Patents

Literature

40results about How to "Improve the electrochemical reaction speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

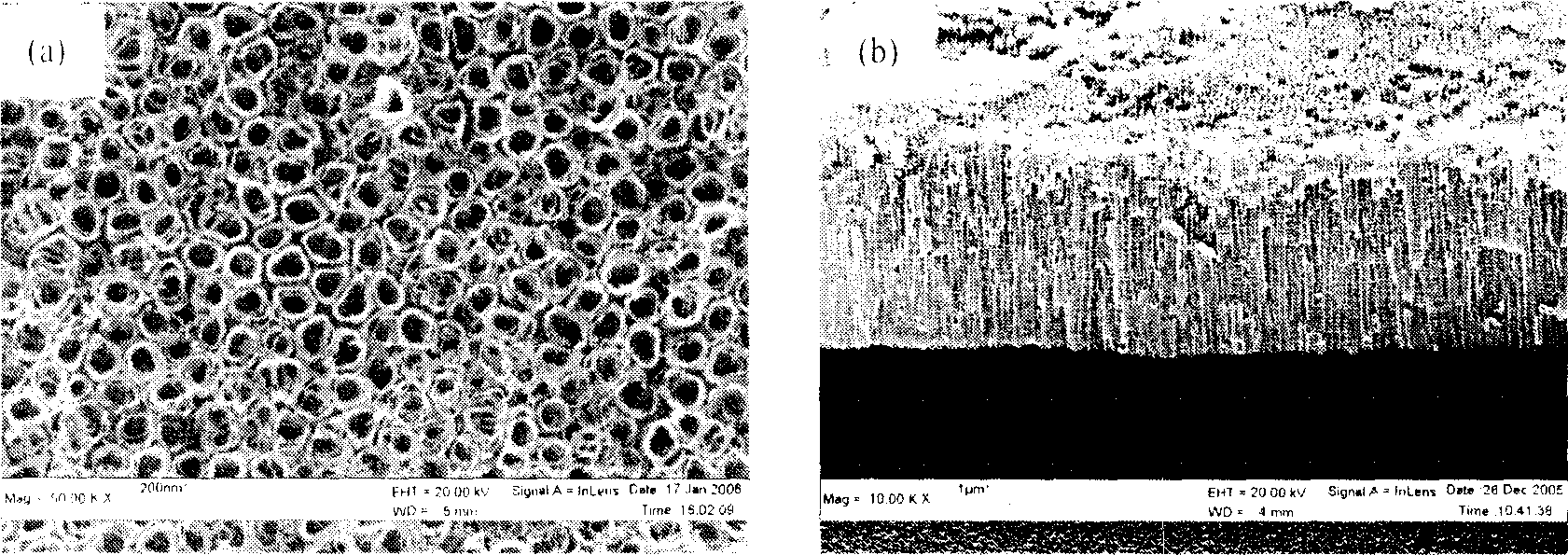

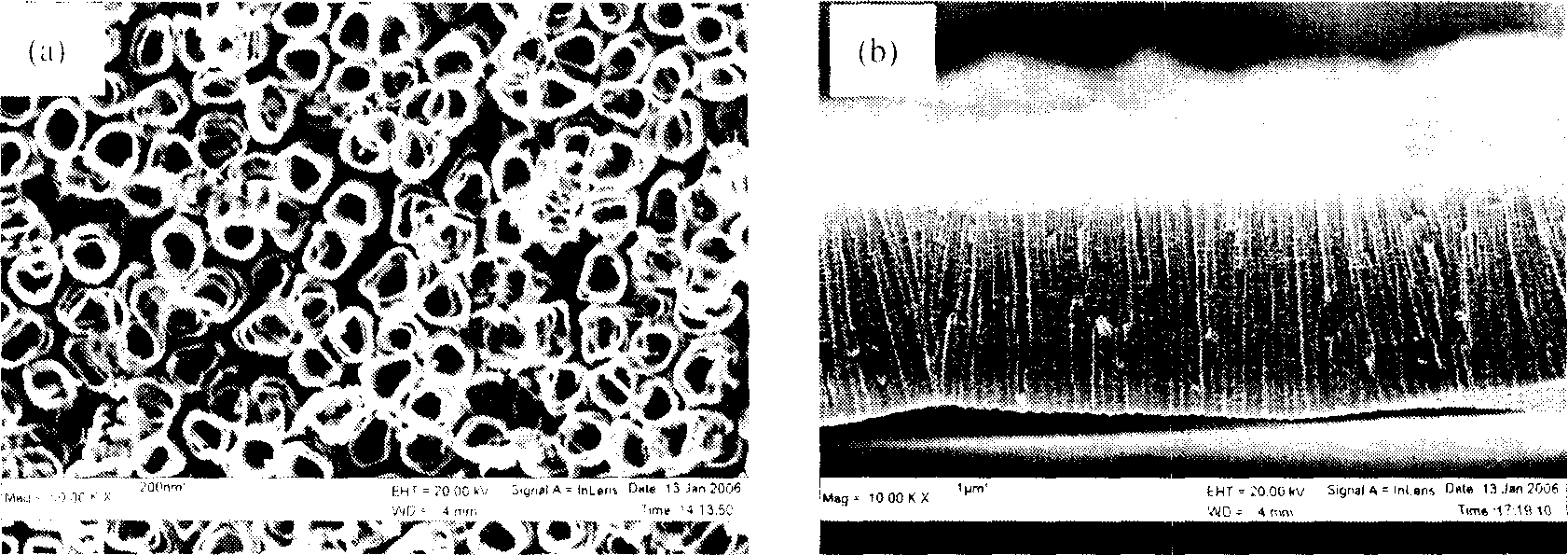

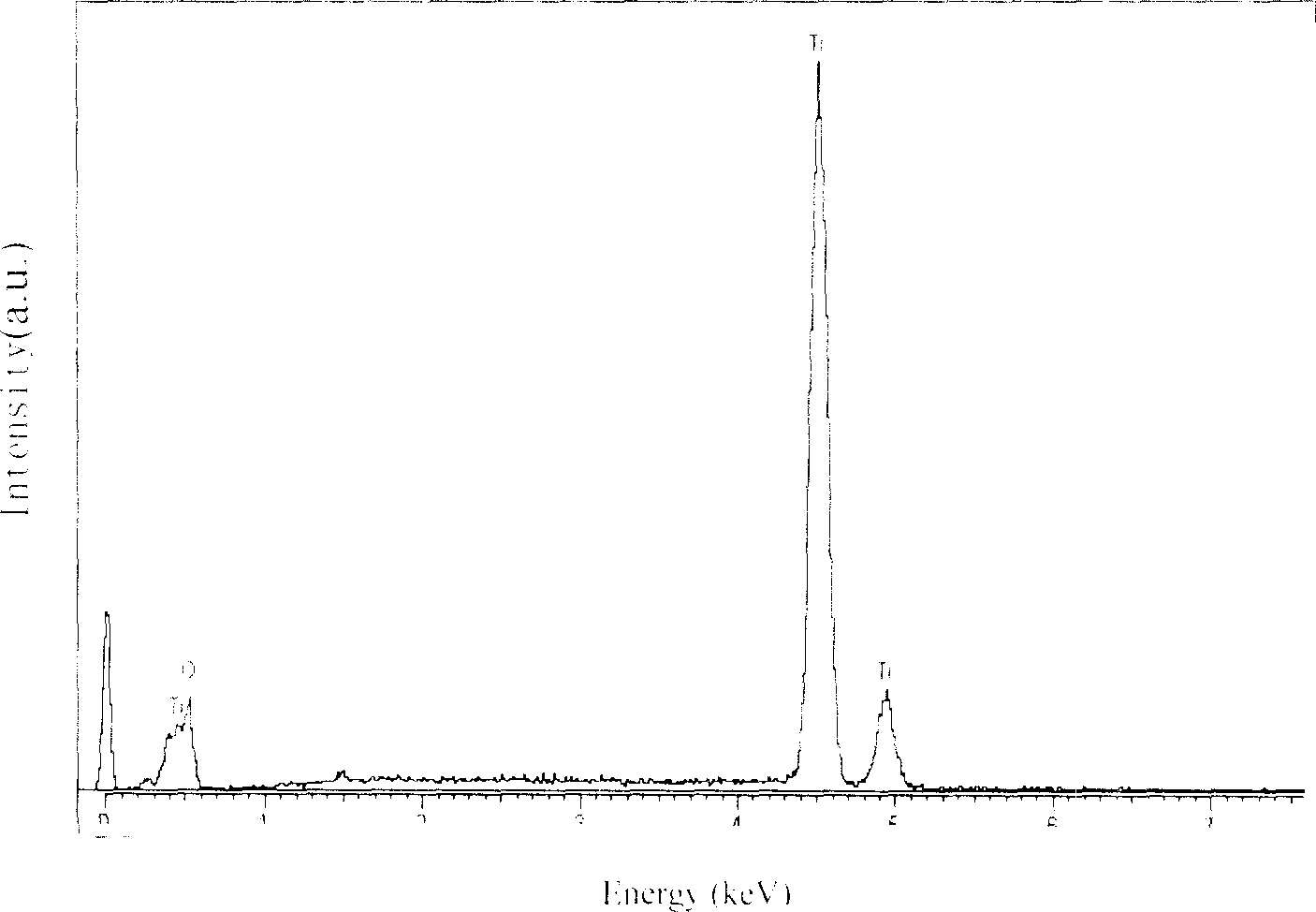

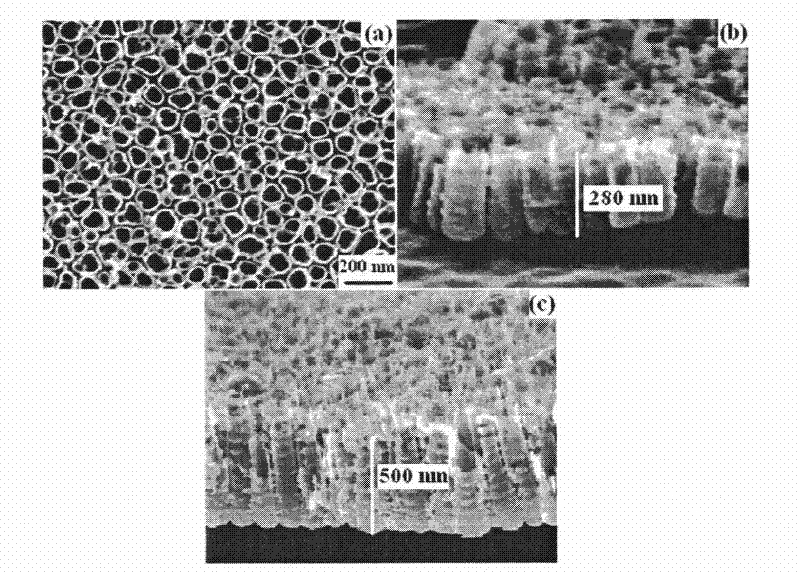

High length-diameter ratio titania nanometer tube array preparation method

InactiveCN1884630AExpand the scope ofImprove the electrochemical reaction speedNanostructure manufactureSurface reaction electrolytic coatingSolventNanotube array

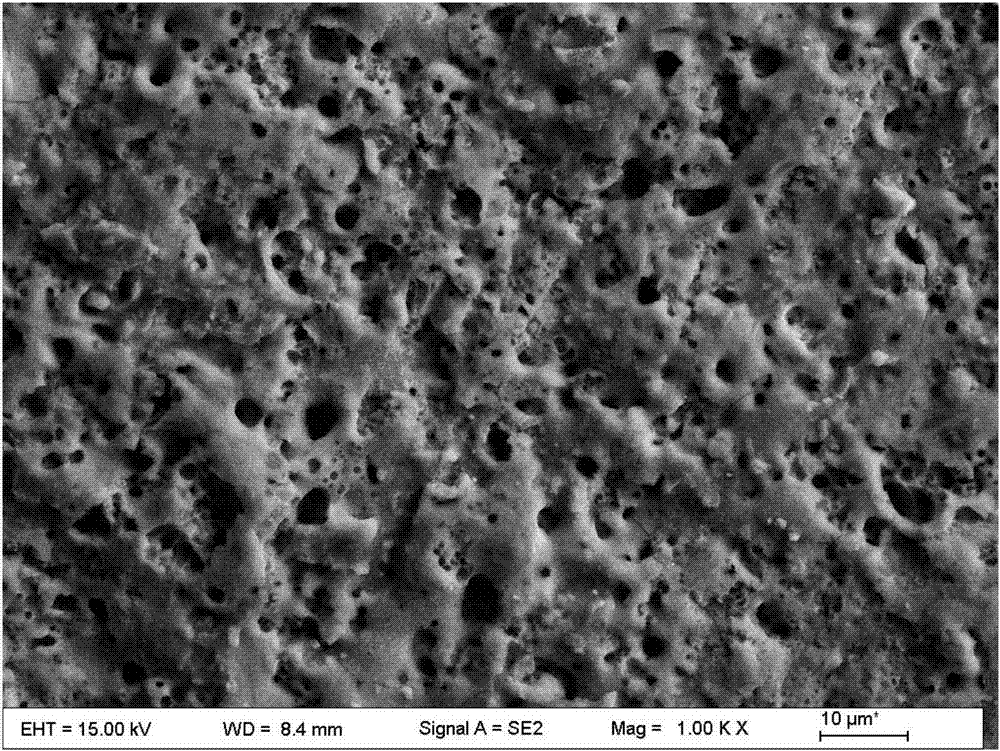

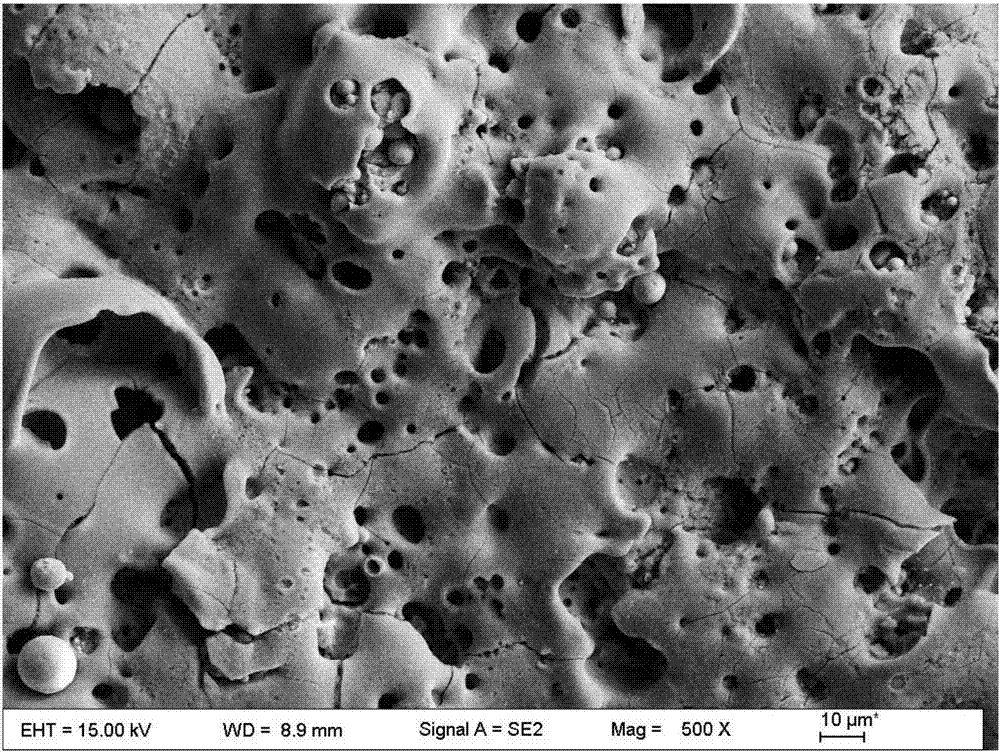

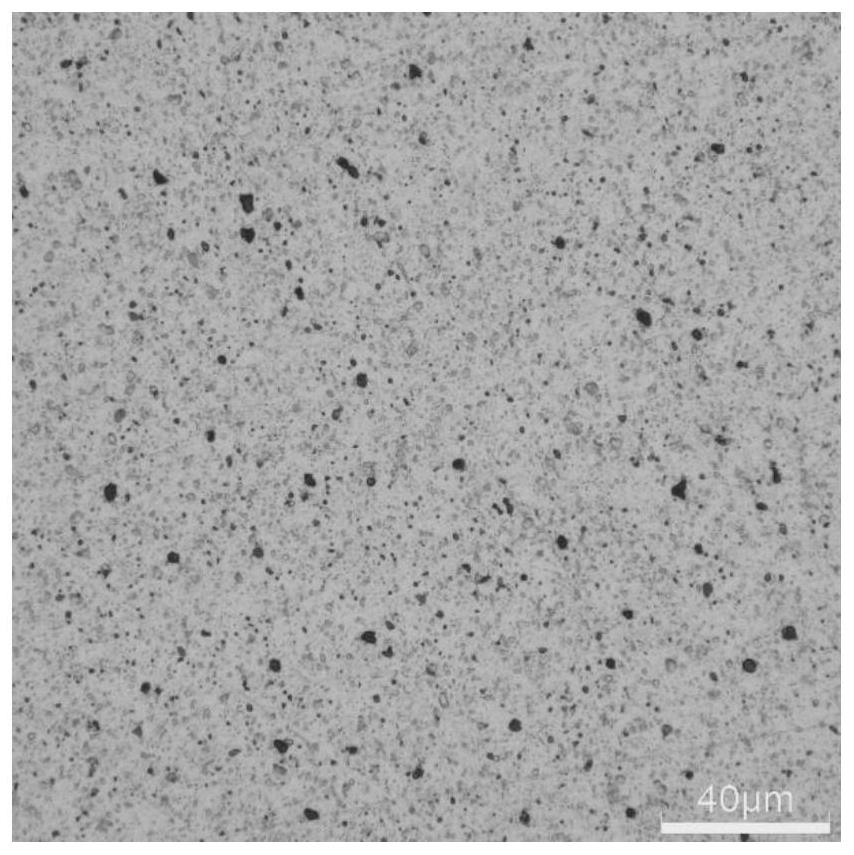

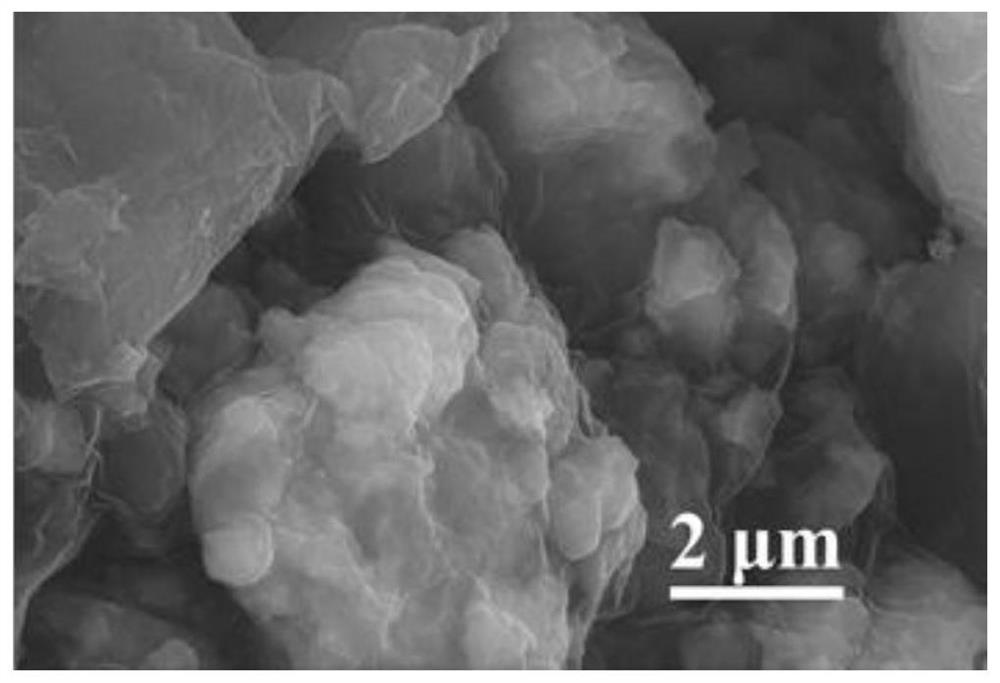

The preparation method of high aspect ratio titanium dioxide nanotube array. It uses new electrolyte that contains fluorin. By electrochemistry anodization method, it coats high aspect ratio TiO2 nanotube array on surface of metal titanium. The substrate is polished and cleaned. The solute of electrolyte is fluorid and supporting electrolyte, then adds alcohol additives. According to the weight %, the content of fluorid is 0.1% - 1% of total electrolyte; the content of supporting electrolyte is 0.4% - 4% of total electrolyte; the content of alcohol additives is 0% - 90% of total electrolyte, the remains are solvent. The metal plate can be used as electrode to anodizate. Then high aspect ratio TiO2 nanotube array film can be generated on surface of substrate.

Owner:XIAMEN UNIV

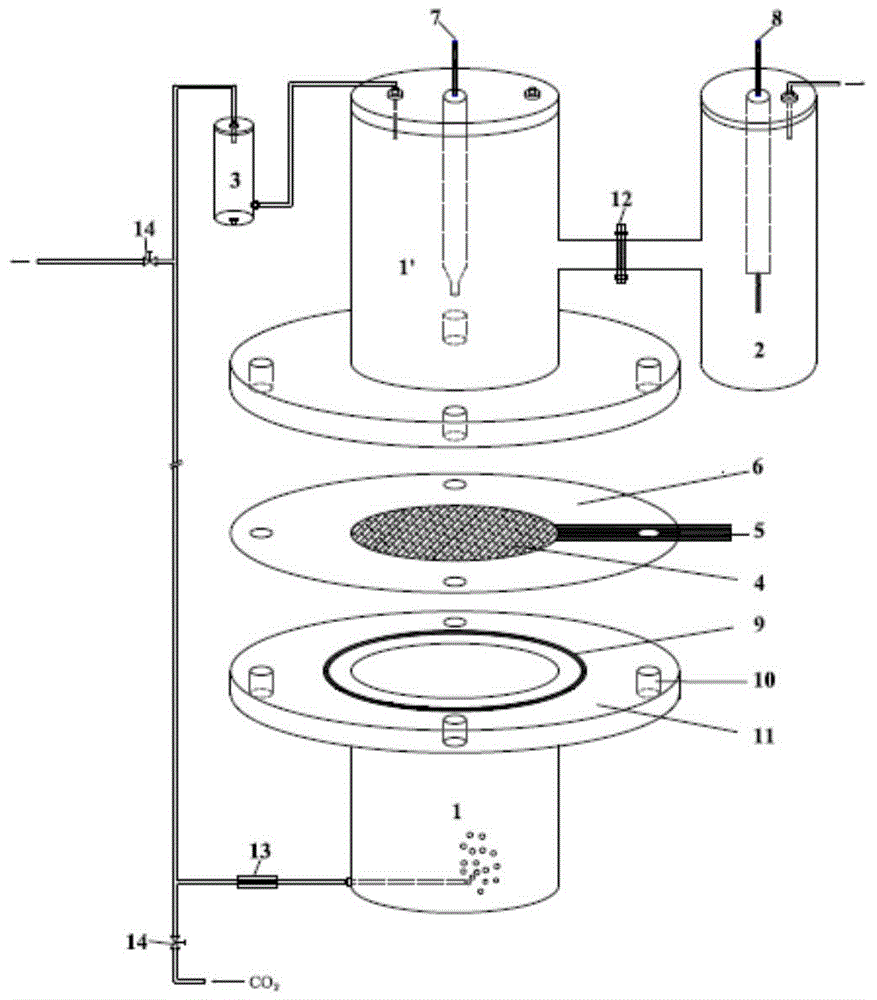

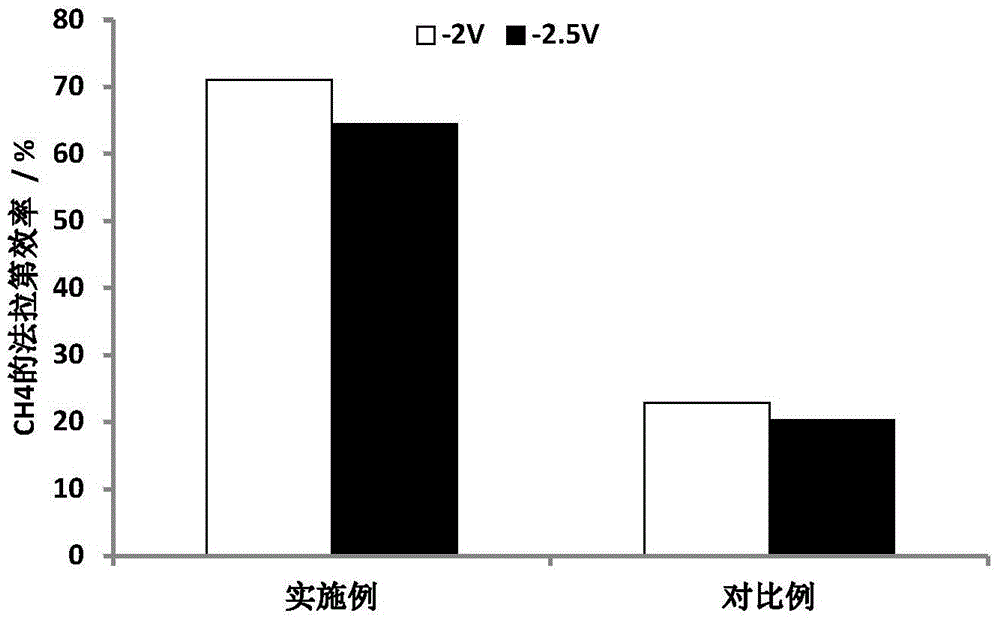

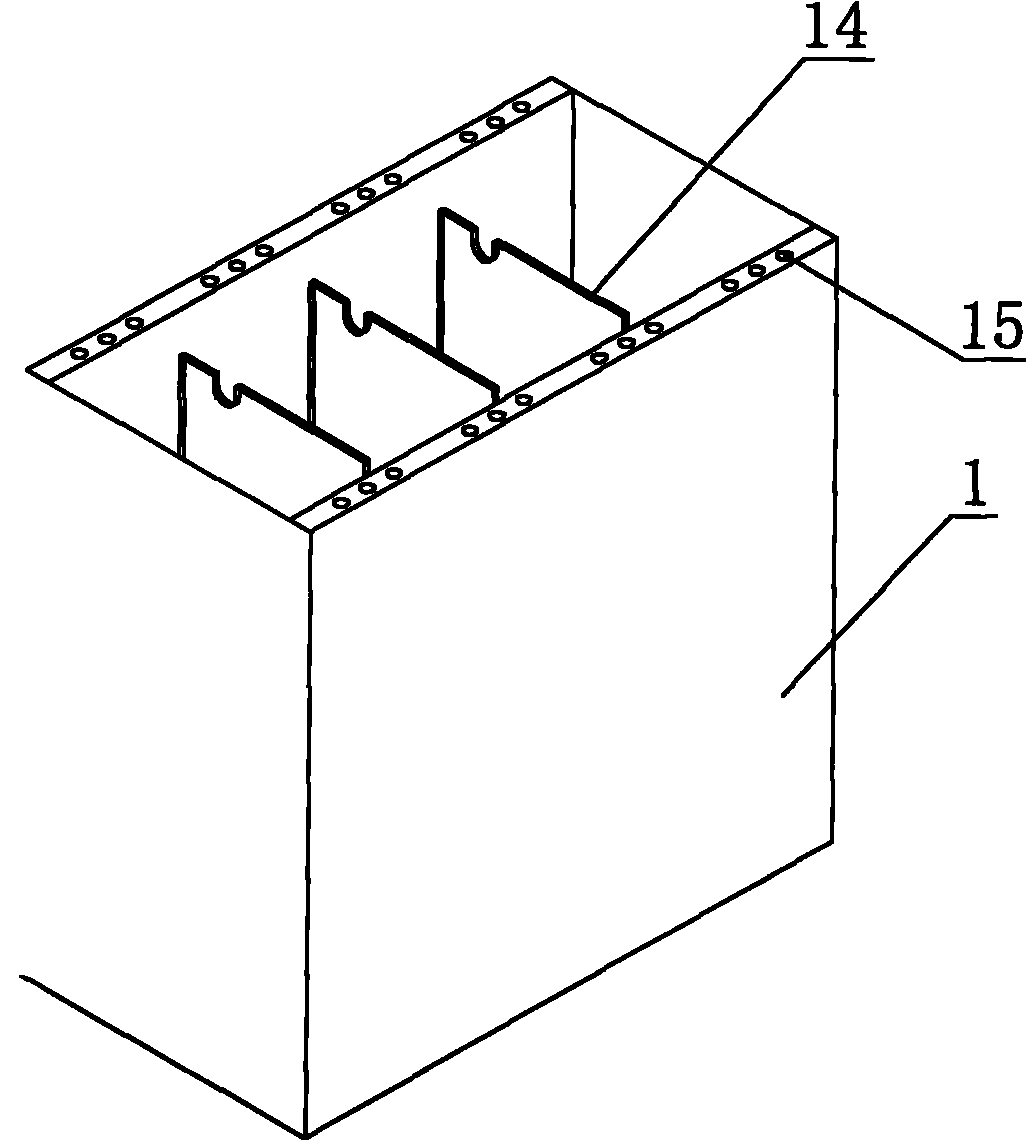

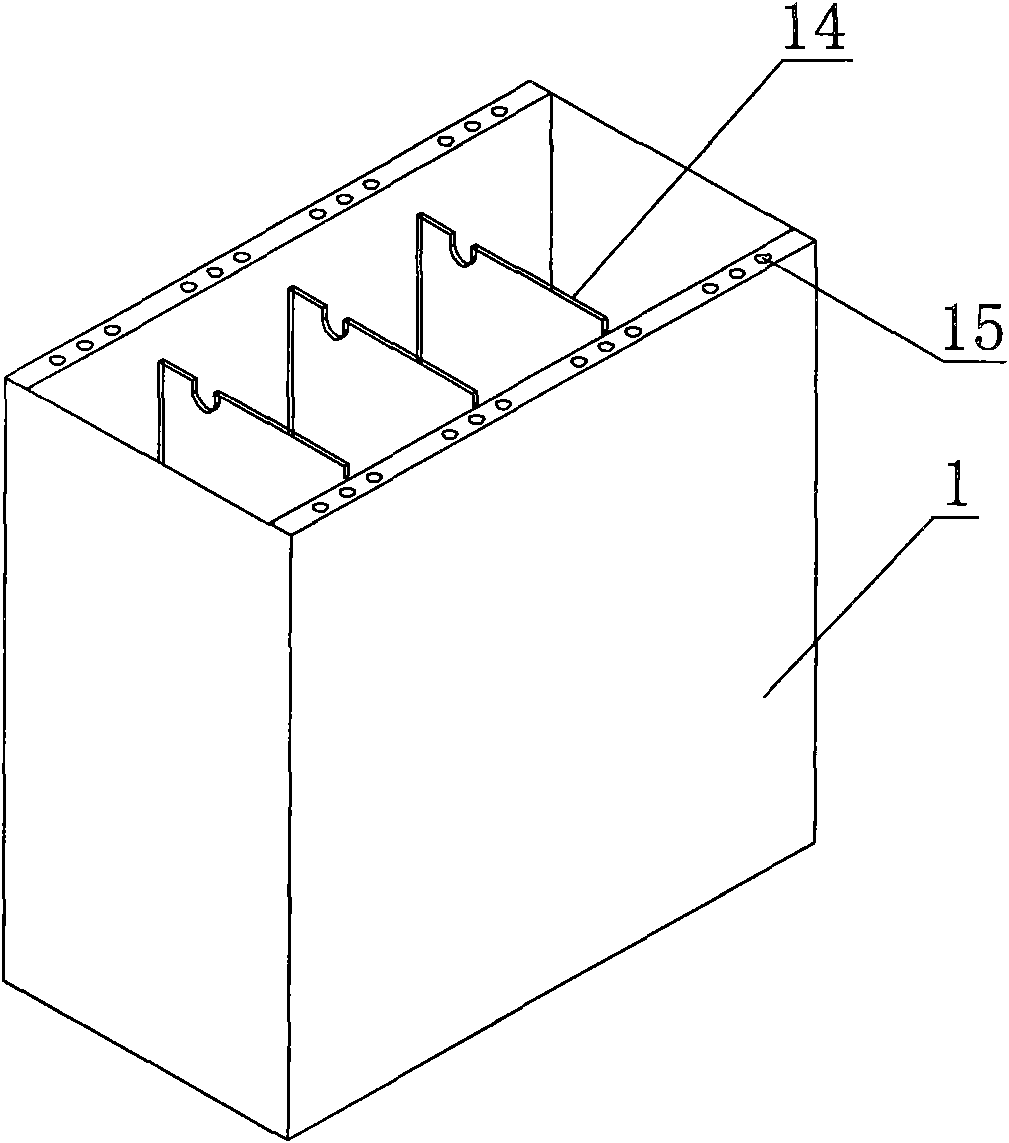

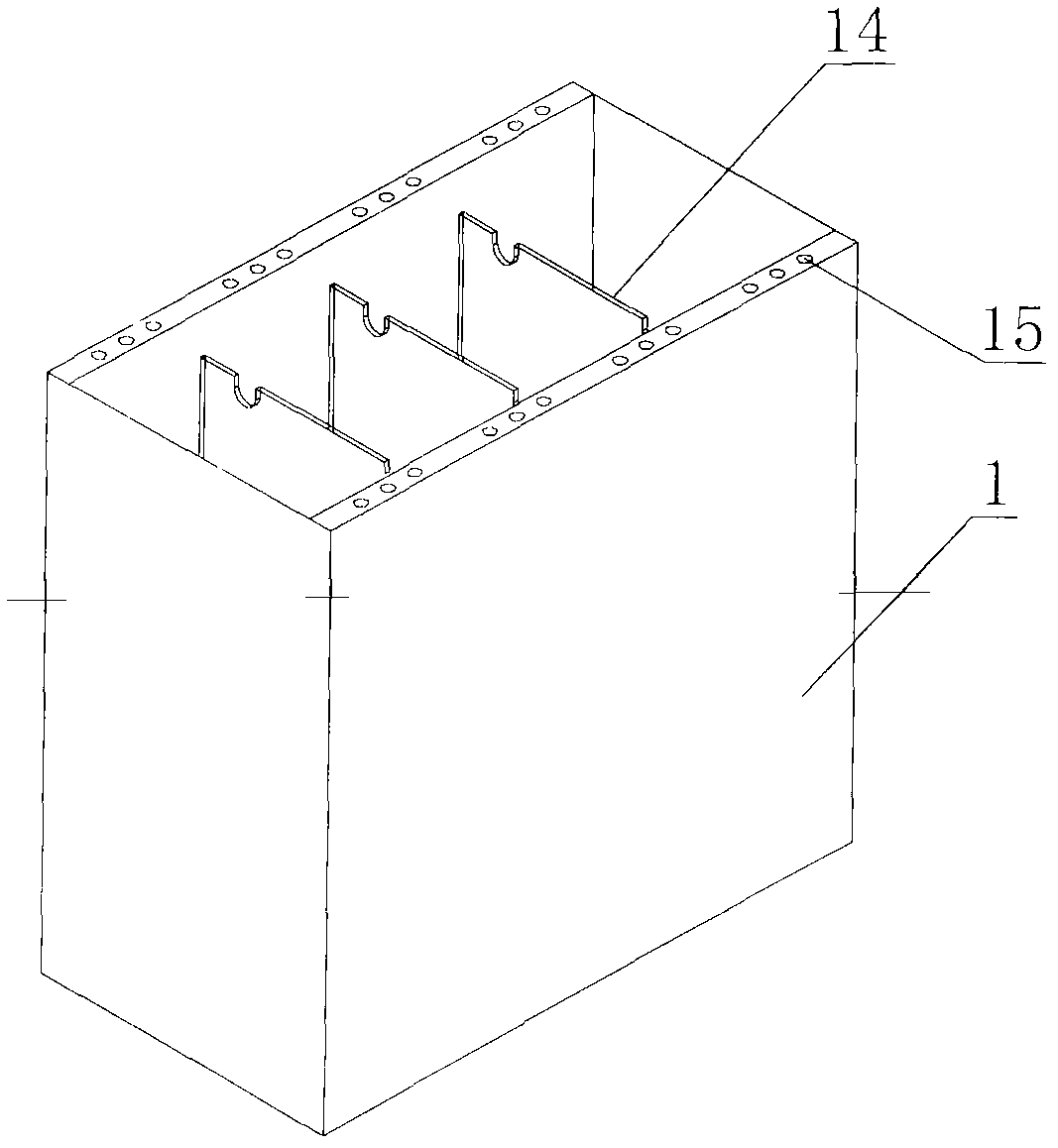

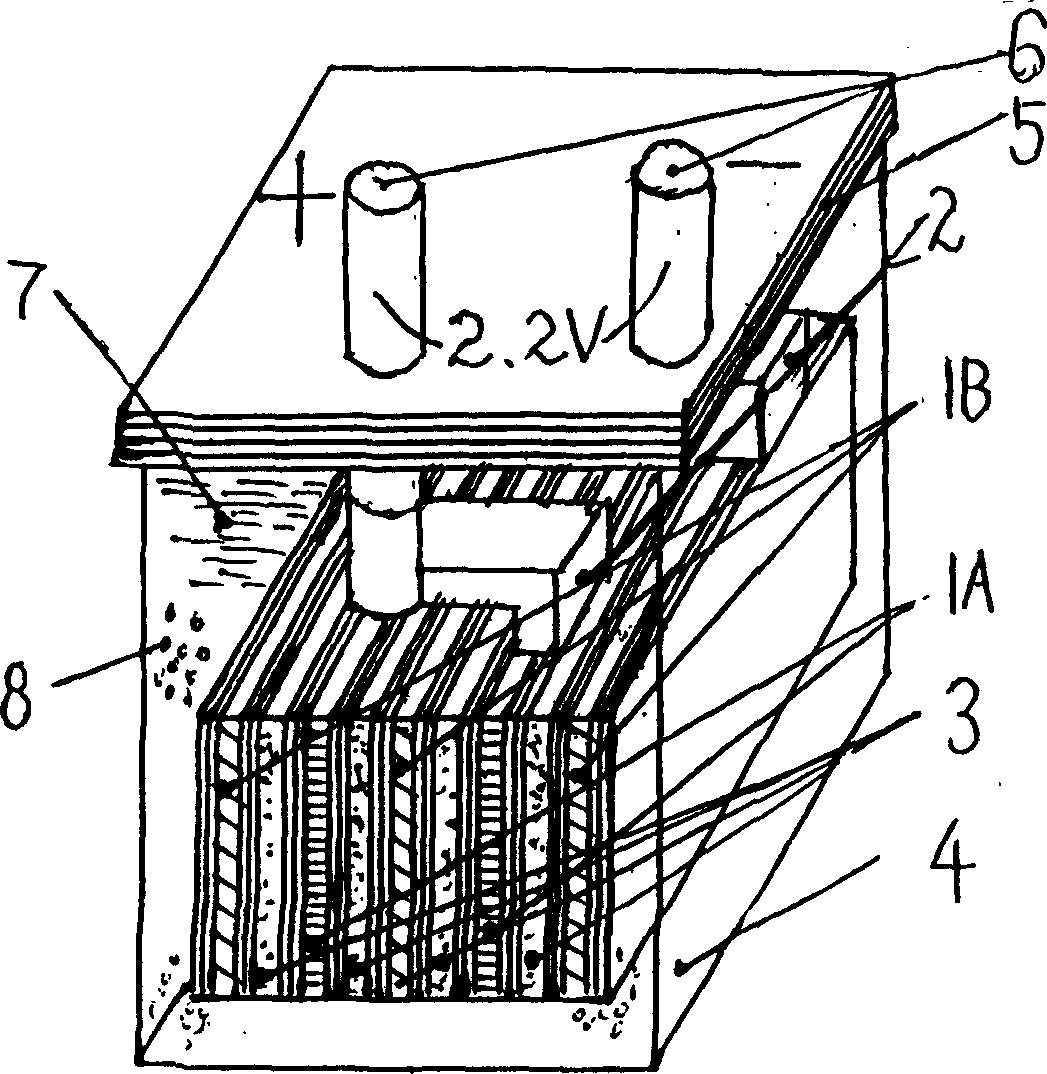

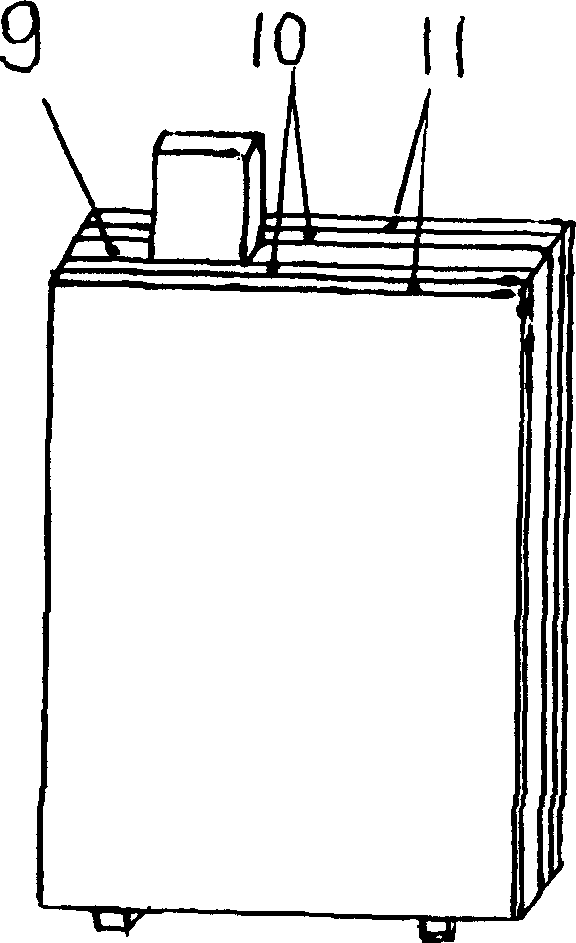

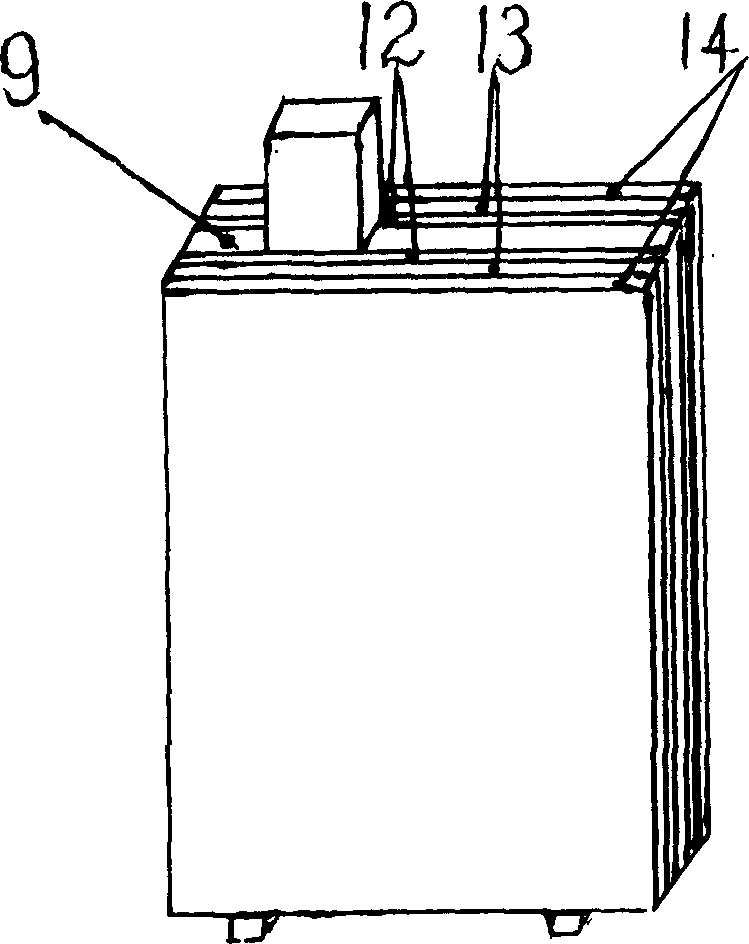

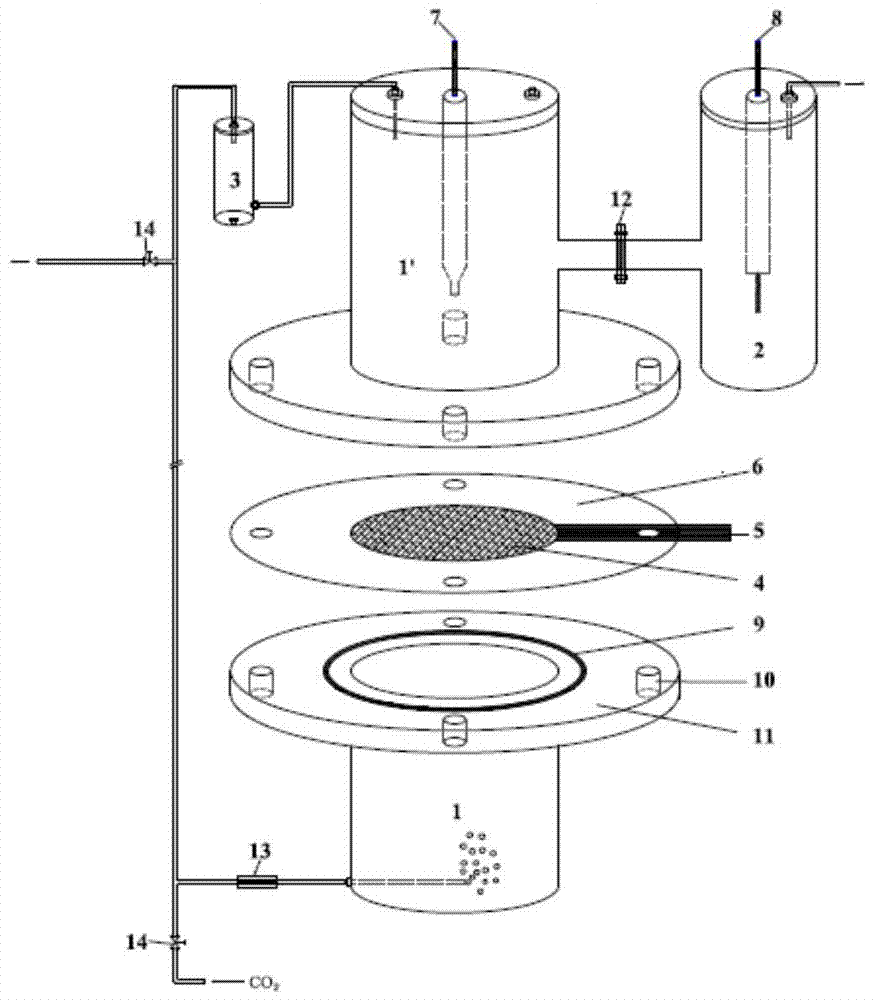

Electrolytic tank and application for electrochemical reduction reaction of carbon dioxide

ActiveCN105316700AImprove the electrochemical reaction speedIncrease the electrochemical reaction areaCellsElectrolytic organic productionElectrochemical responseVapor–liquid separator

The invention discloses an electrolytic tank and application for an electrochemical reduction reaction of carbon dioxide. The electrolytic tank comprises a cathode chamber, an anode chamber and a gas-liquid separator, wherein the cathode chamber is divided into an upper cavity and a lower cavity; the lower cavity is a container with an open upper end, and the upper cavity is a container with an open lower end; the upper cavity is disposed above the lower cavity; first flange plates are disposed at the opening ends of the two cavities respectively; the two cavities are connected through the first flange plates. Compared with a traditional H-type electrolytic tank, the electrolytic tank can remarkably increase the converting rate of the carbon dioxide and improve electrochemical reaction speed and is easy to operate, and the calculation is convenient.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

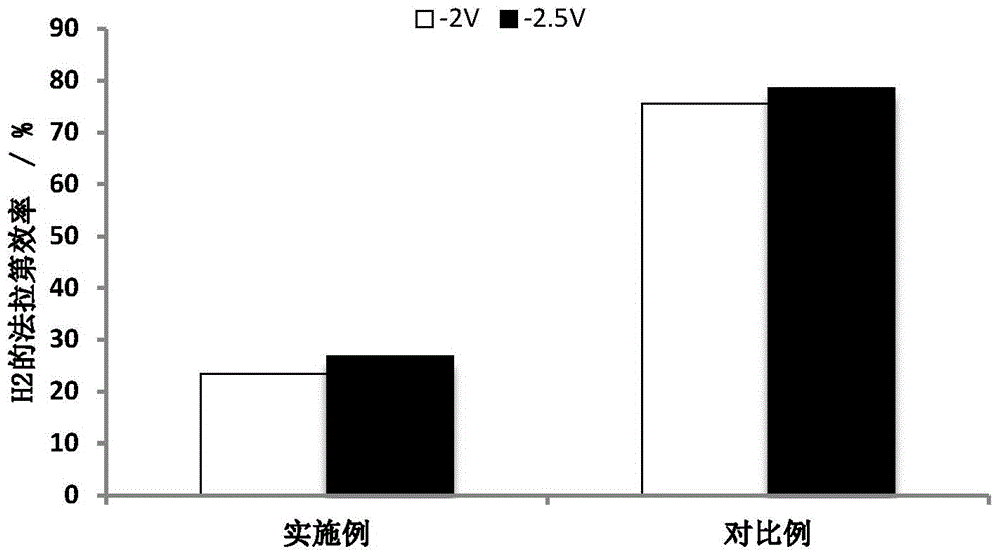

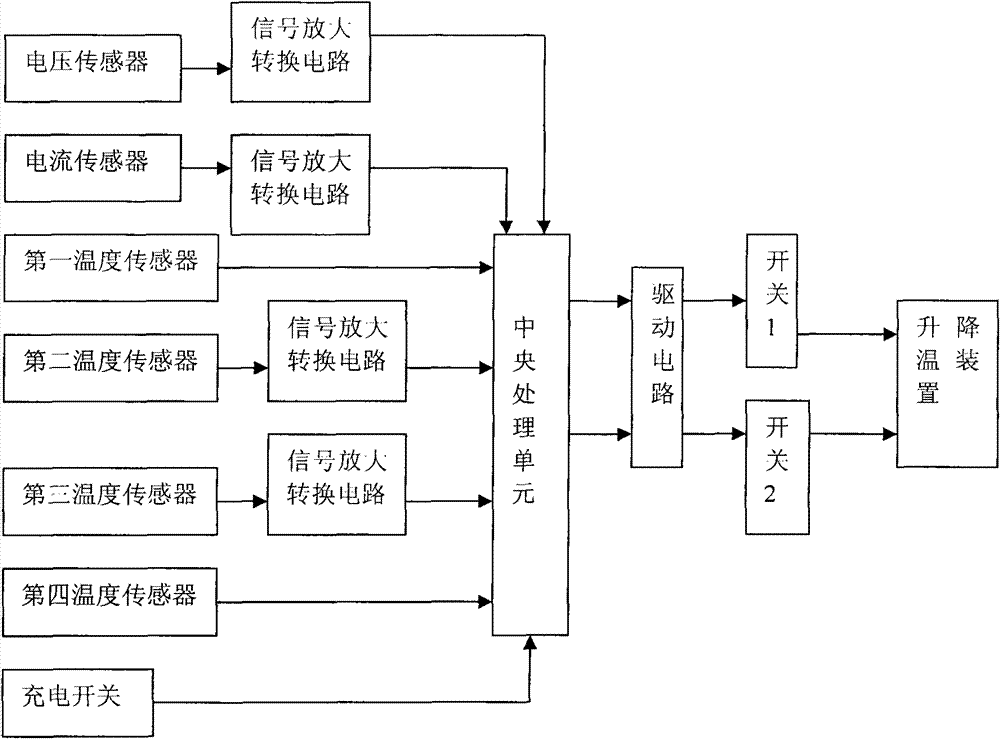

Thermal management system of electric automobile

ActiveCN101885313AGuaranteed output currentGuaranteed output voltageAir-treating devicesElectric propulsion mountingControl signalThermal management system

The invention discloses a thermal management system of an electric automobile, comprising a temperature sensor, a heating and cooling device and a central processing unit, wherein the temperature sensor is used for acquiring the temperature of components generating the raising and the drop of temperature in the electric automobile; the heating and cooling device is used for generating a heat source and a cold source which are transmitted to components needing heating and cooling and is connected with the signal output end of the central processing unit through a control switch; and the central processing unit is used for receiving a signal of the temperature sensor and calculating and outputting the control signal to the heating and cooling device. In the invention, the temperature conditions of various components can be detected by using the temperature sensor and are transmitted to the central processing unit which controls the temperature in time so as to ensure that the temperatures of various components are in a proper range. The system not only can be used for monitoring the temperature of batteries, but also can be used for monitoring the temperature of a motor and a motor controller, thereby avoiding the motor and the motor controller from being damaged due to overhigh temperature. The system can also be used for monitoring the temperature in a carriage and ensures thecomfort degree of the moving space of people.

Owner:李辉 +1

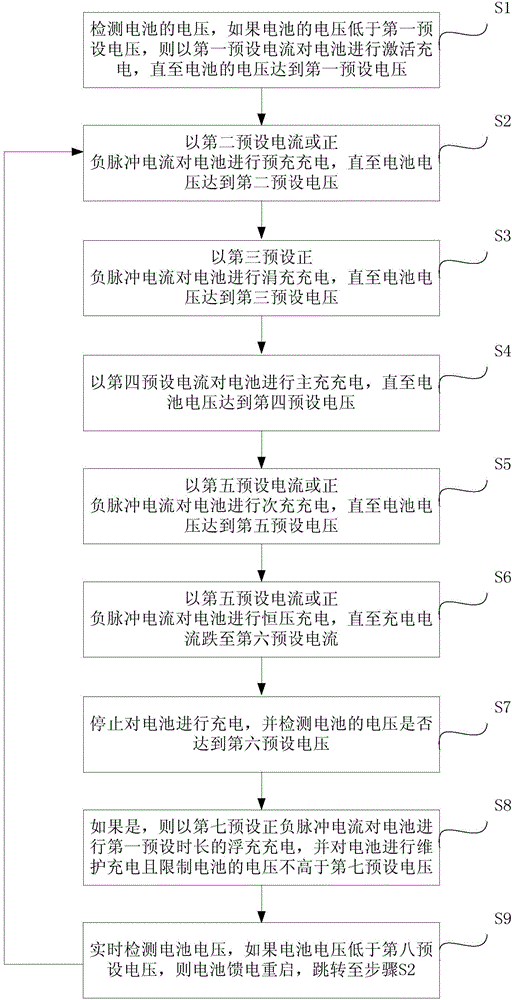

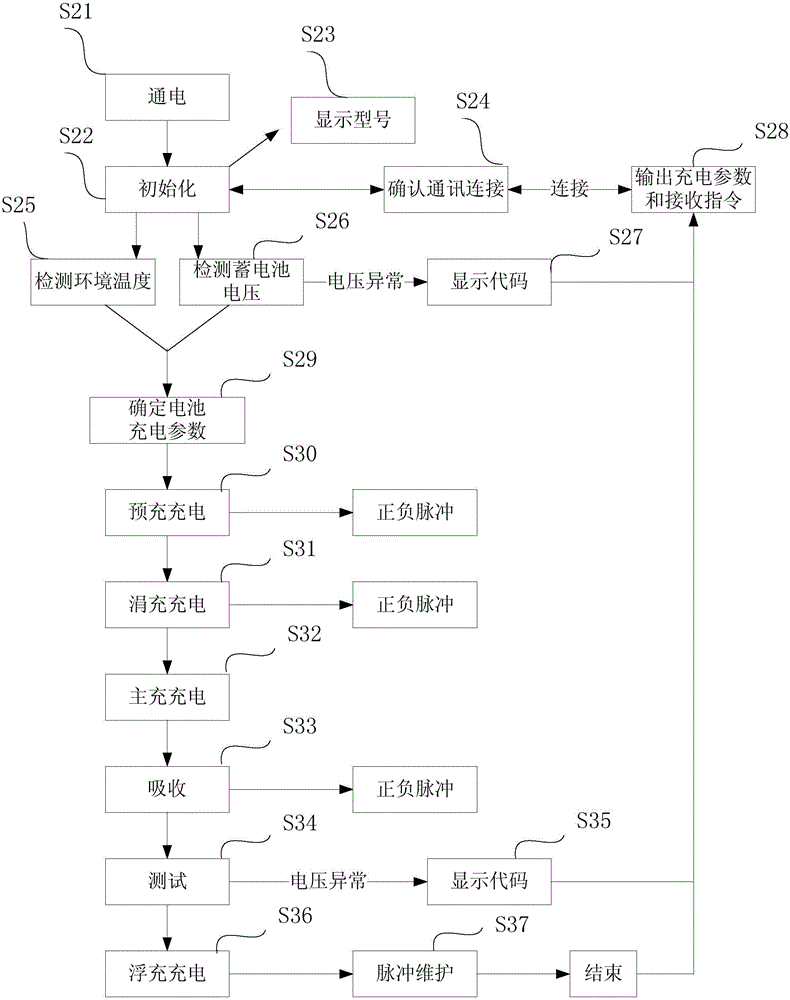

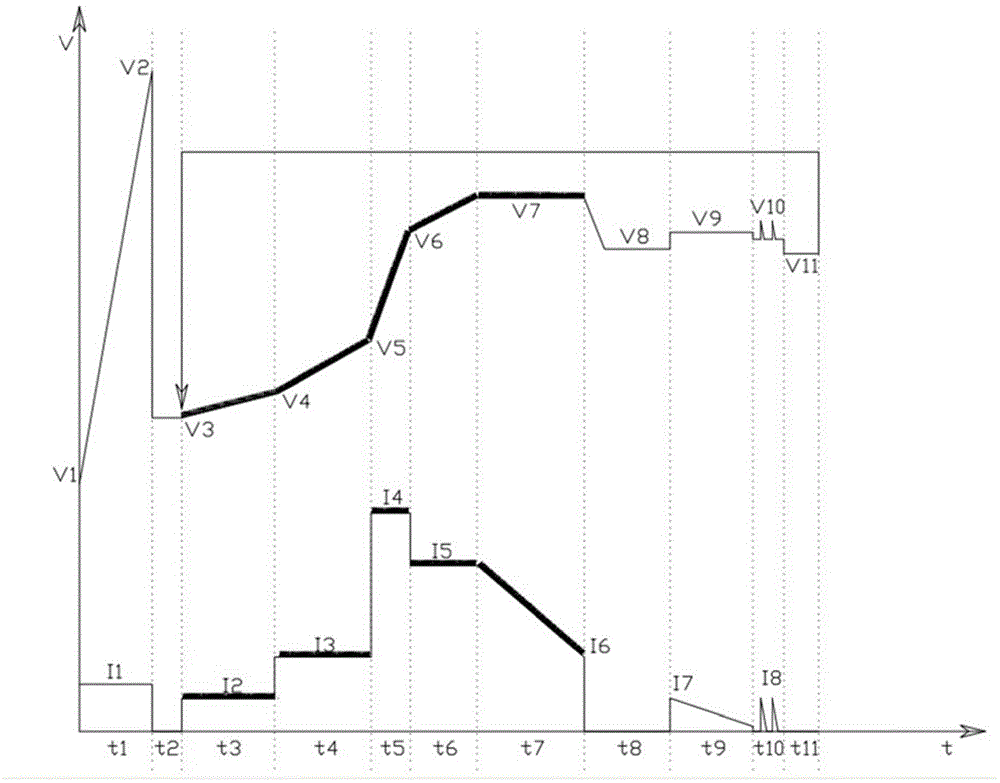

Pulse energy-saving charging method and pulse energy-saving charger

ActiveCN104600386AAvoid damageImprove the electrochemical reaction speedSecondary cells charging/dischargingFloating chargePulse energy

The invention provides a pulse energy-saving charging method and a pulse energy-saving charger. The method comprises the following steps: detecting the voltage of a battery, and activating and charging the battery if the voltage of the battery is lower than a preset voltage; pre-charging the battery by adopting a second preset current or a second positive-negative pulse current; carrying out trickle charge for the battery by adopting a third preset positive-negative pulse current; carrying out the primary charge for the battery by adopting a fourth preset current; carrying out the secondary charge and constant-voltage charge for the battery by adopting a fifth preset current or a fifth preset positive-negative pulse current; stopping the charging for the battery; carrying out the floating charge for the battery by adopting a seventh preset positive-negative pulse current; carrying out the maintenance charge for the battery by adopting an eighth preset positive pulse current; detecting the voltage of the battery in real time, restarting the battery in a feed manner when the battery voltage is lower than an eighth preset voltage, and skipping to the pre-charging step. According to the method, the negative pulse charging way is adopted, so that the current receiving capability of the battery is improved, the service life of the battery is prolonged, and the battery can be automatically restarted when the battery is idle for a long time or is fed so as to be recharged and repaired.

Owner:南京鹏图电源有限公司

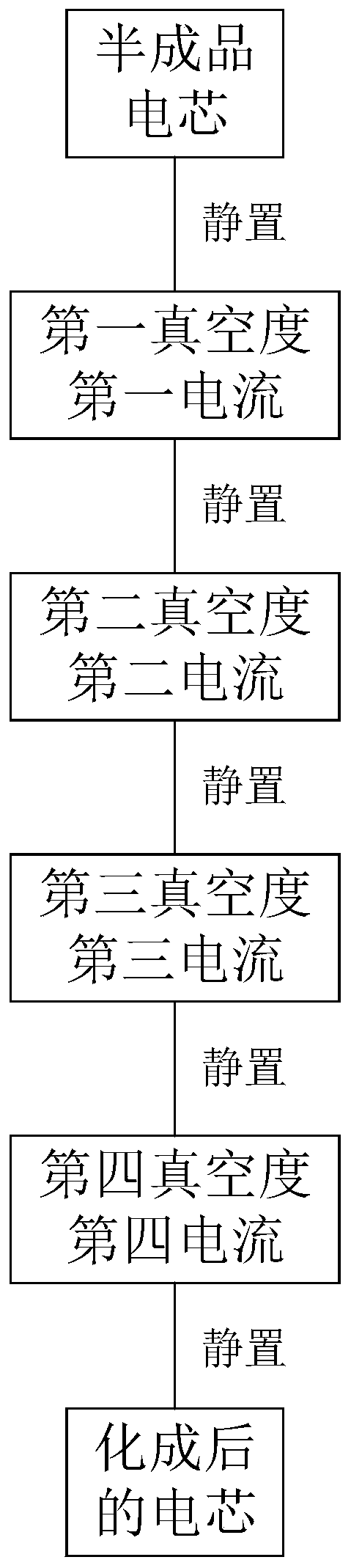

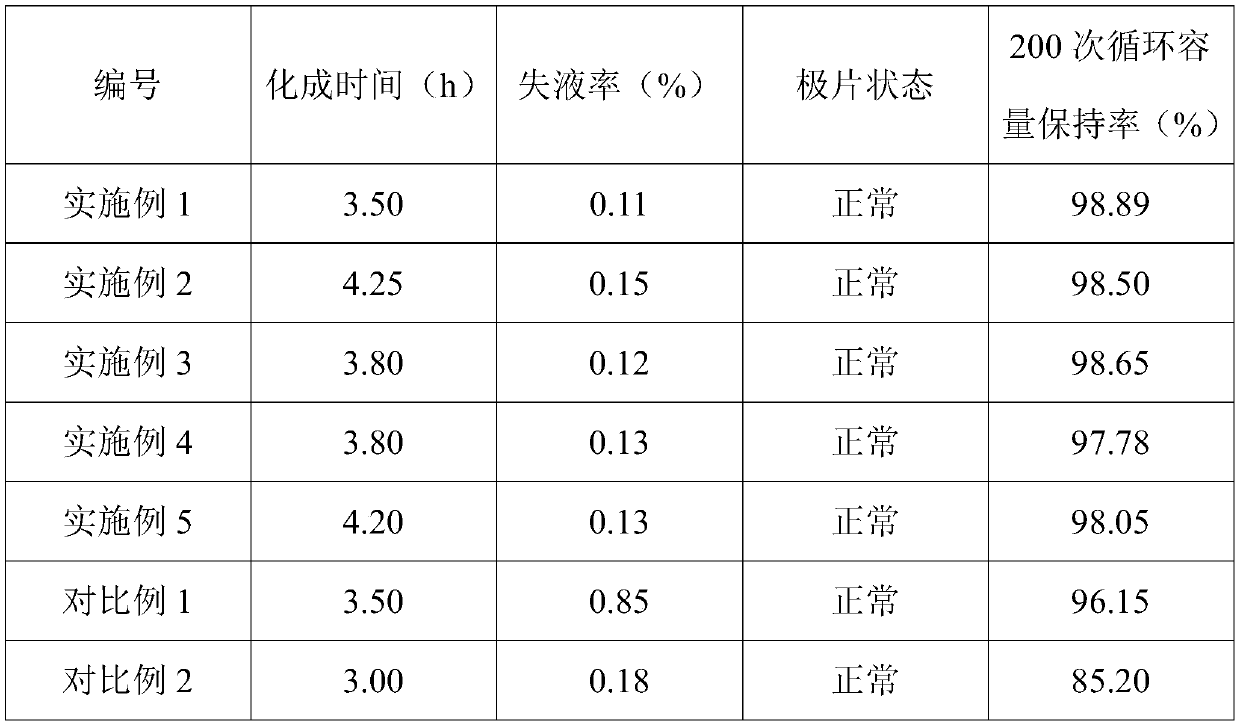

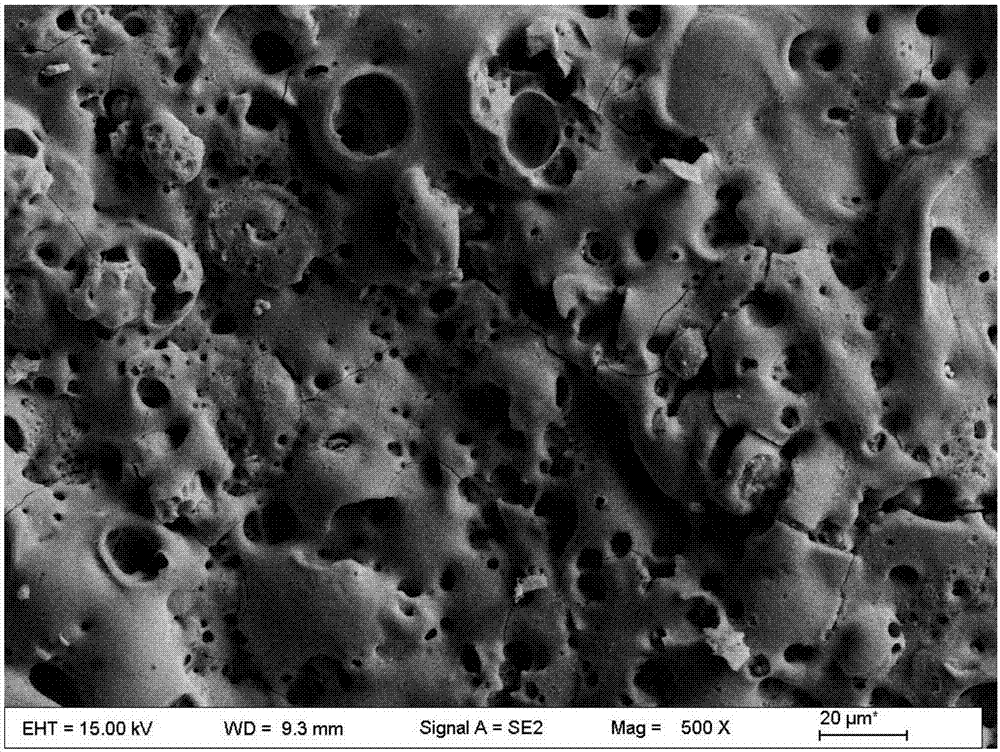

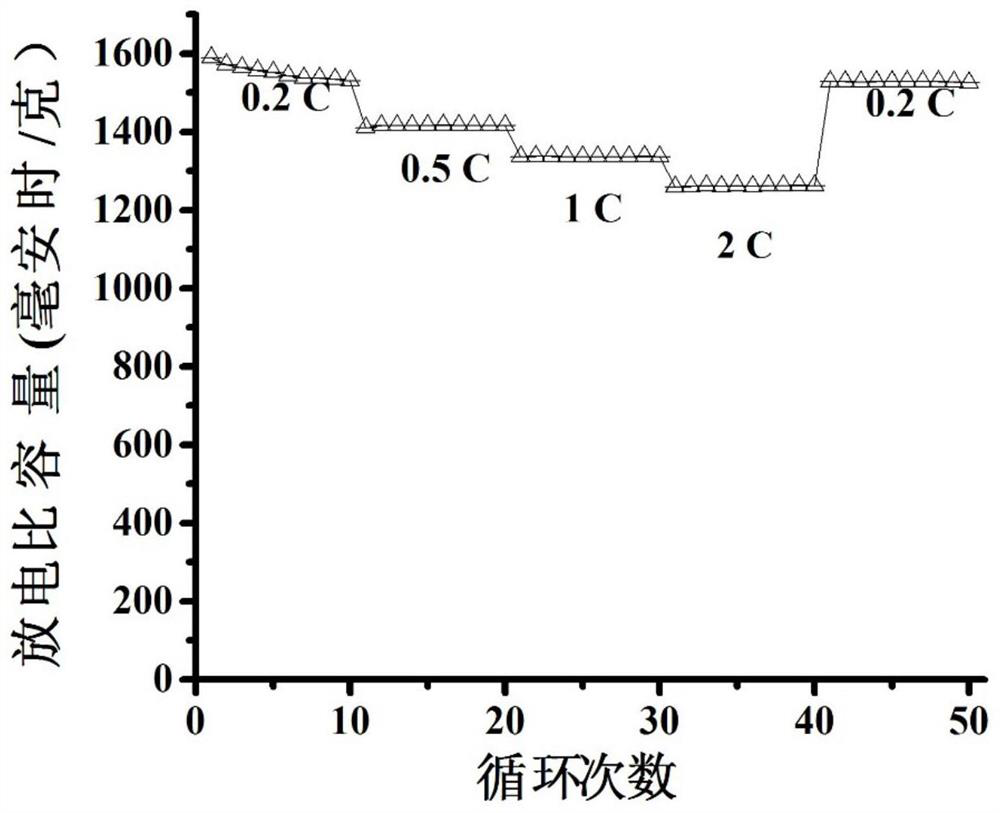

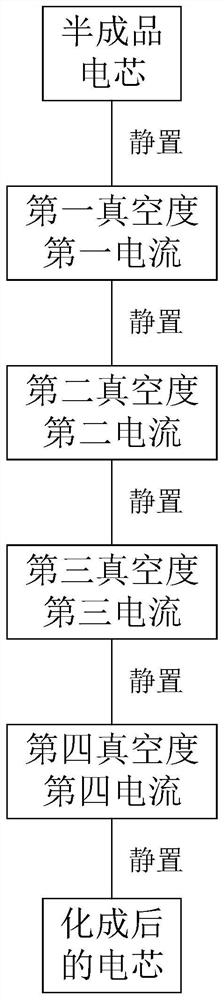

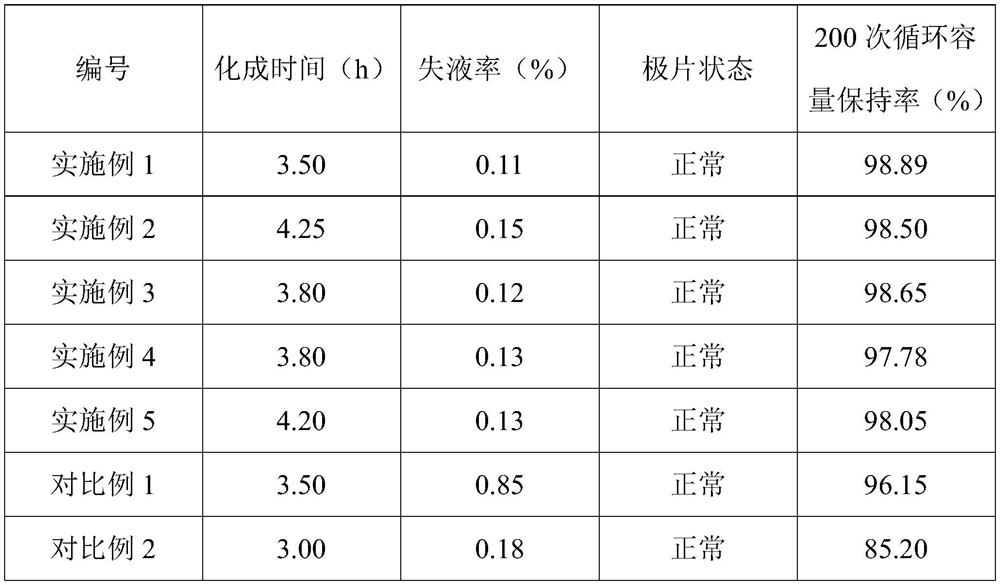

Negative pressure formation method and battery

ActiveCN111554991AFast growthFast formingSecondary cells charging/dischargingPower batteryCharge current

The invention discloses a negative pressure formation method and a battery. The method comprises the following steps: vacuumizing, charging and standing a semi-finished battery cell to obtain a formedbattery cell; performing vacuumizing and chargingt in multiple steps, gradually reducing the vacuum degree of each step, and gradually increasing the charging current. The method provided by the invention can shorten the formation time, reduce the liquid loss in the formation process, improve the consistency and stability of the SEI film, improve the cycle performance of the battery, meet the requirements of high specific energy, quick charging, long service life and the like of the power battery for the new energy automobile, and is particularly suitable for the formation of the lithium ionbattery.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

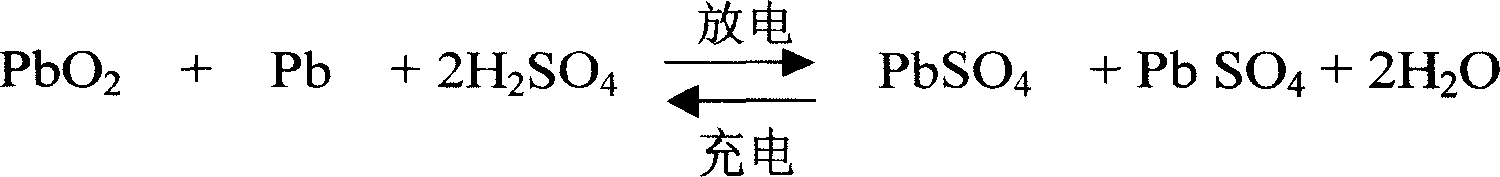

Activity increase agent for lead-acid storage battery

InactiveCN1960049ALarge capacityExtended service lifeLead-acid accumulatorsInternal resistanceEvaporation

The disclosed activator for lead-acid accumulator includes distilled water, sulfuric acid, cobalt sulfate, hydroxylamine sulfate, aluminum sulfate, cadmium sulfate, magnesium sulfate, and binary carboxylic acid. Advantages are: preventing pole plates from vulcanizing, increasing capacity and service life of accumulator, shortening time for charging accumulator, reducing evaporation of electrolyte in use, reducing internal resistance, avoiding overcharge. Moreover, the invention solves self-discharge issue of accumulator effectively.

Owner:蔡植如 +3

Method for preparing titanium alloy bionic coating through compounding of laser and anodic oxidation

ActiveCN106917127AEasy to adjust structureHarm reductionSurface reaction electrolytic coatingTitanium alloyCorrosion

The invention discloses a method for preparing a titanium alloy bionic coating through compounding of laser and anodic oxidation. The method comprises the following steps: placing titanium alloy subjected to laser pretreatment in absolute ethyl alcohol or acetone for ultrasonic cleaning for 5-10 min; taking out and thoroughly rinsing the titanium alloy with distilled water; placing the rinsed titanium alloy in an alkaline degreasing solution for soaking, and then taking out the soaked titanium alloy; sequentially washing the soaked titanium alloy with running hot water and running cold water; placing the washed titanium alloy in an anodic oxidation solution; and by taking stainless steel as the cathode, performing anodic oxidation treatment for 60-90 min to obtain the titanium alloy with a bionic coating. Compared with a traditional anodic oxidation method, the method provided by the invention has the advantages that before anodic oxidation, pollution-free laser is adopted to pre-process the surface of the titanium alloy, so that the surface microstructure of the titanium alloy can be adjusted more easily; besides, the anodic oxidation adopts the main ingredient of malic acid while such strong-acidity substances as hydrofluoric acid, sulfuric acid and nitric acid are not used in the whole process, high safety and no toxicity are achieved, and pollution to the environment and harms to a human body are reduced to the minimum; the bioactivity, the wear resistance and the corrosion resistance of the material are greatly improved, and the service life of an implant is prolonged.

Owner:ZHEJIANG UNIV OF TECH

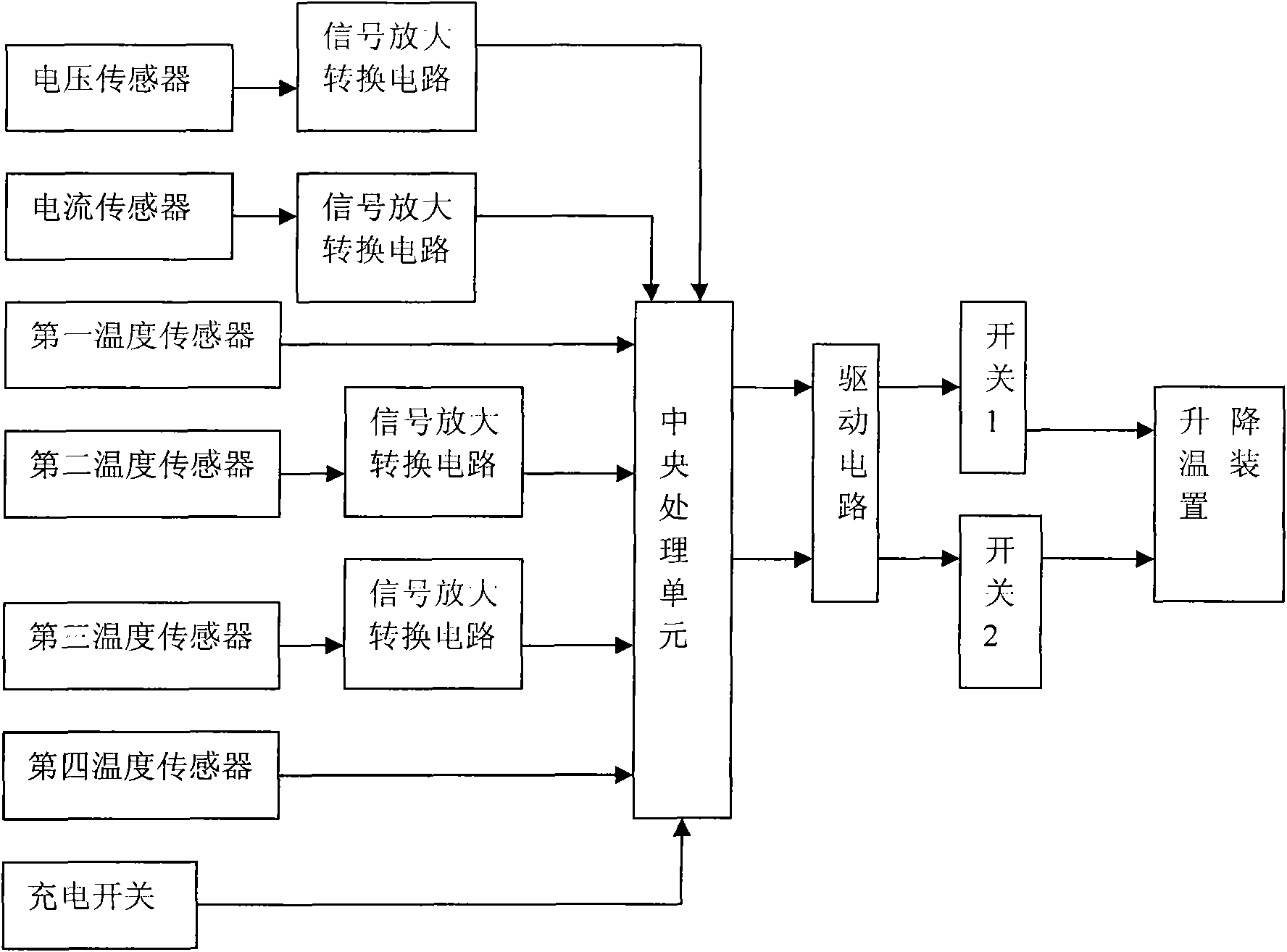

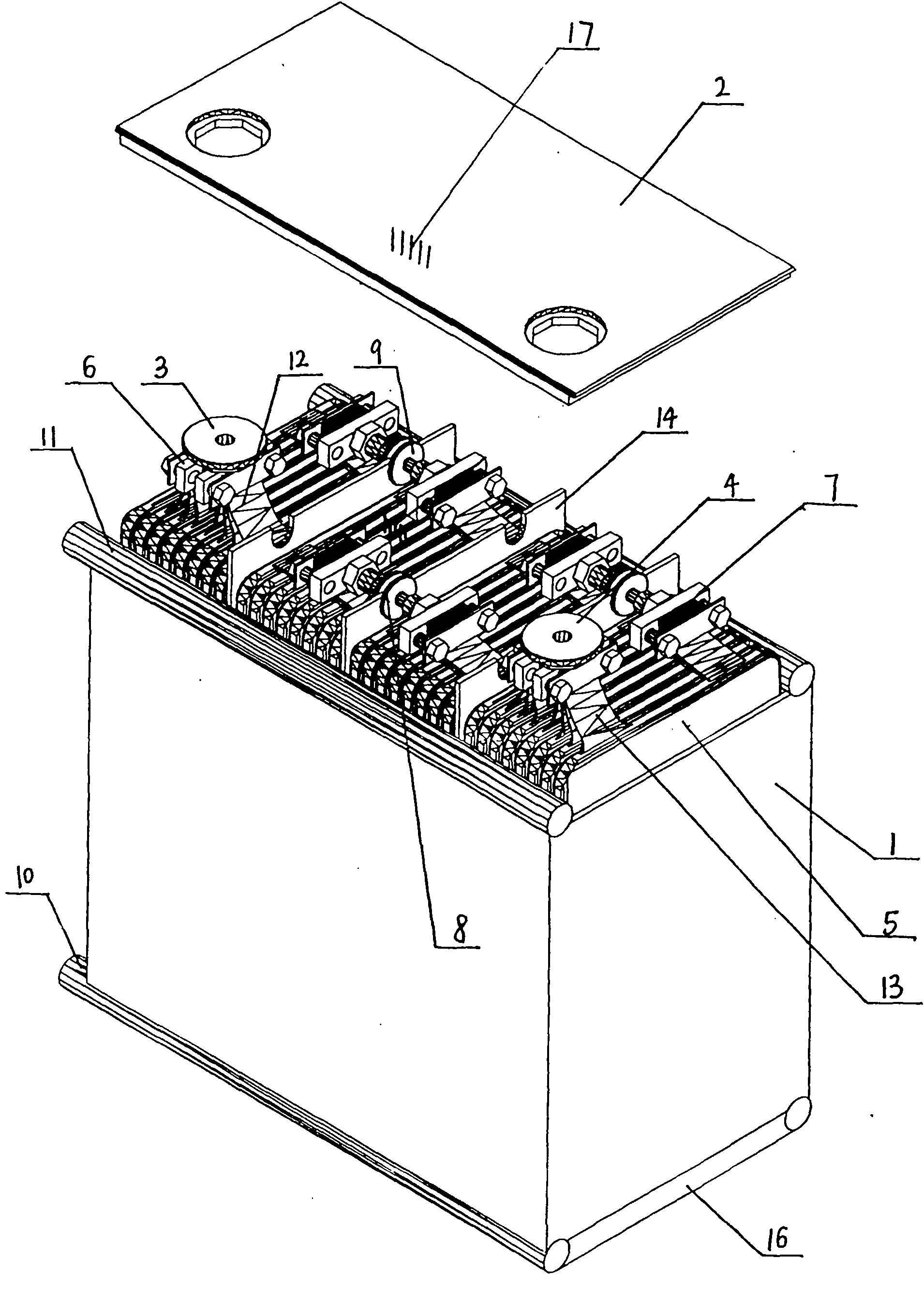

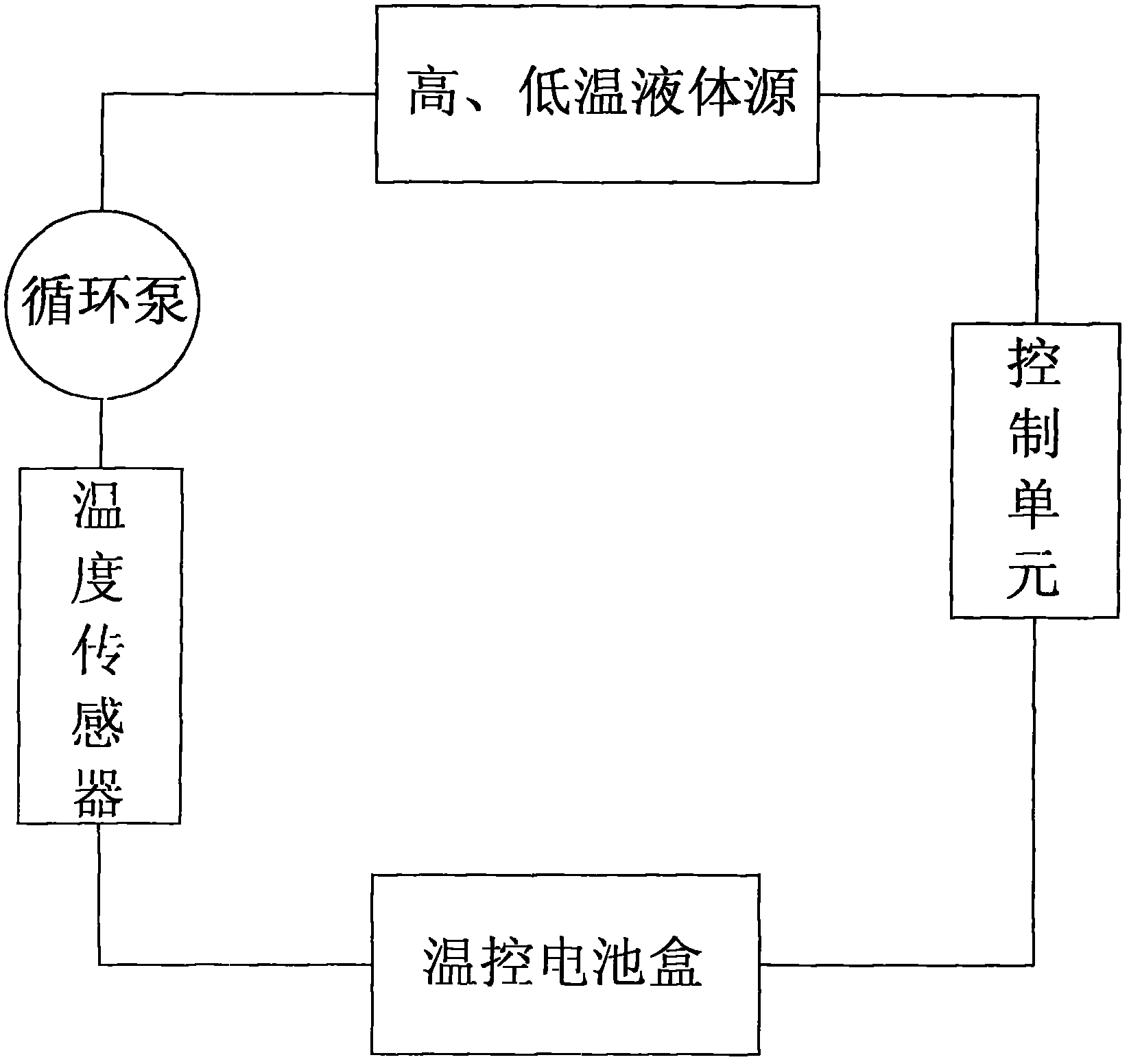

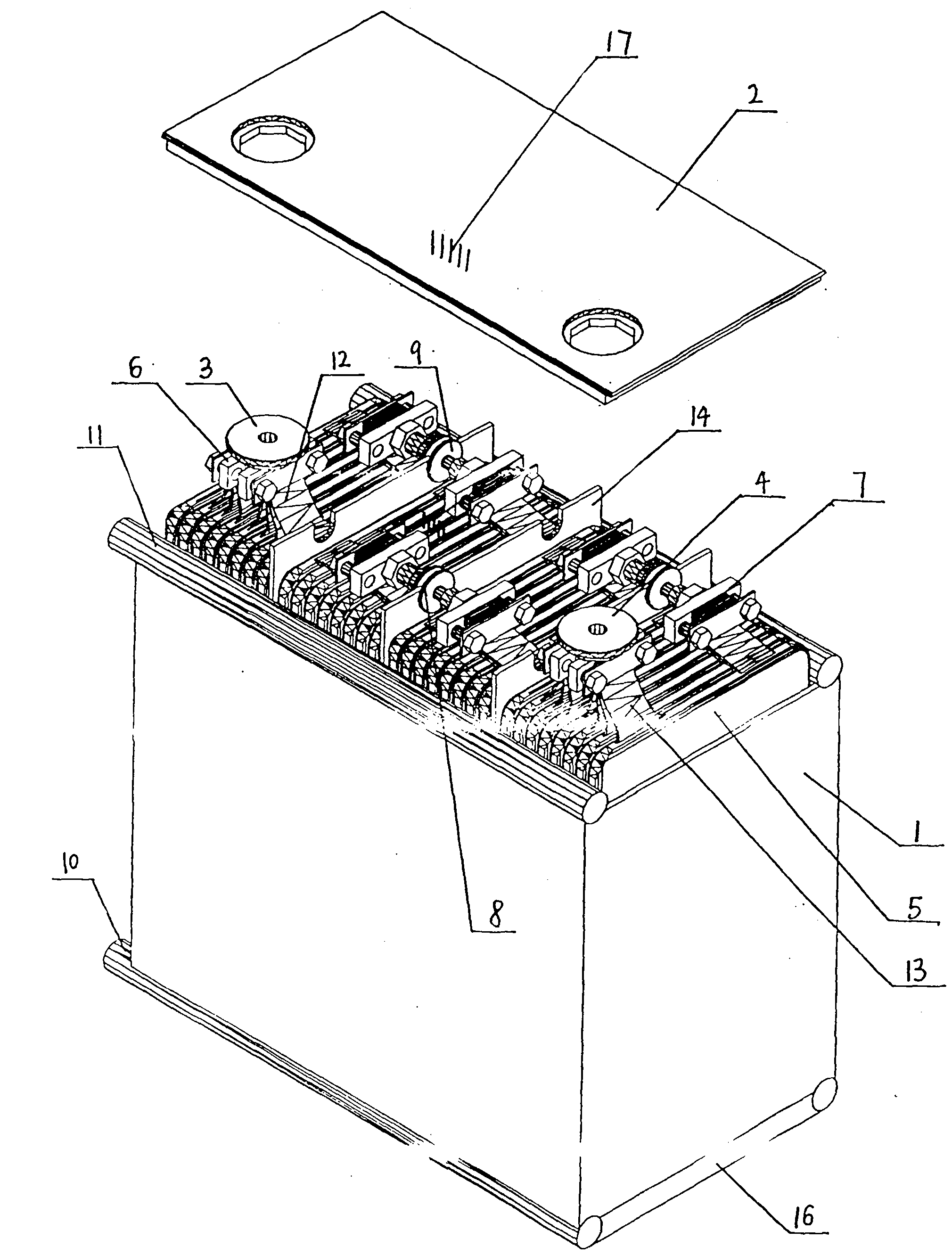

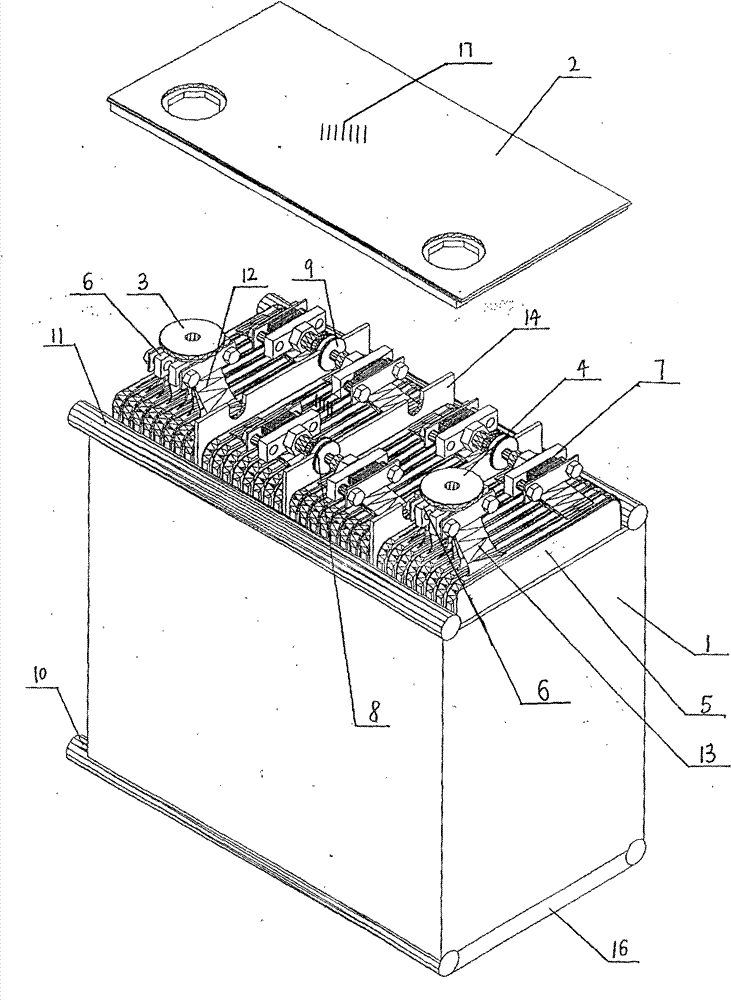

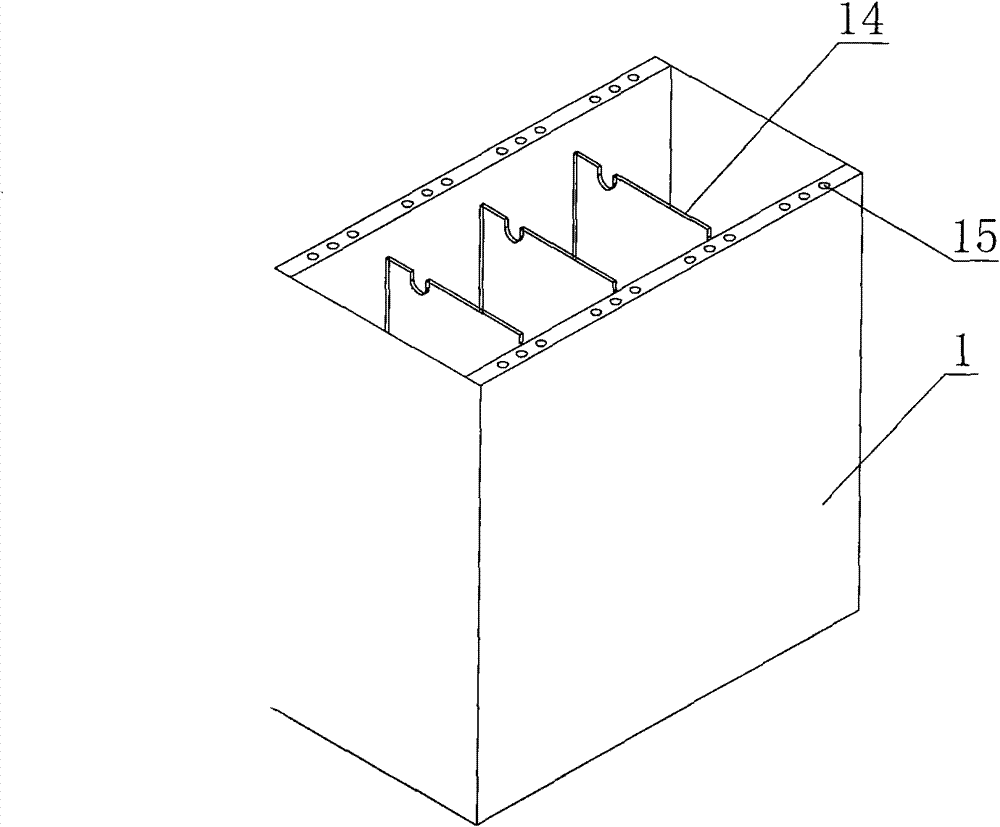

Power lithium battery temperature control device

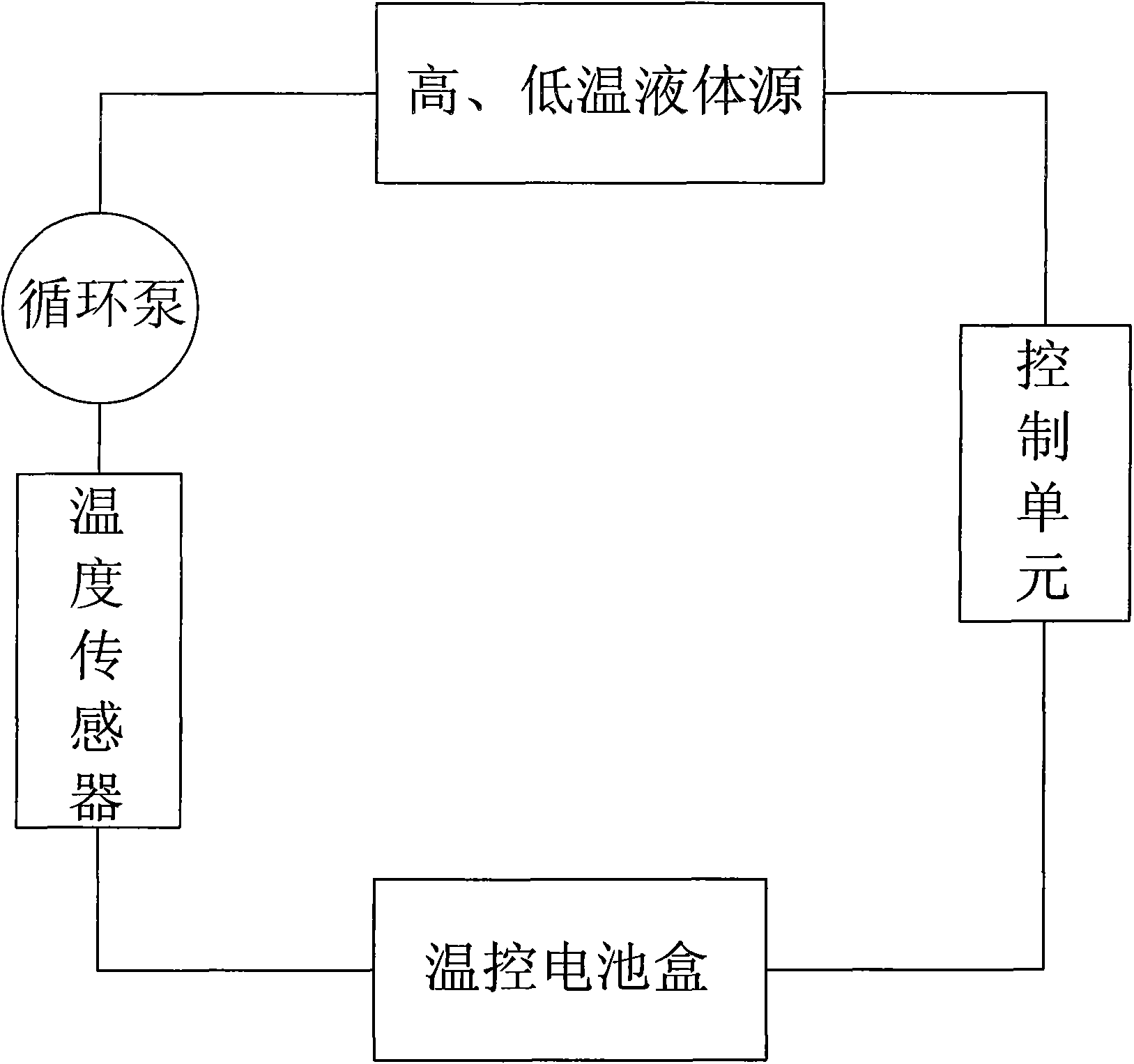

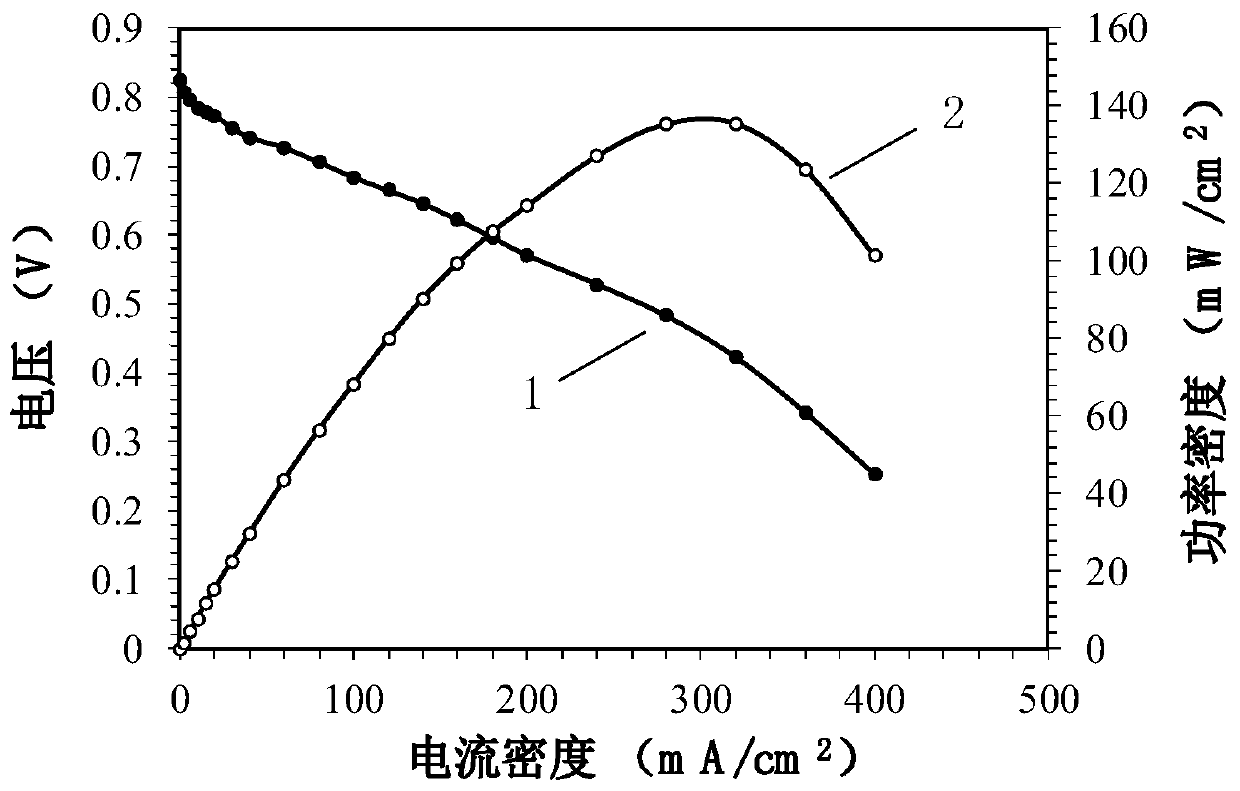

ActiveCN101894987AAccelerateGuaranteed output currentBattery isolationSecondary cellsElectrochemical responseBattery holder

The invention discloses a power lithium battery temperature control device, which comprises a temperature control battery holder, wherein the temperature control battery holder forms a circulation loop with a high and low temperature liquid source through a pipe; the circulation loop is provided with a circulating pump; and a temperature sensor and a control unit are connected between the circulating pump and the temperature control battery holder. In the invention, the temperature sensor detects in real time and the control unit regulates in time, thereby providing a suitable work environment temperature for a lithium battery, improving the electrochemical reaction speed, and ensuring the output current and voltage and discharge capacity of the lithium battery so as to enable the lithiumbattery to achieve the optimal property and meet the utilization requirement of a power source.

Owner:李辉 +1

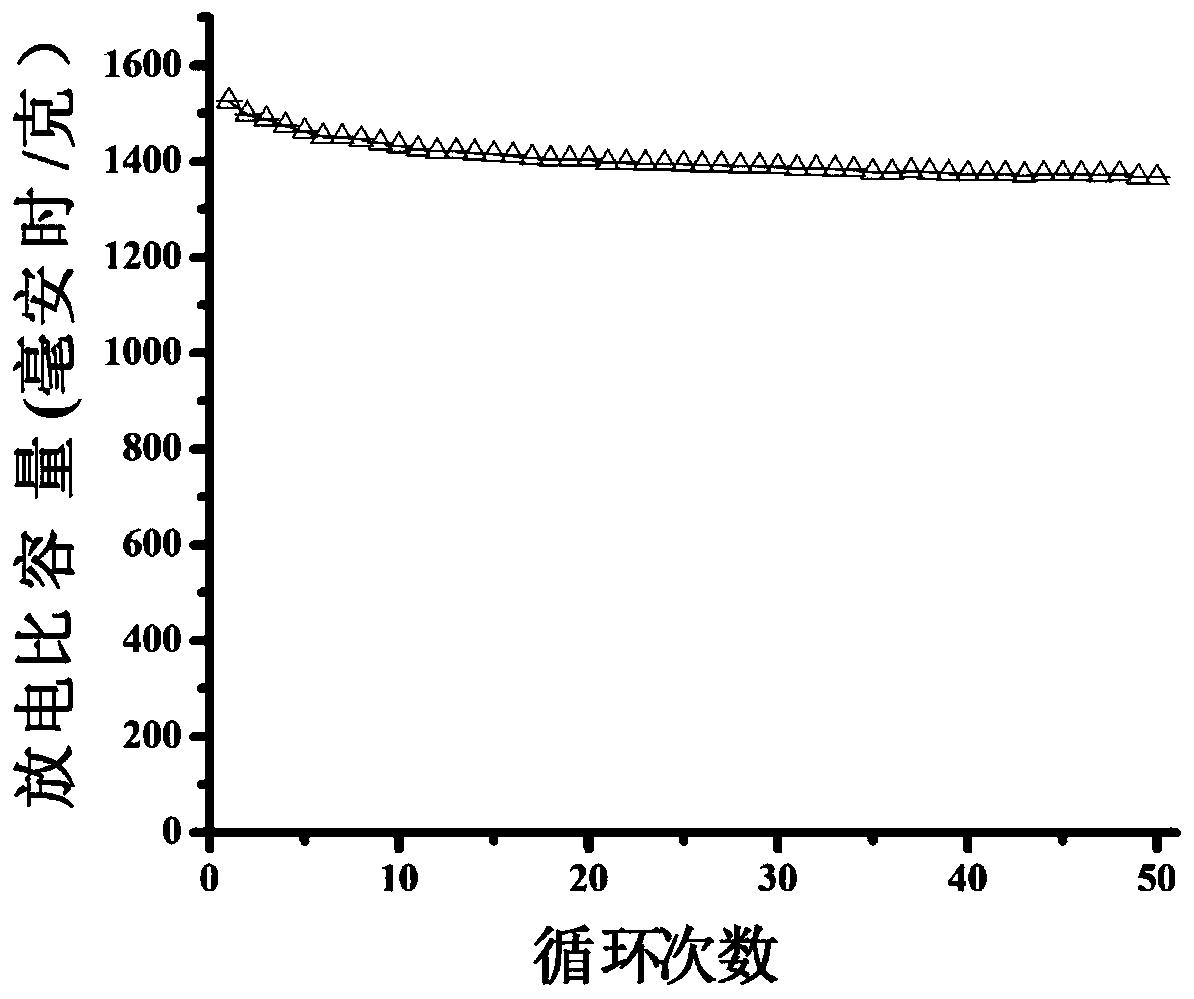

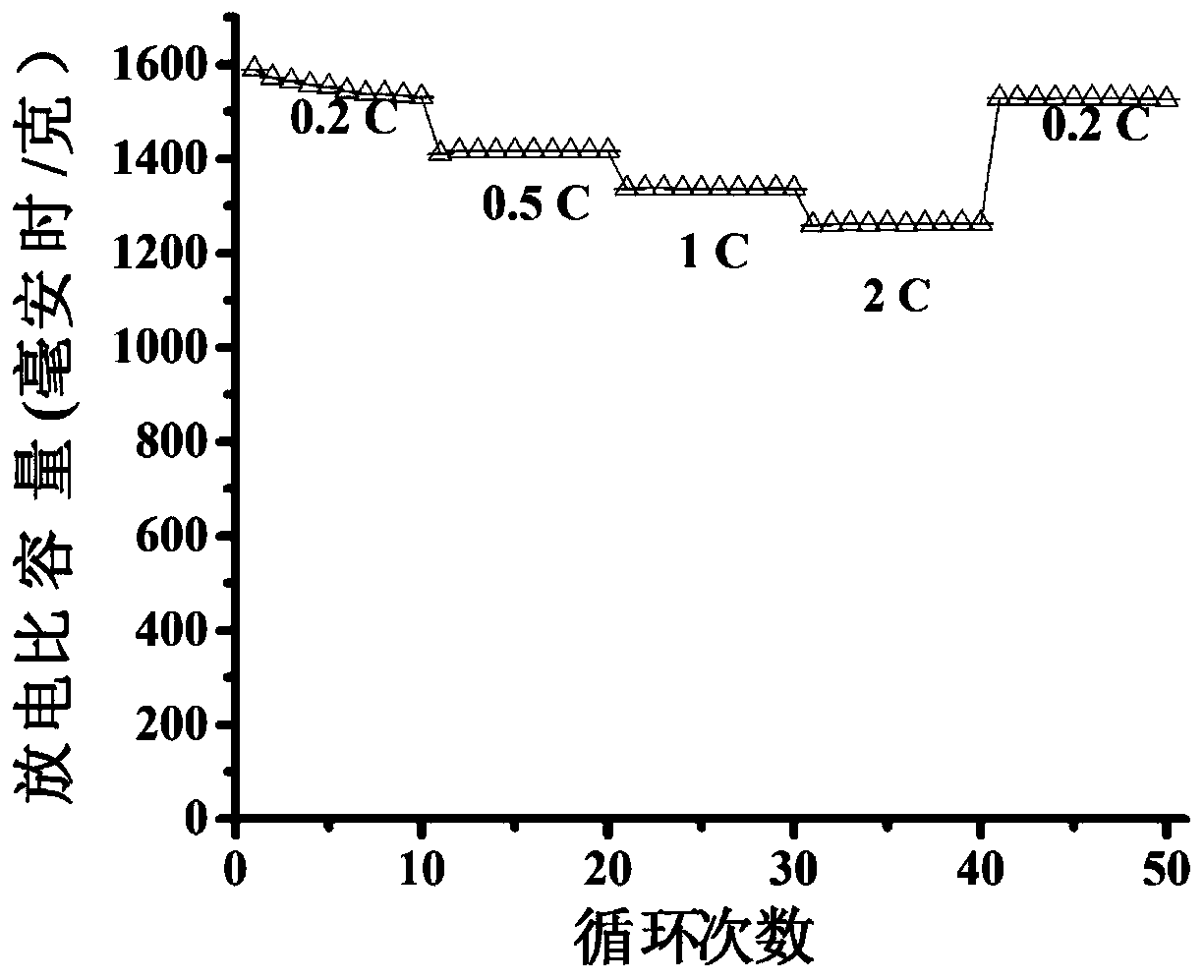

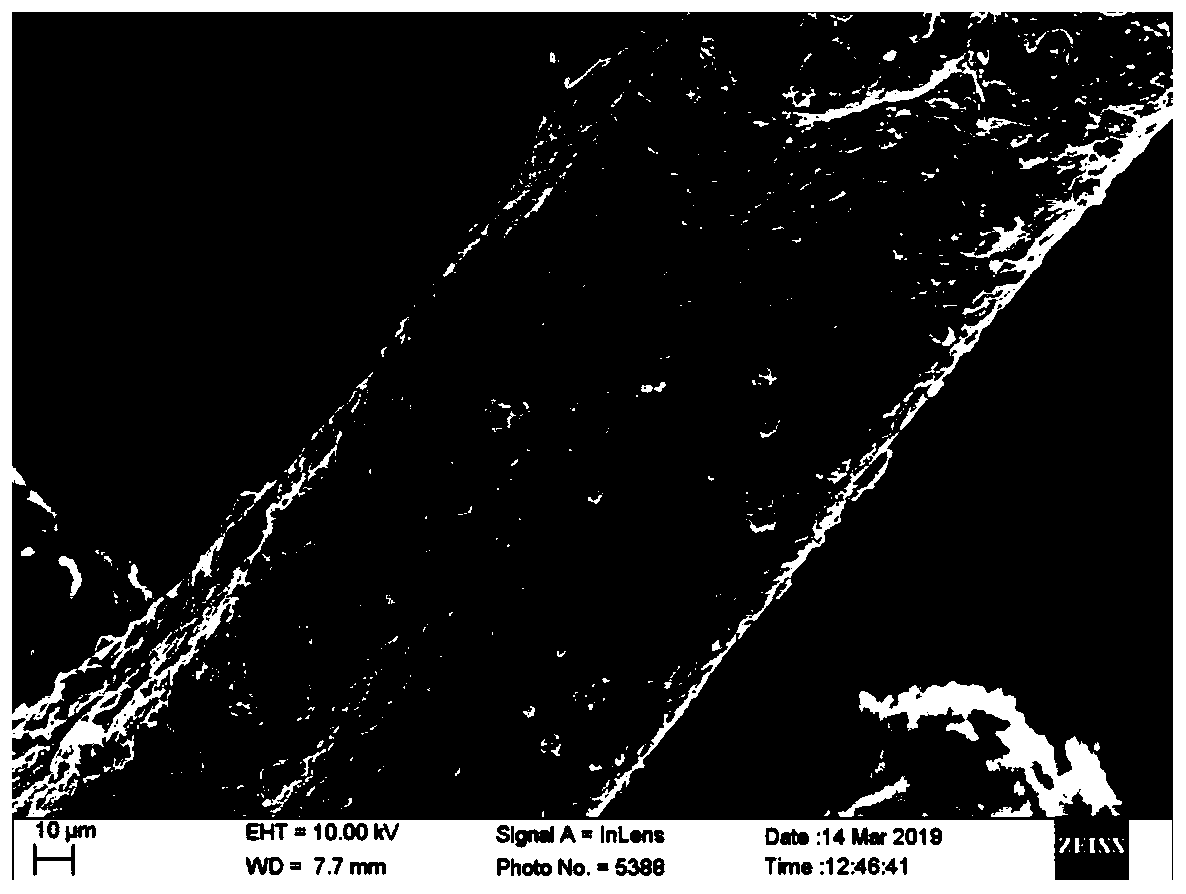

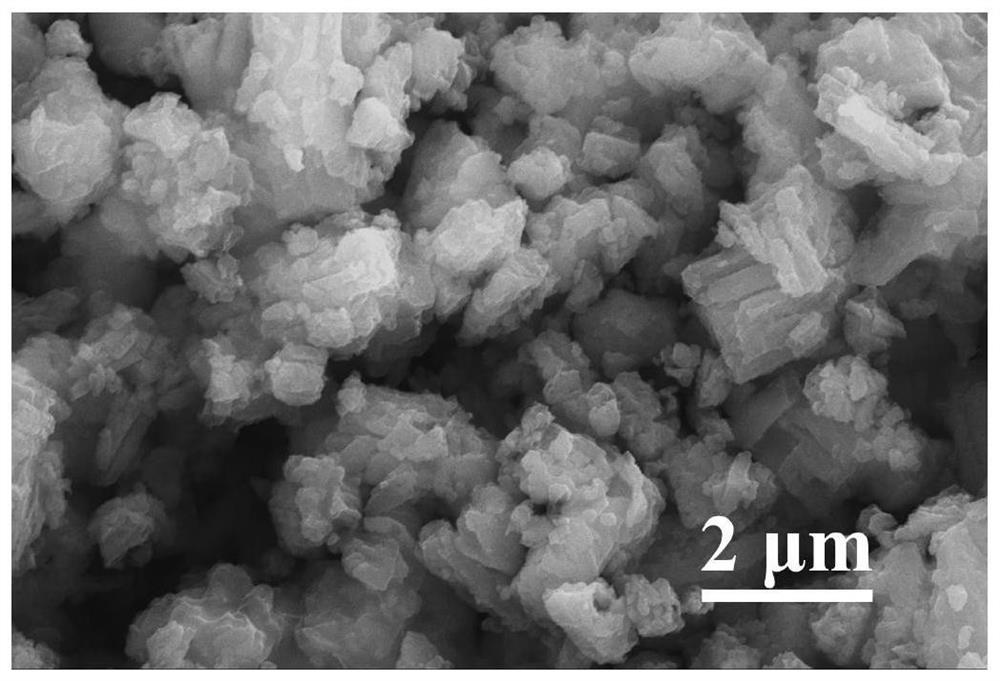

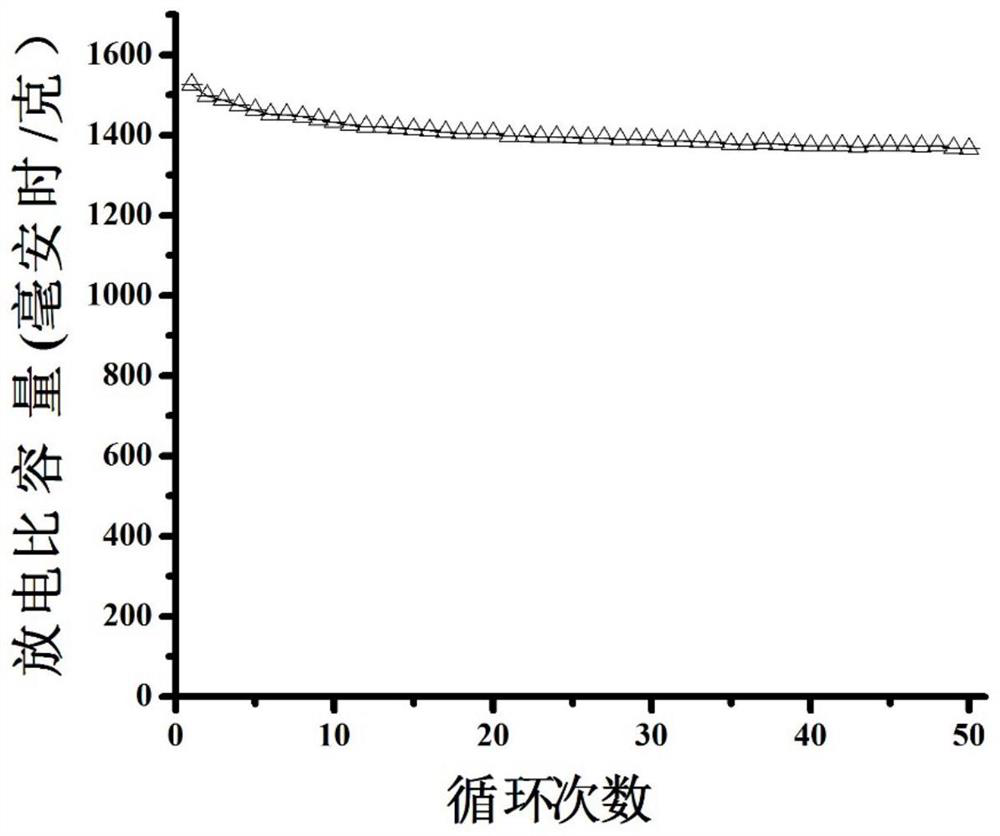

Lithium sulfur battery positive electrode material and preparation method thereof

ActiveCN109755540ALimit the "shuttle effect"Limit shuttle effectCell electrodesLi-accumulatorsElectrochemical responseCarbon composites

The invention relates to a lithium sulfur battery positive electrode material and a preparation method thereof. The method comprises the steps of preparing a mixed solution of N, N-dimethylformamide,methyl alcohol and phthalic acid, adding tetrabutyl titanate by ultrasonic dispersion, placing in a reaction kettle with a polytetrafluoroethylene lining, and performing reaction under 120-150 DEG C to prepare a metal organic framework material MIL-125(Ti); placing the MIL-125(Ti) in a cobalt acetate solution, performing high-temperature calcination under an argon atmosphere to obtain Co3O4 / TiO2 / Ccomposite material after centrifugal separation; and performing thermal processing under nitrogen protection to obtain S-Co3O4 / TiO2 / C composite material after ball-milling and mixing with pure-phasenanometer sulfur powder. By the material, Co3O4 / TiO2 / C is organically combined, and a shuttle effect of a polysulfide can be limited by absorption of carbon material pores; and the dissolving of an intermediate product is prevented by an absorption effect and a catalytic effect, the electrochemical reaction speed of an active material absorbed onto a carrier surface is improved, and the capacity and the cycle property of Li-S battery are improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

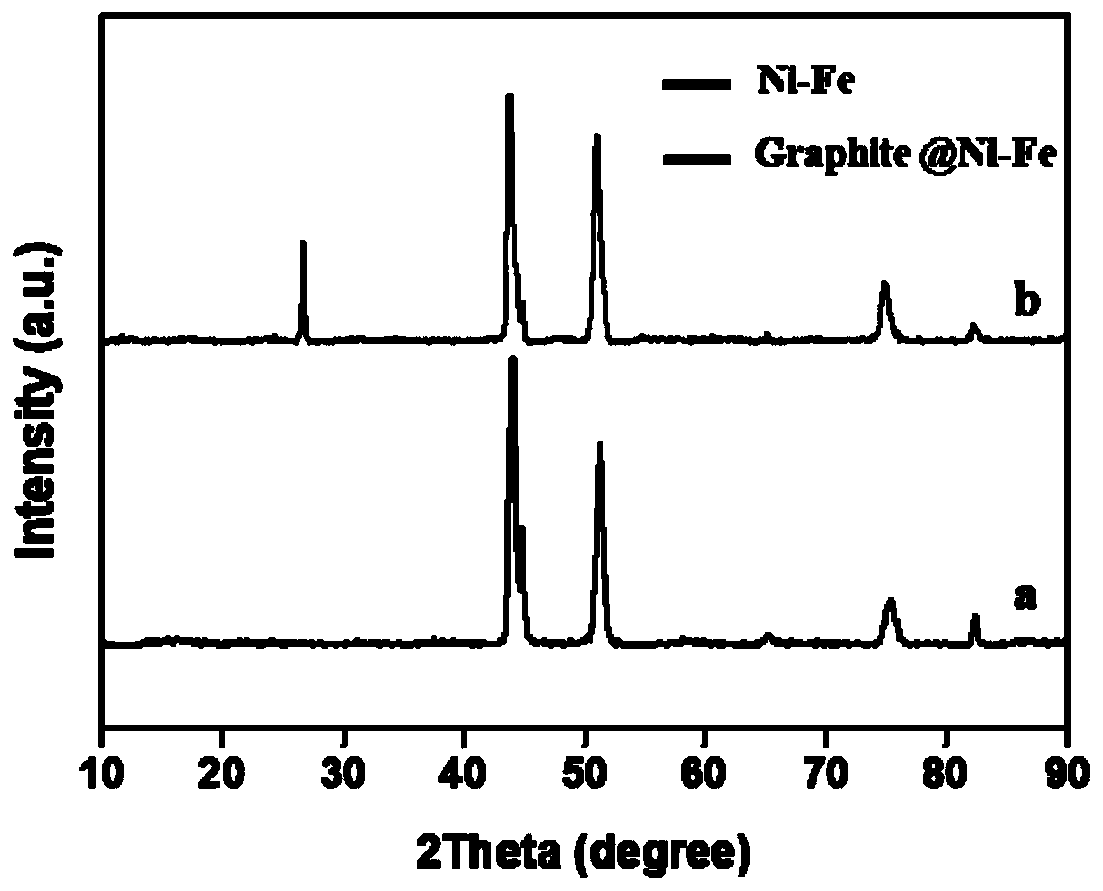

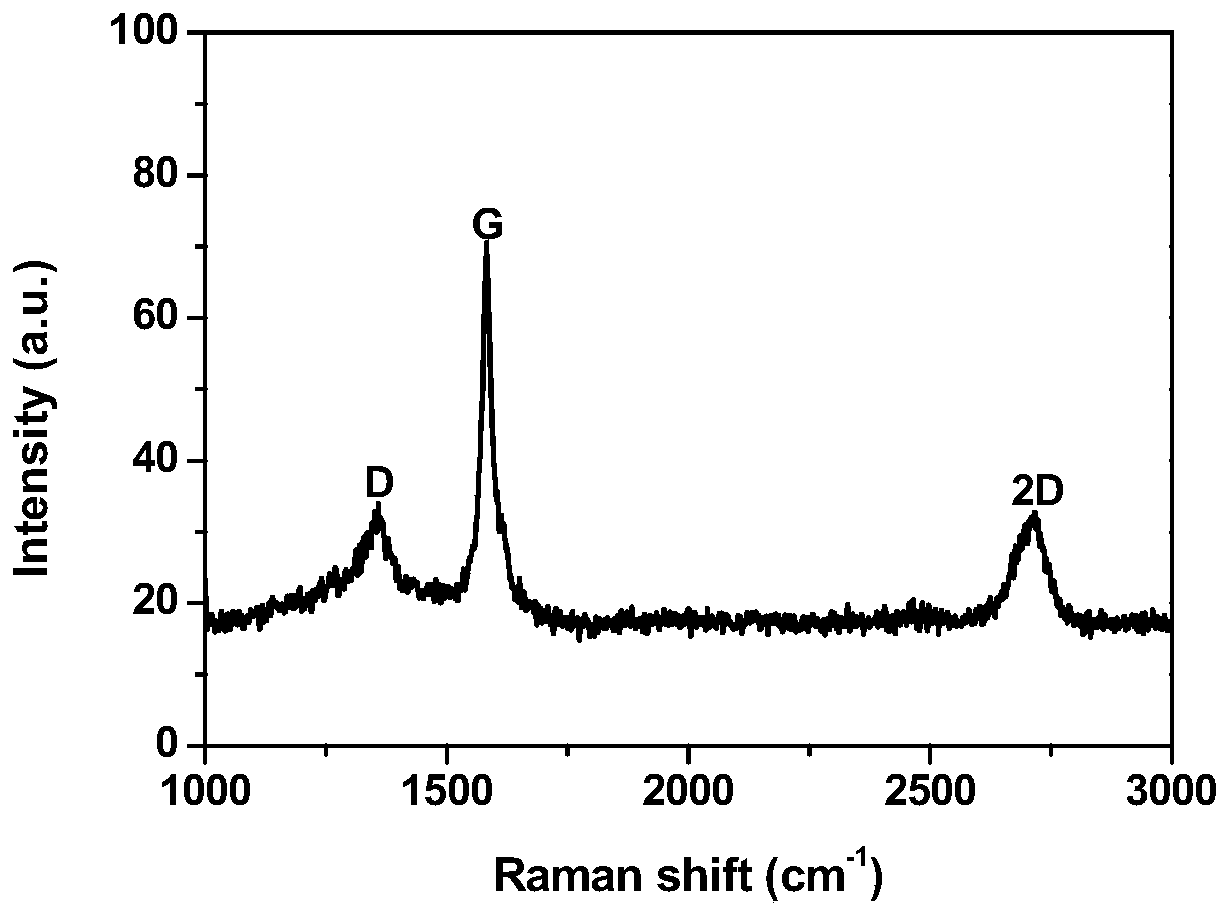

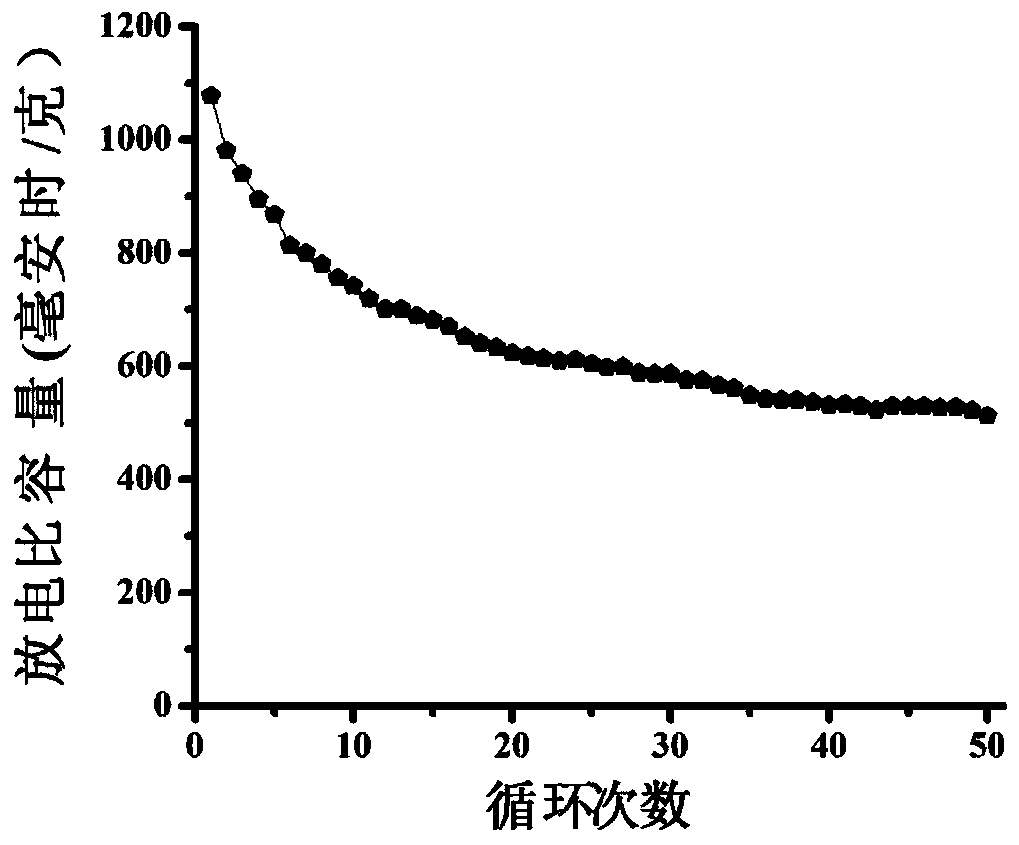

High-performance liquid metal battery negative current collector and preparation method thereof

ActiveCN110752373AImproved magnification performanceImprove electrochemical cycle performanceFinal product manufactureElectrode carriers/collectorsMetallic lithiumGraphite

The invention provides a high-performance liquid metal battery negative current collector and a preparation method thereof, and belongs to the technical field of battery material preparation. A graphene layer is controllably grown in situ on a nickel-based alloy foam skeleton by adopting a chemical vapor deposition method, so that the tight combination of the graphite layer and a nickel-based alloy foam material matrix is realized, and the high-performance negative current collector is obtained. On one hand, a graphite protective layer is used as an effective barrier for preventing corrosion,so that the corrosion time of the nickel-based alloy foam matrix and the invasion path of an erosion substance can be prolonged, and the long-acting stable operation of a liquid metal battery is realized; and on the other hand, the prepared fish-scale-shaped graphite layer has a unique microstructure, so that the wettability of the current collector to liquid metal lithium is improved, and the charging and discharging stability is improved. The liquid metal battery assembled by taking the graphite @ nickel-based alloy foam composite material as the negative current collector has excellent rateperformance and cycle performance.

Owner:UNIV OF SCI & TECH BEIJING

Sodium-sulfur battery positive electrode material and preparation method thereof

ActiveCN109755542ALimit the "shuttle effect"Limit shuttle effectNon-aqueous electrolyte accumulatorsCell electrodesElectrochemical responsePorosity

The invention relates to a sodium-sulfur battery positive electrode material and a preparation method thereof. The sodium-sulfur battery positive electrode material is a sulfur-titanium dioxide-carboncomposite material, and the preparation method includes the following steps: firstly, preparing a metal organic framework material MIL-125, spray-drying and compounding the metal organic framework material MIL-125 with graphene, performing carbonization treatment to obtain a titanium dioxide-carbon composite material, and then doping sulfur to prepare a sulfur-titanium dioxide-carbon composite sodium-sulfur battery positive electrode material by using a ball milling method and a hot melting method. The composite material prepared by using the method has a larger specific surface area and porosity, can limit the 'shuttle effect' of polysulfide, reduces the dissolution of intermediate products, can improve the electrochemical activity of elemental sulfur, shortens the transmission paths ofelectrons and ions, limits the dissolution of polysulfide, and improves the electrochemical reaction speed of active materials adsorbed on the surface of a carrier.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

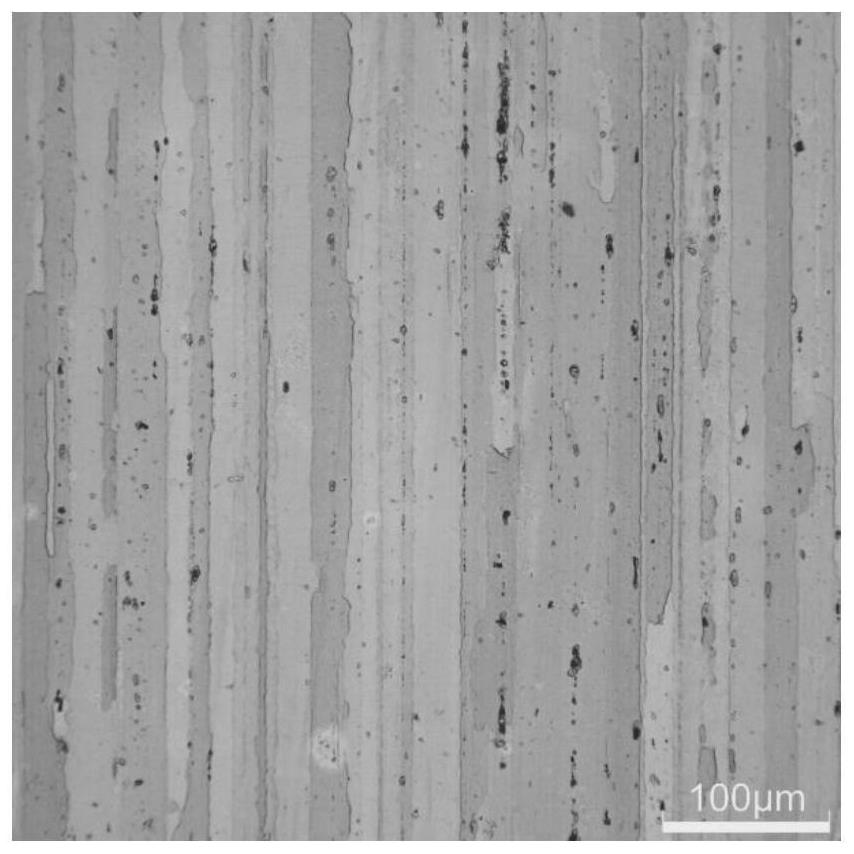

Metallographic corrosion method and metallographic corrosive agent for aluminum alloy

ActiveCN114318341APrevent smearingCorrosion method is simplePreparing sample for investigationHydrogen SulfateGrain boundary

The invention discloses an aluminum alloy metallographic corrosion method and a metallographic corrosive agent thereof. The metallographic corrosion method comprises the following steps that a, a 7055 aluminum alloy sample is subjected to pre-cleaning, hot inlaying, mechanical grinding and mechanical polishing treatment, washed with clear water and blow-dried, and then a metallographic sample is obtained; b, sequentially adding nitric acid, hydrochloric acid, sulfuric acid, hydrofluoric acid and deionized water into a container, and mixing to obtain a metallographic corrosive agent, wherein the metallographic corrosive agent comprises the following components in percentage by volume: 4-5% of nitric acid, 2-3% of hydrochloric acid, 1.5-2.5% of sulfuric acid, 2.5-3.5% of hydrofluoric acid and the balance of deionized water; and c, pouring the metallographic corrosive into a culture dish, placing the culture dish in a constant-temperature environment of 22-28 DEG C, immersing the metallographic sample into the metallographic corrosive, corroding for 25-35 seconds, taking out, washing, drying, and observing. The corrosion method is simple, the corrosion time is short, the effect of the metallographic corrosive agent is fully exerted, and the crystal boundary and crystal grains of the 7055 aluminum alloy are clearly displayed.

Owner:DONGFENG MOTOR GRP

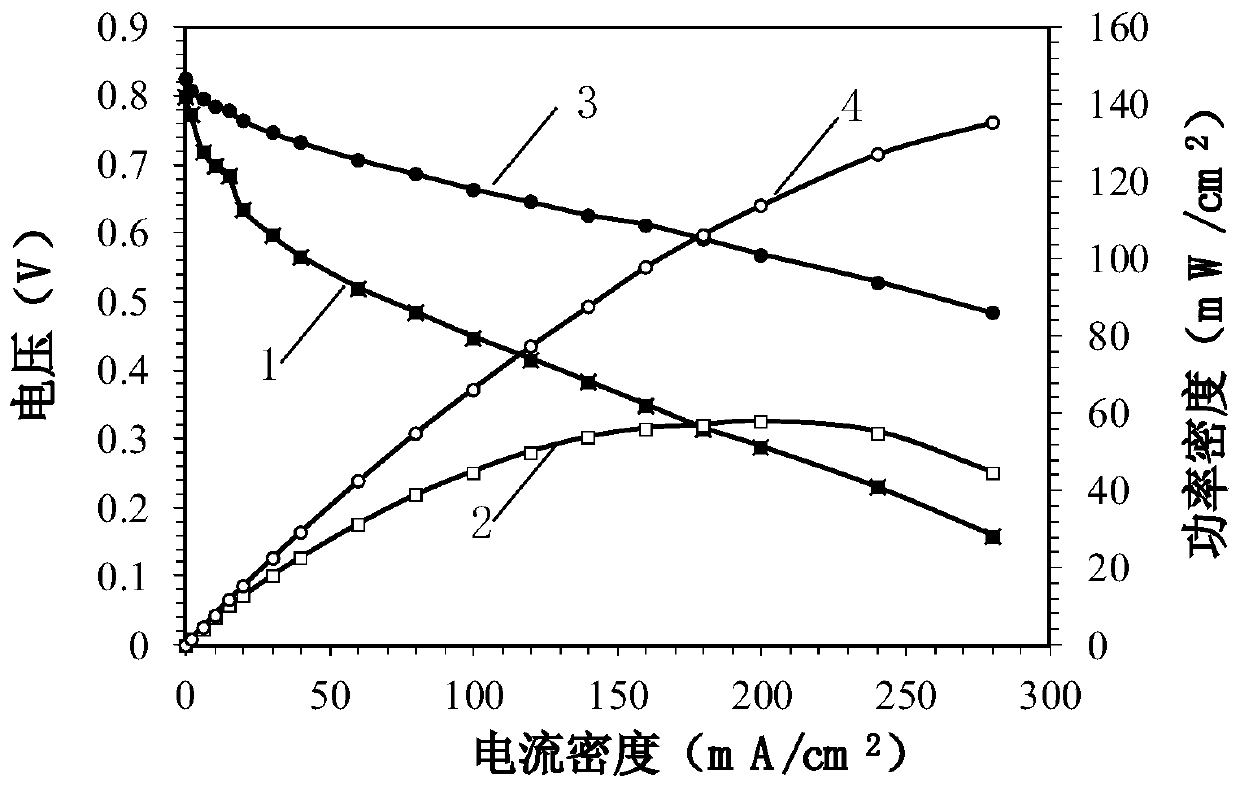

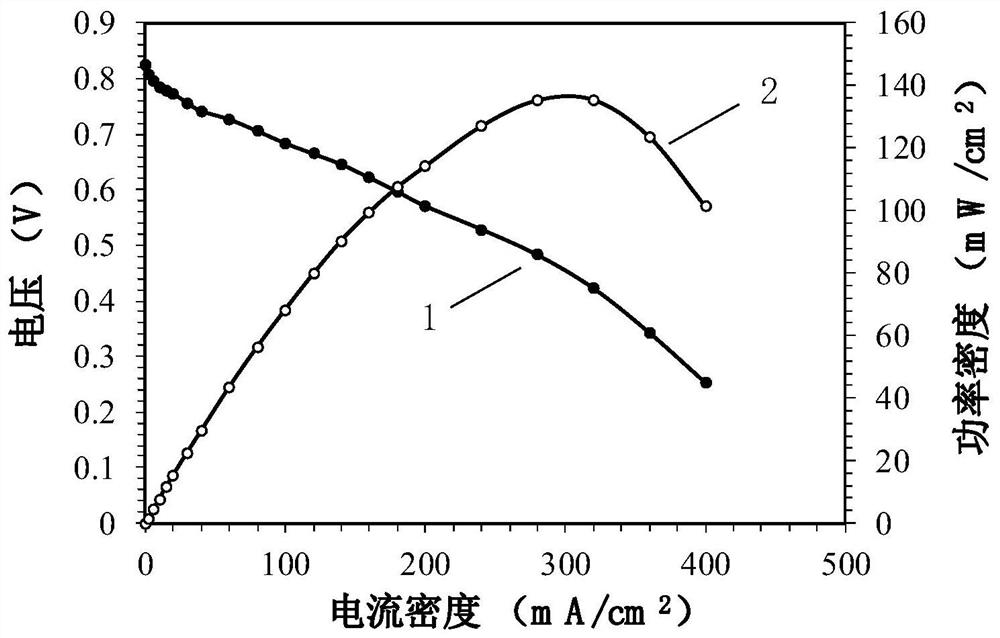

Preparation of monatomic palladium catalyst and application of monatomic palladium catalyst in direct formic acid fuel cell

ActiveCN110690467AAvoid generatingImprove electrocatalytic activityCell electrodesFuel cellsPtru catalystFuel cells

The invention relates to a fuel cell technology, and aims to provide preparation of a monatomic palladium catalyst and application of the monatomic palladium catalyst in a direct formic acid fuel cell. The preparation method comprises the following steps of: preparing an o-phenylenediamine cyclodextrin inclusion compound from o-phenylenediamine and [beta]-cyclodextrin, adding the o-phenylenediamine cyclodextrin inclusion compound into a chloropalladic acid solution, and performing stirring to obtain a palladium coordinated o-phenylenediamine cyclodextrin inclusion compound solution; adding sodium chloride, carrying out liquid nitrogen flash freezing, and performing drying to obtain a precursor; carbonizing the precursor under the protection of nitrogen atmosphere, performing cooling, washing and drying to obtain the monatomic palladium catalyst. The technical route is simple, universality is achieved, and generation of impure phases can be avoided. The monatomic palladium catalyst hashigher electrocatalytic activity, and the cost can be effectively reduced. The co-catalytic application of the monatomic palladium catalyst and the cocatalyst (VO)SO4 provides a new thought for the design and performance improvement of the direct formic acid fuel cell, and is beneficial to the commercial development of the fuel cell.

Owner:ZHEJIANG UNIV

Temperature control device for power lithium battery

InactiveCN102544623ASuitable working environment temperatureGuaranteed output currentSecondary cellsElectrochemical responseEngineering

The invention discloses a temperature control device for a power lithium battery. The temperature control device comprises a temperature controlled battery box communicated with a high-temperature liquid source and a low-temperature liquid source to form a circulation loop via pipelines, wherein a circulating pump is arranged on the circulation loop; a temperature sensor and a control unit are connected between the circulating pump and the temperature controlled battery box; and the high-temperature liquid source, as well as the low-temperature liquid source, comprises a temperature controlled liquid box with both a liquid inlet and a liquid outlet, a radiator is arranged above the temperature controlled liquid box, a metal plate is arranged between the temperature controlled liquid box and the radiator, and semiconductor temperature difference modules are respectively arranged between the metal plate and the temperature controlled liquid box, as well as between the metal plate and the radiator, and are electrically connected with a DC power supply after being coupled with each other. Through real-time detection of the temperature sensor and in-time regulation and control of the control unit, an appropriate work environment temperature can be provided for the lithium battery, the electrochemical reaction speed is increased, and the output current, the output voltage and the discharge capacity of the lithium battery are ensured to enable the lithium battery to play the optimal performance and satisfy the utilization request of the power supply.

Owner:李辉 +1

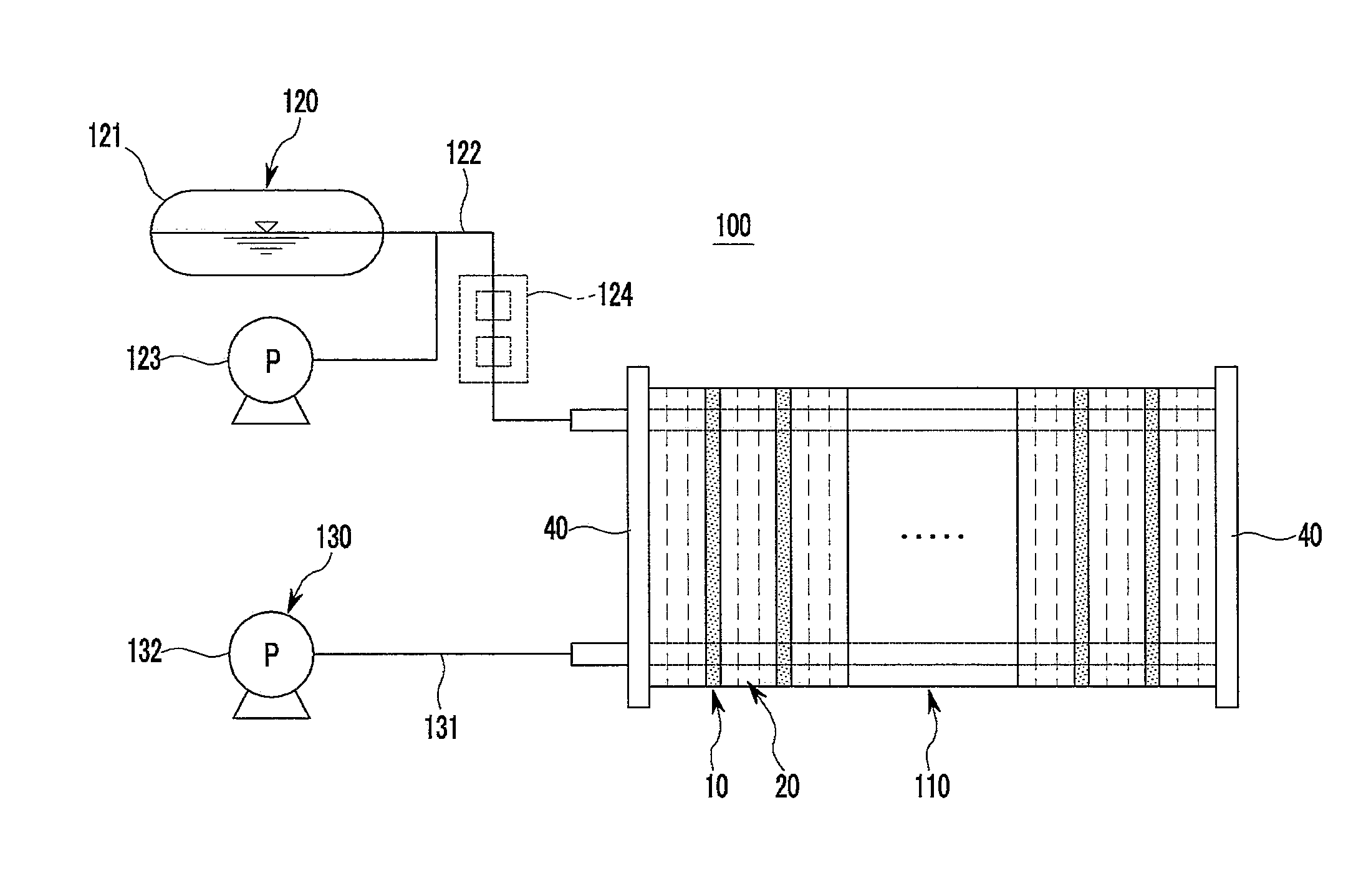

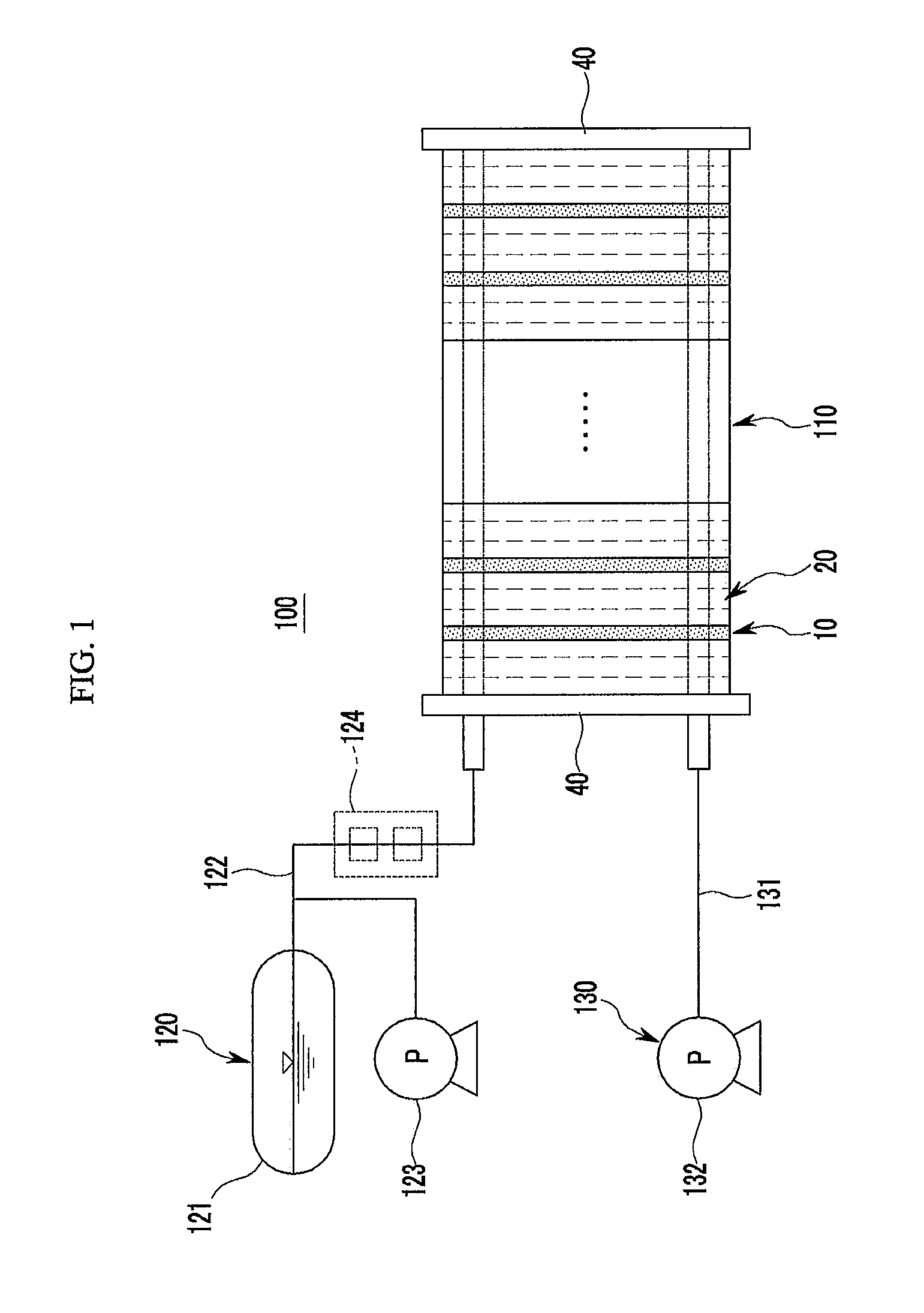

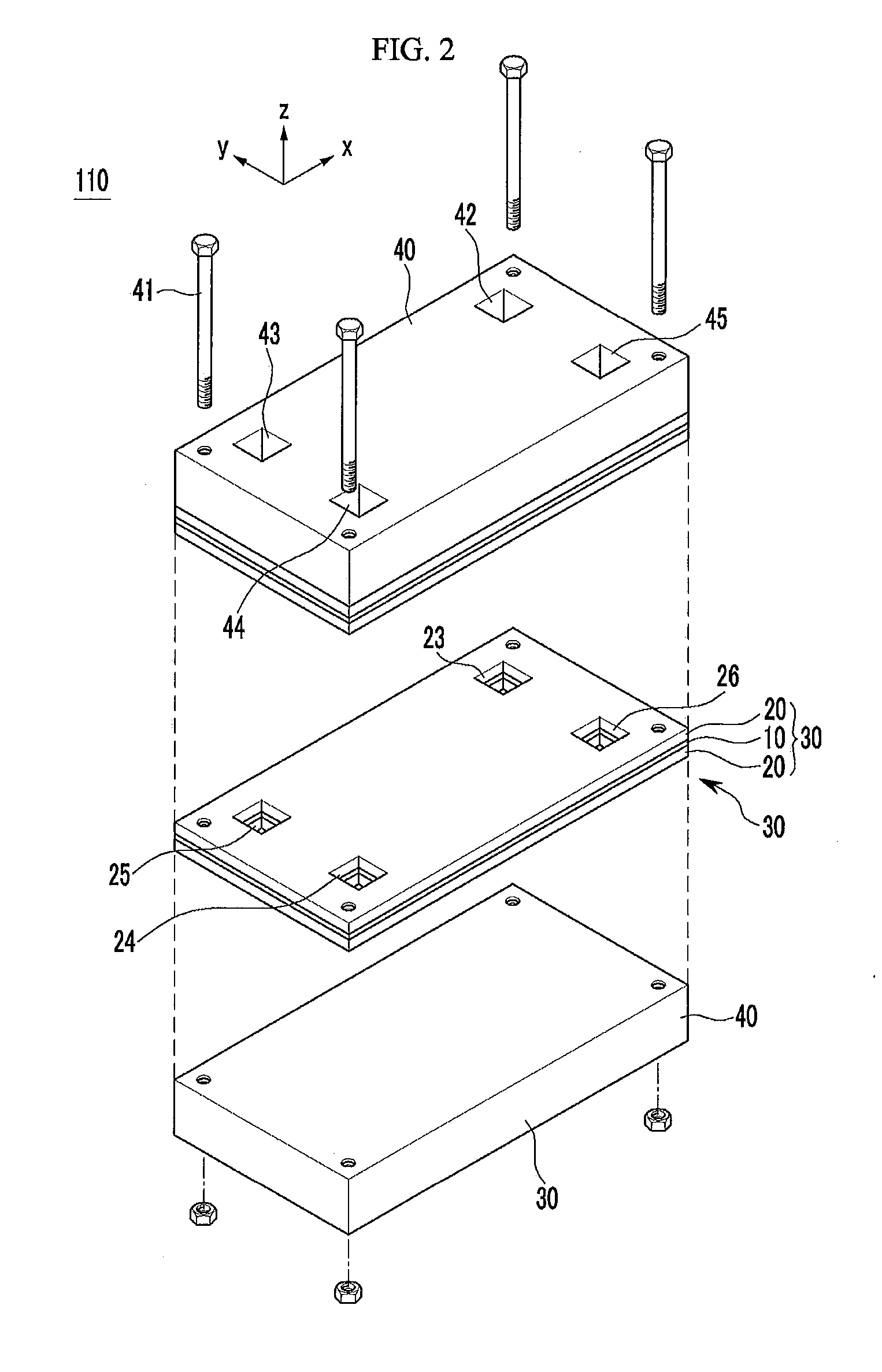

Fuel Cell System and Stack

InactiveUS20130280633A1Minimize temperature gradientMinimizes gradientReactant parameters controlFuel cells groupingElectricityElectrochemical response

Provided is a fuel cell system in which a plurality of electricity generating units each including a unit cell in which an anode electrode and a cathode electrode are formed on both sides of an electrolyte film to use an electrochemical reaction of a fuel and an oxidizing agent to generate an electrical energy and a pair of separating plates which are disposed on both surfaces of the unit cell and have passages through which a fuel and an oxidizing agent are supplied to the anode electrode and the cathode electrode are laminated in which the electricity generating unit has a structure where a fuel flowing direction and / or a flowing direction of the fuel or the oxidizing agent are different between neighboring electricity generating units.

Owner:POHANG IRON & STEEL CO LTD

Quick charged long life accumulator

InactiveCN1434532ALow costMicroporosity increaseFinal product manufactureSecondary cells manufactureInternal resistanceElectrical polarity

This invention discloses a quickly charged long life accumulator including a battery tank made of insulation materials and positive, negative pole plates of multiraw baffles arranged in gaps in the electrolyte and a collelcting bar collecting the pole plates and binding post extending out of the battery cover, the key is to take light metal or compount material as the two pole plates to matrix frame, two sidesurfaces are plated with two layers of coating of active substances, the electrolyte is compound electrolyte with additives enabling huge increases of micro pore rate on the pole plates and quickly penetrates and enters inside to contact with reacted active substances. It can be quickly charged by large current.

Owner:杨崇权

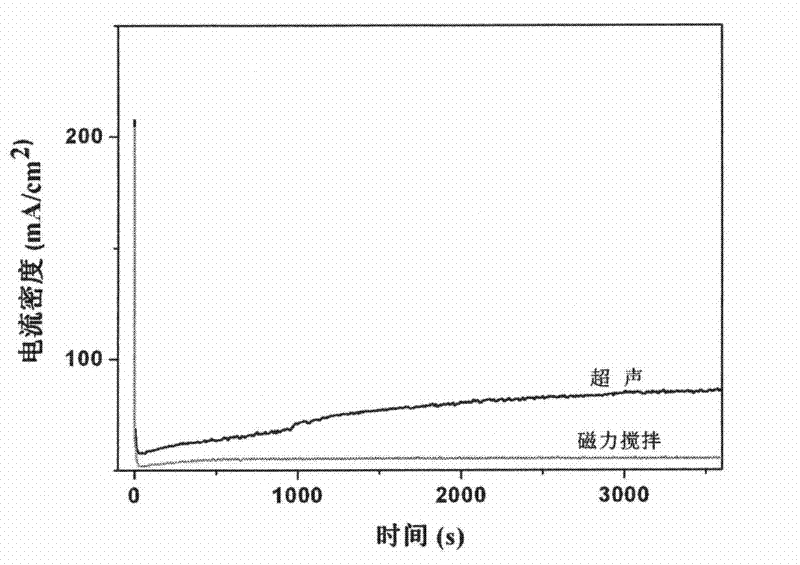

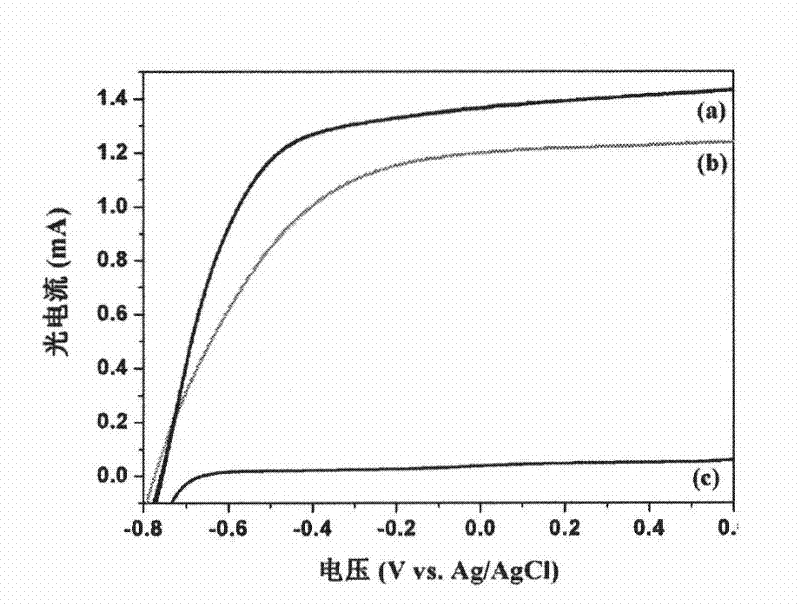

Method for degrading organic substances by using photoelectric catalysis of short TiO2 nano-tube array film electrode

InactiveCN101519233BShort thicknessReduce compoundingWater/sewage treatment by irradiationWater contaminantsUltrasonic dispersionPt element

The invention relates to a method for degrading organic substances by using photoelectric catalysis of a short TiO nano-tube array film electrode, and belongs to the technical field of environment polThe invention relates to a method for degrading organic substances by using photoelectric catalysis of a short TiO nano-tube array film electrode, and belongs to the technical field of environment pol tube length as the electrode, the method has the advantages of low photo-generated charge compound and quick transmission, and shows higher property of degrading the organic substances by photoelecer tube length as the electrode, the method has the advantages of low photo-generated charge compound and quick transmission, and shows higher property of degrading the organic substances by photoelectric catalysis.tric catalysis.lution governance. A cleaned titanium sheet as an anode is placed into an electrolyte solution containing fluorine ions, a platinum electrode as a counter electrode is subjected to anode oxidizing realution governance. A cleaned titanium sheet as an anode is placed into an electrolyte solution containing fluorine ions, a platinum electrode as a counter electrode is subjected to anode oxidizing reaction, the reacted electrolyte solution is subjected to ultrasonic dispersion during the whole anode oxidizing reaction, and the reactants are sintered after the anode oxidization is ended to obtain tction, the reacted electrolyte solution is subjected to ultrasonic dispersion during the whole anode oxidizing reaction, and the reactants are sintered after the anode oxidization is ended to obtain the short TiO2 nano-tube array film electrode. By using the obtained short TiO2 nano-tube array film electrode as a working electrode, Ag-AgCl as a reference electrode and Pt as the counter electrode,he short TiO2 nano-tube array film electrode. By using the obtained short TiO2 nano-tube array film electrode as a working electrode, Ag-AgCl as a reference electrode and Pt as the counter electrode,0.01 to 1 mole of sodium sulfate solution is added into organic pollutant solution, and then the organic pollutants can be degraded. By adopting the firm TiO2 nano-tube array film electrode with short0.01 to 1 mole of sodium sulfate solution is added into organic pollutant solution, and then the organic pollutants can be degraded. By adopting the firm TiO2 nano-tube array film electrode with shorter

Owner:SHANGHAI JIAOTONG UNIV

Method for preparing ultra-small oxide and carbon compounded lithium battery negative electrode material by microwave method

PendingCN113666411AAlleviate volume expansionImprove conductivityNegative electrodesSecondary cellsMicrowave methodLithium electrode

The invention relates to a method for preparing an ultra-small oxide and carbon compounded lithium battery negative electrode material by a microwave method. The invention belongs to the field of preparation of lithium ion battery negative electrode materials. The invention aims to solve the technical problems that the existing lithium ion battery is low in comprehensive performance such as capacity and conductivity, the preparation process is relatively complicated, and the cost is relatively high. The method comprises the following steps: 1, preparing a salt solution to enable metal ions to permeate into a metal-organic framework (MOF) material; separating the ion-permeated MOF material from the solution by suction filtration, and drying to obtain an ion-permeated MOF material; 2, mixing the ion-permeated MOF material and graphene, grinding, and then carrying out microwave short-time heating; and 3, washing and removing impurities from the product to obtain the ultra-small oxide and carbon compounded lithium battery negative electrode material. The nano-particle size of the product is 2-10nm, and the product can have high capacity under low oxide loading.

Owner:HARBIN INST OF TECH

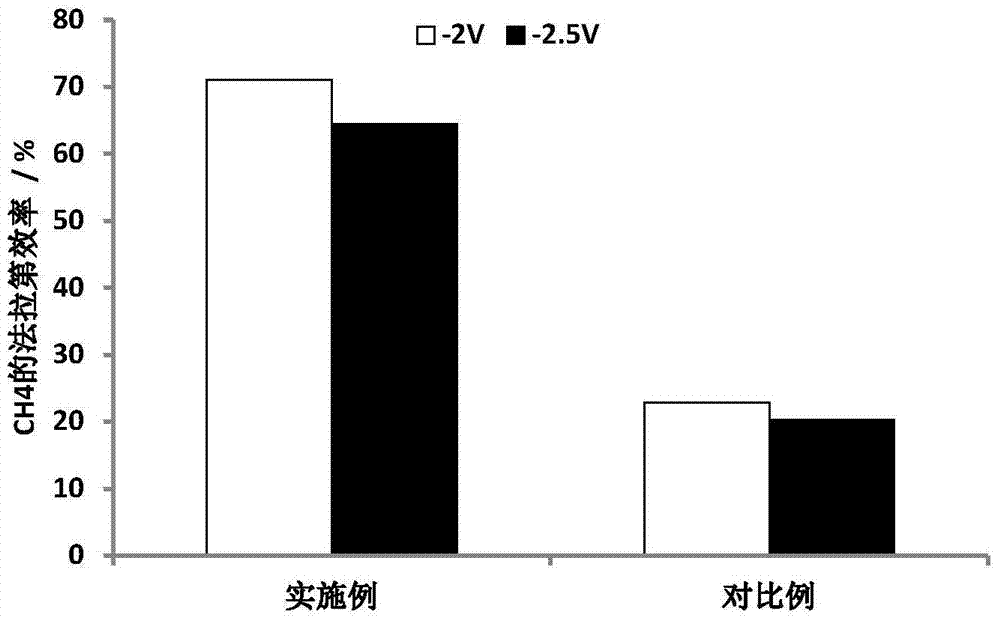

Direct formic acid fuel cell with vanadium sulfate oxide homogeneous assisted catalysis

ActiveCN110571463ARealize the electrochemical reactionAvoid dehydrationFuel cellsElectrochemical responseCatalytic effect

The invention relates to a fuel cell technology and aims to provide a direct formic acid fuel cell with vanadium sulfate oxide homogeneous assisted catalysis. The preparation method for modified formic acid fuel in the fuel cell comprises the following steps of: heating one liter of concentrated sulfuric acid with a mass concentration of 98 wt% to 70-90 DEG C, adding 0.1-1 mol of NH4VO3 and conducting stirring and reacting for 5 h, after cooling to room temperature, adding 1-4 liters of formic acid aqueous solution with a mass concentration of 30-60 wt% to obtain modified formic acid fuel containing a (VO)SO4 cocatalyst. (VO)SO4 is added into the formic acid solution to play a co-catalytic role, dehydration reaction of formic acid on a solid catalyst is prevented, and catalyst poisoning iseffectively avoided. The cocatalyst exists in the formic acid solution, is not restricted by the supported area of the solid catalyst, can play the role of the cocatalyst to the maximum extent and does not reduce the supported amount of the main catalyst on the solid carrier. The active center is homogeneous and has high activity, and the electrochemical reaction speed of the formic acid is greatly improved. A new idea is provided for design and performance improvement of direct formic acid fuel cells.

Owner:ZHEJIANG UNIV

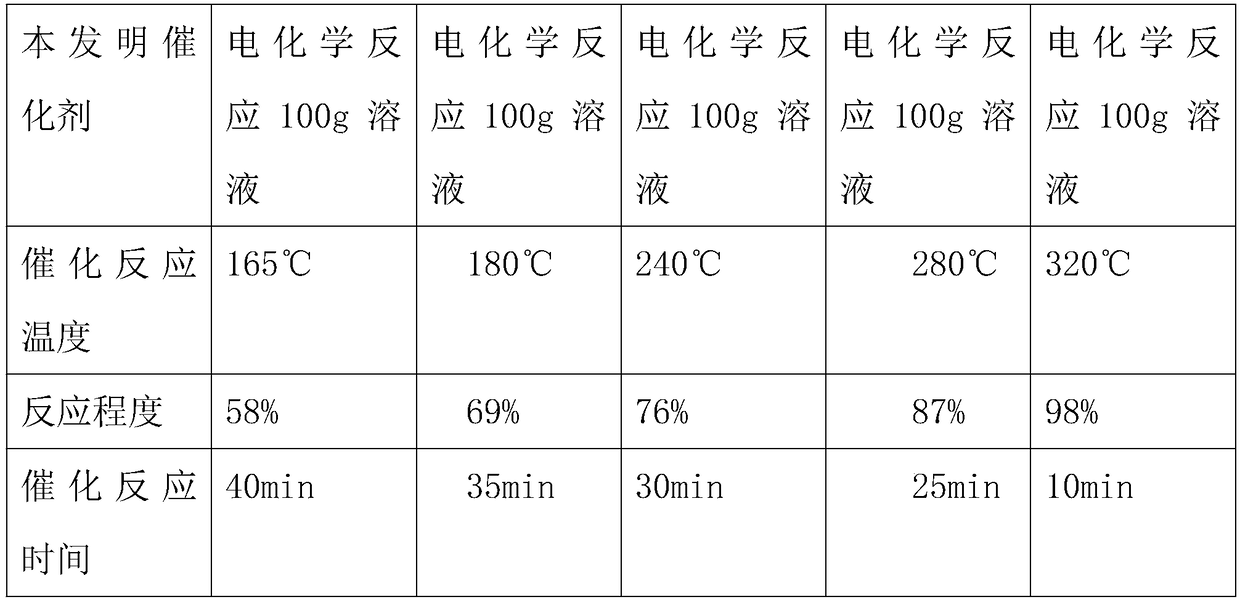

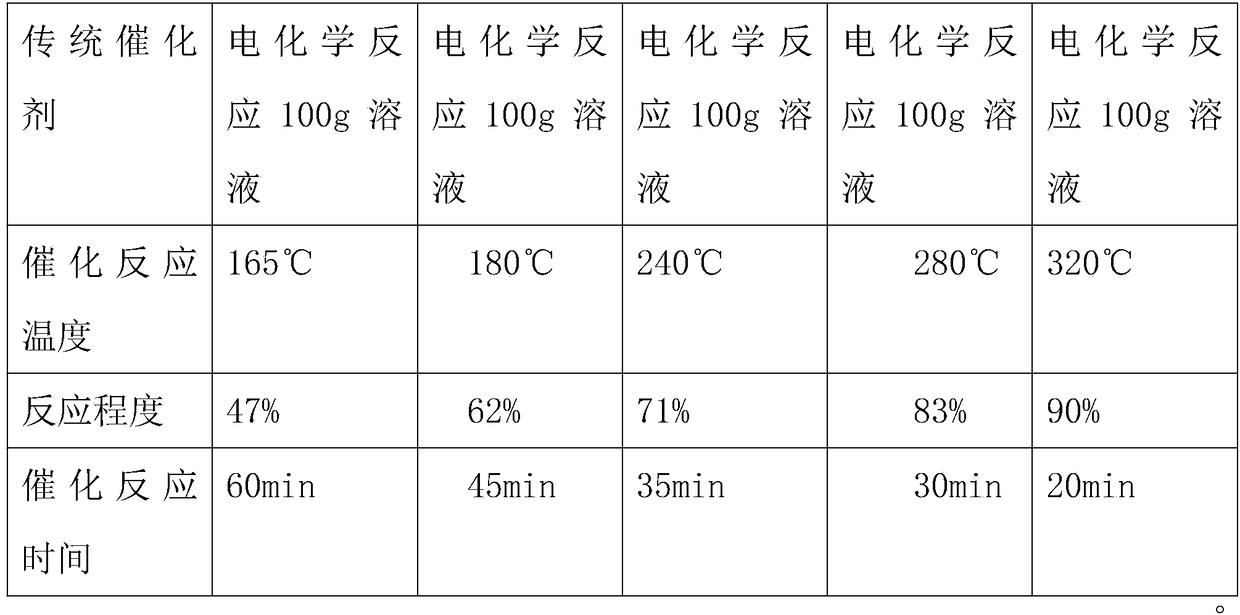

Catalyst for electrochemical application

InactiveCN108855231ALow costImprove the electrochemical reaction speedOrganic-compounds/hydrides/coordination-complexes catalystsPotassiumElectrochemistry

The invention discloses a catalyst for electrochemical application. The catalyst is prepared from the following raw materials in parts by weight: 4 to 7 parts of benzidine, 3 to 9 parts of sodium ferrocyanide, 3.5 to 6 parts of hexacyano ethane, 0.75 to 1.5 parts of ruthenium trichloride, 2.5 to 5 parts of ruthenium acetate, 7 to 14 parts of potassium hexachlororuthenate, 2 to 4 parts of nanoscaleplatinum powder, 0.8 to 2 parts of bismuth oxide, 3 to 6 parts of titanium dioxide, 4 to 8 parts of bismuthinite powder, 0.2 to 0.4 part of disodium tetrachloropalladate, 0.15 to 0.3 part of palladium dichloride, 0.3 to 0.5 part of tin sulfide, 0.4 to 0.6 part of transition mixed metal and 15 to 30 parts of a mixed solution. The prepared catalyst for electrochemical application disclosed by the invention can effectively accelerate electrochemical reaction speed at the normal-temperature or high-temperature; the whole catalyst has the advantages of low raw material cost, simple processing method and worth of popularization.

Owner:ZAOZHUANG UNIV

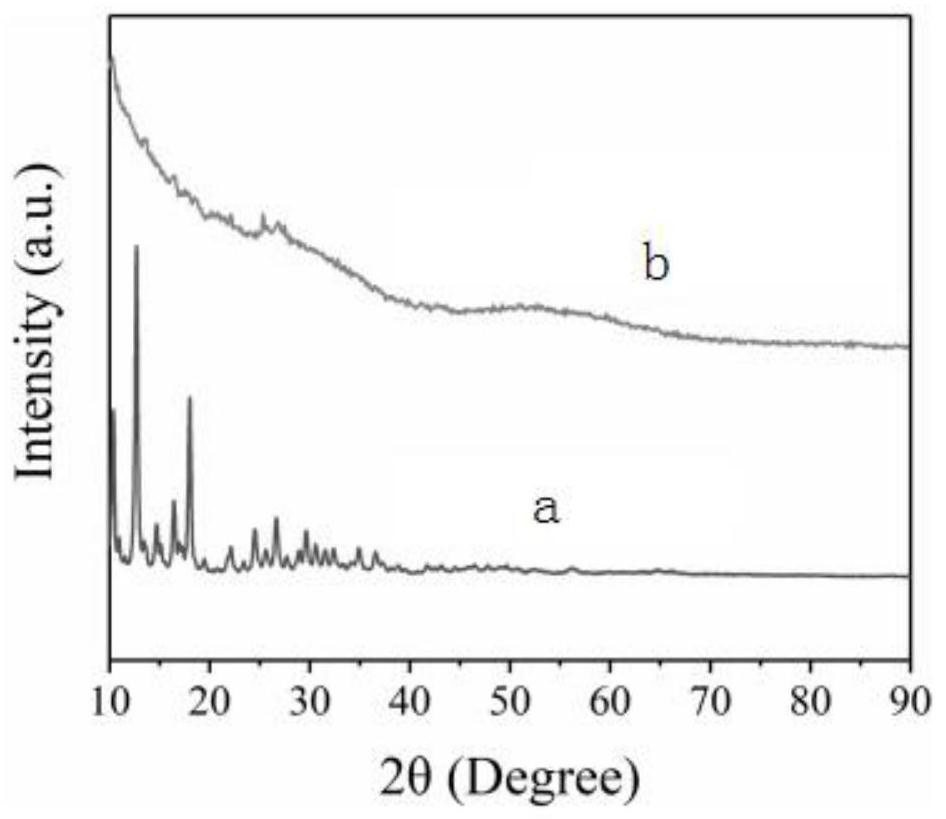

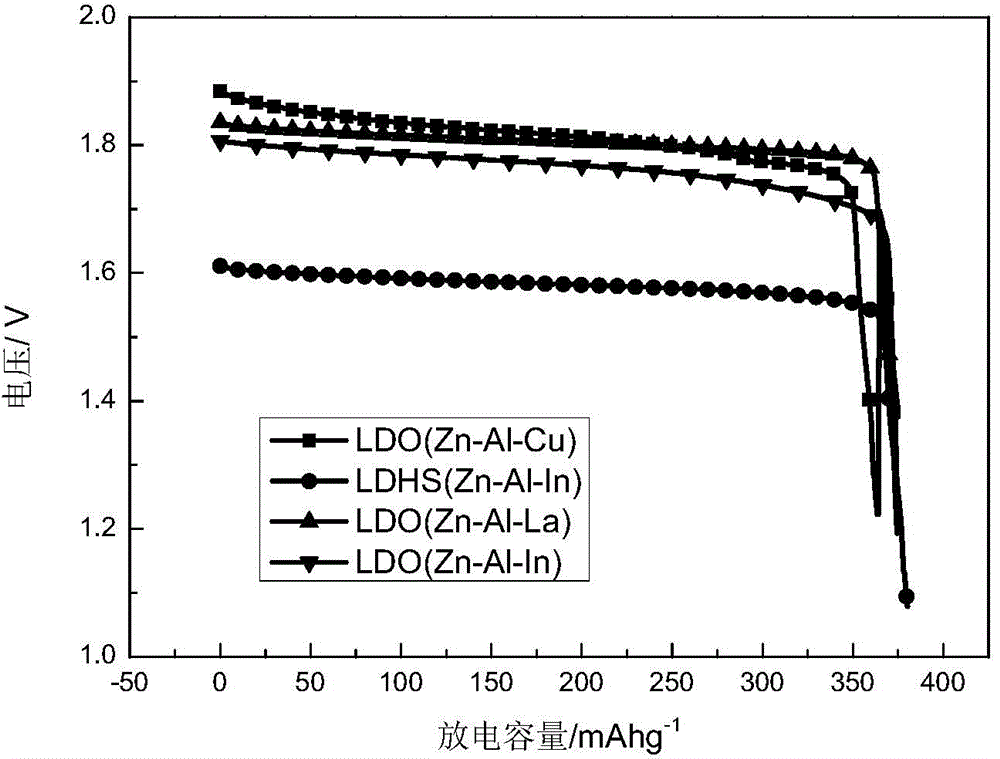

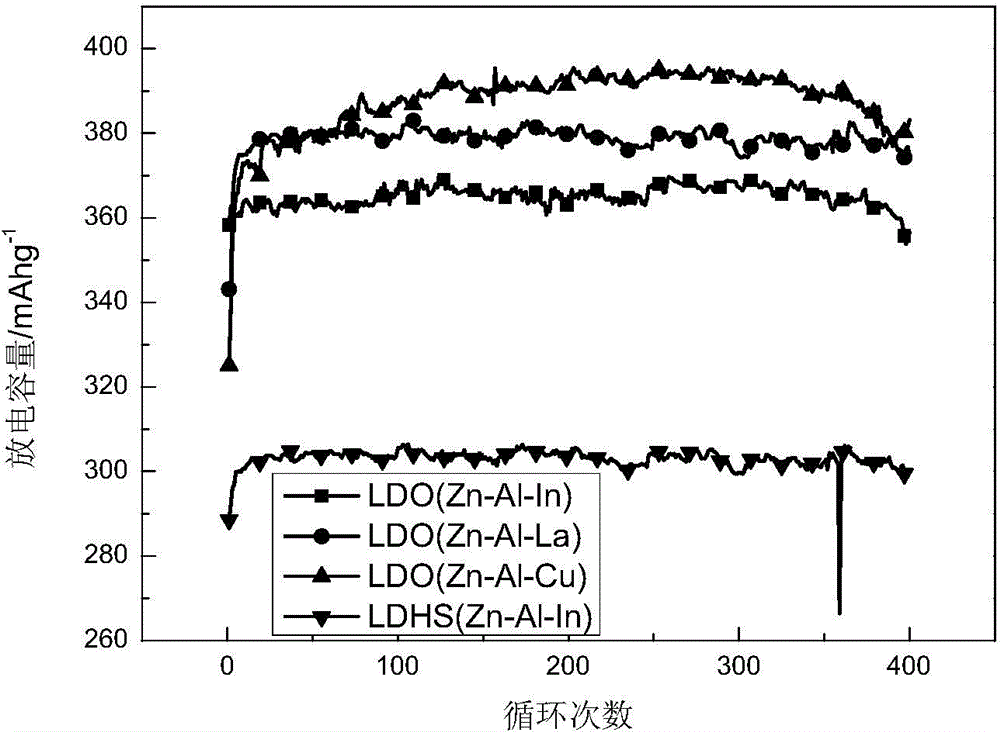

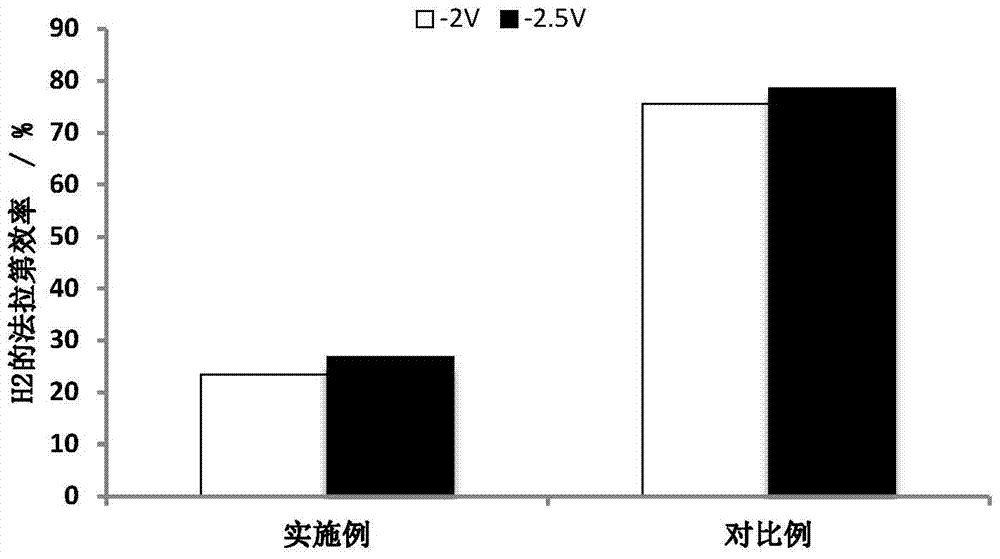

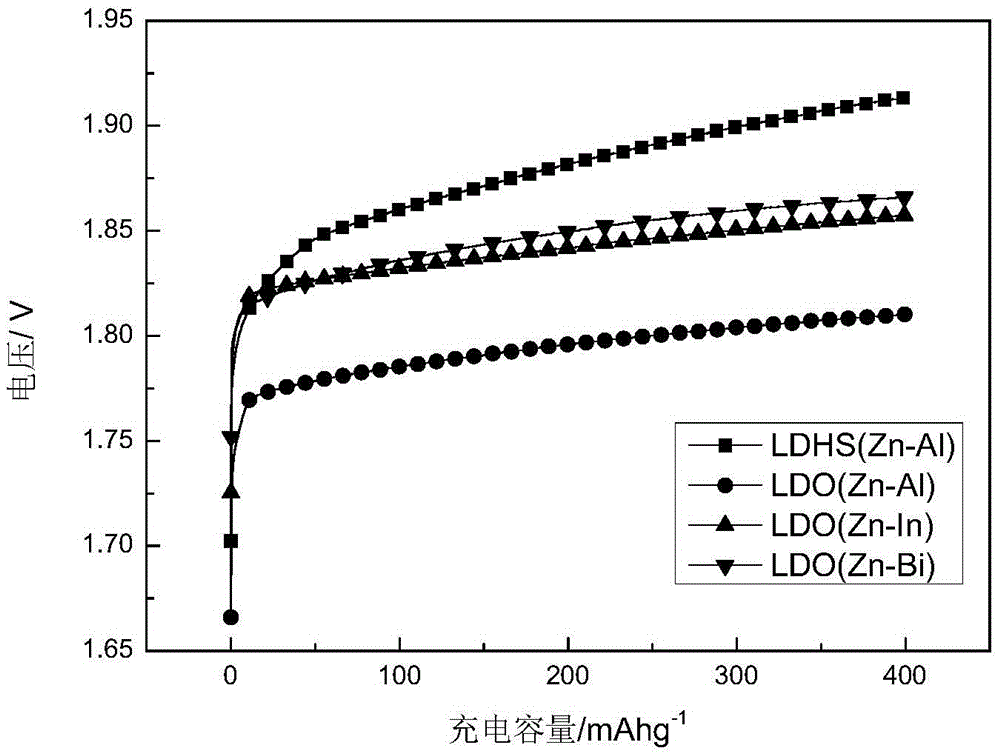

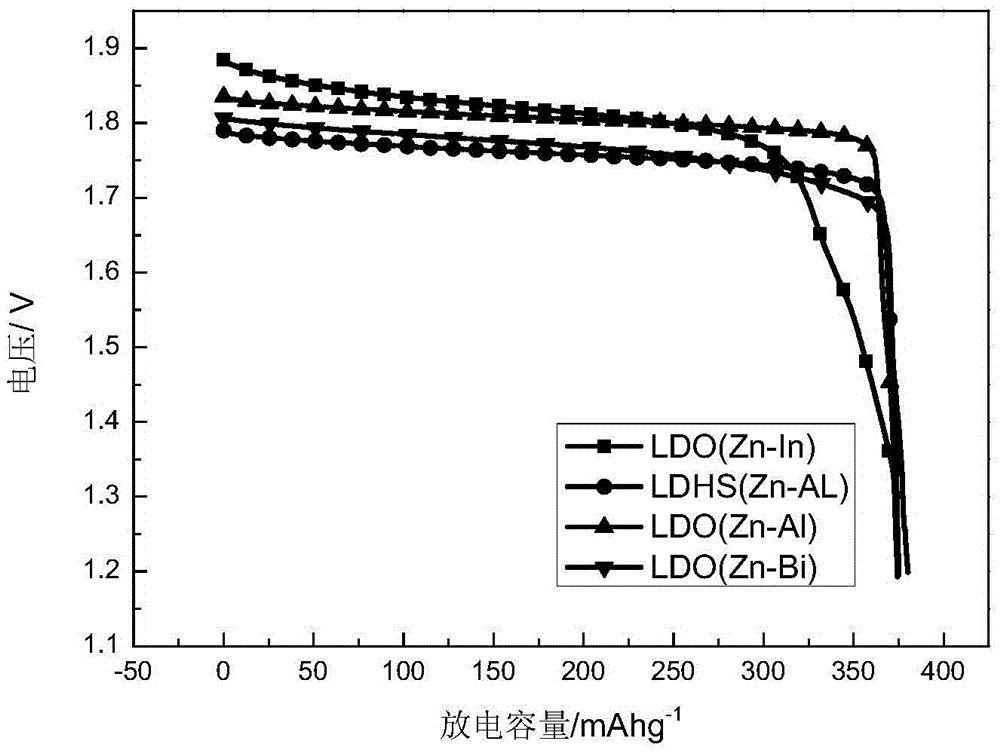

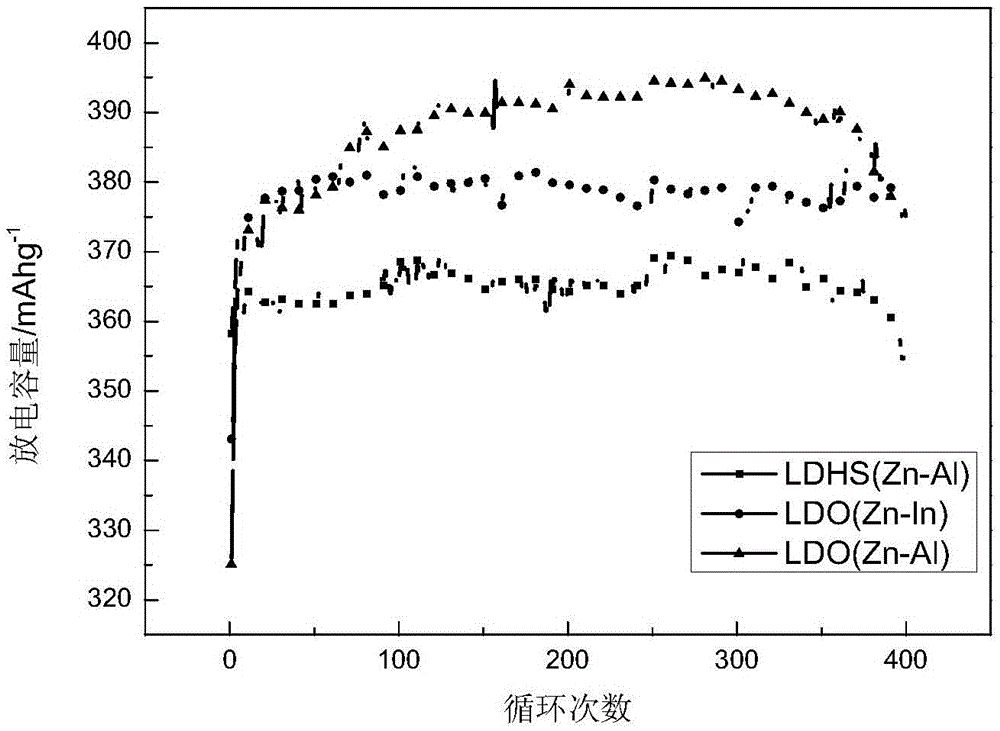

Application of a zinc-based ternary layered composite oxide as an electrode material for a zinc-nickel battery

InactiveCN103579588BIncrease conduction rateImprove the electrochemical reaction speedAlkaline accumulator electrodesDissolutionZinc nitrate

The invention discloses an application of a zinc-based ternary layered composite oxide to a zinc-nickel battery electrode material. The zinc-based ternary layered composite oxide is obtained by calcining carbonate type ternary zinc-based hydrotalcite; the ternary zinc-based hydrotalcite is prepared from zinc nitrate and two selected from divalent metal oxides and trivalent metal nitrates without the zinc nitrate. The zinc-based ternary layered composite oxide is used as an active substance so that the deformation of a zinc cathode is weakened, the dissolution of the active substance of the zinc cathode is inhibited, the reversibility of a zinc-nickel battery electrode is improved and the service life of the zinc-nickel battery electrode is prolonged.

Owner:CENT SOUTH UNIV

An electrolytic cell for electrochemical reduction of carbon dioxide and its application

ActiveCN105316700BImprove conversion rateIncrease concentrationCellsElectrolytic organic productionElectrochemical responseVapor–liquid separator

The invention discloses an electrolytic cell for electrochemical reduction of carbon dioxide and its application, comprising a cathode chamber, an anode chamber and a gas-liquid separator; It is a container with an open lower end, the upper cavity is placed above the lower cavity, and a first flange is provided at the opening ends of the two cavities, and the two cavities are connected through the first flange; it is different from the traditional H Compared with the type electrolytic cell, it can significantly improve the conversion rate of carbon dioxide, increase the electrochemical reaction speed, and at the same time, it is easy to operate and convenient to calculate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation of Single-atom Palladium Catalyst and Its Application in Direct Formic Acid Fuel Cell

ActiveCN110690467BAvoid generatingImprove electrocatalytic activityCell electrodesFuel cellsPtru catalystFuel cells

Owner:ZHEJIANG UNIV

Application of a zinc-based binary layered composite oxide as an electrode material for a zinc-nickel battery

InactiveCN103579595BIncrease profitGood electrical contactAlkaline accumulator electrodesMetal nitrateMaterials science

The invention discloses an application of a zinc-based binary layered composite oxide to a zinc-nickel battery electrode material. The zinc-based binary layered composite oxide is obtained by calcining carbonate type binary zinc-based hydrotalcite; the binary zinc-based hydrotalcite is prepared from zinc nitrate and one selected from trivalent metal oxides. The zinc-based binary layered composite oxide is used as an active substance so that the deformation of a zinc cathode is weakened, the dissolution of the active substance of the zinc cathode is inhibited, the reversibility of a zinc-nickel battery electrode is improved and the service life of the zinc-nickel battery electrode is prolonged.

Owner:CENT SOUTH UNIV

Thermal management system of electric automobile

ActiveCN101885313BGuaranteed output currentGuaranteed output voltageAir-treating devicesElectric propulsion mountingControl signalEngineering

The invention discloses a thermal management system of an electric automobile, comprising a temperature sensor, a heating and cooling device and a central processing unit, wherein the temperature sensor is used for acquiring the temperature of components generating the raising and the drop of temperature in the electric automobile; the heating and cooling device is used for generating a heat source and a cold source which are transmitted to components needing heating and cooling and is connected with the signal output end of the central processing unit through a control switch; and the central processing unit is used for receiving a signal of the temperature sensor and calculating and outputting the control signal to the heating and cooling device. In the invention, the temperature conditions of various components can be detected by using the temperature sensor and are transmitted to the central processing unit which controls the temperature in time so as to ensure that the temperatures of various components are in a proper range. The system not only can be used for monitoring the temperature of batteries, but also can be used for monitoring the temperature of a motor and a motor controller, thereby avoiding the motor and the motor controller from being damaged due to overhigh temperature. The system can also be used for monitoring the temperature in a carriage and ensures thecomfort degree of the moving space of people.

Owner:李辉 +1

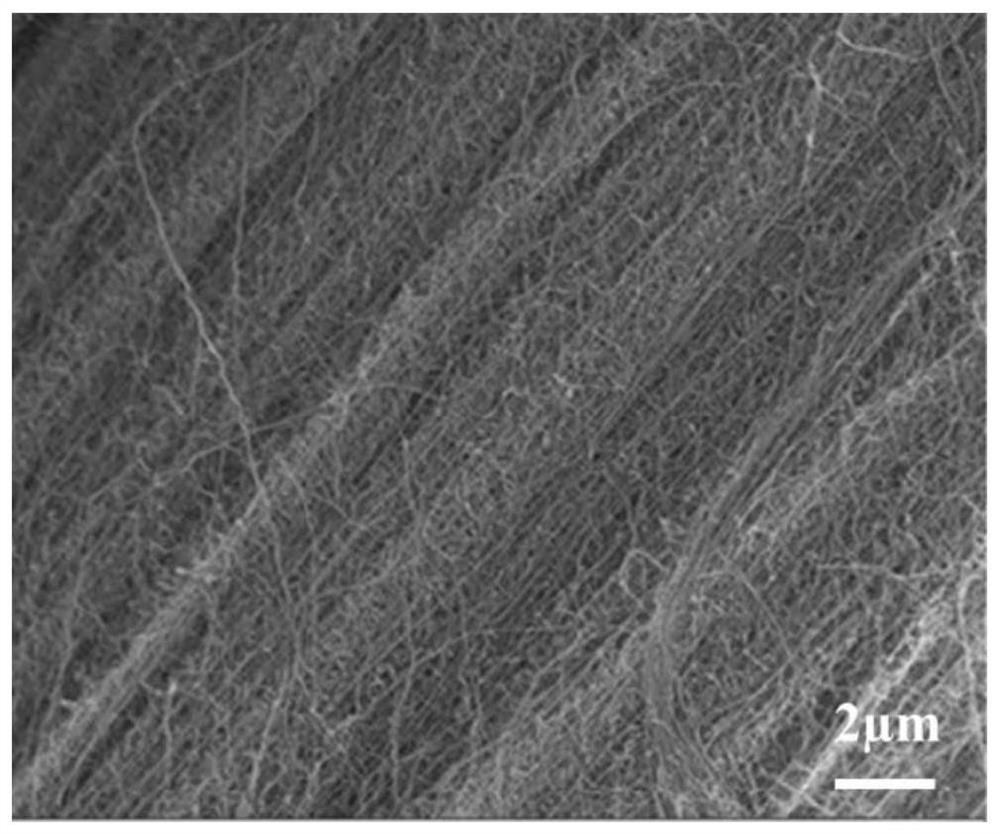

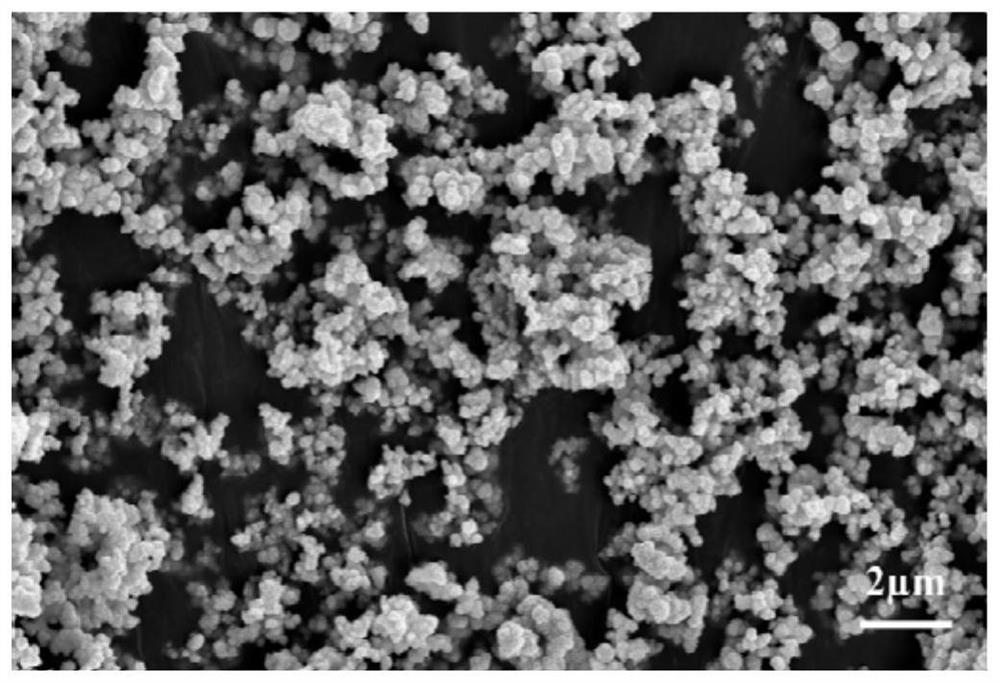

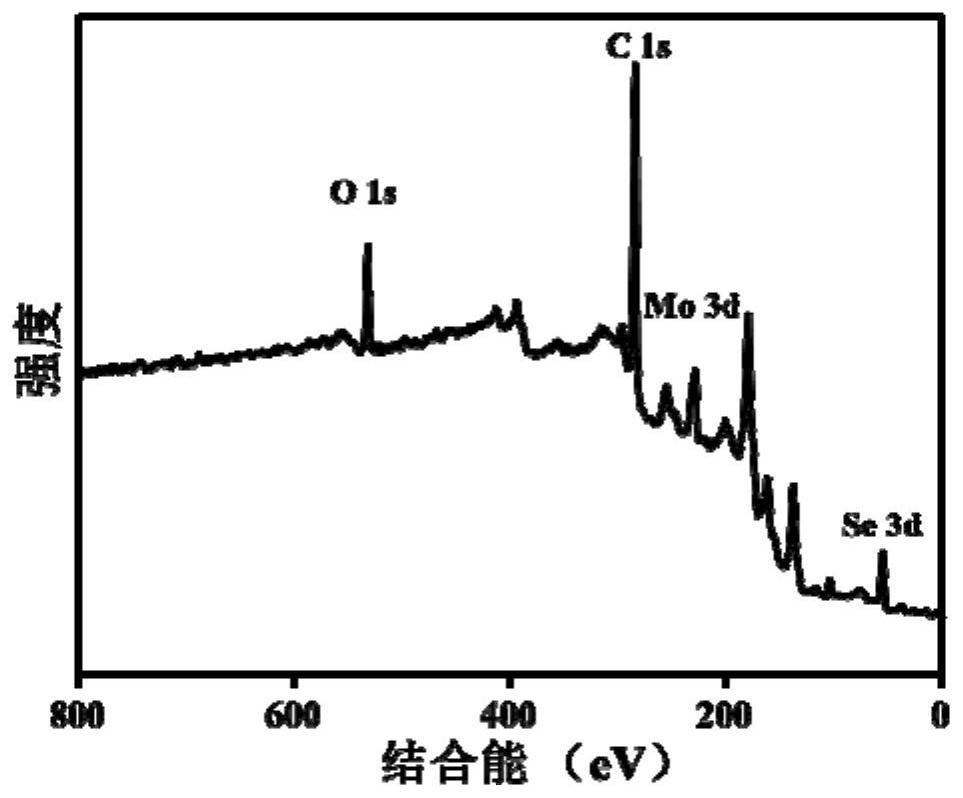

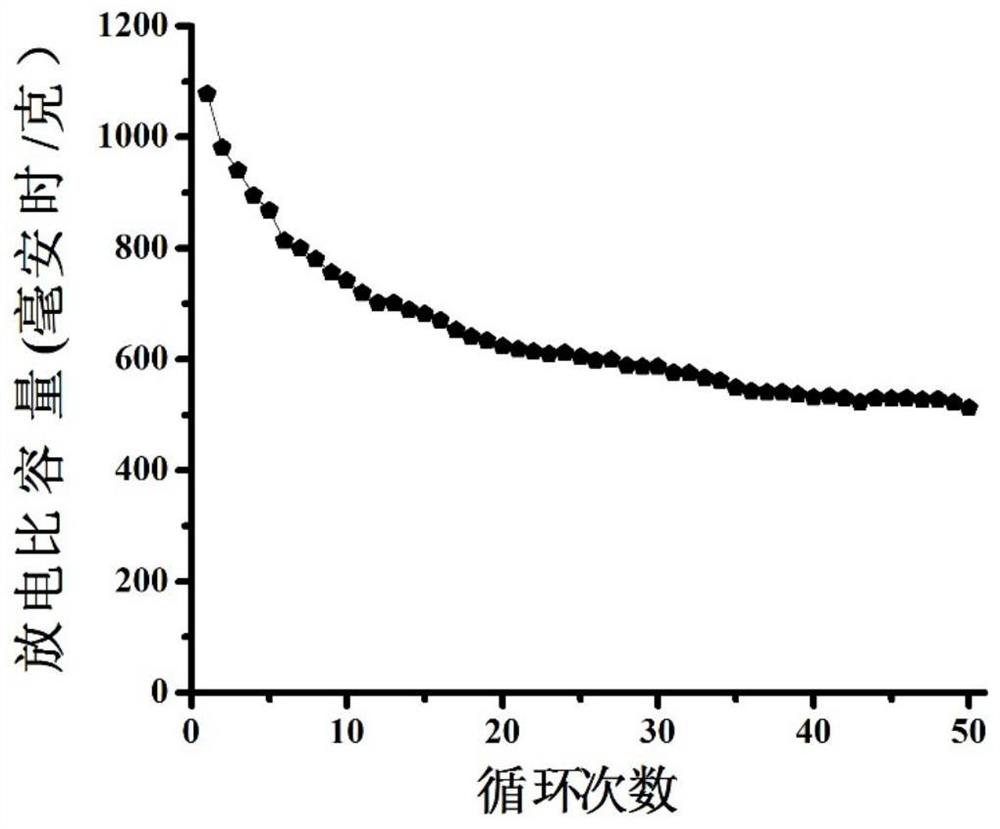

A molybdenum diselenide/carbon nanotube array composite electrode, preparation method and application

ActiveCN110890224BSlow release volume expansionImprove cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureCarbon nanotubeMolybdenum diselenide

The invention discloses a molybdenum diselenide / carbon nanotube array composite electrode, a preparation method and an application. Sodium molybdate, selenium powder and sodium borohydride are mixed according to a molar ratio of 1:3:1 and dissolved in deionized water. and anhydrous ethanol, then put the carbon nanotube array into the mixed solution, and conduct a hydrothermal reaction at 180-220°C for 36-48 hours to obtain a molybdenum diselenide / carbon nanotube array composite electrode; disselenide The molybdenum / carbon tube array composite electrode film is pressed on the current collector by pressure to obtain the supercapacitor electrode. In the present invention, molybdenum diselenide and carbon nanotube arrays are combined as an electrode material, and its specific surface area is greatly increased, and it has more abundant active sites, and these advantages enable its high theoretical specific capacity to be fully utilized. No binder is added when preparing the composite electrode, which not only reduces the weight of the entire electrode, but also makes the active component and the current collector directly and tightly combined, greatly reducing the contact resistance of the electrode.

Owner:NORTHWEST UNIV

A kind of sodium-sulfur battery cathode material and preparation method thereof

ActiveCN109755542BLimit the "shuttle effect"Limit shuttle effectNon-aqueous electrolyte accumulatorsCell electrodesCarbon compositesElectrochemical response

The invention relates to a sodium-sulfur battery positive electrode material and a preparation method thereof. The sodium-sulfur battery positive electrode material is a sulfur-titanium dioxide-carboncomposite material, and the preparation method includes the following steps: firstly, preparing a metal organic framework material MIL-125, spray-drying and compounding the metal organic framework material MIL-125 with graphene, performing carbonization treatment to obtain a titanium dioxide-carbon composite material, and then doping sulfur to prepare a sulfur-titanium dioxide-carbon composite sodium-sulfur battery positive electrode material by using a ball milling method and a hot melting method. The composite material prepared by using the method has a larger specific surface area and porosity, can limit the 'shuttle effect' of polysulfide, reduces the dissolution of intermediate products, can improve the electrochemical activity of elemental sulfur, shortens the transmission paths ofelectrons and ions, limits the dissolution of polysulfide, and improves the electrochemical reaction speed of active materials adsorbed on the surface of a carrier.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

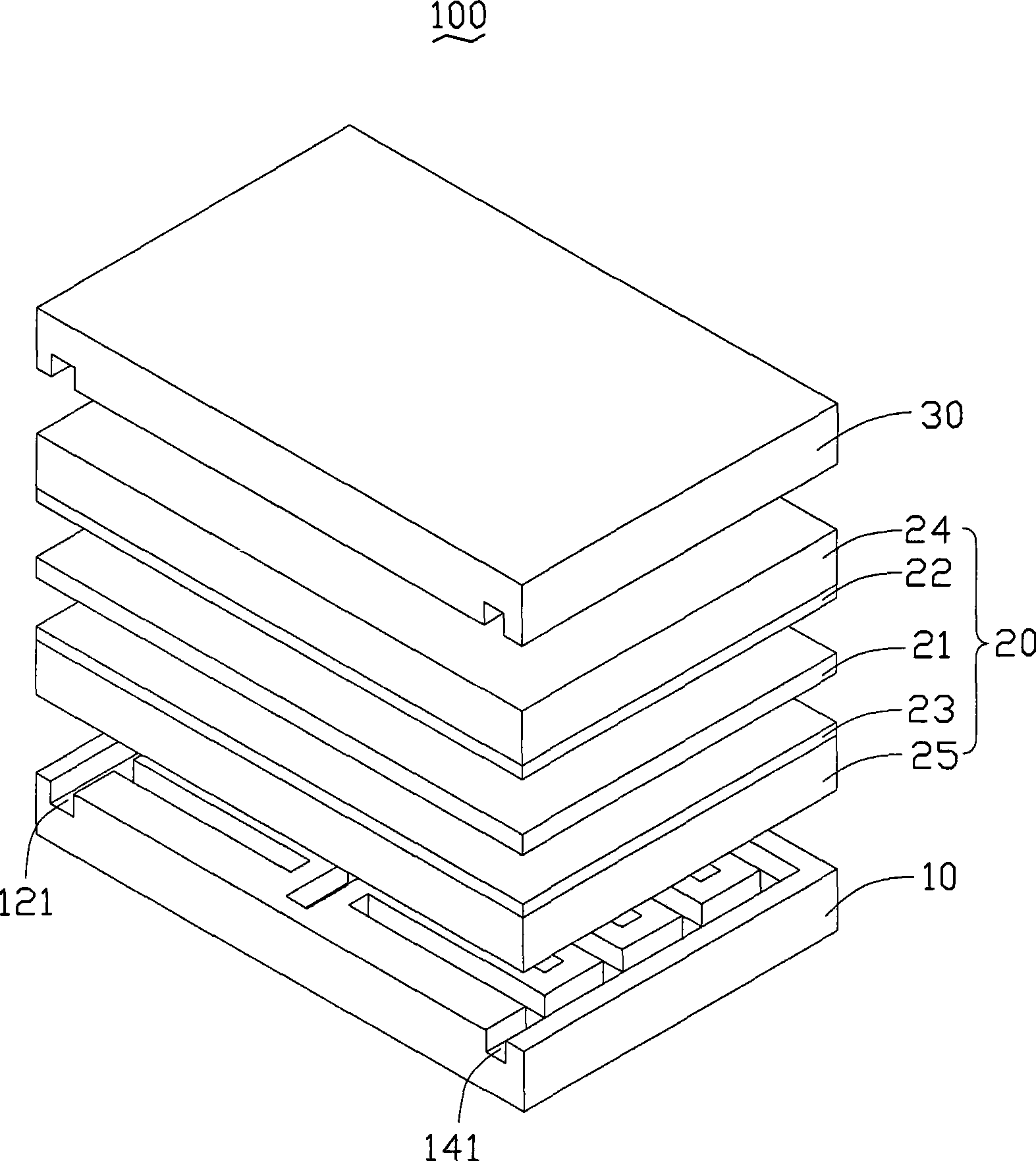

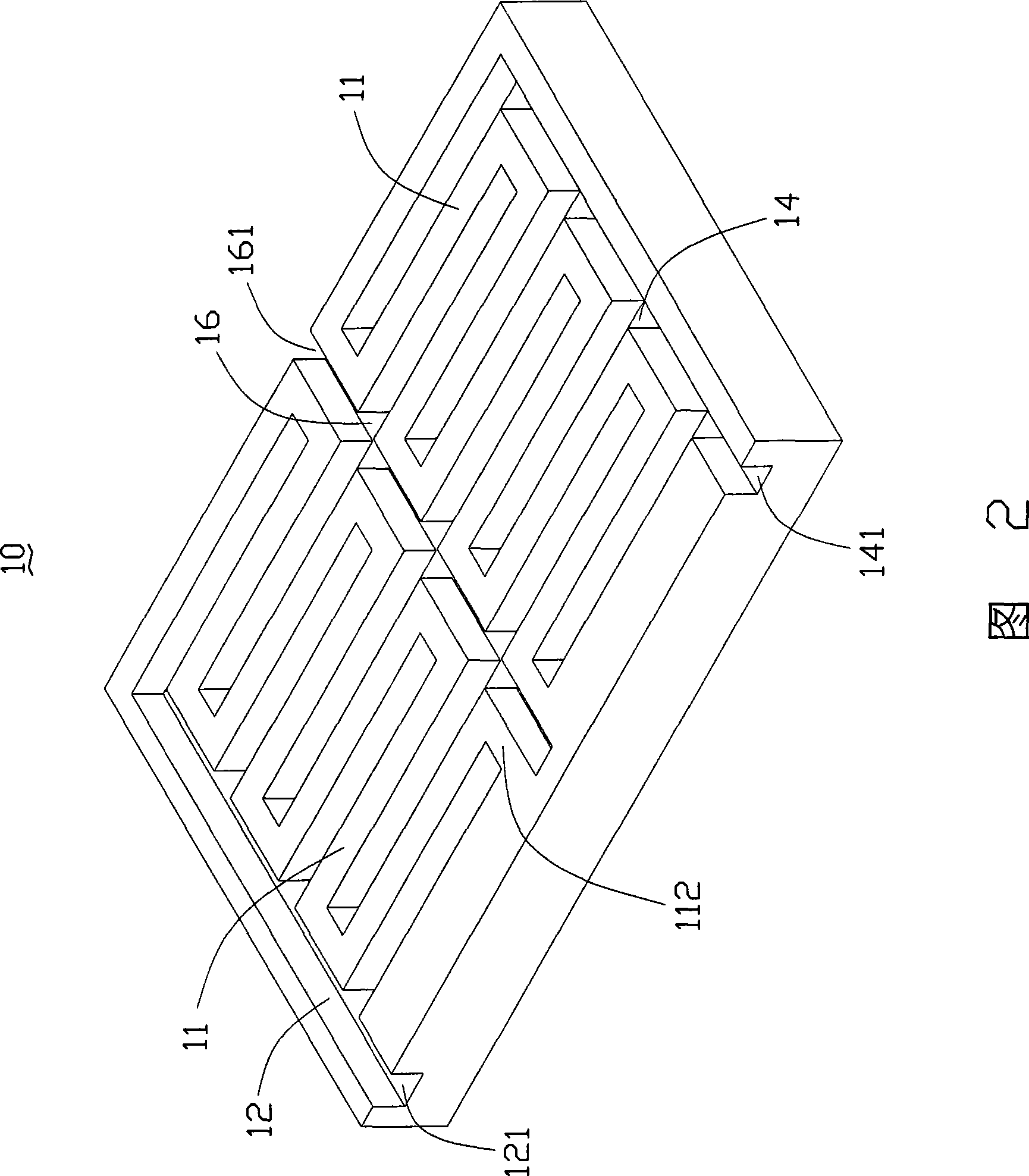

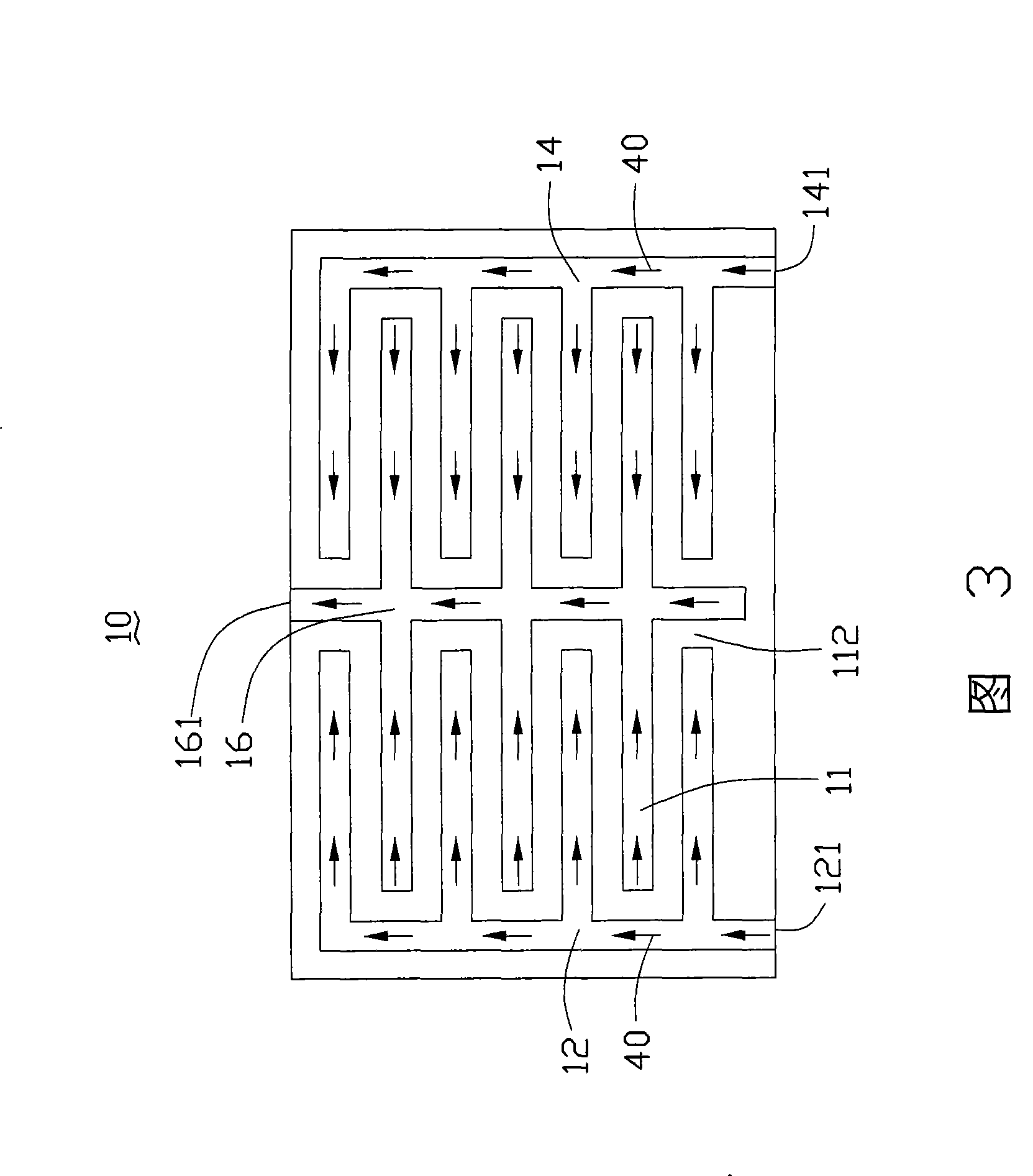

Fuel cell polar plate and fuel cell using the same

InactiveCN101304094BImprove power generation efficiencyImprove the electrochemical reaction speedCell electrodesSolid electrolyte fuel cellsFuel cellsEngineering

The invention discloses a polar plate of a fuel cell, wherein, one surface of the polar plate is provided with a channel, the channel comprises two groups of intake channels and one group of outgassing channels, the two groups of intake channels are respectively positioned at the two sides of the outgassing channel, a separator is arranged between the each group of intake channels and the outgassing channel, and the separator separates the intake channel from the outgassing channel so as to impel gas to enter a gas diffusion layer adjacent to the separator in a compulsory convective way. The arrangement of the two groups of intake channels and the separator can effectively reinforce the compulsory convective diffusion effect of flows in the channel of the polar plate, can carry away surplus moisture accumulated in the gas diffusion layer, and can increase the generation efficiency of the fuel cell.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

A kind of positive electrode material of lithium-sulfur battery and preparation method thereof

ActiveCN109755540BLimit the "shuttle effect"Limit shuttle effectCell electrodesLi-accumulatorsCarbon compositesElectrochemical response

The invention relates to a lithium-sulfur battery cathode material and a preparation method thereof. The method comprises: preparing a mixed solution of N,N-dimethylformamide, methanol, and phthalic acid, ultrasonically dispersing and adding tetrabutyl titanate, and placing it in a polytetrafluoroethylene-lined reaction kettle at 120- The metal-organic framework material MIL-125(Ti) was prepared by reaction at 150°C; the MIL-125(Ti) was placed in a cobalt acetate solution, and after centrifugation, it was calcined at a high temperature under an argon atmosphere to obtain tricobalt tetroxide / titanium dioxide / carbon composite material; After ball milling and mixing with pure-phase nano-sulfur powder, heat treatment under nitrogen protection to obtain sulfur-cobalt tetroxide / titanium dioxide / carbon composite material. The material organically combines cobalt tetroxide / titanium dioxide / carbon, and the adsorption of carbon material pores can limit the "shuttle effect" of polysulfides, inhibit the dissolution of intermediate products through adsorption and catalysis, and improve the surface activity of adsorption on the carrier The electrochemical reaction speed of the material is improved, and the capacity and cycle performance of the Li-S battery are improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

A kind of negative pressure formation method and battery

ActiveCN111554991BFast growthFast formingSecondary cells charging/dischargingPower batteryCharge current

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com