Preparation of Single-atom Palladium Catalyst and Its Application in Direct Formic Acid Fuel Cell

A palladium catalyst and atomic technology, applied in the field of direct formic acid fuel cell and its single-atom palladium catalyst preparation, can solve the problems of unexpanded universal method and easy aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

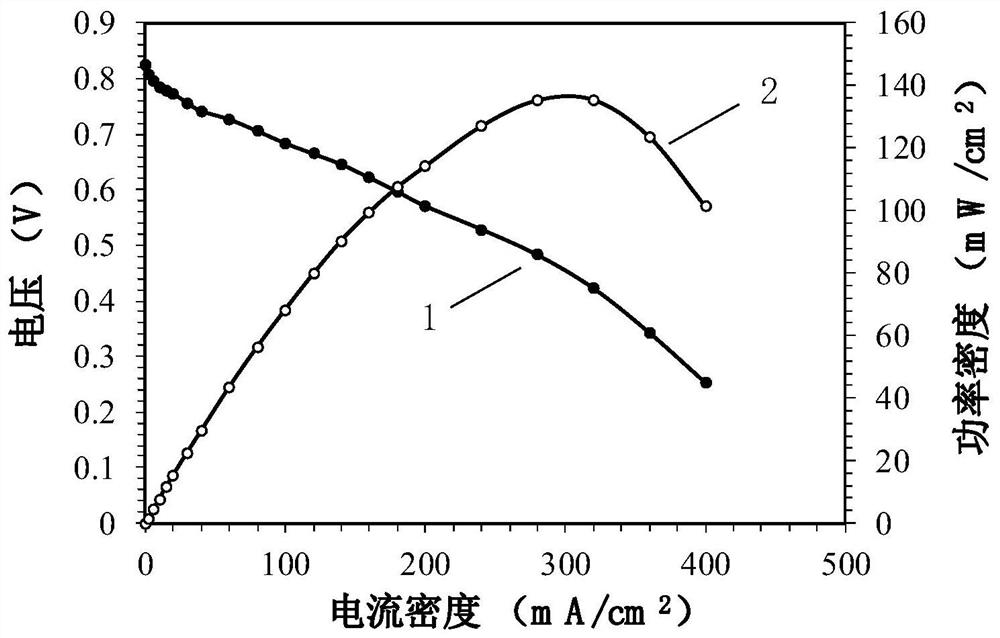

Image

Examples

Embodiment 1

[0065] Embodiment one: o-phenylenediamine solution preparation

[0066] At 90° C., 5 g of o-phenylenediamine was dissolved in 95 mL of deionized water, and dispersed by ultrasonic vibration (ultrasonic frequency 40 kHz) for 5 minutes to obtain a solution of o-phenylenediamine with a concentration of 5 wt%.

Embodiment 2

[0067] Example 2: Preparation of β-cyclodextrin inclusion compound of o-phenylenediamine

[0068] At 90°C, dissolve 7g of o-phenylenediamine in 93mL of deionized water, and disperse for 5 minutes with ultrasonic vibration (ultrasonic frequency 40kHz) to obtain a solution of o-phenylenediamine with a concentration of 7wt%. Take 100mL of deionized water and dissolve 10g of β- Add o-phenylenediamine solution after the cyclodextrin, and disperse for 30 minutes with ultrasonic vibration (ultrasonic frequency 40kHz), the o-phenylenediamine enters the cyclodextrin cavity to form a cyclodextrin inclusion complex of o-phenylenediamine, and after vacuum drying, the obtained o-Phenylenediamine Cyclodextrin Inclusion Compound.

Embodiment 3

[0069] Example 3: Palladium-Coordinated Ortho-Phenylenediamine Cyclodextrin Inclusion Compound Solution

[0070] At 90°C, dissolve 10 g of o-phenylenediamine in 90 mL of deionized water, and disperse for 5 minutes with ultrasonic vibration (ultrasonic frequency 40 kHz) to obtain a solution of o-phenylenediamine with a concentration of 10 wt %. Take 100 mL of deionized water and dissolve 25 g of β- Add o-phenylenediamine solution after the cyclodextrin, and disperse for 30 minutes with ultrasonic vibration (ultrasonic frequency 40kHz), the o-phenylenediamine enters the cyclodextrin cavity to form a cyclodextrin inclusion complex of o-phenylenediamine, and after vacuum drying, the obtained o-Phenylenediamine Cyclodextrin Inclusion Compound.

[0071] Dissolve 0.01 g of chloropalladium acid in 200 mL of deionized water to obtain a chloropalladium acid solution, take 10 g of the above-mentioned o-phenylenediamine cyclodextrin inclusion compound, add it to the chloropalladium acid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com