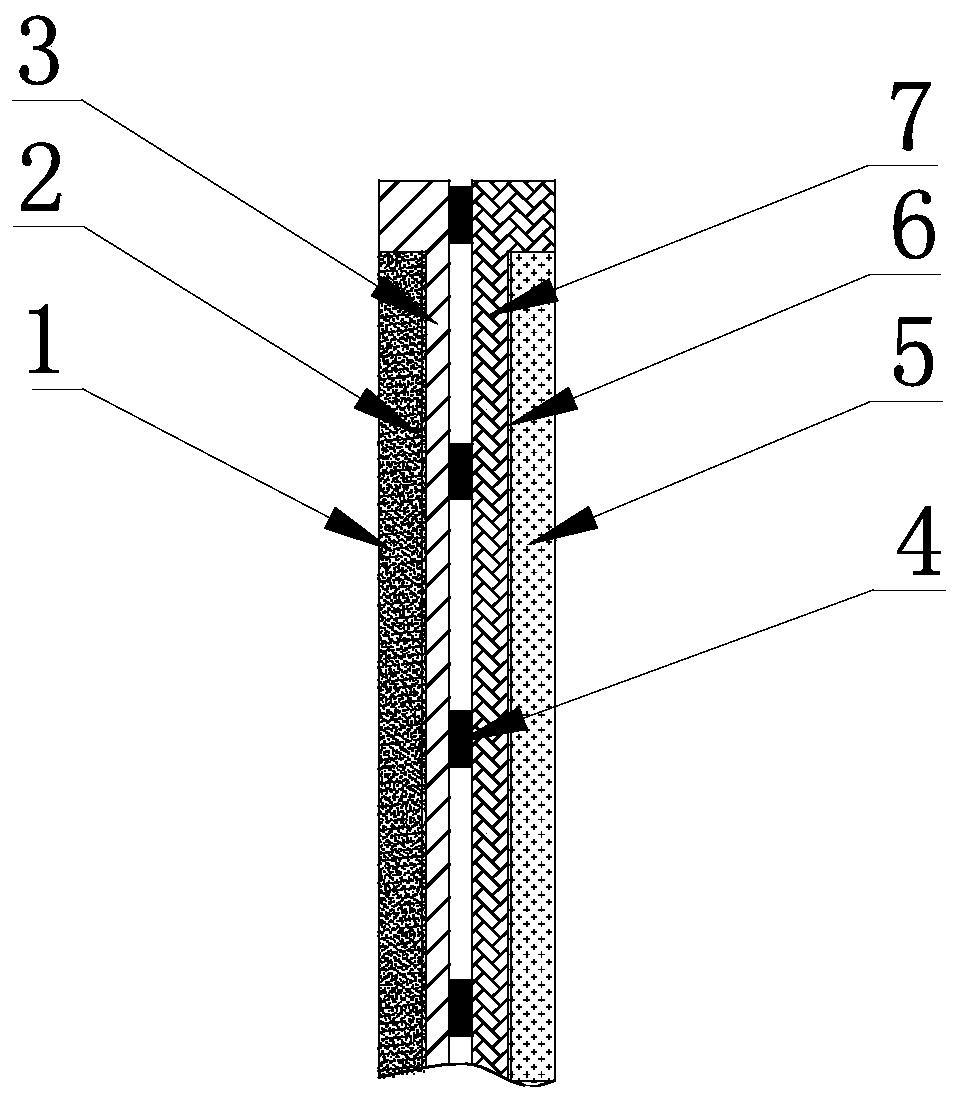

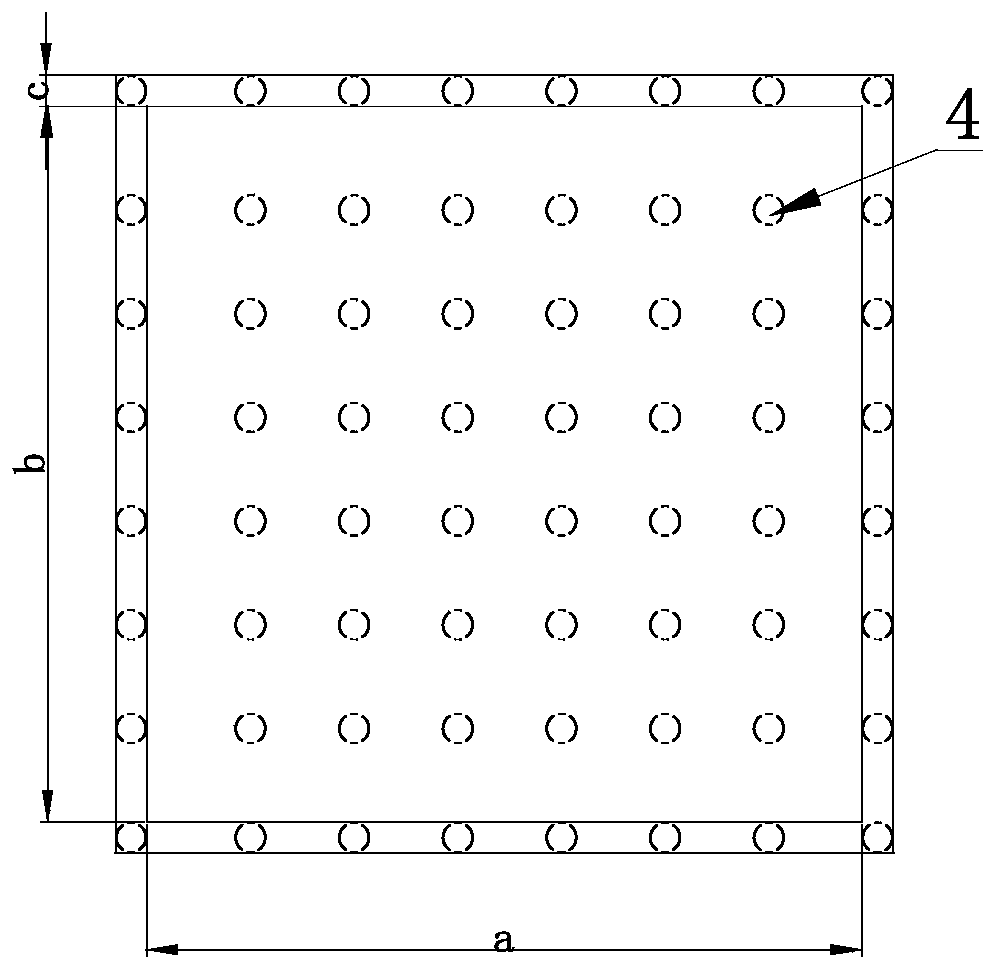

[0044] Such as Figure 1~2 As shown, a bipolar battery plate includes a bipolar grid, and the bipolar grid is composed of a titanium foil 3 and a copper plate 7, and one side of the titanium foil 3 and the copper plate 7 are provided with Frame, titanium foil 3 The inner bottom of the frame is electroplated with a positive lead-plated layer 2, the positive lead-plated layer 2 is coated with a positive electrode active material 1, the inner bottom of the copper plate 7 frame is electro-plated with a negative lead-plated layer 6, and the negative lead-plated layer 6 is coated with The negative electrode active material 5 , the titanium foil 3 and the other side of the copper plate 7 are connected by brazing joints 4 .

[0045] The thickness of the bottom of the titanium foil 3 is 0.1 mm, the height of the frame is 5 mm, and the width c is 6 mm; the thickness of the bottom of the copper plate 7 is 0.7 mm, the height of the frame is 5 mm, and the width c is 6 mm. The titanium foil...

Embodiment 2

[0081] Such as Figure 1~2 As shown, a bipolar battery plate includes a bipolar grid, and the bipolar grid is composed of a titanium foil 3 and a copper plate 7, and one side of the titanium foil 3 and the copper plate 7 are provided with Frame, titanium foil 3 The inner bottom of the frame is electroplated with a positive lead-plated layer 2, the positive lead-plated layer 2 is coated with a positive electrode active material 1, the inner bottom of the copper plate 7 frame is electro-plated with a negative lead-plated layer 6, and the negative lead-plated layer 6 is coated with The negative electrode active material 5 , the titanium foil 3 and the other side of the copper plate 7 are connected by brazing joints 4 .

[0082] The thickness of the bottom of the titanium foil 3 is 0.15 mm, the height of the frame is 5 mm, and the width c is 6 mm; the thickness of the bottom of the copper plate 7 is 0.7 mm, the height of the frame is 5 mm, and the width c is 6 mm. The titanium foi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com