Quick charged long life accumulator

A battery and battery tank technology, applied in the direction of lead-acid batteries, lead-acid battery construction, secondary battery manufacturing, etc., can solve the problems of inability to travel long distances, low porosity of active materials, etc., to increase the contact surface and increase rapid penetration Effects of speed and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

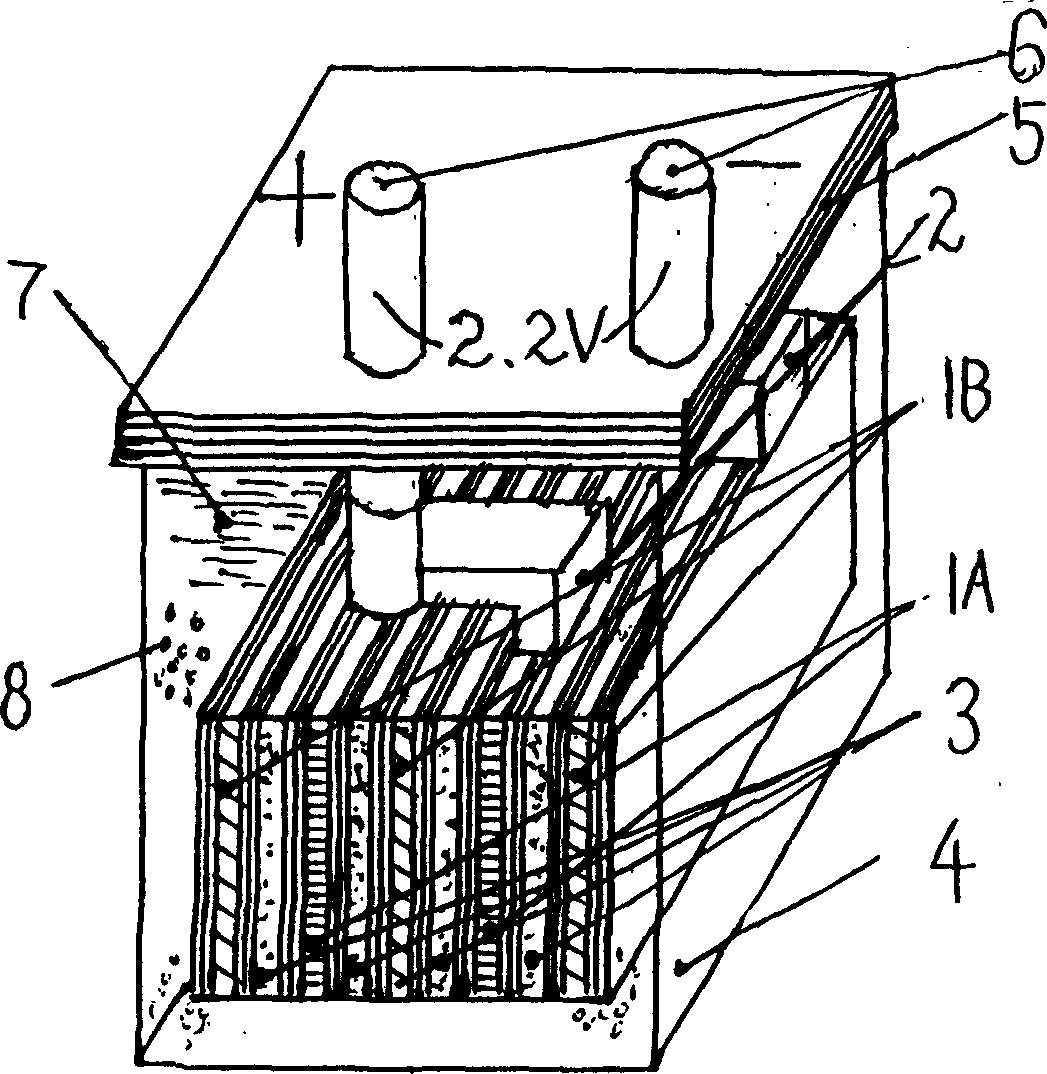

[0007] In preferred embodiment 2 of the present invention, the coating or coating on the outer surface of the bipolar plates (1A, 1B) can be granular crystal lead dioxide.

[0008] In preferred embodiment 3 of the present invention, the light metal may be aluminum or aluminum alloy, titanium Ti or titanium alloy, or other similar light metal materials.

[0009] The preferred embodiment 4 of the present invention is that the composite material can be glass fiber, carbon fiber or other similar composite materials.

[0010] In preferred embodiment 5 of the present invention, the separator 3 may be made of liquid-rich liquid-absorbent composite glass fiber, or carbon fiber or other non-metallic materials.

[0011] In preferred embodiment 6 of the present invention, the base frame of the two polar plates (1A, 1B) can be formed with an arc-shaped bend at one end, or both ends with arc-shaped bends.

Embodiment 7

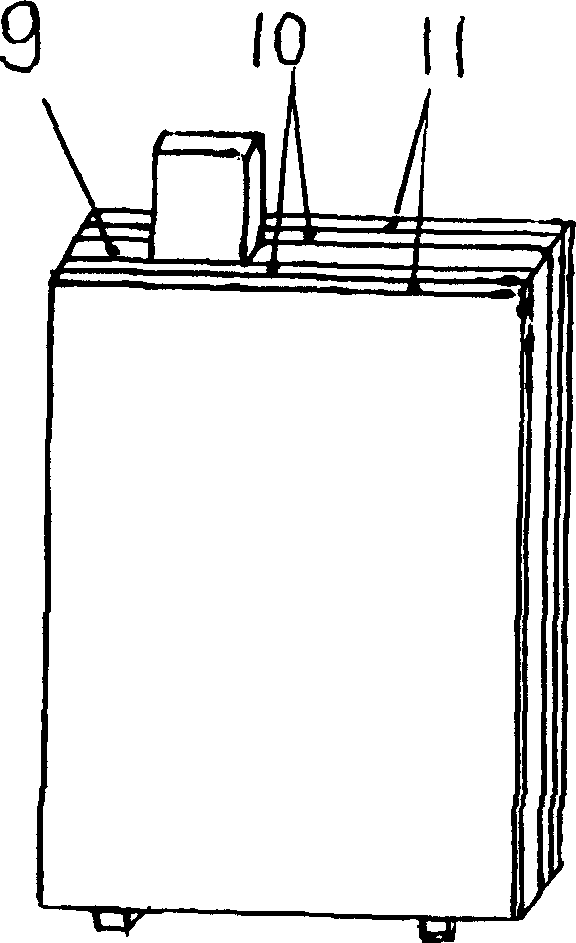

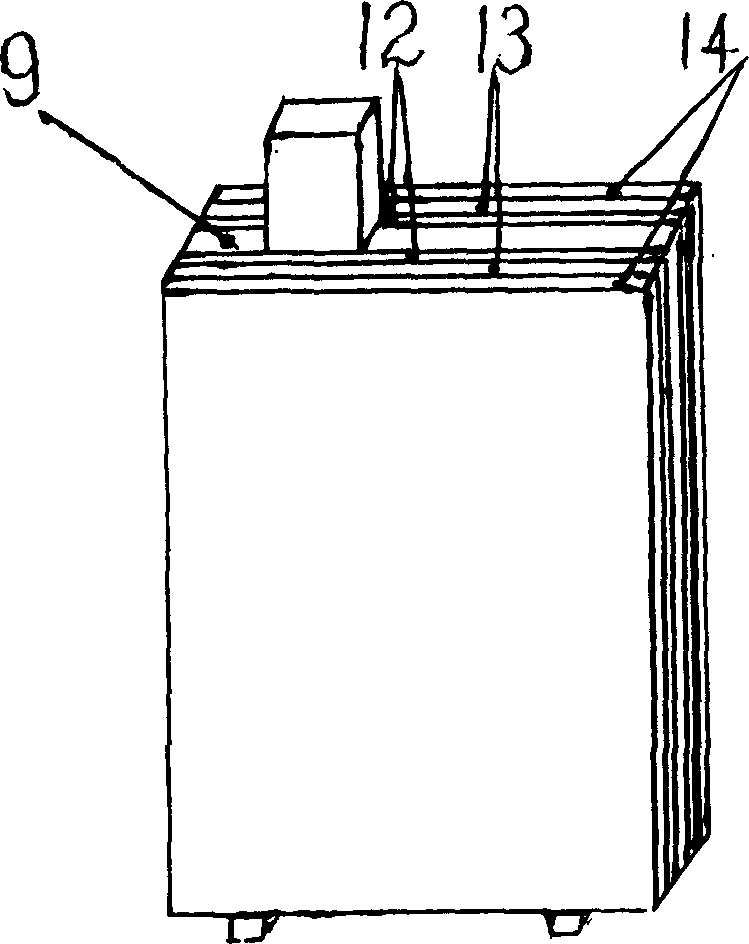

[0012] Preferred embodiment 7 of the present invention can be the storage battery completed by the above-mentioned 1-6 embodiment, and the polar plates (1A, 1B) that are arranged and combined by separators 3 in the electrolyte of the battery tank 4 are placed horizontally Yes, the bipolar plates can also be placed vertically to form a bipolar battery structure in which the plates are placed horizontally or vertically. But there is at least one pair of unipolar plates.

Embodiment 8

[0013] Preferred embodiment 8 of the present invention, can be according to the form of above-mentioned embodiment 1--7, adds polyfluoroalkane sulfonic acid or ethylene imine, lead sulfate, carbon powder in battery dilute sulfuric acid solution electrolyte.

[0014] Compared with the prior art, the present invention has the following advantages and beneficial effects:

[0015] 1. The battery plate adopts double-layer or multi-layer coating, among which the newly added pb and cd coatings are used as transition layers, which do not directly participate in the chemical reaction of the battery.

[0016] 2. Only one type of active material is used to make the plate, and the cost of the coating is lower than that of traditional batteries using two active materials with different formulations, which simplifies production and technical management.

[0017] 3. Use pbo from dark to black crystals 2 The active material used as the plate is more effective than the traditional brown fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com