Cathode active material and preparation method thereof and lithium ion secondary battery prepared by cathode active material

A negative electrode active material and oxide technology, applied in the field of negative electrode active material and its preparation, can solve the problems that restrict the performance of the battery, and achieve the effect of avoiding the contact short circuit of the positive and negative electrodes, dense and uniform coating layer, and reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

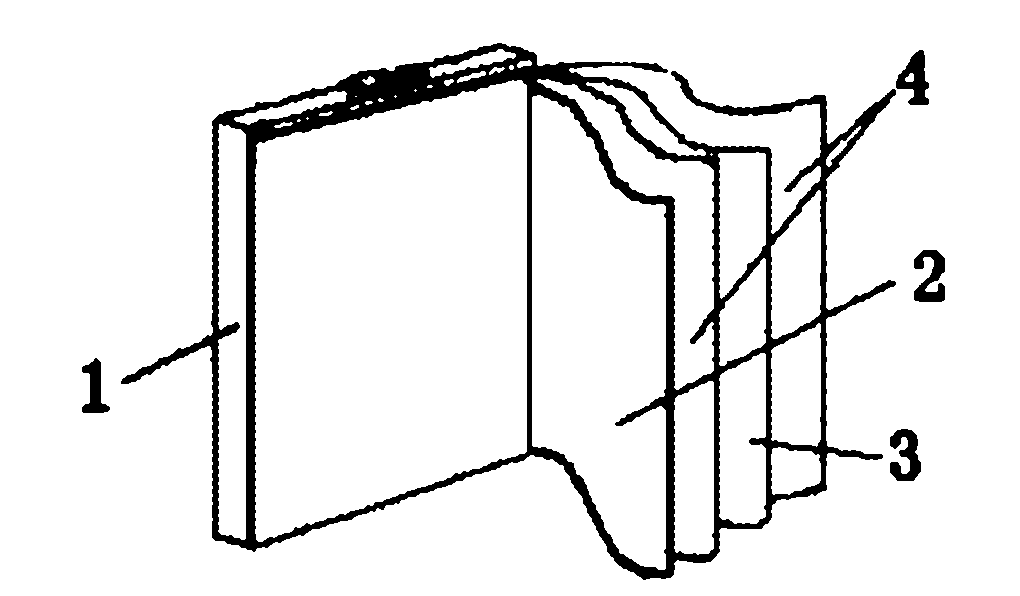

Image

Examples

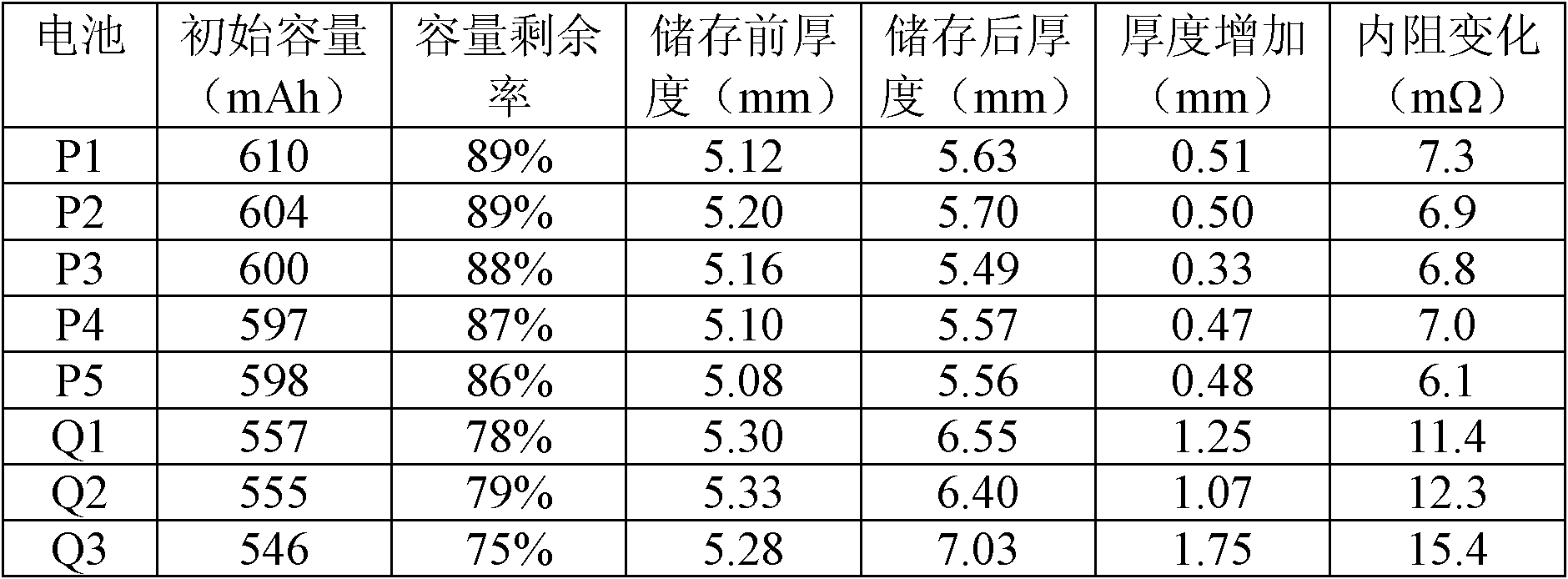

Embodiment 1

[0022] Mix spherical oxides and rod-shaped oxides to obtain mixed oxides, put the mixed oxides into a solution of N-methylpyrrolidone with a mass fraction of 4% polyvinylidene fluoride and ball mill and mix for 1 hour, then add lithium titanate and Ball milling and mixing for 3 hours to obtain a slurry, heat the slurry and stir at 170°C until the sample is dried to obtain a titanium-based composite material, the titanium-based composite material is passed through Ar or N 2 Or bake at 600° C. for 24 hours under vacuum, and then cool down to room temperature to obtain the negative electrode active material. The spherical oxide and the rod-shaped oxide are respectively zirconia. It can be purchased from a supplier, the aspect ratio (the ratio of the longest side to the thickness) of the rod-shaped oxide is 6, the particle size of the spherical oxide and the longest side of the rod-shaped oxide are 7 μm, and the mixed oxide The mass fraction of rod-shaped oxides in the product is ...

Embodiment 2

[0024] Mix spherical oxides and rod-shaped oxides to obtain mixed oxides, put the mixed oxides into a solution of N-methylpyrrolidone with a mass fraction of 4% polyvinylidene fluoride and ball mill and mix for 1 hour, then add lithium titanate and Ball milling and mixing for 3 hours to obtain a slurry, heat the slurry and stir at 170°C until the sample is dried to obtain a titanium-based composite material, the titanium-based composite material is passed through Ar or N 2 Or bake at 600° C. for 30 hours under vacuum, and then cool down to room temperature to obtain the negative electrode active material. The spherical oxide and the rod-shaped oxide are respectively magnesium oxide. Lithium titanate can be prepared by methods disclosed in the art, or It can be purchased through a supplier, the aspect ratio (the ratio of the longest side to the thickness) of the rod-shaped oxide is 2, the particle size of the spherical oxide and the longest side of the rod-shaped oxide are 10 μm...

Embodiment 3

[0026] Mix spherical oxides and rod-shaped oxides to obtain mixed oxides, put the mixed oxides into a solution of N-methylpyrrolidone with a mass fraction of 4% polyvinylidene fluoride and ball mill and mix for 1 hour, then add lithium titanate and Ball milling and mixing for 3 hours to obtain a slurry, heat the slurry and stir at 170°C until the sample is dried to obtain a titanium-based composite material, the titanium-based composite material is passed through Ar or N 2 Or bake at 600° C. for 36 hours under vacuum, and then cool down to room temperature to obtain the negative electrode active material. The spherical oxide and the rod-shaped oxide are respectively yttrium oxide, and lithium titanate can be prepared by methods disclosed in the art. It can be purchased through a supplier, the aspect ratio (the ratio of the longest side to the thickness) of the rod-shaped oxide is 4, the particle size of the spherical oxide and the longest side of the rod-shaped oxide are 0.005 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com