A modulation method for curing and setting the color and dry gluten period of Yunnan characteristic yellow sun-cured tobacco varieties

A preparation method and a technology for drying yellow tobacco, which are applied in the fields of tobacco, tobacco preparation, application, etc., can solve problems such as no public reports, and achieve the effects of ensuring sensory quality, soft leaves and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

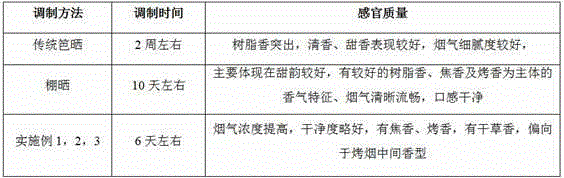

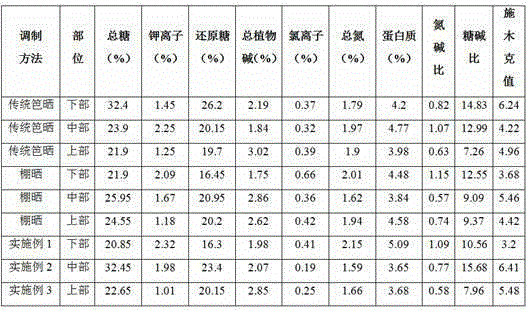

Examples

Embodiment 1

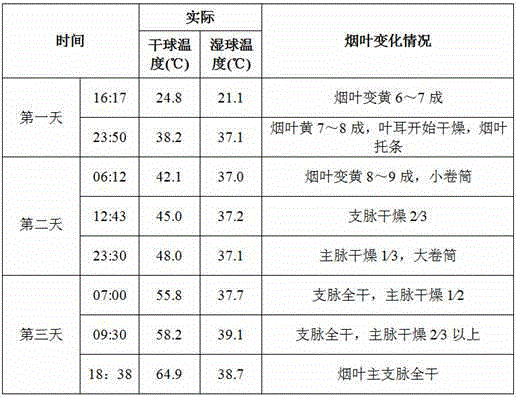

[0022] (1) For the fresh tobacco leaves at the lower part of the sun-yellow smoke Yunshai No. 1 with the same maturity in the field, use conventional fence drying or shed drying to make the tobacco leaves 60% to 70% yellow, so that the tobacco leaves wither and turn yellow;

[0023] (2) Put the tobacco leaves in step (1) into a conventional flue-cured furnace, raise the temperature to 36-38°C after 5 hours, control the wet bulb temperature to 36-37°C, keep the temperature stable for 2-4 hours, and bake the tobacco leaves to 7-38°C 80% yellow;

[0024] (3) Raise the dry bulb temperature to 40-42°C at a rate of 1°C in 2 hours, control the wet bulb temperature at 37-38°C, keep the temperature stable for 2-4 hours, and roast the tobacco leaves to 80-90% yellow;

[0025] (4) Raise the temperature of the dry bulb to 45-48°C at a rate of 1°C in 2 hours, control the temperature of the wet bulb at 37-38°C, keep the temperature stable for 2-4 hours, and roast the tobacco leaves until th...

Embodiment 2

[0029] (1) For the fresh tobacco leaves in the middle of Sun-Yellow Yanyan Yunshai No. 1 with the same maturity in the field, the tobacco leaves will be 60% to 70% yellow by conventional sun-drying, so that the tobacco leaves will wither and turn yellow;

[0030] (2) Put the tobacco leaves in step (1) into a conventional flue-cured furnace, raise the temperature to 36-38°C after 5 hours, control the wet bulb temperature to 36-37°C, keep the temperature stable for 2-4 hours, and bake the tobacco leaves to 7-38°C 80% yellow;

[0031] (3) Raise the dry bulb temperature to 40-42°C at a rate of 1°C in 2 hours, control the wet bulb temperature at 37-38°C, keep the temperature stable for 2-4 hours, and roast the tobacco leaves to 80-90% yellow;

[0032] (4) Raise the temperature of the dry bulb to 45-48°C at a rate of 1°C in 2 hours, control the temperature of the wet bulb at 37-38°C, keep the temperature stable for 2-4 hours, and roast the tobacco leaves until they are all yellow an...

Embodiment 3

[0036] (1) The fresh tobacco leaves on the upper part of the yellow sun-dried tobacco Yunshai No. 1 with the same maturity are harvested in the field, and the tobacco leaves made by conventional shed sun-dried tobacco leaves reach 60% to 70% yellow, so that the tobacco leaves wither and turn yellow;

[0037] (2) Put the tobacco leaves in step (1) into a conventional flue-cured furnace, raise the temperature to 36-38°C after 5 hours, control the wet bulb temperature to 36-37°C, keep the temperature stable for 2-4 hours, and bake the tobacco leaves to 7-38°C 80% yellow;

[0038] (3) Raise the dry bulb temperature to 40-42°C at a rate of 1°C in 2 hours, control the wet bulb temperature at 37-38°C, keep the temperature stable for 2-4 hours, and roast the tobacco leaves to 80-90% yellow;

[0039] (4) Raise the temperature of the dry bulb to 45-48°C at a rate of 1°C in 2 hours, control the temperature of the wet bulb at 37-38°C, keep the temperature stable for 2-4 hours, and roast t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com