Pulse energy-saving charging method and pulse energy-saving charger

A charging method and charger technology, applied in secondary battery charging/discharging, electrochemical generators, circuits, etc., can solve the problems of being unable to display the charging state in real time, hindering the electrochemical reaction of the battery, and being unable to understand in real time, to achieve Improve the electrochemical reaction speed, realize the real-time control of multiple machines, and improve the effect of current receiving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0038] An embodiment of the present invention provides a pulse energy-saving charging method, which can provide a negative pulse multi-stage intelligent control method for the battery.

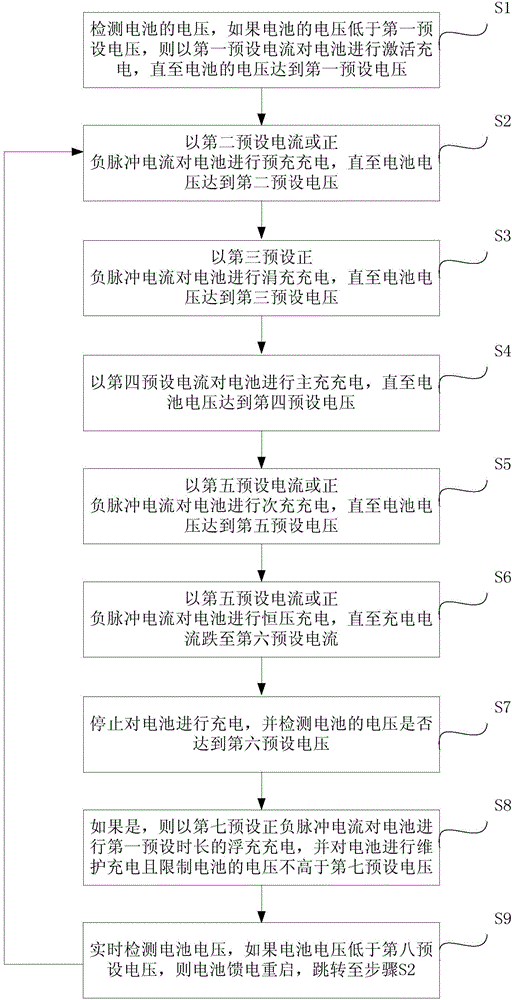

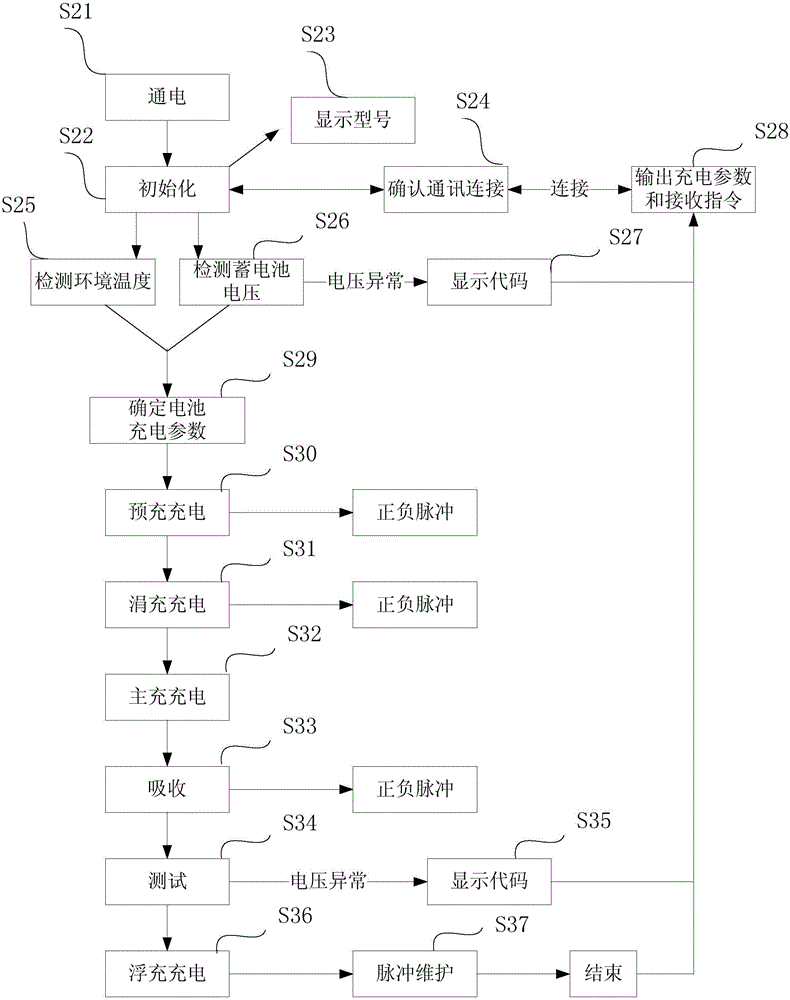

[0039] like figure 1 As shown, the pulse energy-saving charging method of the embodiment of the present invention includes the following steps:

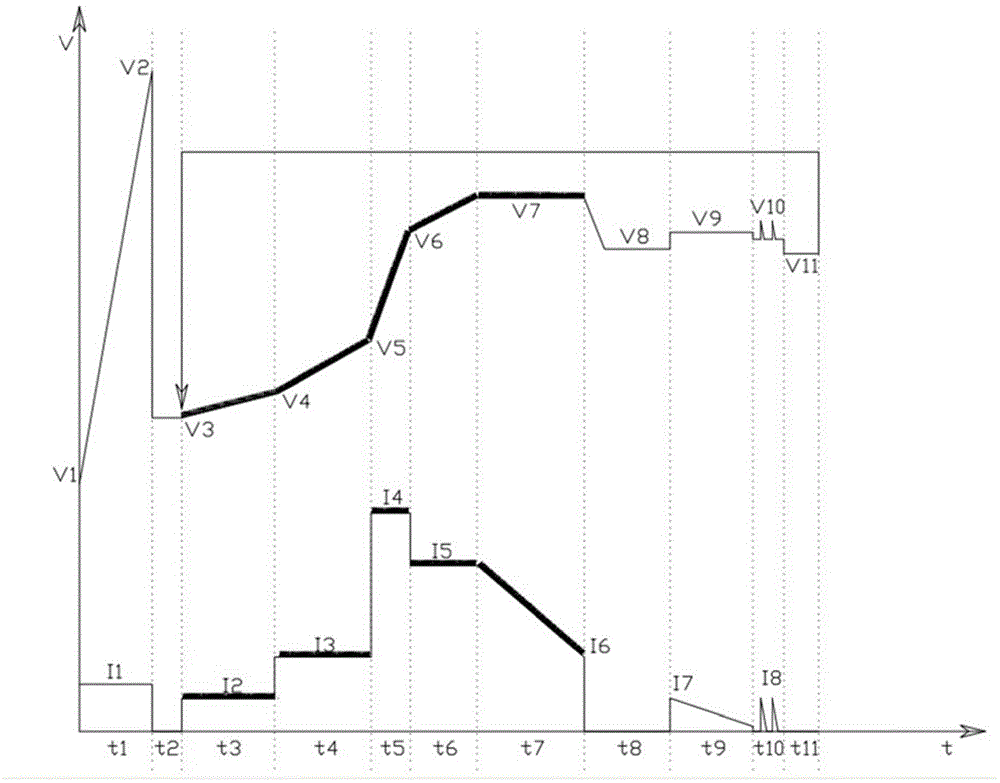

[0040] Step S1, activate charging: detect the voltage of the battery to be charged, if the voltage of the battery is lower than the first preset voltage V3, activate the battery with the first preset c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com