Quick-dry pigment ink and preparation method thereof

A pigment ink, quick-drying technology, applied in ink, household utensils, applications, etc., can solve the problems of affecting the writing effect, the line is not easy to dry, and the release effect is strong or weak, so as to improve the practicality, increase the effect, and eliminate precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The mass parts of quick-drying pigment ink components are as follows:

[0032] Element Quantity (parts) water 60 pigment 5 preservative 1 filler 1 lubricant 2 Dispersant 6 stabilizer 2 Resist 2 D 2 antioxidant 2 Defoamer 2 Anti-offset agent 1 Film former 3 penetrant 1

[0033] Prepare the ink as follows:

[0034] S1, the solid pigment is ground into powder by a grinder;

[0035] S2. Adding fillers, preservatives, lubricants, dispersants, wetting agents, antioxidants, film-forming agents and penetrating agents to the deionized water, and stirring evenly with a stirring device to obtain a solvent;

[0036] S3, adding the ground pigment into the solvent while stirring to prepare the color paste;

[0037] S4, filter the prepared color paste, and filter out larger solid impurities;

[0038] S5, add sulfuric acid into the color paste, and stir evenly;

[0039] S6. Add resist...

Embodiment 2

[0044] Element Quantity (parts) water 75 pigment 10 preservative 2 filler 3 lubricant 4 Dispersant 11 stabilizer 4 Resist 4 D 5 antioxidant 3 Defoamer 5 Anti-offset agent 3 Film former 7 penetrant 2

[0045] Prepare the ink as follows:

[0046] S1, the solid pigment is ground into powder by a grinder;

[0047] S2. Adding fillers, preservatives, lubricants, dispersants, wetting agents, antioxidants, film-forming agents and penetrating agents to the deionized water, and stirring evenly with a stirring device to obtain a solvent;

[0048] S3, adding the ground pigment into the solvent while stirring to prepare the color paste;

[0049] S4, filter the prepared color paste, and filter out larger solid impurities;

[0050] S5, add sulfuric acid into the color paste, and stir evenly;

[0051] S6. Add resist to the color paste and stir until uniform

[0052] S7, add anti-offset agent...

Embodiment 3

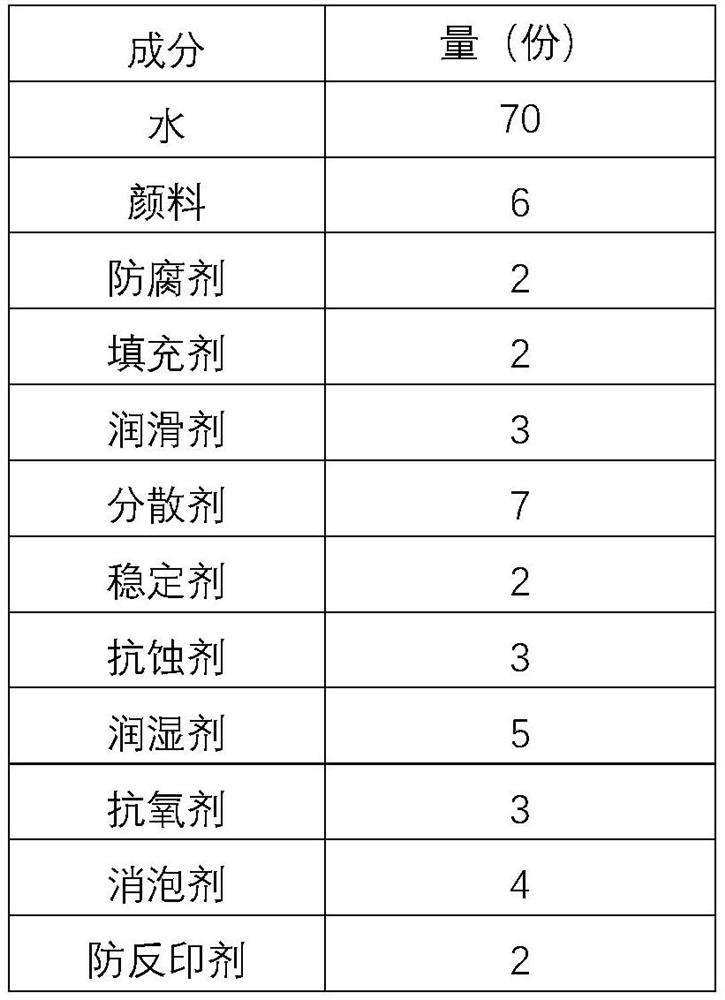

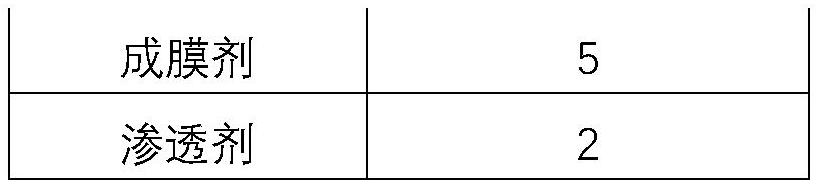

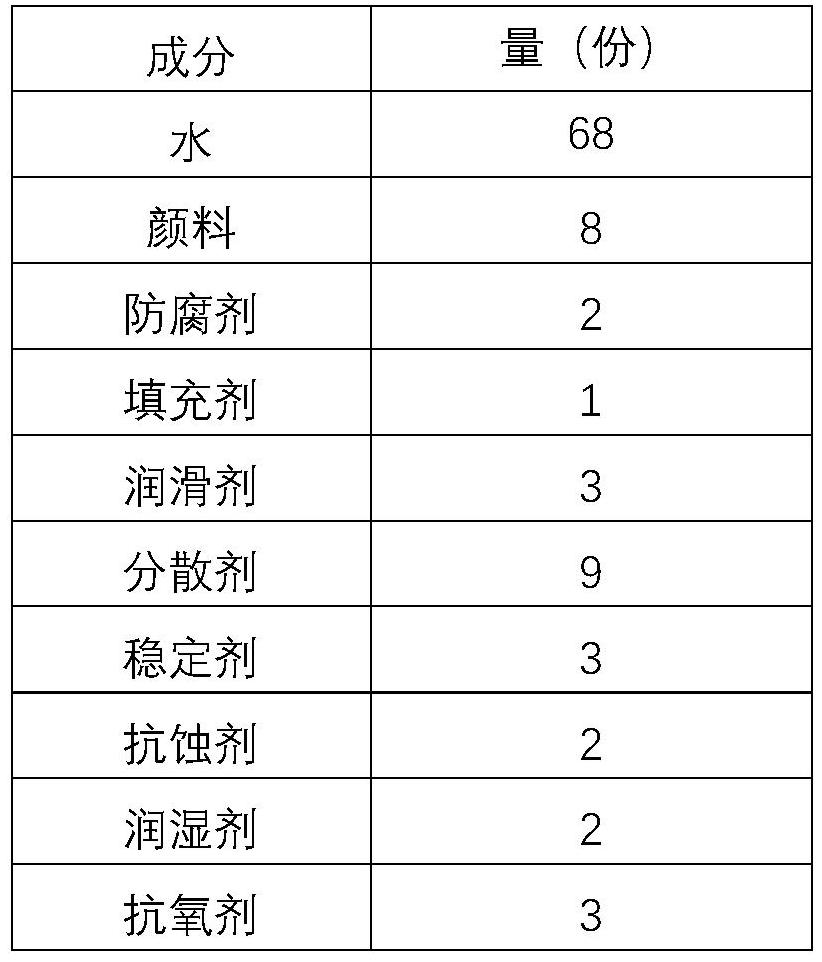

[0056]

[0057]

[0058] Prepare the ink as follows:

[0059] S1, the solid pigment is ground into powder by a grinder;

[0060]S2. Adding fillers, preservatives, lubricants, dispersants, wetting agents, antioxidants, film-forming agents and penetrating agents to the deionized water, and stirring evenly with a stirring device to obtain a solvent;

[0061] S3, adding the ground pigment into the solvent while stirring to prepare the color paste;

[0062] S4, filter the prepared color paste, and filter out larger solid impurities;

[0063] S5, add sulfuric acid into the color paste, and stir evenly;

[0064] S6. Add resist to the color paste and stir until uniform

[0065] S7, add anti-offset agent to the color paste and stir until uniform;

[0066] S8, adding defoamer, stirring until uniform, and standing for 1-2 hours, until there is no bubble in the color paste, and quick-drying pigment ink is obtained;

[0067] Write the prepared quick-drying pigment ink on the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com