High-performance liquid metal battery negative current collector and preparation method thereof

A liquid metal battery and current collector technology, which is applied in battery electrodes, active material electrodes, electrode carriers/current collectors, etc., can solve the problems that current collectors cannot solve corrosion and wettability at the same time, and achieve excellent rate performance and electrochemical performance. Cycling performance, increase in electrochemical reaction speed, and the effect of extending the intrusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A high-performance liquid metal battery negative electrode collector, comprising the following steps:

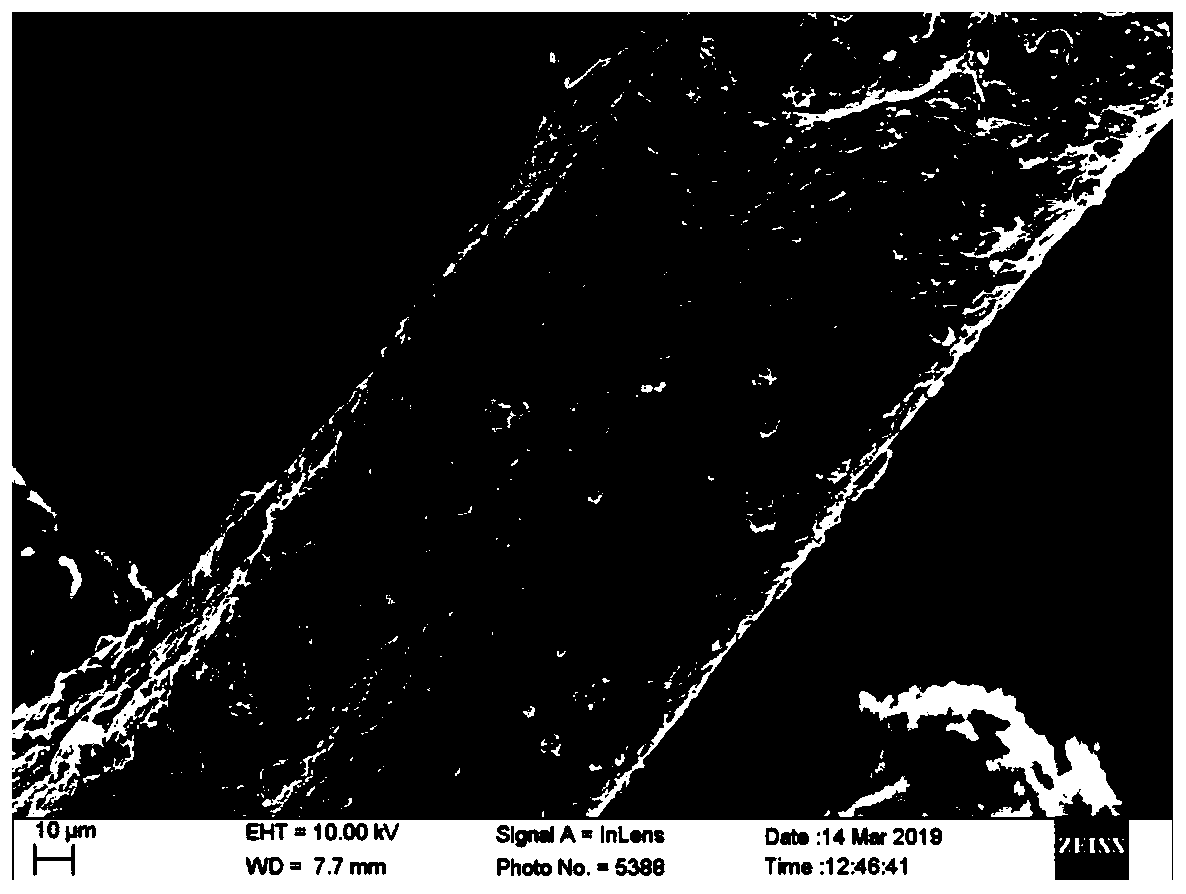

[0033] Step 1: Cut the foamed Ni matrix material with a pore size of 40PPI, a porosity of 90%, and a thickness of 100mm into a cylindrical sample with a size of φ100mm×100mm, soak it in acetone, ultrasonically clean it for 30 minutes, and rinse it with alcohol to Remove the oil on the surface of the material, and finally use N 2 Dry with air to obtain the cleaned matrix material.

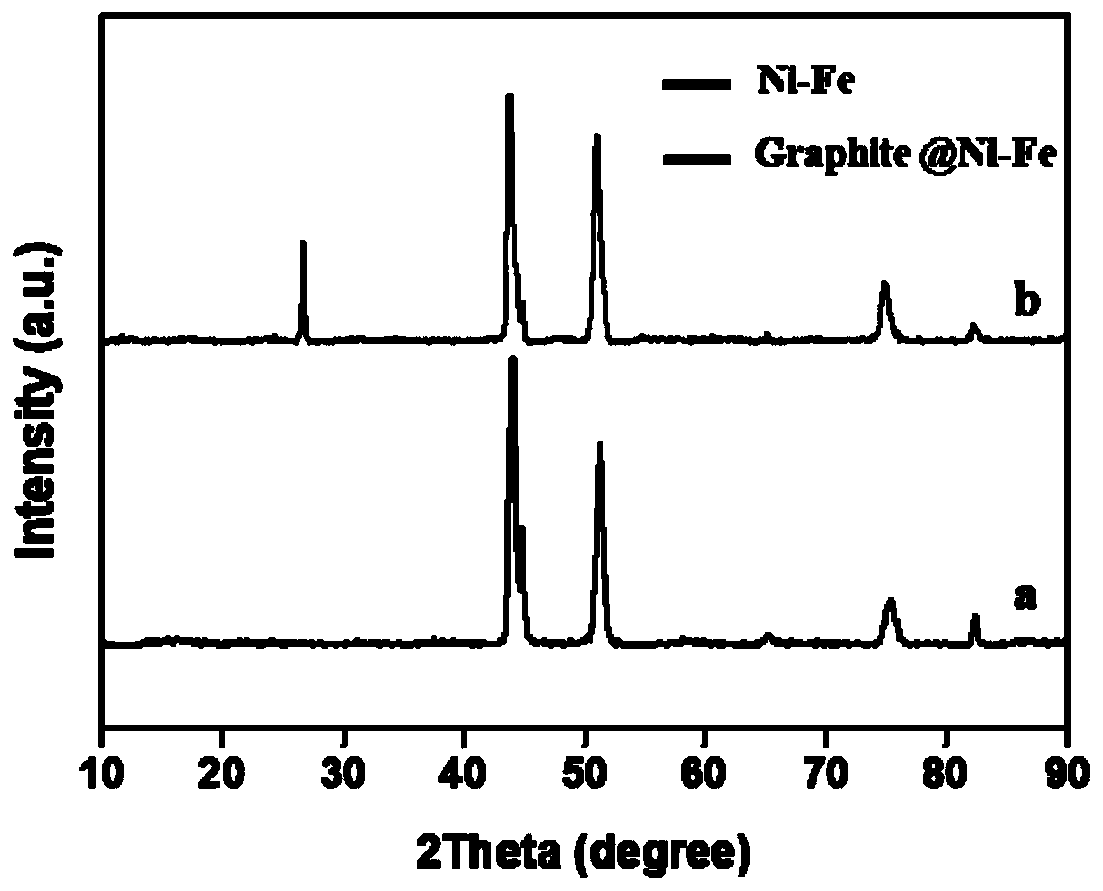

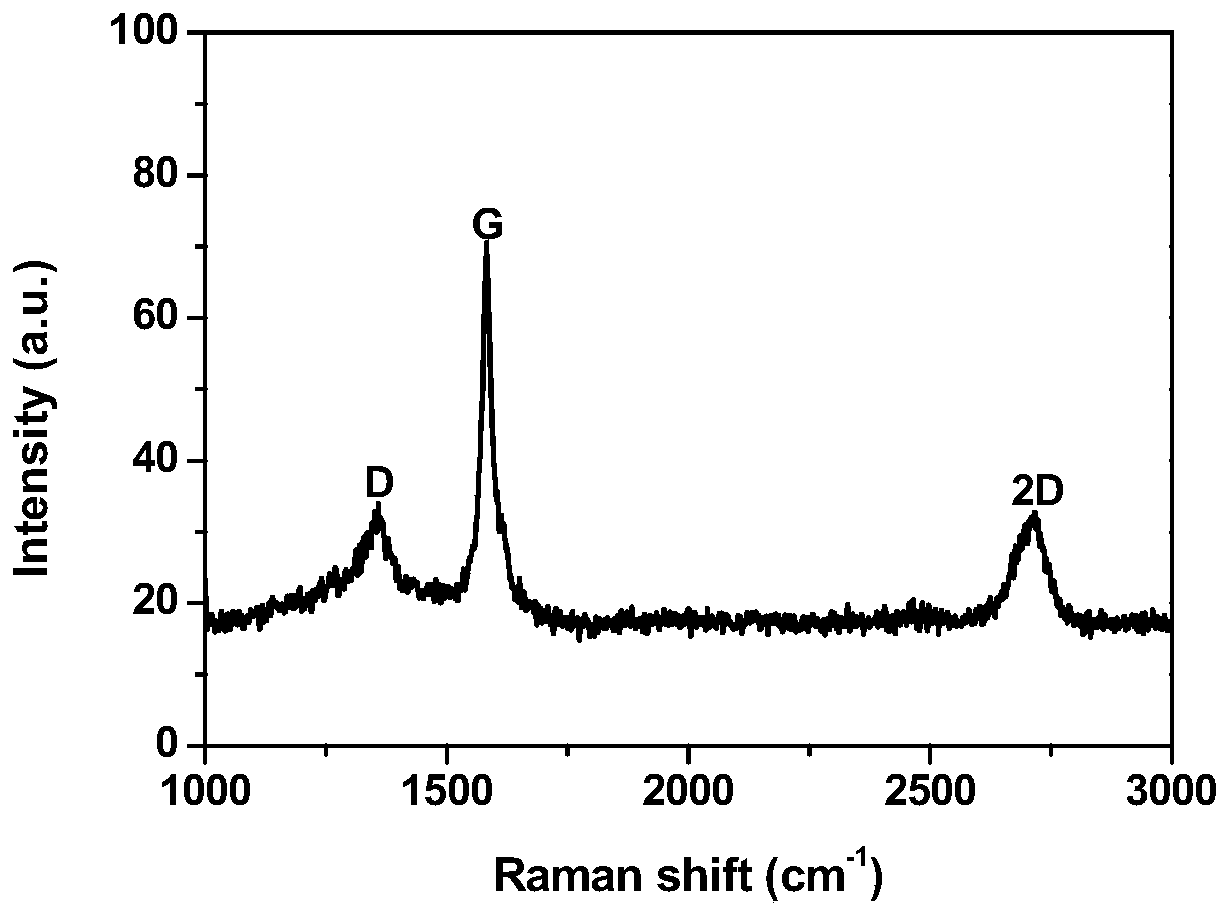

[0034] Step 2: Anneal the foamed Ni matrix material cleaned in step 1 first. The specific heating program is to heat from room temperature to the target temperature of 1000°C at a heating rate of 5°C / min, keep it warm for 30min, and then heat it at 10°C / min Lower the temperature to 850°C, which is the cracking temperature of the carbon source in the subsequent chemical vapor deposition stage, and keep it warm for 20 minutes. The purpose of annealing treatment is to reduce the oxide on the ...

Embodiment 2

[0037] A high-performance liquid metal battery negative electrode collector, comprising the following steps:

[0038] Step 1: Cut the foamed Ni-Fe matrix material with a pore size of 80PPI, a porosity of 95%, and a thickness of 5mm into a cylindrical sample with a size of φ5mm×5mm, soak it in acetone, ultrasonically clean it for 30min, and rinse it with alcohol , to remove the oil on the surface of the material, and finally use N 2 Dry with air to obtain the cleaned matrix material.

[0039]Step 2: Anneal the foamed Ni-Fe matrix material cleaned in step 1 first. The specific heating program is to heat from room temperature to the target temperature of 900°C at a heating rate of 5°C / min, keep it warm for 10 minutes, and then heat it at 10°C / min to 700°C, which is the cracking temperature of the carbon source in the subsequent chemical vapor deposition stage, and kept for 20 minutes. The purpose of annealing treatment is to reduce the oxide on the surface of the matrix skeleto...

Embodiment 3

[0042] A high-performance liquid metal battery negative electrode collector, comprising the following steps:

[0043] Step 1: Cut the foamed Ni-Fe matrix material with a pore size of 60PPI, a porosity of 98%, and a thickness of 10mm into a cylindrical sample with a size of φ10mm×10mm, soak it in acetone, ultrasonically clean it for 30min, and then rinse it with alcohol , to remove the oil on the surface of the material, and finally use N 2 Dry with air to obtain the cleaned matrix material.

[0044] Step 2: Anneal the foamed Ni-Fe matrix material cleaned in step 1 first. The specific heating program is to heat from room temperature to the target temperature of 1000°C at a heating rate of 5°C / min, keep it warm for 10 minutes, and then heat it at 10°C / min to 800°C, which is the cracking temperature of the carbon source in the subsequent chemical vapor deposition stage, and kept for 20 minutes. The purpose of annealing treatment is to reduce the oxide on the surface of the matr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com