Method for preparing titanium alloy bionic coating through compounding of laser and anodic oxidation

An anodic oxidation and titanium alloy technology, applied in the field of bionic structure layer, can solve the problems of uncontrollable surface pore structure and process pollution, etc., and achieve the effect of improving service life, accelerating element diffusion, and lowering the harm to human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of samples and reagents

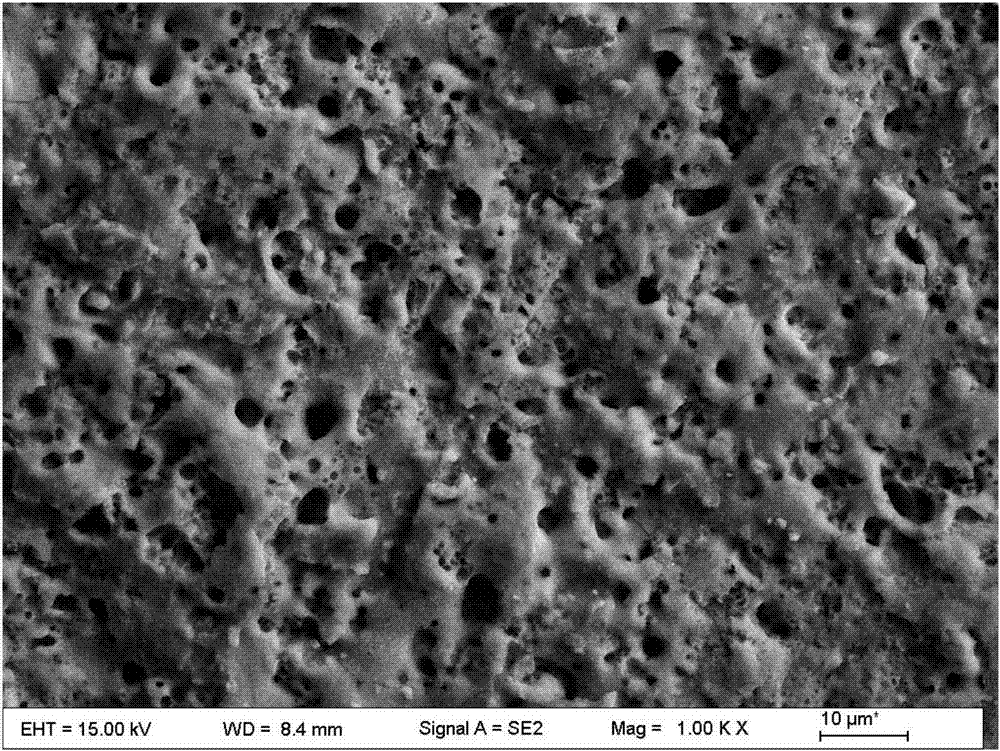

[0036] Take 20×20×5mm TC4 titanium alloy and use 500w IPG fiber laser. Under the conditions of a laser power of 500W, a spot diameter of 0.1mm, a scanning distance of 0.06mm, and a scanning speed of 1000mm / s, the alloy surface was scanned to obtain the TC4 titanium alloy sample 1 after laser pretreatment.

[0037] Control sample: TC4 titanium alloy without laser pretreatment.

[0038] (2) Anodizing treatment

[0039] Put the TC4 titanium alloy sample 1 and the control sample after laser pretreatment in step (1) into anhydrous acetone for ultrasonic cleaning for 5-10 minutes, then rinse with distilled water and put them in an alkaline degreasing solution at 60°C. Soak for 20min, then wash with flowing hot water at 80℃ and then wash with cold water; then put it in anodizing solution as anode, using stainless steel as cathode, the area ratio of anode to cathode is 1:2, and the current density is 9A / dm in the pulse power supply. 2 , The pu...

Embodiment 2

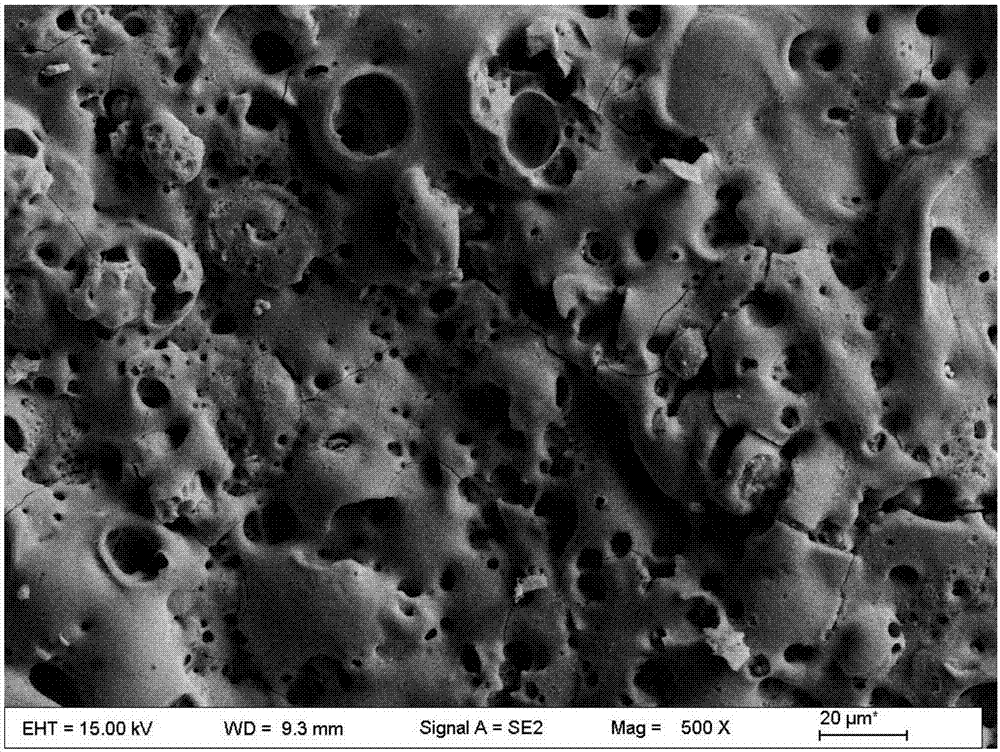

[0043] The laser scanning speed is 1500mm / s, and the composition of the anodizing solution is: malic acid 25g / L, Na 2 SiO 3 5g / L, CaCl 2 3g / L, Na 2 HPO 4 3g / L, the solvent is deionized water. The current density of the pulse power supply is 7A / dm 2 , The punching frequency is 1Hz, the duty ratio is 50%, the temperature is 10℃, and the stirring speed is 100r / min for 60min. The other same product 1 is prepared to obtain the titanium alloy sample 2 with the bionic coating, and observe it Surface topography.

Embodiment 3

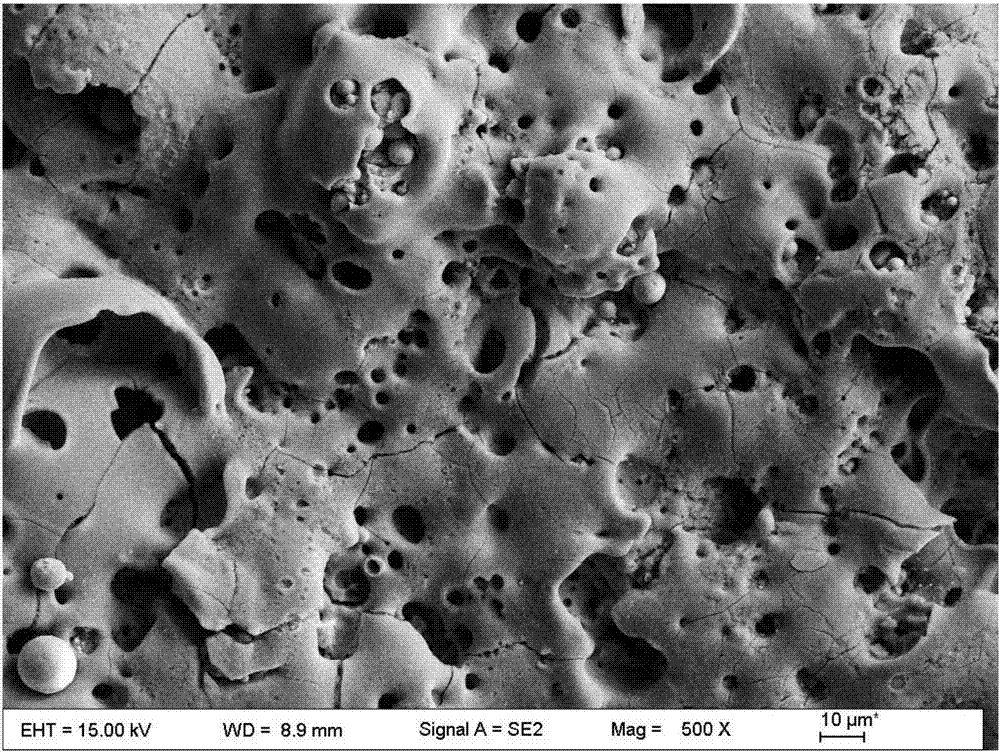

[0045] The laser scanning speed is 3000mm / s, and the composition of the anodizing solution is: malic acid 5g / L, Na 2 SiO 3 5g / L, CaCl 2 3g / L, Na 2 HPO 4 3g / L, the solvent is deionized water. The current density of the pulse power supply is 5A / dm 2 , The punching frequency is 1Hz, the duty cycle is 50%, the temperature is 10℃, and the stirring speed is 100r / min for 60min. The other operations are the same as the preparation of product 1, and the titanium alloy sample 3 with bionic coating is obtained. Observe Its surface morphology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com