Metallographic corrosion method and metallographic corrosive agent for aluminum alloy

A metallographic corrosion and aluminum alloy technology, which is applied in the preparation of test samples, etc., can solve the problems of prolonging the preparation time of metallographic samples, unsatisfactory picture color and incomplete structure display, etc., and achieves the reduction of metal standards. Electrode potential, speed up electrochemical reaction, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

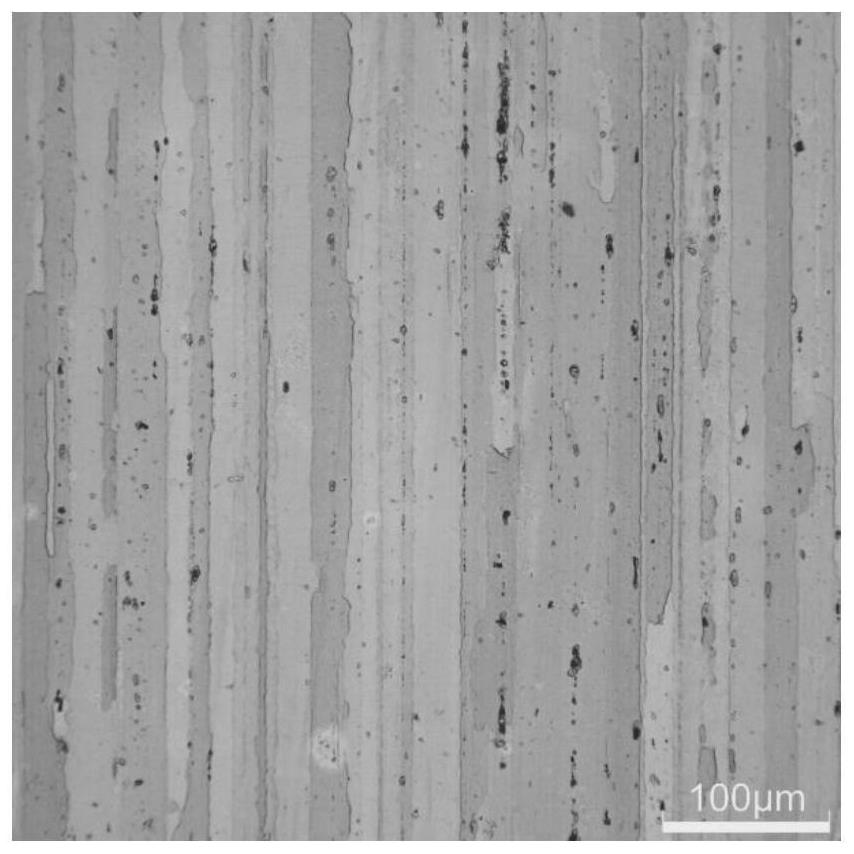

[0032] A kind of 7055 aluminum alloy metallographic corrosion method provided by the invention comprises the following steps:

[0033] a. The 7055 aluminum alloy sample is pre-cleaned, hot-mounted, mechanically ground and mechanically polished in sequence, rinsed with water, and dried with cold air to obtain a metallographic sample;

[0034] The above-mentioned pre-cleaning treatment is cleaning with absolute ethanol to remove dirt and oil on the surface of the sample.

[0035] The hot mounting process is to use phenolic resin powder (this example uses the phenolic resin powder of Naibo Company, the model is HM1) for hot mounting, and the resin powder is added to reach more than 1 / 3 of the volume of the cavity mold in the mounting machine, and the heating temperature of the mounting machine is set The temperature is 170°C, the heating time is 800s, the holding time is 200s, and the pressure in the chamber is 8000N.

[0036] Mechanical grinding is coarse grinding and fine grin...

Embodiment 2

[0041] A kind of 7055 aluminum alloy metallographic corrosion method provided by the invention comprises the following steps:

[0042] a. same as step a in embodiment 1;

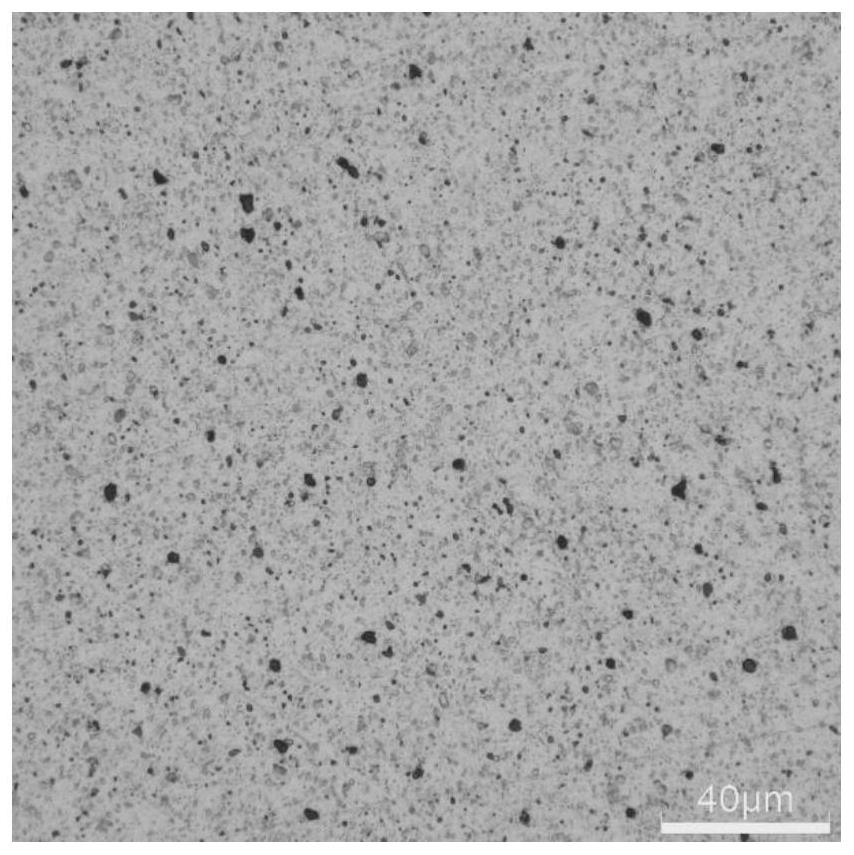

[0043] b. Add 4mL of nitric acid, 2.5mL of hydrochloric acid, 2mL of sulfuric acid, 3mL of hydrofluoric acid, and 88.5mL of deionized water into the container and mix to obtain a metallographic etchant. same as in 1;

[0044] c. Pour the metallographic etchant into the petri dish, place the petri dish in a constant temperature water bath at 25°C, immerse the metallographic sample obtained in step a into the metallographic etchant, corrode the sample for 30 seconds, and rinse with absolute ethanol After cleaning, dry it with cold air, and observe the metallographic structure of the 7055 aluminum alloy under a digital metallographic microscope.

Embodiment 3

[0046] A kind of 7055 aluminum alloy metallographic corrosion method provided by the invention comprises the following steps:

[0047] a. same as step a in embodiment 1;

[0048] b. Add 5mL of nitric acid, 2mL of hydrochloric acid, 1.5mL of sulfuric acid, 2.5mL of hydrofluoric acid, and 89mL of deionized water in the container and mix to obtain a metallographic etchant. same as in 1;

[0049] c. Pour the metallographic etchant into the petri dish, place the petri dish in a constant temperature water bath at 25°C, immerse the metallographic sample obtained in step a into the metallographic etchant, corrode the sample for 30 seconds, and rinse with absolute ethanol After cleaning, dry it with cold air, and observe the metallographic structure of the 7055 aluminum alloy under a digital metallographic microscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com