Method for degrading organic substances by using photoelectric catalysis of short TiO2 nano-tube array film electrode

A nanotube array and thin-film electrode technology, which is applied in the field of environmental pollution control, can solve problems affecting the separation efficiency and transfer rate of photogenerated charges, reduce the stability of nanotube array electrodes, and weak binding force between nanotubes and substrates, so as to shorten the anode Oxidation time, improved electrochemical reaction speed, and low photogenerated charge recombination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

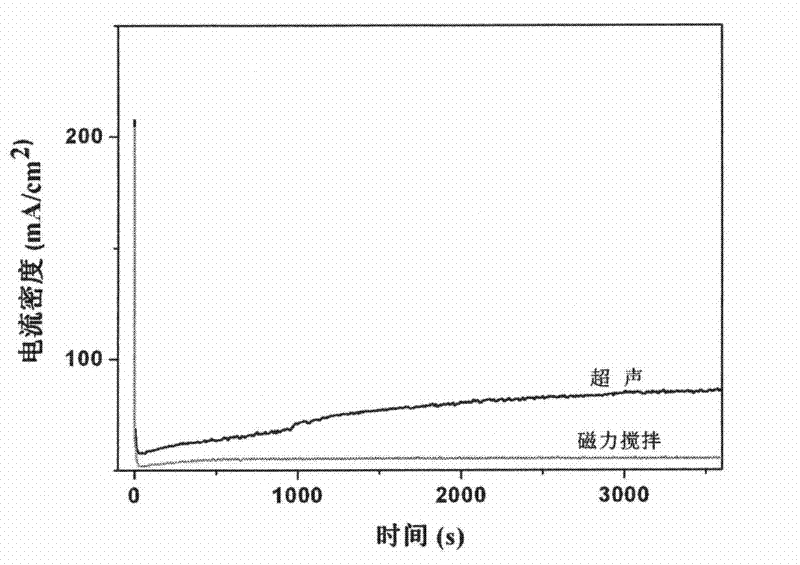

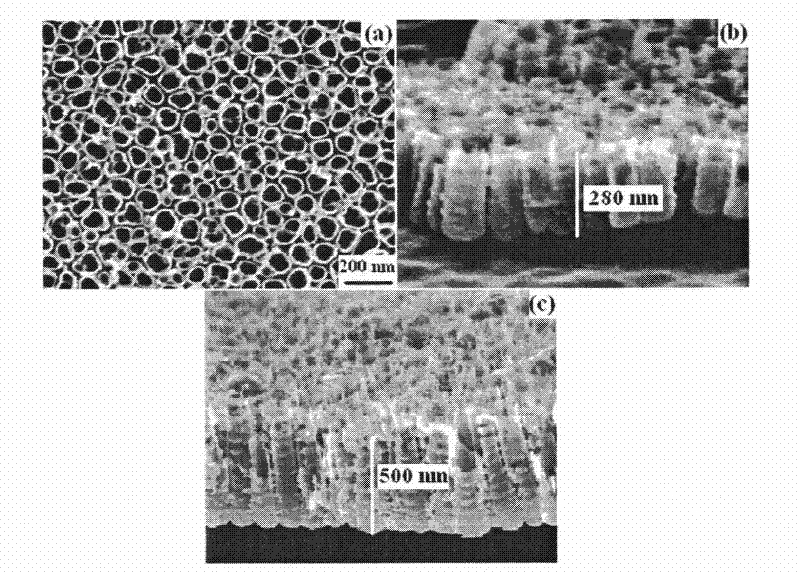

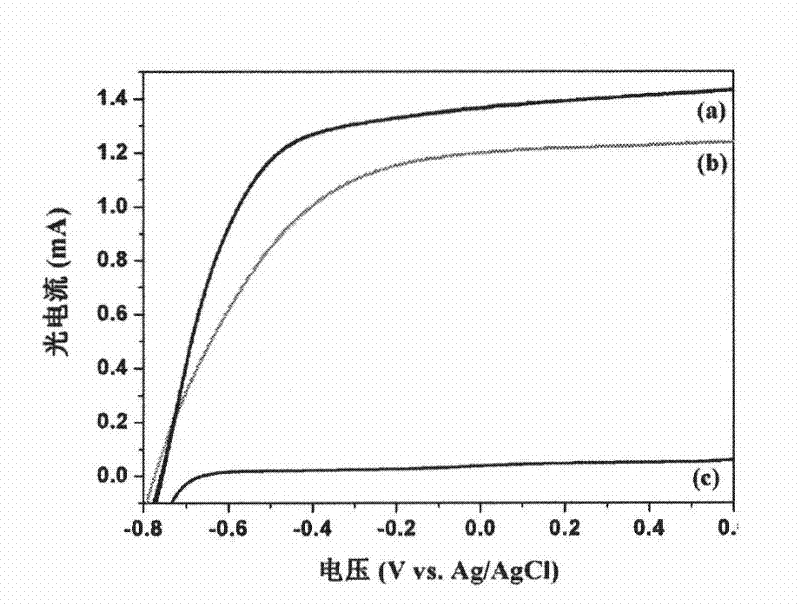

Embodiment 1

[0020] The cleaned titanium sheet is used as the anode, and the platinum sheet is used as the counter electrode to assemble a two-electrode system, and hydrofluoric acid aqueous solution is added to the reaction vessel as the electrolyte, so that the mass percentage of fluorine ions in the solution reaches 0.5%, and the voltage is adjusted to 20V . During the entire anodic oxidation reaction process, the electrolyte solution is ultrasonically dispersed, and the ultrasonic frequency is 40KHz. After 30 minutes of reaction, the ultrasonic wave is stopped, and the short TiO can be obtained. 2 Nanotube array film samples. Take off the sample, rinse with water and place it in an oven to dry, after being cooled to room temperature, observe through SEM, the prepared titanium-based TiO2 nanotube array, the pipe length is 280nm (see figure 1 ). After sintering the sample in air atmosphere at 400°C for 3 hours, short TiO 2 The nanotube array film electrode can be used as a photoelectr...

Embodiment 2

[0028] The cleaned titanium sheet is used as the anode, and the platinum sheet is used as the counter electrode to assemble a two-electrode system, and hydrofluoric acid aqueous solution is added in the reaction vessel as the electrolyte, so that the mass percentage of fluorine ions in the solution reaches 0.2%, and the voltage is adjusted to 30V . During the entire anodic oxidation process, the electrolyte solution is ultrasonically dispersed, and the ultrasonic frequency is 25KHz. After 1 hour of reaction, short TiO can be obtained. 2 Nanotube array film samples. Remove the sample, wash it with water and dry it in an oven. After cooling to room temperature, observe through SEM, the prepared titanium-based TiO 2 Nanotube array with a tube length of 300nm. After the sample was sintered in an air atmosphere at 500°C for 0.5 hours, short TiO 2 The nanotube array film electrode can be used as a photoelectrocatalytic electrode for the degradation of organic pollutants.

[0029...

Embodiment 3

[0031] The cleaned titanium sheet is used as the anode, and the platinum sheet is used as the counter electrode to assemble a double-electrode system, and hydrofluoric acid aqueous solution is added to the reaction vessel as the electrolyte, so that the mass percentage of fluorine ions in the solution reaches 0.7%, and the voltage is adjusted to 10V . During the entire anodic oxidation process, the electrolyte solution is ultrasonically dispersed, and the ultrasonic frequency is 80KHz. After 60 minutes of reaction, short TiO can be obtained. 2 Nanotube array film samples. Remove the sample, wash it with water and dry it in an oven. After cooling to room temperature, observe through SEM, the prepared titanium-based TiO 2 Nanotube array with a tube length of 70nm. After the sample was sintered in an oxygen atmosphere at 600°C for 3 hours, short TiO 2 The nanotube array film electrode can be used as a photoelectrocatalytic electrode for the degradation of organic pollutants. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com