Fuel cell polar plate and fuel cell using the same

A fuel cell plate and fuel cell technology, which is applied to fuel cell parts, fuel cells, solid electrolyte fuel cells, etc., can solve the problems of affecting gas transmission, hindering electrochemical reactions, and low power generation efficiency of fuel cells. The effect of increasing speed and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

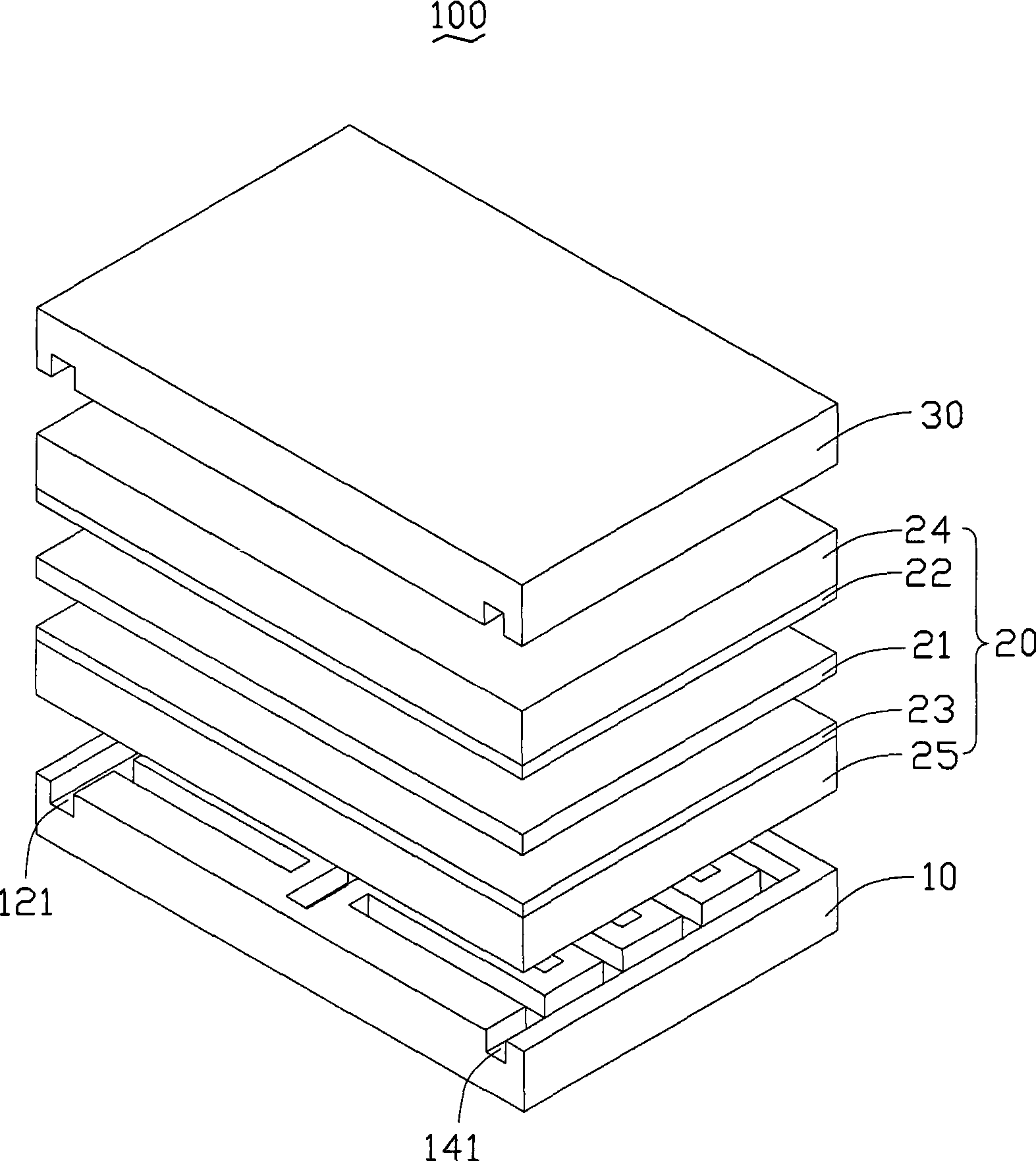

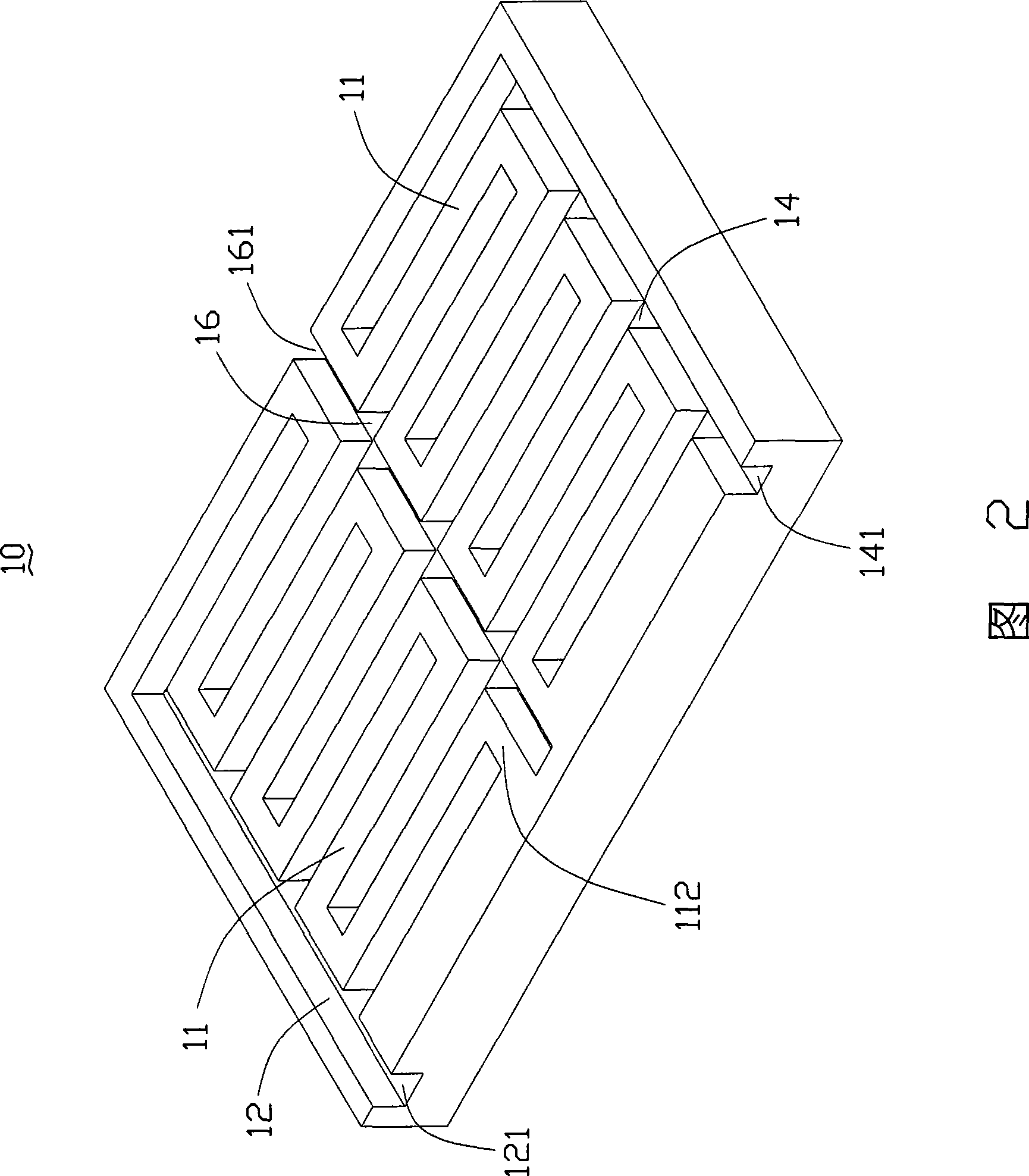

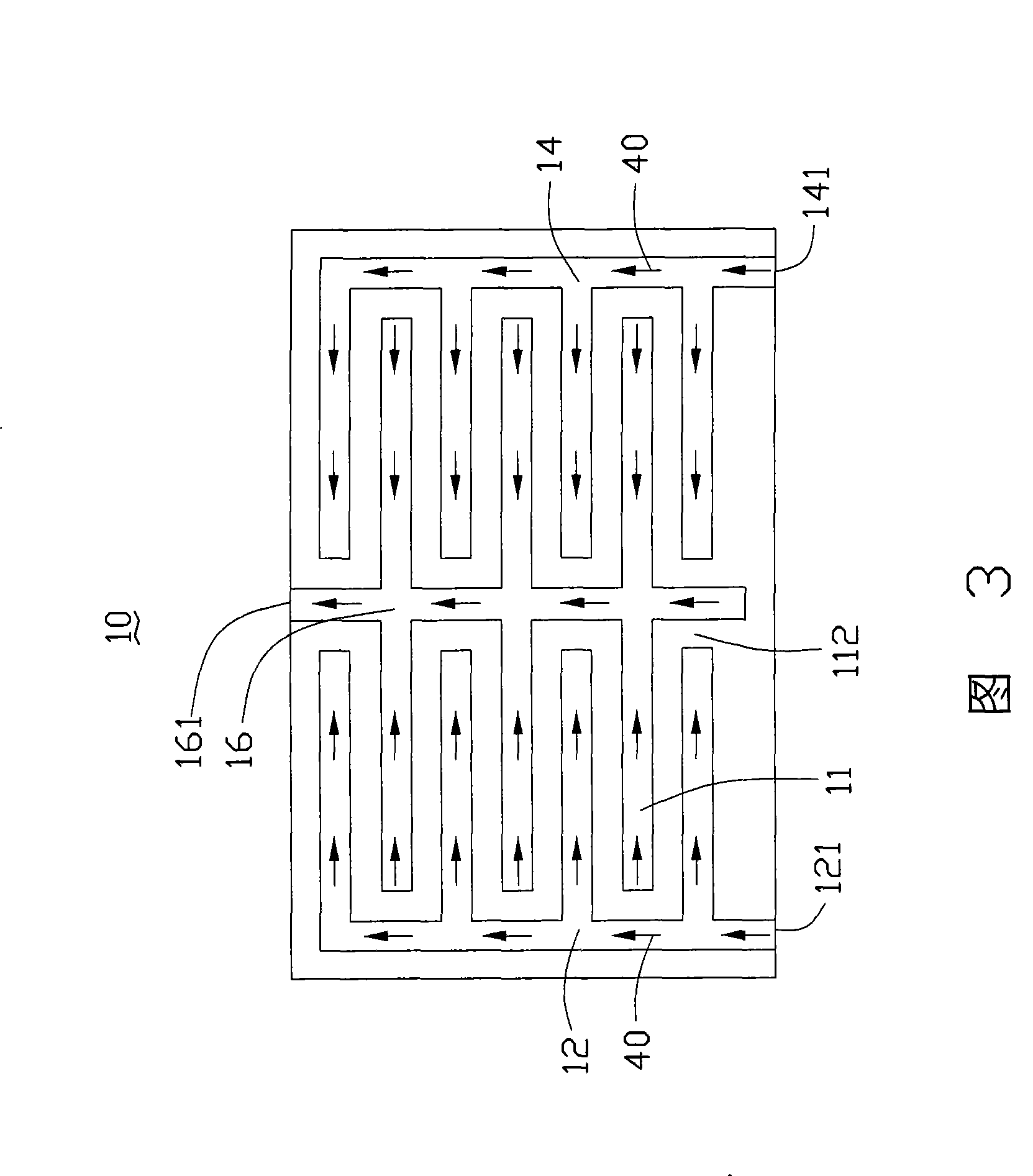

[0017] figure 1 Shown is a schematic structural diagram of one embodiment of the fuel cell of the present invention. The fuel cell 100 includes a lower electrode plate 10, a membrane electrode group 20 and an upper electrode plate 30. The membrane electrode group 20 is sandwiched between the lower electrode plate 10 and the upper electrode plate 30. The membrane electrode assembly 20 includes a proton exchange membrane 21, two catalyst layers 22, 23 and two gas diffusion layers 24, 25. The two catalyst layers 22, 23 are respectively sandwiched between the proton exchange membrane 21 and the two gas diffusion layers 24 , 25 between. The upper electrode plate 30 and the lower electrode plate 10 mainly play the role of gas conduction, conduction and water conduction in the fuel cell 100. The two gas diffusion layers 24 and 25 are made of porous materials. The gas (such as hydrogen or air) entering from the upper plate 30 and the lower plate 10 enters the two gas diffusion layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com