Patents

Literature

56results about How to "Clear grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

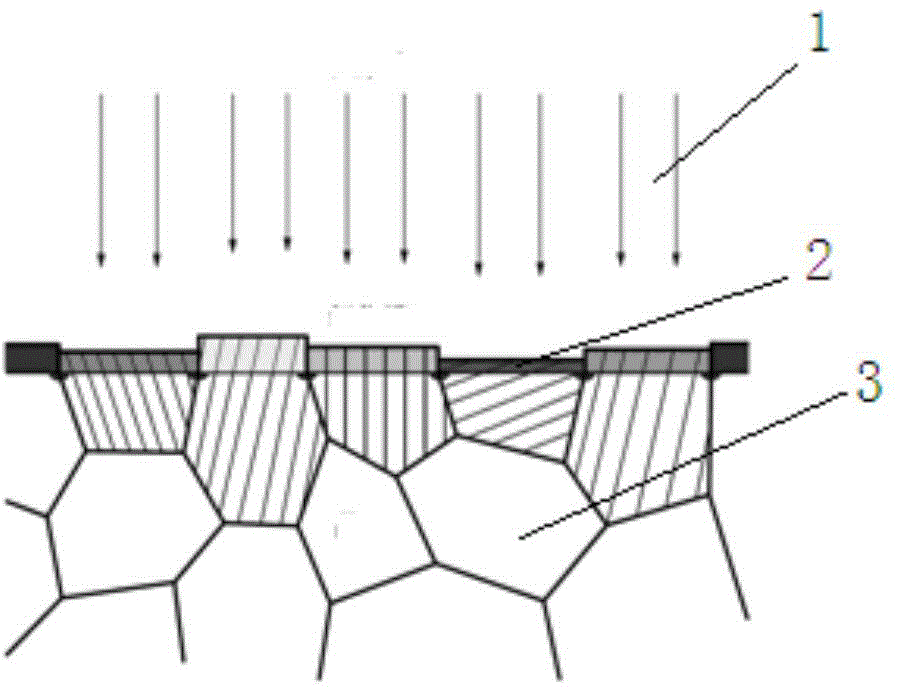

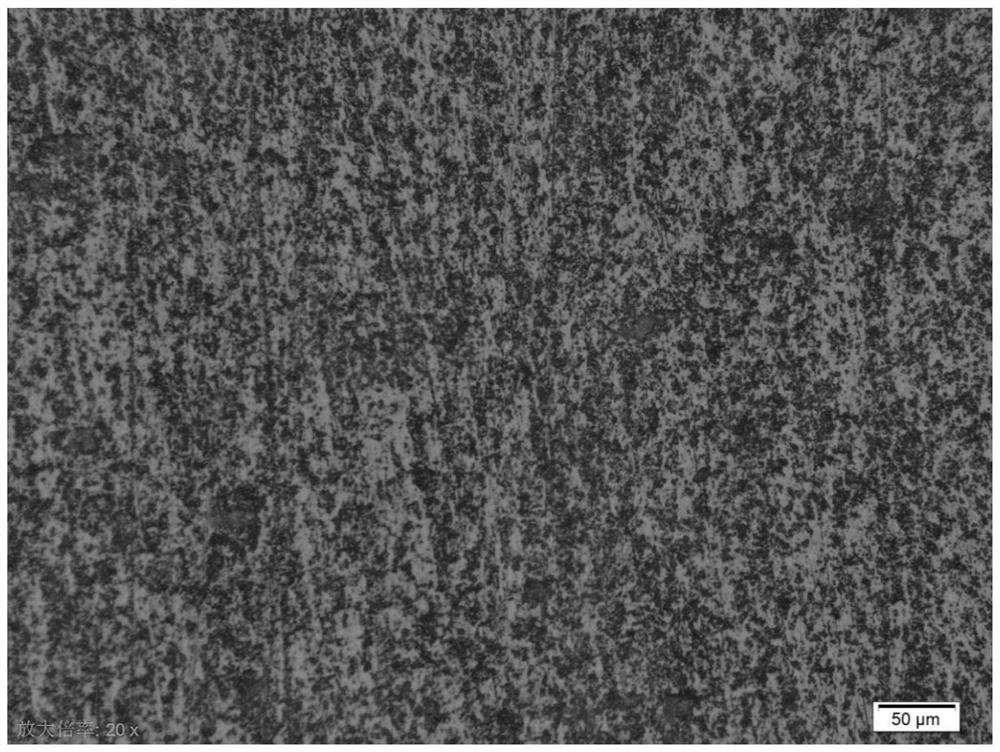

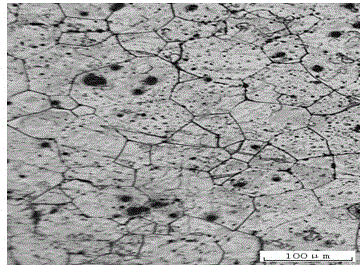

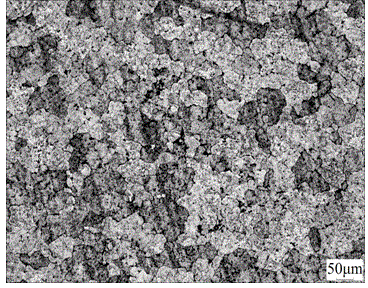

Electrochemical metallographic etching method universal for nickel-based alloys

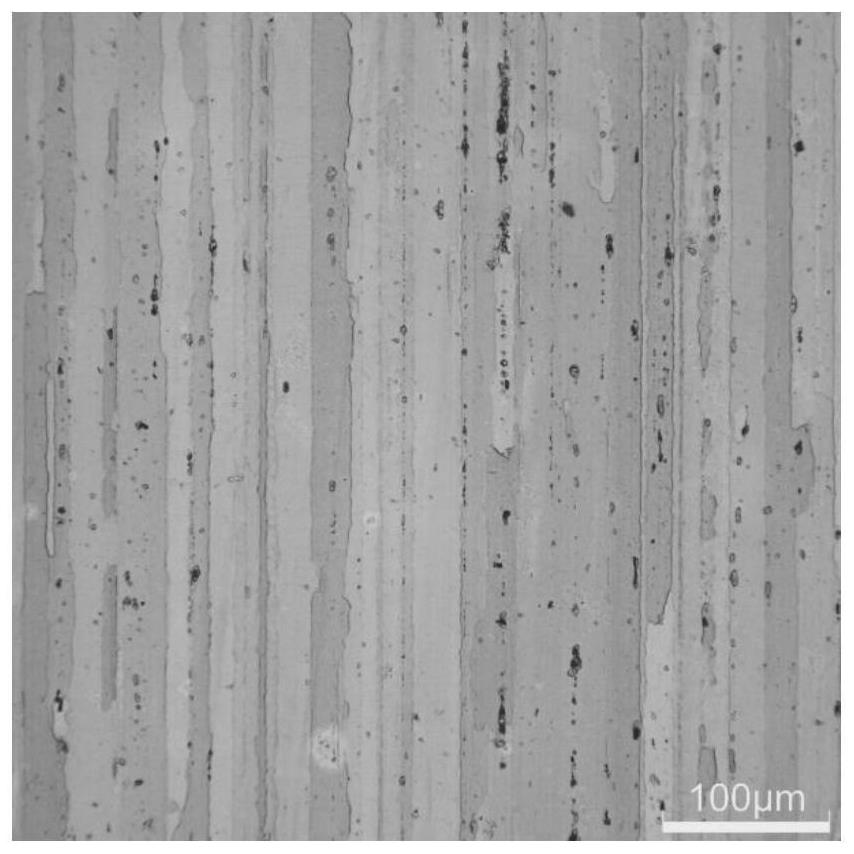

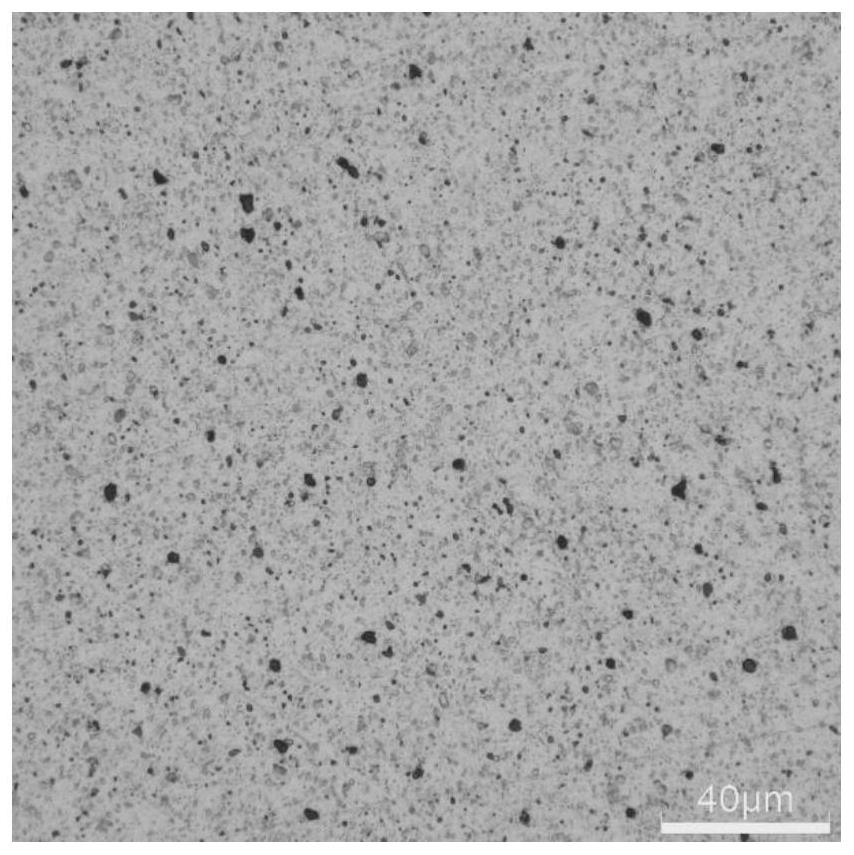

InactiveCN101655426AFlat surfaceClear grain boundariesPreparing sample for investigationGlycerolPhosphoric acid

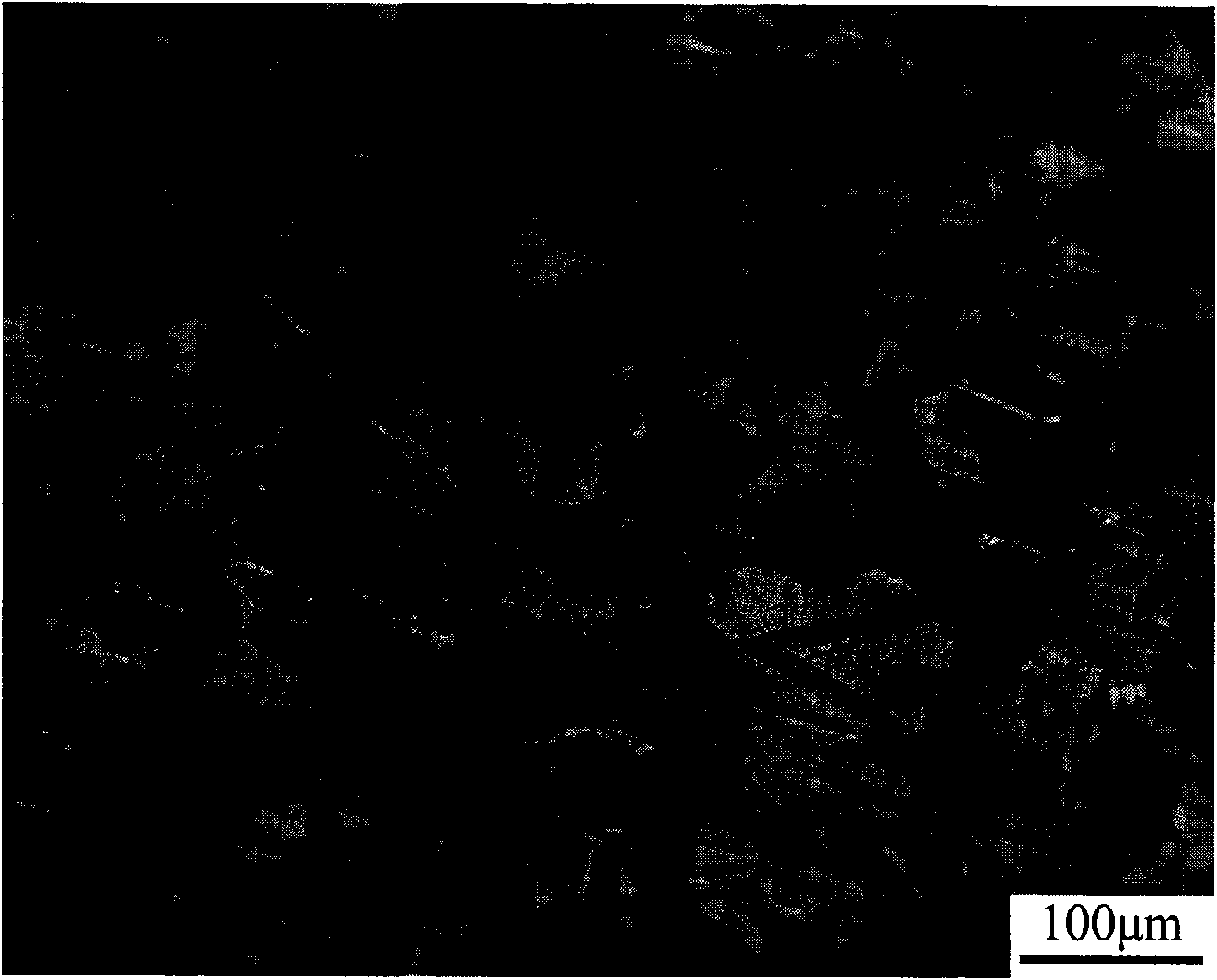

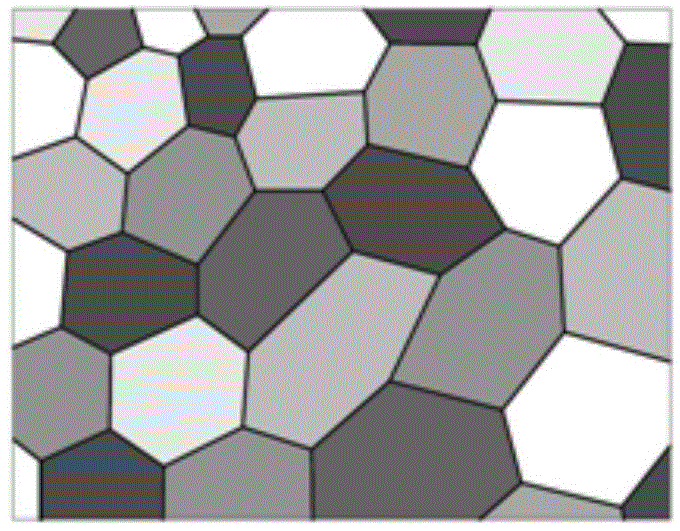

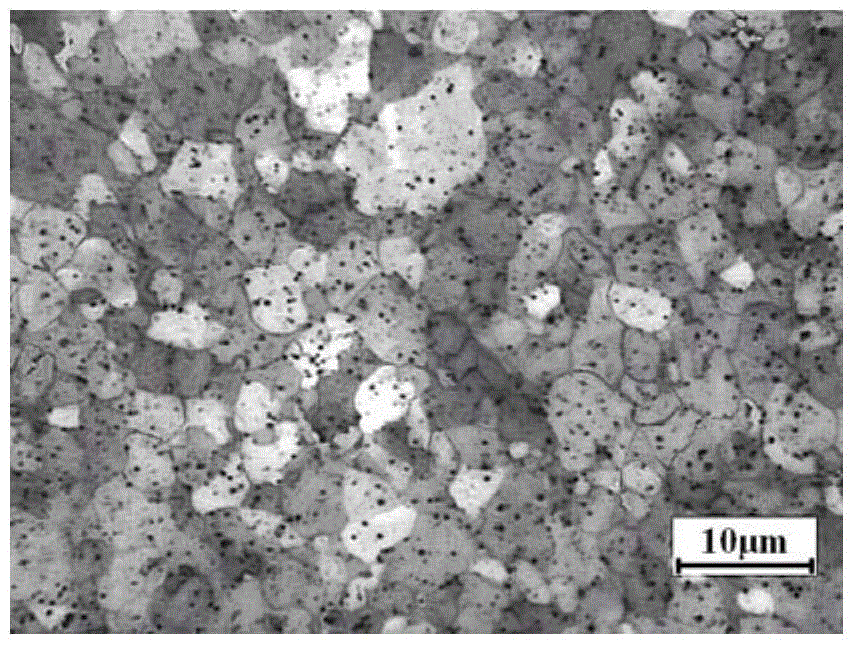

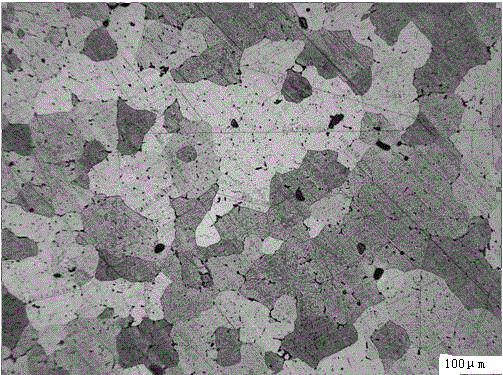

The invention discloses an electrochemical metallographic etching method universal for nickel-based alloys and relates to the electrochemical etching of the metallographic structure of a metal material. The method adopts the electrochemical metallographic etching method and takes an etching solution as a conducting medium, a metallographic specimen to be observed as an anode and a platinum electrode as cathode; the etching-control conditions comprise: the constant etching voltage: 2V / cm<2>-8Vcm<2>, the etching time: 1min-5min, the etching solution thereof contains in percentage by weight, 65%-85% of phosphoric acid, 5%-15% of sulfuric acid, 8%-15% of chromic acid and 3%-8% of glycerol, the prepared high-temperature corrosion-proof nickel-based alloys such as G-3, 825, X750 and the like have flat surface of metallograph, clear crystal boundary and clear crystal grain. Compared with chemical etching method, the electrochemical metallographic etching method has easily-controlled experimental conditions, good experimental repeatability and high experimental efficiency and is suitable for Ni-Fe-Cr alloys.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of metallographic samples of zirconium and zirconium alloy

The invention relates to a preparation method of metallographic samples of zirconium and zirconium alloy. The preparation method comprises the following steps: (a) sample pretreatment, namely sampling a to-be-tested material, ultrasonically cleaning to remove oil stain on the surface of a sample; (b) coarse grinding and fine grinding, namely grinding the sample processed in the step (a) on metallographic sand paper, wherein particle size marks of the utilized sand paper sequentially are 400#, 800#, 1200#, 2000# and 3000#; (3) chemical polishing, namely preparing a solution in a volume ratio that HF to HNO3 to H2O is 10 to 45 to 45, dipping the solution with an absorbent ball, and lightly wiping the surface of the sample with the absorbent ball for several times until the surface of the sample presents a polished surface as bright as a mirror; (d) cleaning, namely lightly wiping the surface of the polished sample in the step (c) by dipping absolute ethyl alcohol with the absorbent ball so as to remove complexes generated by chemical polishing; (e) oxidation cooling, namely dehydrating the cleaned sample, arranging the sample in a constant temperature region of a muffle furnace for oxidation for 2-10 minutes until the color of the surface of the sample is changed from bright white to faint yellow, taking out the sample, cooling, and carrying out metallographic observation and particle size evaluation.

Owner:HUNAN UNIV

7A05 aluminum alloy corrosion solution

InactiveCN105200427AClear grain boundaryClear grainPreparing sample for investigationDistilled waterFluorhydric Acid

The invention discloses a 7A05 aluminum alloy corrosion solution. The 7A05 aluminum alloy corrosion solution is prepared by adding certain amounts of nitric acid, hydrochloric acid and hydrofluoric acid into distilled water, and comprises the following ingredients by volume: 3.5% of nitric acid, 2.5% of hydrochloric acid, 10.5% of hydrofluoric acid and the balance of distilled water. During preparation of the 7A05 aluminum alloy corrosion solution, nitric acid, hydrochloric acid and hydrofluoric acid are added in sequence. After the 7A05 aluminum alloy corrosion solution is utilized for corroding a 7A05 aluminum alloy, grain boundaries and grains of the corroded 7A05 aluminum alloy are clearly displayed; the corrosion effect is relatively good, the metallographic specimen preparation period is greatly shortened, and the corrosion period is relatively short.

Owner:何小红

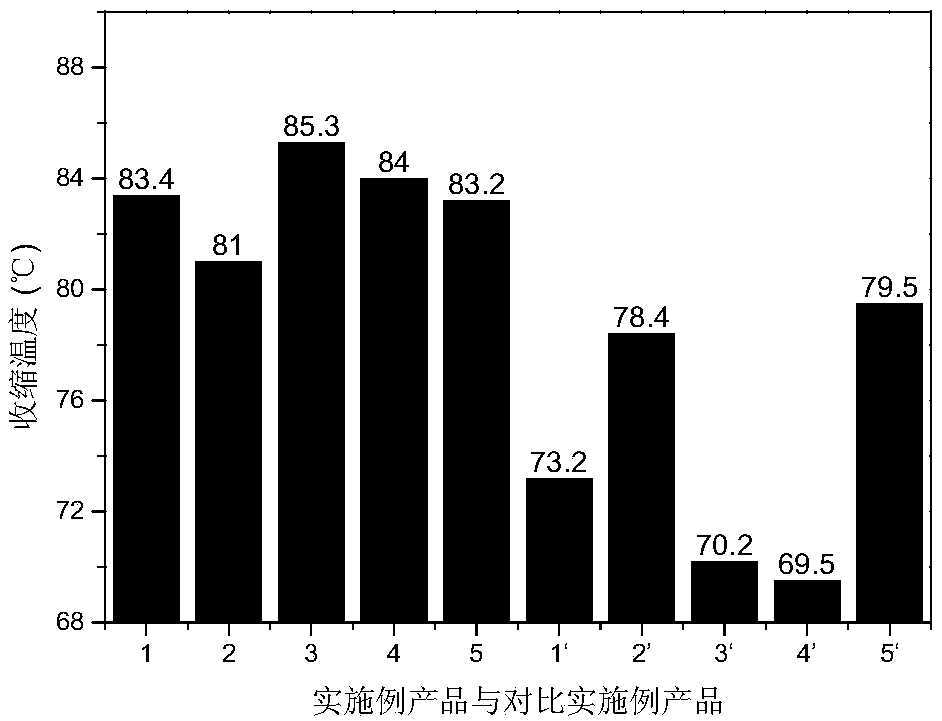

Method for tanning sheepskin through synergy of organic amine and epoxy resin composition tanning agent

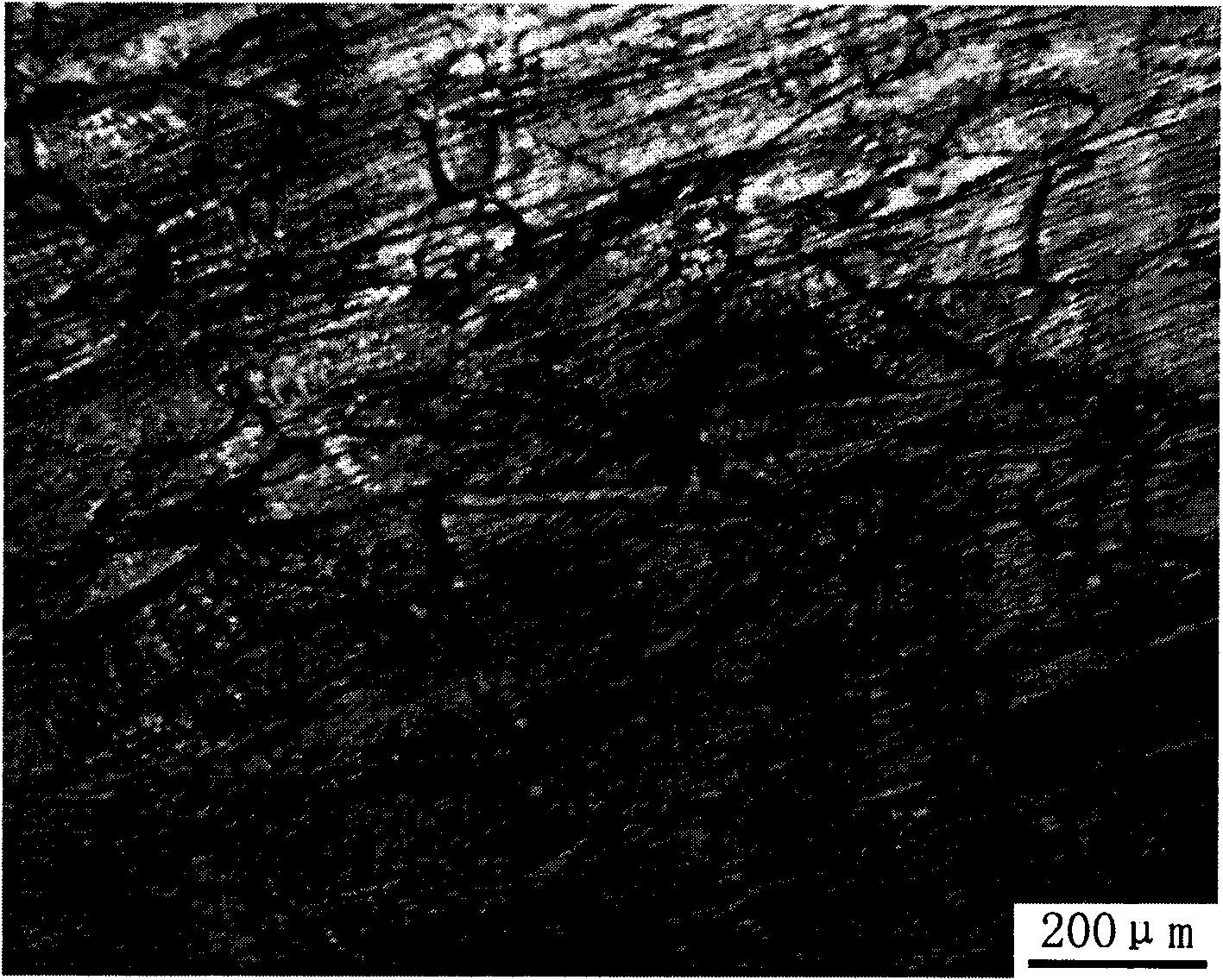

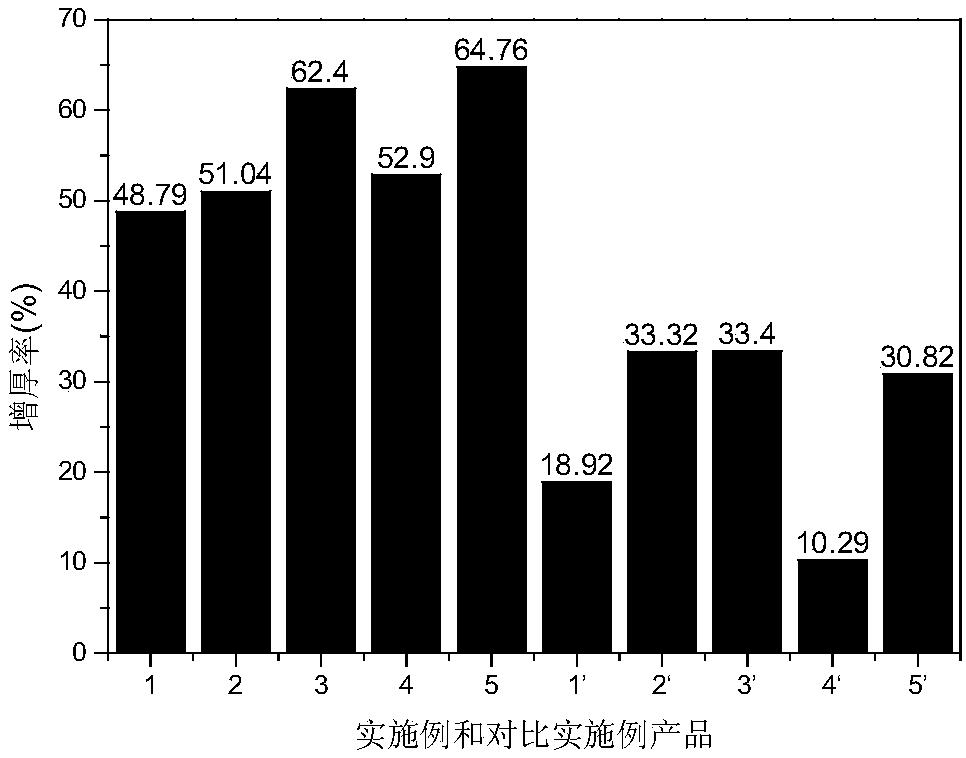

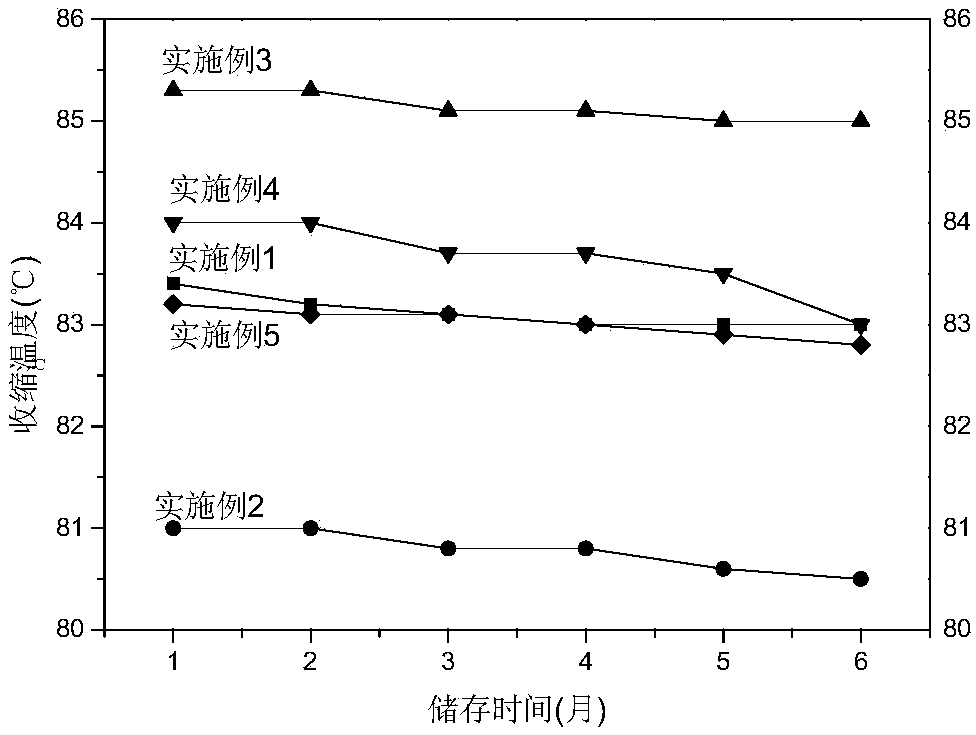

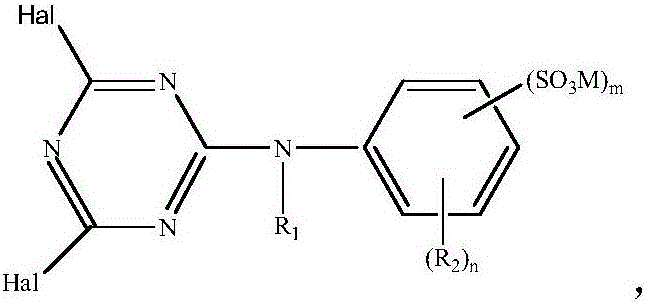

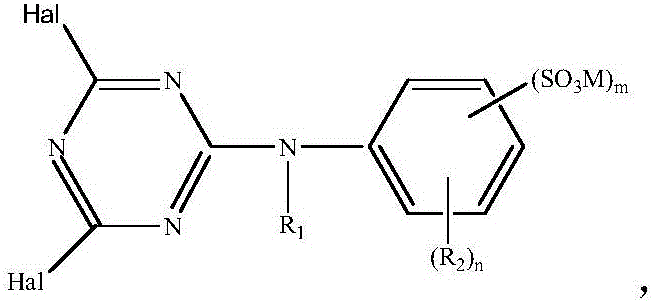

ActiveCN107828923AImprove heat and humidity stabilityImprove tanning effectTanning treatmentLeather impregnationEpoxyFiber

The invention discloses a method for tanning sheepskin through synergy of organic amine and an epoxy resin composition tanning agent. The method comprises the steps that softened or acid removing sheepskin is processed by an organic amine bath lotion, and then the epoxy resin composition tanning agent is added for tanning. As the organic amine permeates into skin fibers, the organic amine can cooperate with the epoxy resin composition tanning agent to make amido of the organic amine and amido on skin collagen fibers have a reaction, a net-shaped crosslink structure is formed, and accordingly the damp heat resistance stability of leather is improved, the epoxy resin can serve as the main tanning agent to tan the sheepskin, the tanning performance is improved, the tanned sheepskin leather isclear in grain surface, rich in body, pure white in color and good in yellowing resistance performance, and the storage life of the tanned leather is longer than six months at the room temperature.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

No-salt pickling-free short-process no-chrome tanning method

ActiveCN105925735AReduce pollutionShort processTanning treatmentPre-tanning chemical treatmentEngineeringPollution

The invention discloses a no-salt pickling-free short-process no-chrome tanning method. One the basis of advantages and disadvantages of chrome and requirements for environment protection, the no-salt pickling-free no-chrome tanning method suitable for production and feasible is needed at the present, and the finished leather quality of the method can be favorably compared with that of a traditional chrome tanning technology. The no-salt pickling-free short-process no-chrome tanning method comprises the steps that softened naked leather is directly tanned with no-chrome tanning agents to obtain wet white leather; the uniformly shaved wet white leather is tanned with substitute type synthetic tanning agents, then tanned with vegetable tanning agents and finally tanned with a defined amount of aluminum tanning agents; and a no-salt pickling-free no-chrome tanning leather blank is obtained. According to the no-salt pickling-free short-process no-chrome tanning method, the shrinkage temperature of the obtained no-chrome tanning crust leather is higher than 95 DEG C, and a body of the finished leather is soft and rich and capable of being favorably compared with chrome tanning leather in the quality, performance and other aspects; and meanwhile, the pickling process is omitted, the tanning time is shortened, and the consumption of sodium chloride and chrome salt in the leather production process and the pollution of the sodium chloride and the chrome salt to human and the environment are eradicated.

Owner:JIAXING UNIV

Positive ion polyacrylate leather finishing agent and preparation method thereof

ActiveCN102719165AReduce usageDelicate feelCoatingsLeather surface finishingCross-linkFunctional monomer

The invention provides a positive ion polyacrylate leather finishing agent and a preparation method thereof. The positive ion polyacrylate leather finishing agent comprises 16-33 wt% of polyacrylate, 0.5-3 wt% of emulsifier and 65-83 wt% of water, wherein the polyacrylate is obtained by that a positive ion functional monomer and an acrylate monomer are subjected to polymerization reaction under the effect of an initiator and a cross-linking agent; and the positive ion functional monomer is one or more of dimethylaminoethyl methacrylate, methacrylate trimethylammonium chloride and trimethyl ammonium chloride n-methyl acrylamide. The positive ion polyacrylate leather finishing agent provided by the invention is mainly used for coating a leather bottom layer, and can be used for improving the appearance and the grade of finished leather. The finished leather is natural and soft after being coated with the positive ion polyacrylate leather finishing agent. Furthermore, the leather finishing agent provided by the invention does not contain APEO (alkylphenol ethoxylates), and no methanol is released. Moreover, the preparation method has the advantages of suitability for industrial production and stabilization in batch.

Owner:SICHUAN DOWELL SCI & TECH INC

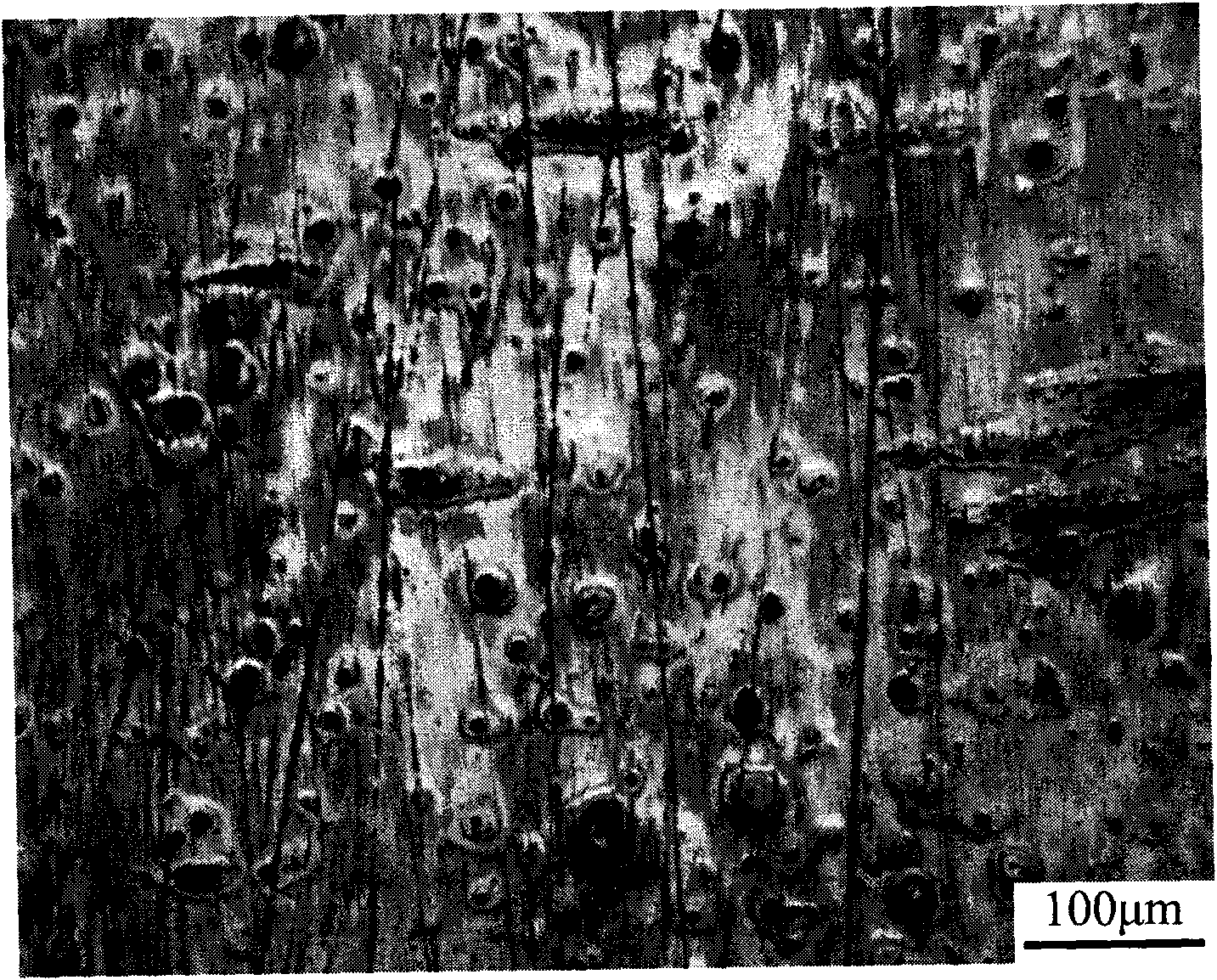

Metallographic corrosion method and metallographic corrosive agent for aluminum alloy

ActiveCN114318341APrevent smearingCorrosion method is simplePreparing sample for investigationHydrogen SulfateGrain boundary

The invention discloses an aluminum alloy metallographic corrosion method and a metallographic corrosive agent thereof. The metallographic corrosion method comprises the following steps that a, a 7055 aluminum alloy sample is subjected to pre-cleaning, hot inlaying, mechanical grinding and mechanical polishing treatment, washed with clear water and blow-dried, and then a metallographic sample is obtained; b, sequentially adding nitric acid, hydrochloric acid, sulfuric acid, hydrofluoric acid and deionized water into a container, and mixing to obtain a metallographic corrosive agent, wherein the metallographic corrosive agent comprises the following components in percentage by volume: 4-5% of nitric acid, 2-3% of hydrochloric acid, 1.5-2.5% of sulfuric acid, 2.5-3.5% of hydrofluoric acid and the balance of deionized water; and c, pouring the metallographic corrosive into a culture dish, placing the culture dish in a constant-temperature environment of 22-28 DEG C, immersing the metallographic sample into the metallographic corrosive, corroding for 25-35 seconds, taking out, washing, drying, and observing. The corrosion method is simple, the corrosion time is short, the effect of the metallographic corrosive agent is fully exerted, and the crystal boundary and crystal grains of the 7055 aluminum alloy are clearly displayed.

Owner:DONGFENG MOTOR GRP

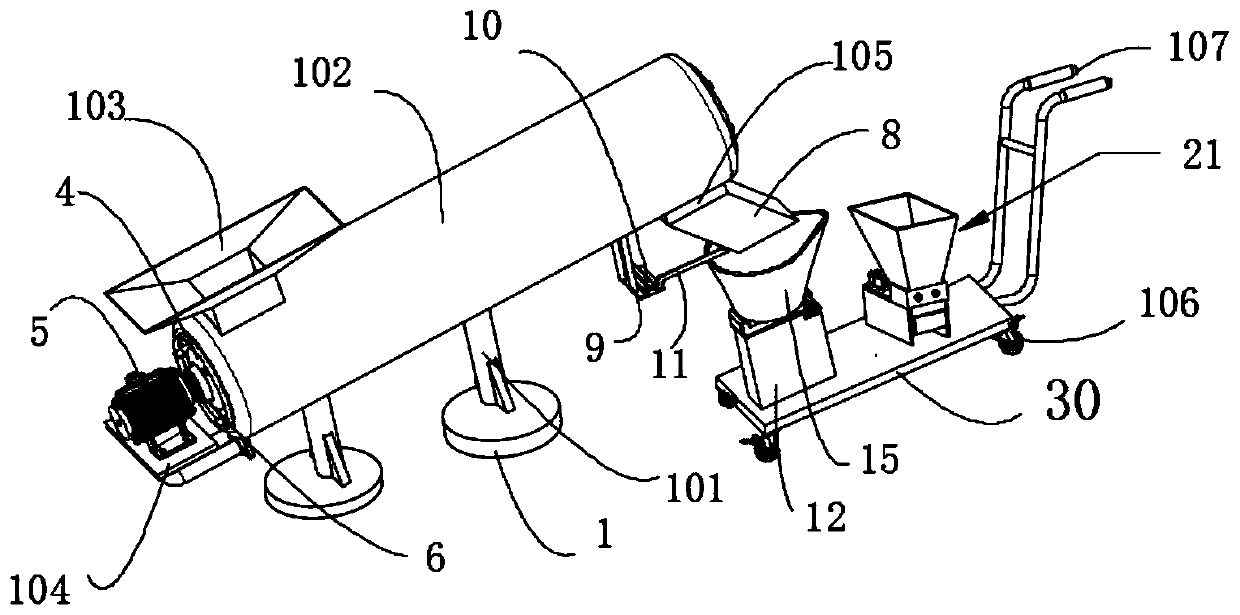

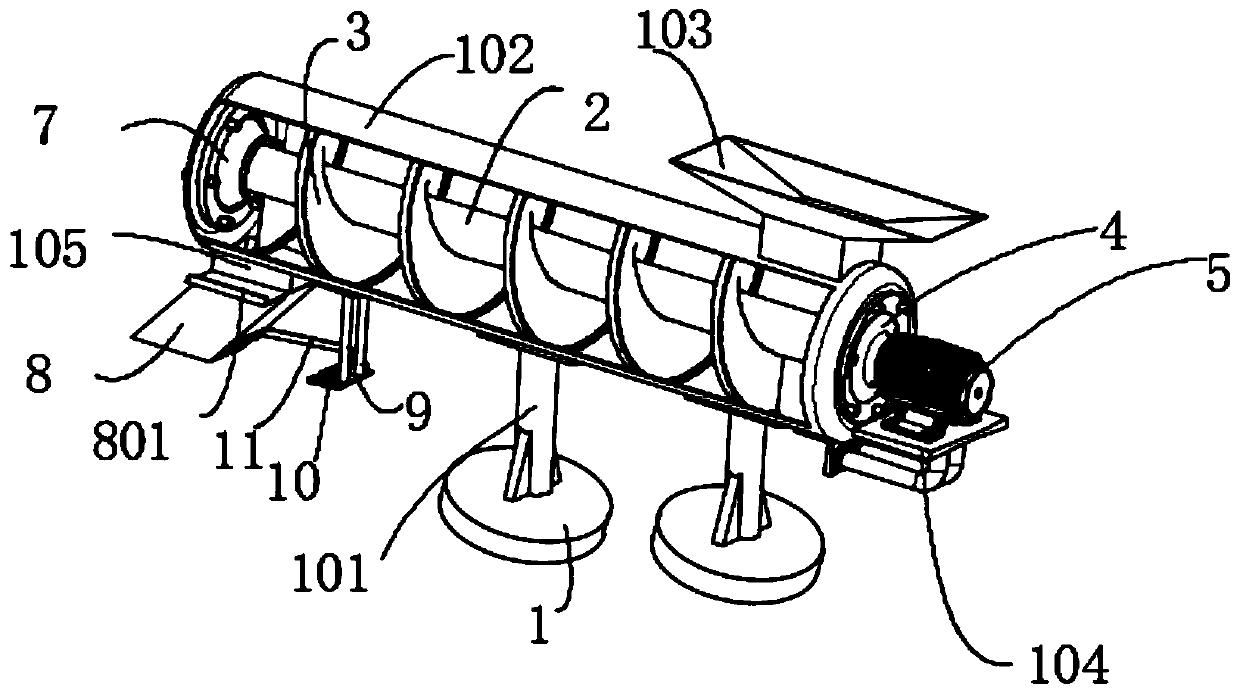

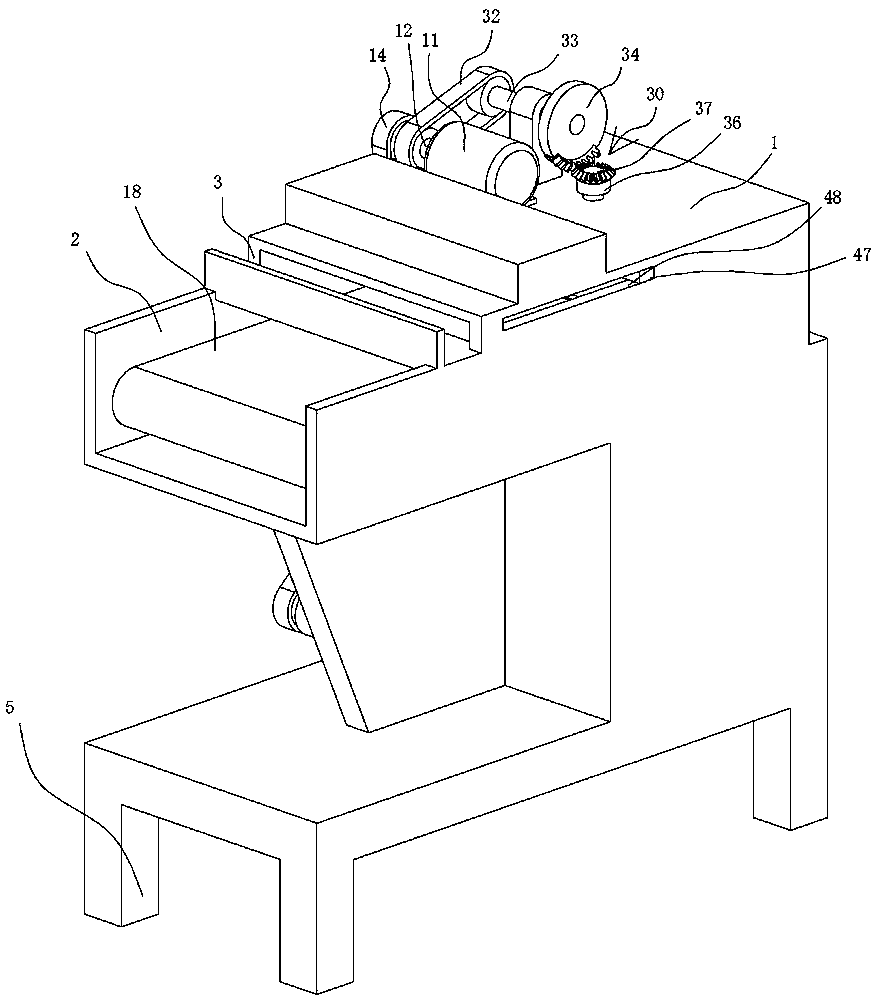

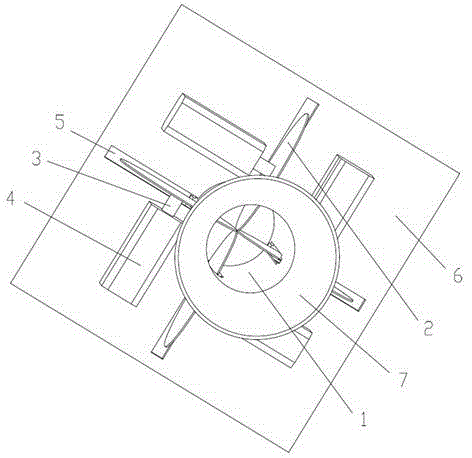

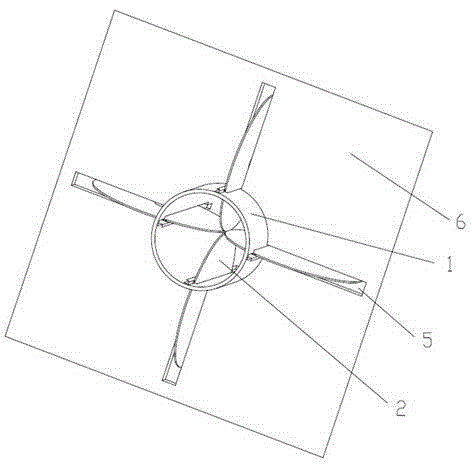

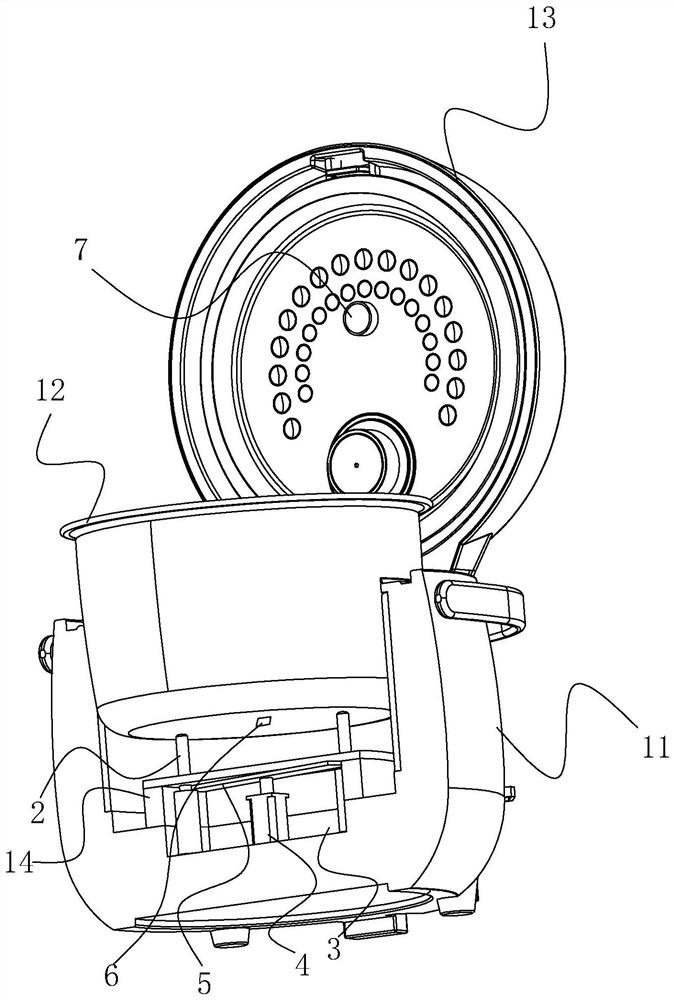

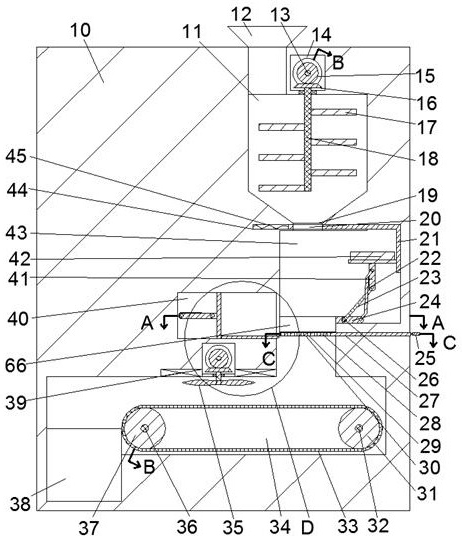

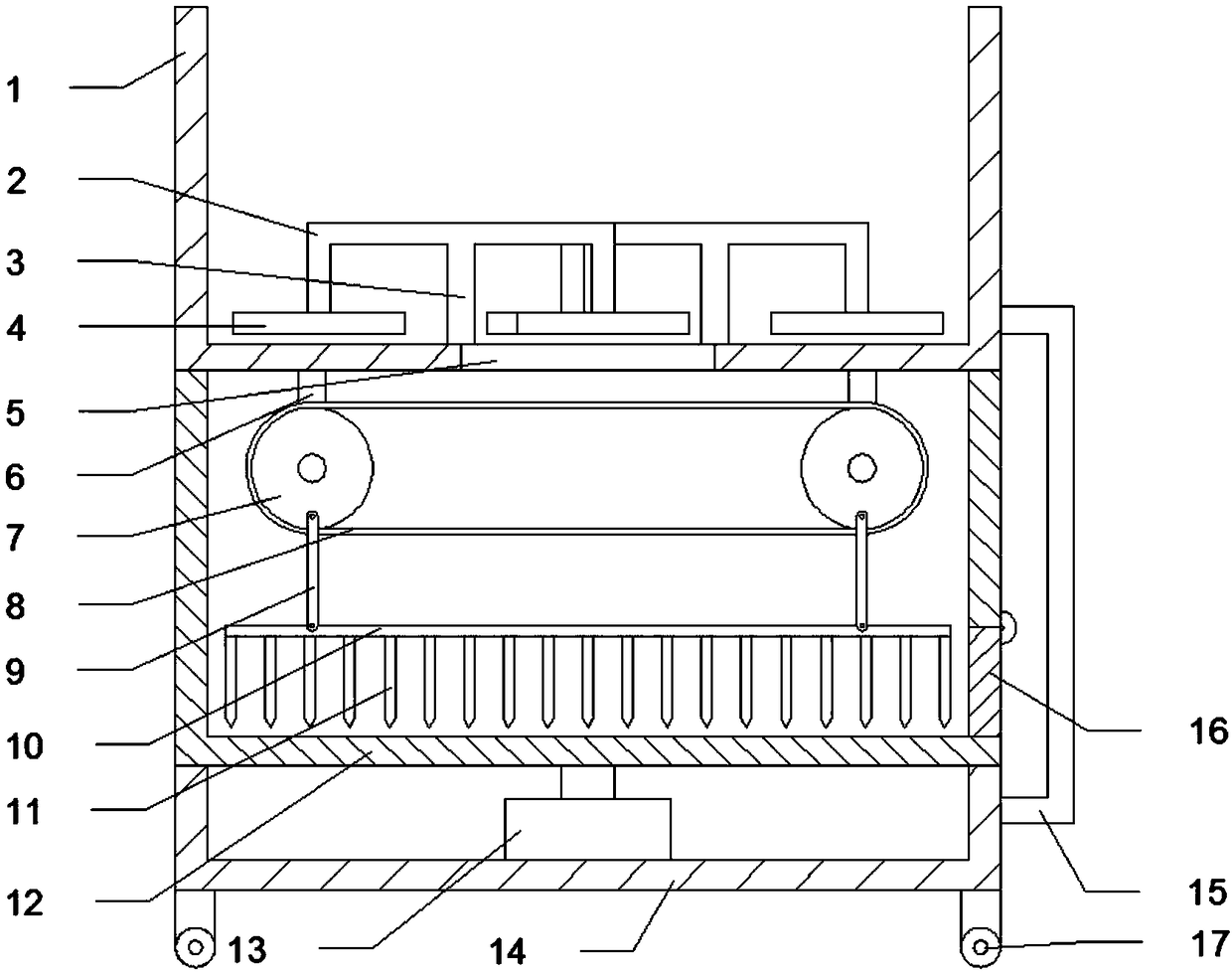

Quantitative feedstuff feeder

ActiveCN111264407AQuality improvementImprove feeding efficiencyAnimal feeding devicesAvicultureBiotechnologyAgricultural science

Owner:ZHEJIANG UNIV CITY COLLEGE

Chromium-contained retaining-filling agent and preparation method thereof

The invention provides a preparation method of a chromium-contained retaining-filling agent. The method comprises the steps that (1), 100 parts of chrome leather scrap hydrolysate, 20 parts to 100 parts of retanning agents, 1 part to 5 parts of masking agents and 3 parts to 5 parts of fatting agents are metered, then, the masking agents and the solid retanning agents are dissolved with water, the fatting agents are diluted and emulsified through water, and acidifying or alkalizing agents are compounded with water to form acidifying or alkalizing agent solutions; (2), the chrome leather scrap hydrolysate is heated to 45 DEG C to 50 DEG C under stirring, then, the chrome leather scrap hydrolysate, the masking agents, and the solid retanning agents or / and liquid-state retanning agents which are at the same temperature and obtained in the step (1) are added into the chrome leather scrap hydrolysate and are evenly mixed, then, the acidifying or alkalizing agent solutions are added to adjust the pH value of mixed liquor to 1.5 to 4.5, undissolved substances are filtered out, and the chromium-contained retaining-filling agent is obtained, wherein the solid content ranges from 40 percent to 45 percent, the content of chromium sesquioxide ranges from 1.5 percent to 5 percent, and the pH value ranges from 1.5 to 4.5. According to the method, chromium and skin collagen protein in chrome leather scrap can be utilized at the same time, the prepared hromium-contained retaining-filling agent is more comprehensive in performance, and problems caused by an existing chemical modification manner can be solved.

Owner:SICHUAN UNIV +1

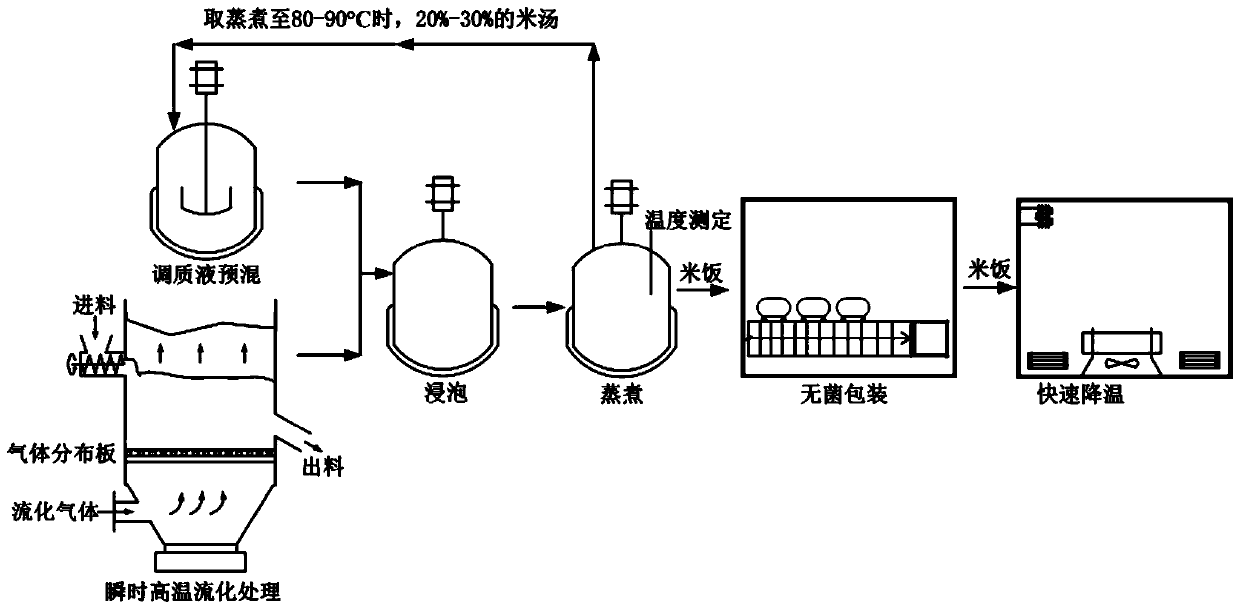

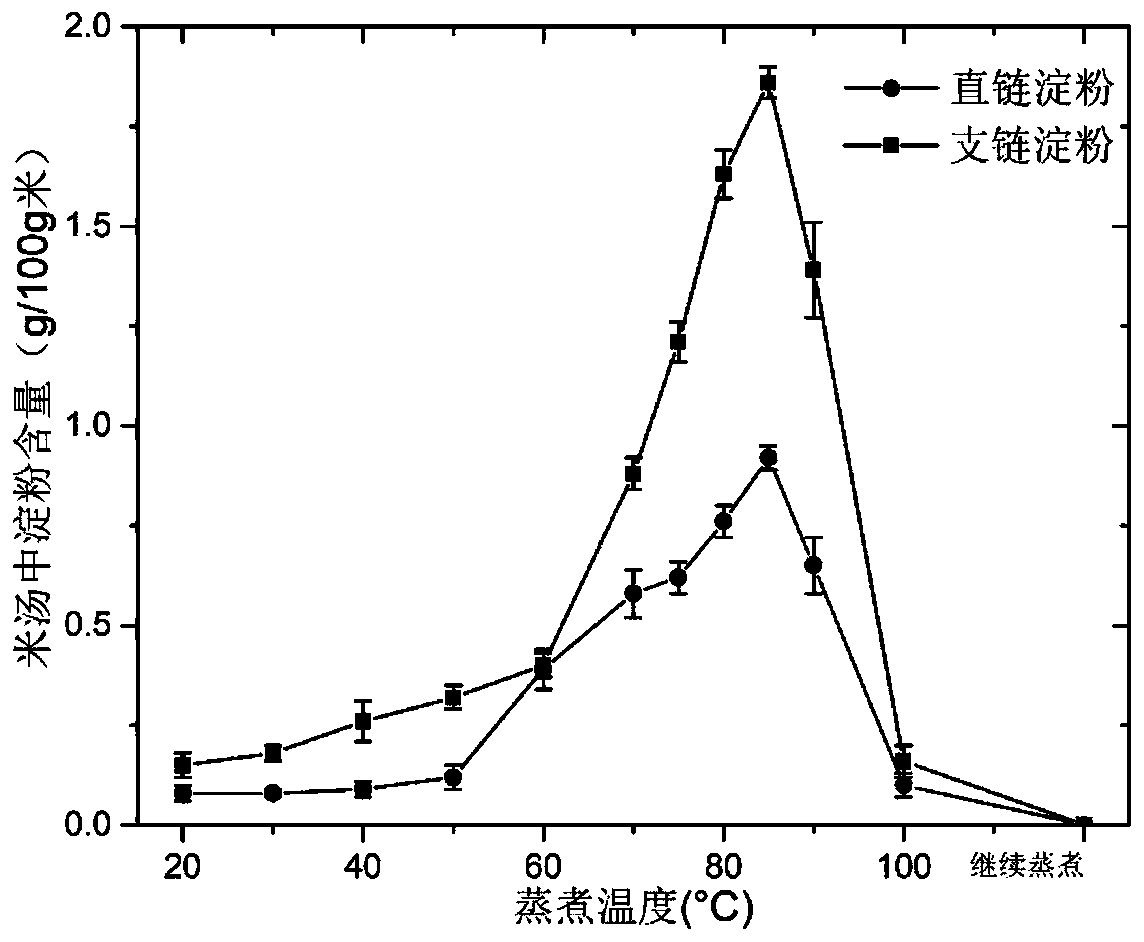

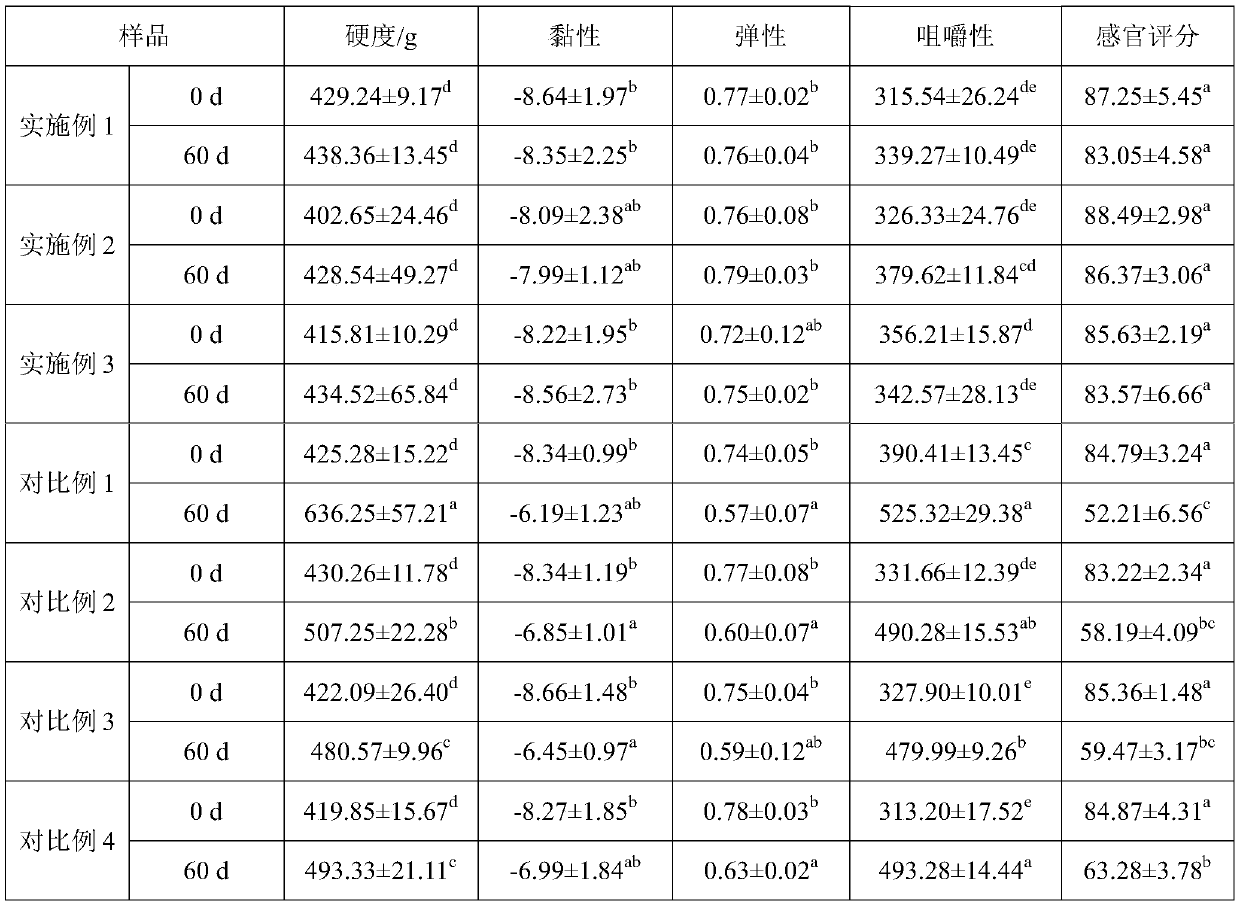

Rice conditioning process and instant rice production method

ActiveCN110301592AGreat tasteIncreasing the thicknessLipidic food ingredientsSurface waterEdible oil

The invention belongs to the technical field of food processing and discloses a rice conditioning process and an instant rice production method. On the basis of an instant high-temperature fluidization technique, rice conditioning pretreatment is realized; by a rice water refilling technique, preparation of conditioning liquid of soft rice flour and edible oil compound rice water is realized; by adoption of a rapid cooling film-forming technique, surface water retaining film increasing is realized so as to enhance water retention capacity, viscoelasticity and glossiness of rice. The productionmethod mainly includes steps of rice washing and draining, conditioning, cooking, aseptic packaging and quick cooling for film forming. By the rice conditioning process and the instant rice production method, industrial continuous production can be realized, and produced instant rice is glutinous without adhesion and great in taste after storage for 60 days.

Owner:JIANGNAN UNIV

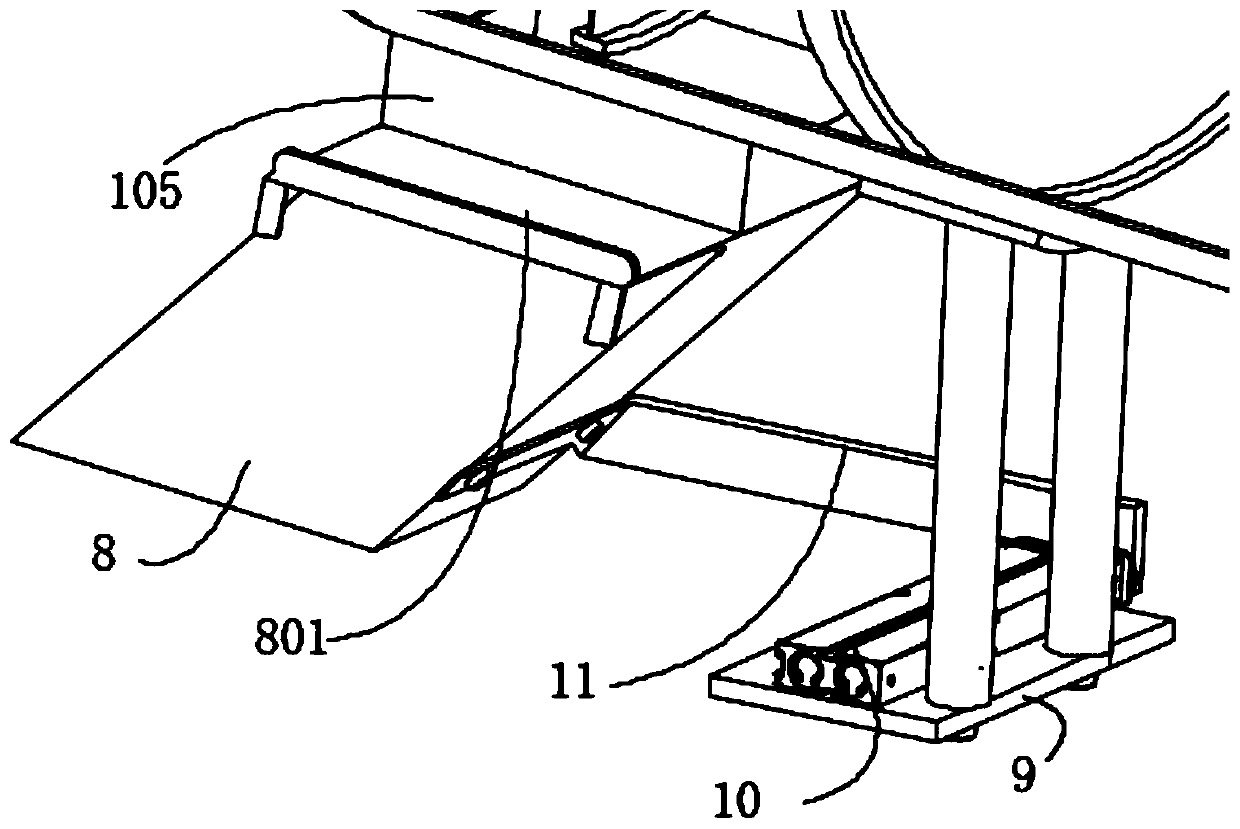

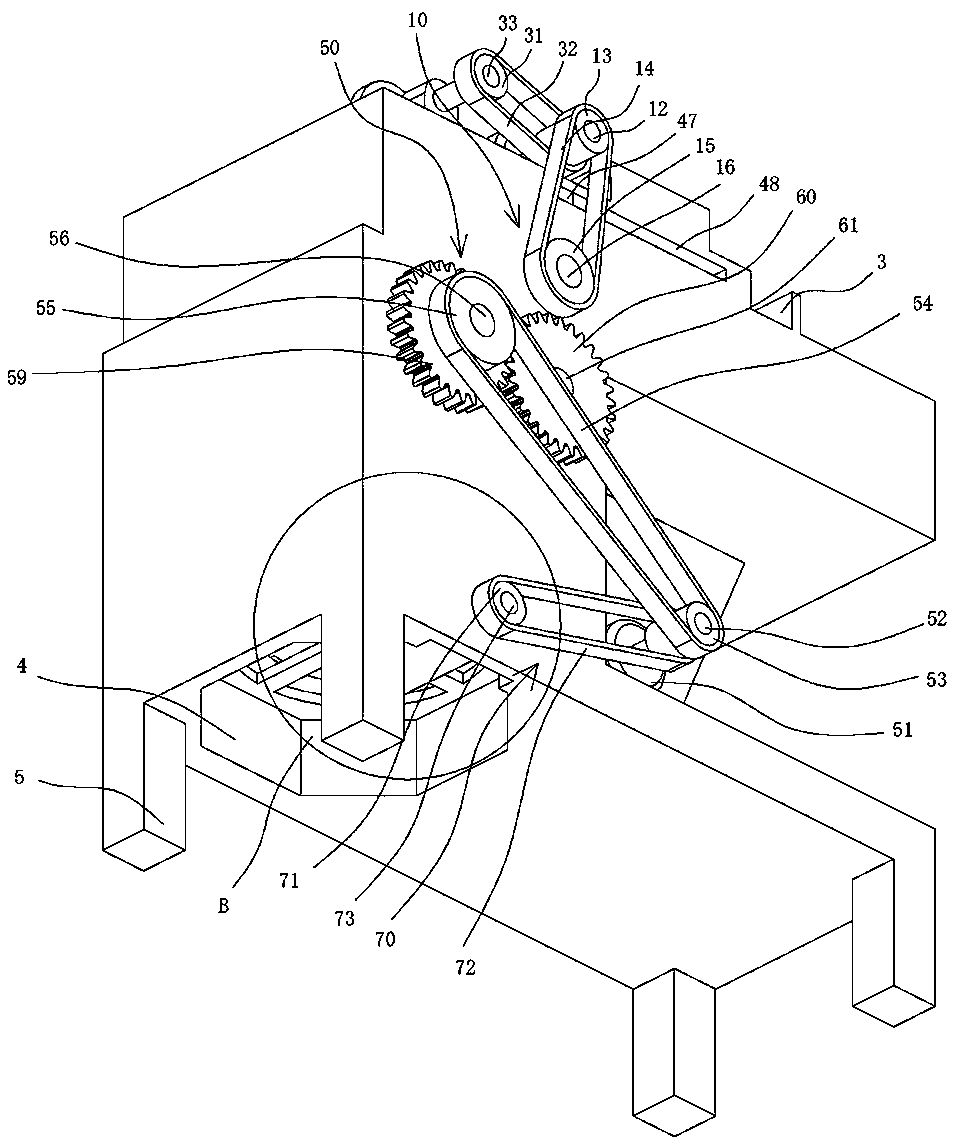

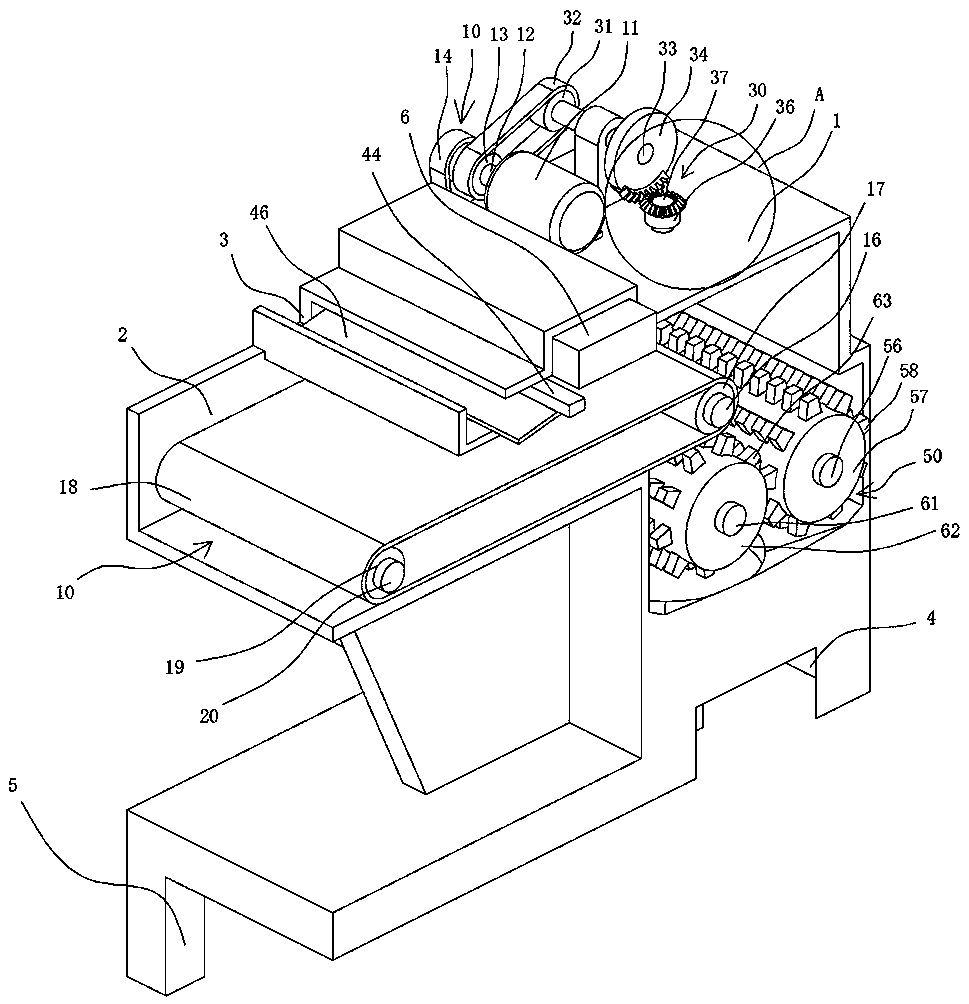

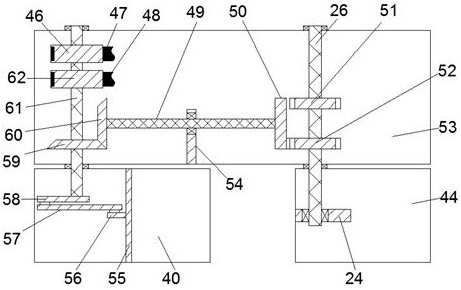

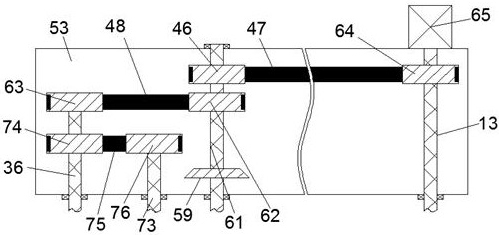

Wood waste crushing and grinding machine

PendingCN110774396AReduce the chance of failureImprove reliabilityWood working apparatusWood wastePulverizer

The invention discloses a wood waste crushing and grinding machine. The machine comprises a machine body, wherein a feed port is formed in the one end of the machine body, a discharging port is formedin the other end of the machine body, a blanking port is formed in one side of the machine body, and a plurality of evenly distributed supporting legs are arranged at the bottom end of the machine body. The machine is characterized in that a transport mechanism is arranged at one end of the machine body, a transmission mechanism which rotates intermittently is arranged on the other side of the transport mechanism, a screening mechanism is arranged at one end of the transmission mechanism, the other end of the screening mechanism is arranged on one side of the transport mechanism, a crushing mechanism is arranged at the other end of the machine body, and a grinding mechanism is arranged on one side of the crushing mechanism, and is arranged on one side of the discharging port. The machinehas the beneficial effects that to-be-processed wood waste is screened, metal materials, such as screws, easily doped in the wood waste are separated, parts for crushing are protected, and the servicelife of the machine is prolonged.

Owner:TAIZHOU LUBA ELECTRICAL TECH CO LTD

Freeze-drying grapefruit tea and processing method thereof

The invention belongs to the field of processing of tea products, and particularly provides free-drying grapefruit tea and a processing method thereof. The freeze-drying grapefruit tea product is prepared by selecting fresh grapefruits, cleaning, cutting, peeling, rapidly freezing and hardening, sublimating and drying, and packaging. The free-drying grapefruit tea can effectively retain the nutritional ingredients and aroma components of the grapefruits, after the grapefruit tea is brewed, fruit particles are full and clear, and the original aroma of the grapefruit is emitted, and the grapefruit tea tastes sour and sweet, can be preserved at room temperature for a long time, and has good market prospect.

Owner:中宝(福建)食品科技有限公司

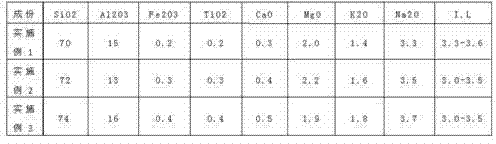

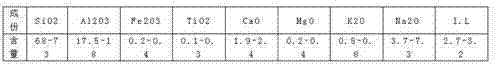

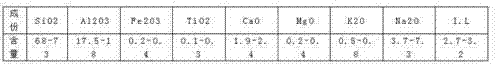

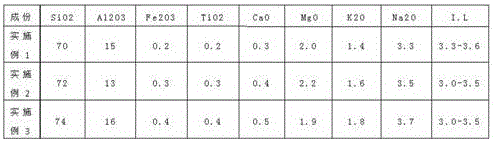

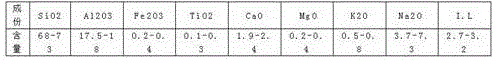

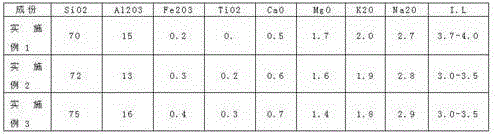

Production method of polished tiles having jade stone texture

A production method of polished tiles having a jade stone texture, wherein the polished tiles is prepared from following raw materials: high-whiteness albite powder being 5-10 wt% in the content of sodium, feldspar, clay, talcum being 28-32 wt% in the content of MgO, anorthite being 2.0-4.0 wt% in the content of CaO and bone ash being 45-50 wt% in the content of CaO. The production method includes following steps: powder producing, blank body moulding, high-temperature sintering and polishing. During the blank body moulding, firstly more than more than one stacks of a granular powder material is randomly arranged on a material arranging trolley in the form of a large-granular materials, and then a layer of mixed powder material is arranged at the periphery of the granular powder material. The powder materials are press-compacted by a press roller and then are cracked naturally, wherein the cracks are filled with a super-transparent jade material. Finally the prepared materials are fed into a die cavity for being compression-moulded. Compared with a method in the prior art, the production method is free of addition of a reinforcing agent and a whitening agent (such as zirconium silicate) which are harmful to environment. The polished tile has a super-transparent sense just like jade stone, is fine-and-smooth and has a layered sense, is clear in bottom pattern, and has such an excellent jade-like texture.

Owner:广东博华陶瓷有限公司

TC18 titanium alloy corrosion solution

InactiveCN105220151AClear grain boundaryClear grainPreparing sample for investigationOXALIC ACID DIHYDRATEPhysical chemistry

The invention discloses a TC18 titanium alloy corrosion solution. The corrosion solution is prepared by adding a certain amount of nitric acid, oxalic acid and hydrofluoric acid into distilled water, wherein the volume ratio of hydrofluoric acid, oxalic acid, nitric acid and distilled water is 1: 2.5: 3: 5. During preparation, nitric acid, oxalic acid and hydrofluoric acid are added successively. After TC18 titanium alloy is corroded by the corrosion solution, the crystal boundary and the crystalline grain of the titanium alloy are clearly showed. The corrosion effect is good, the metallographic sample preparation time is greatly shortened, and the corrosion time is short.

Owner:黎维品

Method for improving yield of leather

The invention discloses a method for improving yield of leather. The method for improving the yield of leather comprises the following steps: softening a raw material; recovering the state of fresh leather; removing ingredients not required in processing of fur; after a first layer and a second layer of an overall-thickness limed skin are separated by a splitting procedure, feeding the second layer of the limed skin in a tanning rotary drum for deliming, softening and pickling; then adding 5% of a glutaraldehyde tanning agent in the rotary drum, rotating for 180 minutes, and carrying out permeation reaction fully until a leather center becomes yellowish; adding 200% of water, and controlling the temperature to be 45 DEG C; adding 0.2% of a rewetting agent, rotating for 60 minutes, and then draining water; continuing adding 150% of water, and controlling temperature to be 45 DEG C; adding 2% of sodium formate and 0.3% of sodium bicarbonate, rotating for 30 minutes, and controlling the PH value to be 5.4+ / -0.1; adding 2.5% of acid proteinase, rotating for 120 minutes, and then draining the water; carrying out a retanning technology; dyeing household leather; and carrying out fat liquoring.

Owner:ZHEJIANG MINGXIN XUTENG LEATHER IND CO LTD

Novel 45CrNi4VA steel corrosion solution

InactiveCN105220153ADisplay clearShorten metallographic sample preparation timePreparing sample for investigationFluorhydric AcidCorrosion

The invention discloses novel 45CrNi4VA steel corrosion solution. The novel 45CrNi4VA steel corrosion solution comprises mixed acid; the mixed acid is prepared by adding a certain quantity of hydrofluoric acid, hydrochloric acid and alcohol in distilled water, wherein the volume fractions of the components are 4.5% of hydrofluoric acid, 8% of hydrochloric acid and 2% of alcohol; the balance is the distilled water; and the adding sequence of the components is nitric acid, hydrochloric acid and alcohol. The prepared corrosion solution can enable the gold phase corrosion of 45CrNi4VA steel to become simple and quick, saves the cost, and in particular, is suitable for the corrosion of the 45CrNi4VA steel.

Owner:胡磊磊

Preparation method of cooked rice food with rich nutrition

InactiveCN107319341AMinimal denaturationReduce lossesSeed preservation by coatingSteam cookingGlutaminase

The invention discloses a preparation method of cooked rice food with rich nutrition. The preparation method comprises steps as follows: peanut protein powder and a phosphate buffer solution are mixed and stirred uniformly, wherein the phosphate buffer solution is neutral, protein glutaminase is added, the mixture is stirred, filtered, washed and subjected to spray drying, and a prepared material is obtained; rice, mung beans and corn are uniformly mixed and washed clean, the prepared material is added and stirred uniformly, the mixture is cooled, kept at the constant temperature, unfrozen, heated, kept at the constant temperature, subjected to steam cooking treatment and microwave cooking treatment, sent to a drum cooler to be cooled, steamed under high pressure, cooled and sterilized, and the cooked rice food with rich nutrition is obtained.

Owner:全椒县崇明米业有限公司

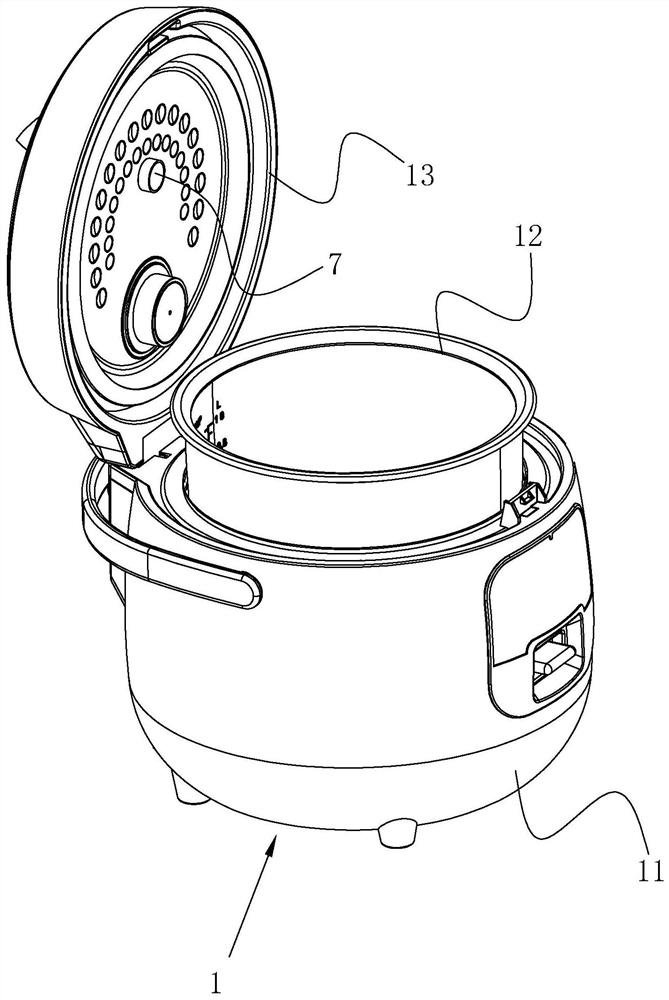

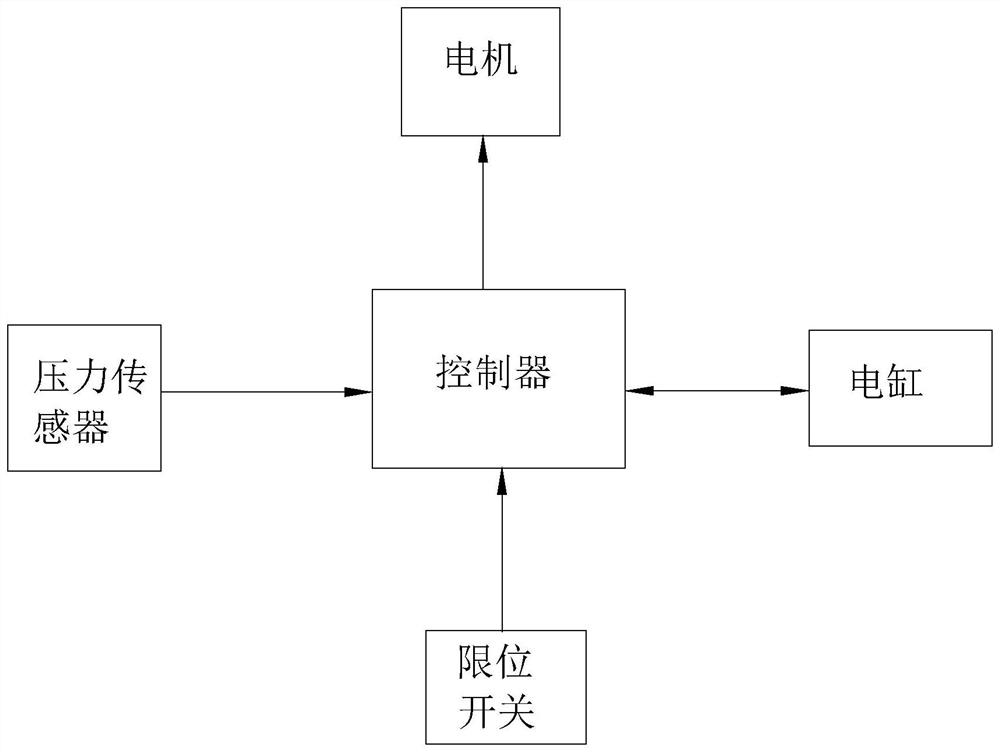

Heating control system of electric cooker and method thereof

InactiveCN112021916AMeets requirementsClear grainFluid pressure measurementTime-controlled ignitorsControl systemProcess engineering

The invention relates to a heating control system of an electric rice cooker and a method thereof. The heating control system comprises a heating disc installed in an electric cooker body, an inner container placed in the cooker body, a driving piece placed in the cooker body, a pressure sensor placed in the cooker body and a controller installed in the cooker body. The pressure sensor is arrangedto be used for detecting the weight of the inner container before and after water injection, a first reference value and a second reference value are set, and when the pressure signal is larger thanthe first reference value and smaller than the second reference value, the controller sends out a water injection signal to inform a user that water can be added into the inner container at the moment; when the pressure signal is larger than the second reference value, the controller sends out a stop signal to indicate that the water in the inner container meets the water amount required by cooking, and the ratio of the water to the rice in the inner container is in a proper state, so that the rice cooked by using the electric cooker is softer, more glutinous, moderate and clear in grain, andbetter meets the requirements of users.

Owner:广东惠嘉福实业有限公司

Quick-freeze sea urchin with shell and preparation method thereof

The invention relates to a preparation method of quick-freeze sea urchin with shells, comprising the following steps successively: opening the shell of the sea urchin with a hole of which the diameter is 3 to 4. 5cm at the mouth part of the sea urchin; using non-iodized edible refined salt to prepare salt water of which the concentration is 3 to 4% to rinse the sea urchin; freezing the sea urchin quickly, then packaging the sea urchin, paving a cold accumulating bag at the bottom of the wrapper, paving the sea urchin after the upper layer of the cold accumulating bag is paved with sponge, and paving plastic wrap and sponge on each layer of the sea urchin. The invention also relates to quick-freeze sea urchin with shells prepared by the method. By adopting the preparation method in the invention, the quick-freeze sea urchin with shells not only can be ensured fresh but also can be stored for a long while, thereby obtaining the quick-freeze sea urchin with shells capable of being eaten freshly and being stored for a long while.

Owner:ZHANGZIDAO GRP

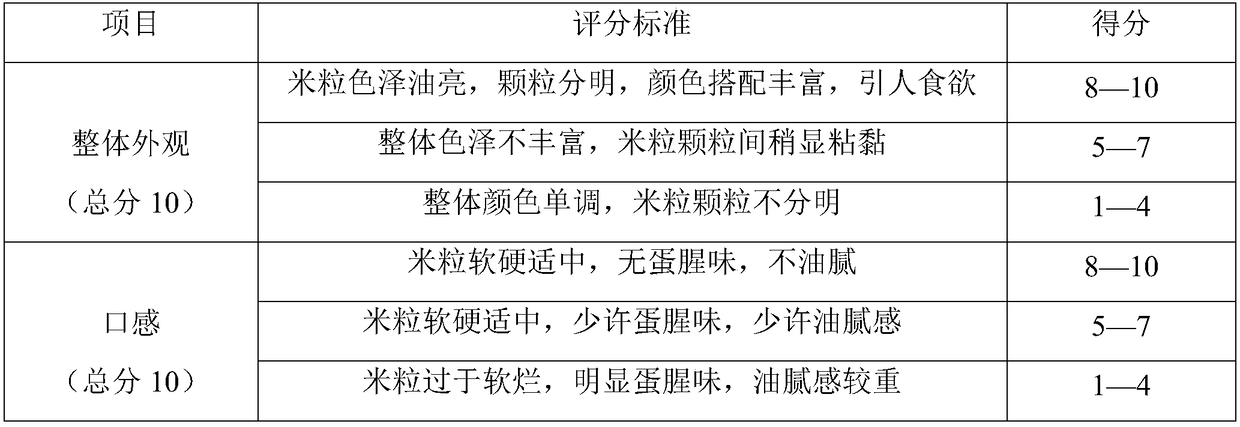

Fried rice with egg capable of being preserved at normal temperature

The invention discloses fried rice with egg capable of being preserved at normal temperature. The product is prepared by processing main raw materials, including egg granules, cooked rice, diced chicken, diced carrots and cauliflower, and assistant materials, including salt, plant oil, dry green onion, chili sauce and spices. The rice is cooked by boiling rice for 4 min, steaming the rice for 3-5min and refrigerating the rice at 0-6 DEG C for 2-8 hours. The egg granules is prepared by stir-frying eggs into egg cake by adding a certain amount of cooking wine, white pepper powder, white sugar and salt, and cutting the egg cake into rhombus granules; the diced carrots is prepared by cutting chicken breast, adding starch, salt, dark soy sauce, cooking wine and white sugar, and blanching the chicken in water. The fried rice with egg has good color appearance. The rice is glossy in color, has good granular sensation, is moderated in hardness and is nutritional and delicious. Through high-temperature sterilization, the fried rice with egg can be preserved at normal temperature and is very convenient.

Owner:HUBEI SHENDAN HEALTHY FOOD

Fur retanning technology for preventing leather fading

ActiveCN108774650AComfortable touchClear grainTanning treatmentPre-tanning chemical treatmentOrganic acidBoron containing

The invention relates to the field of leather processing, in particular to a fur retanning technology for preventing leather fading. Pollution-free leather with few defects is subjected to water removal treatment; by mass percent, 100-120 parts of leather and 200-300 parts of water are added in a drum, 0.6-1.8 parts of acid proteinase and 0.5-1.4 parts of polyethoxylated fatty alcohols are added,organic acid is used for adjusting the solution pH value to 2-5.5, and 150-200 parts of water and 0.5-1.5 parts of dye are added; and after rotation is conducted for 10-20 min, 2-8 parts of glyoxal, 0.3-0.8 part of tween 80, 1.5-5 parts of protein filler and 3-8 parts of a boron-containing fading preventing retanning agent are added, uniform dissolving is conducted after rotation is conducted for10-20 min, the temperature is controlled to range from 40 DEG C to 50 DEG C, and after rotation is conducted for 80-120 min and water is drained, the retanning procedure can be finished.

Owner:嘉兴宏远汽车座椅股份有限公司

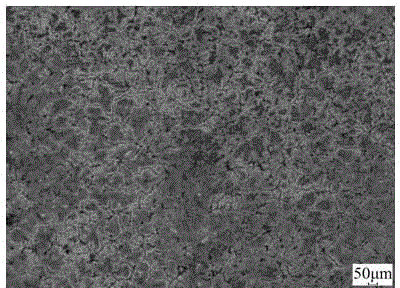

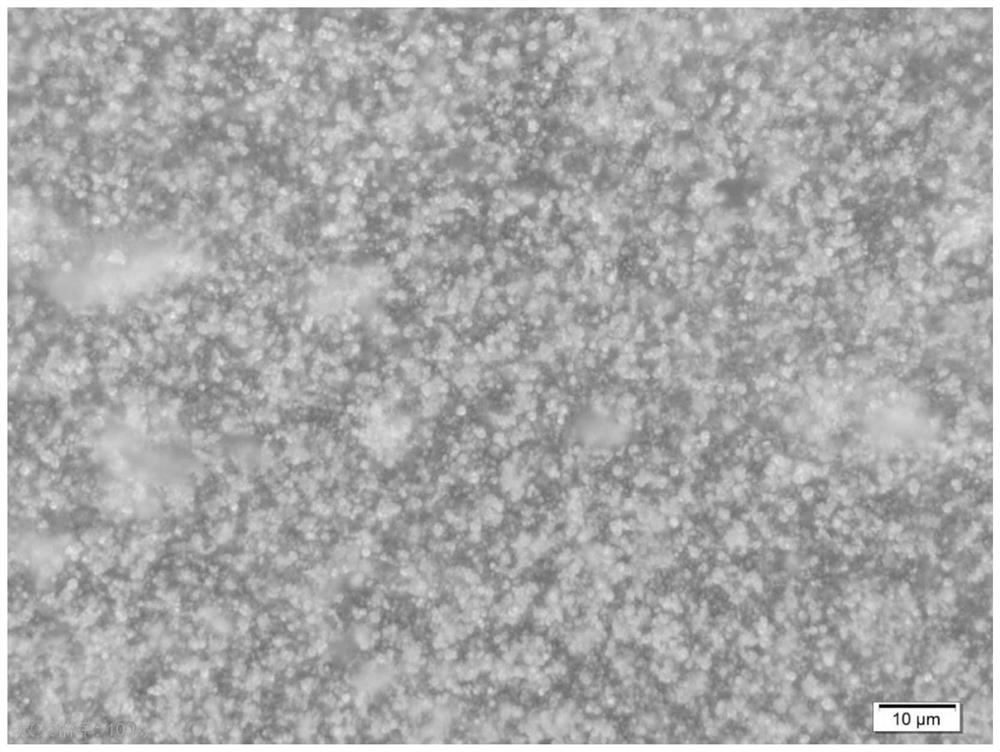

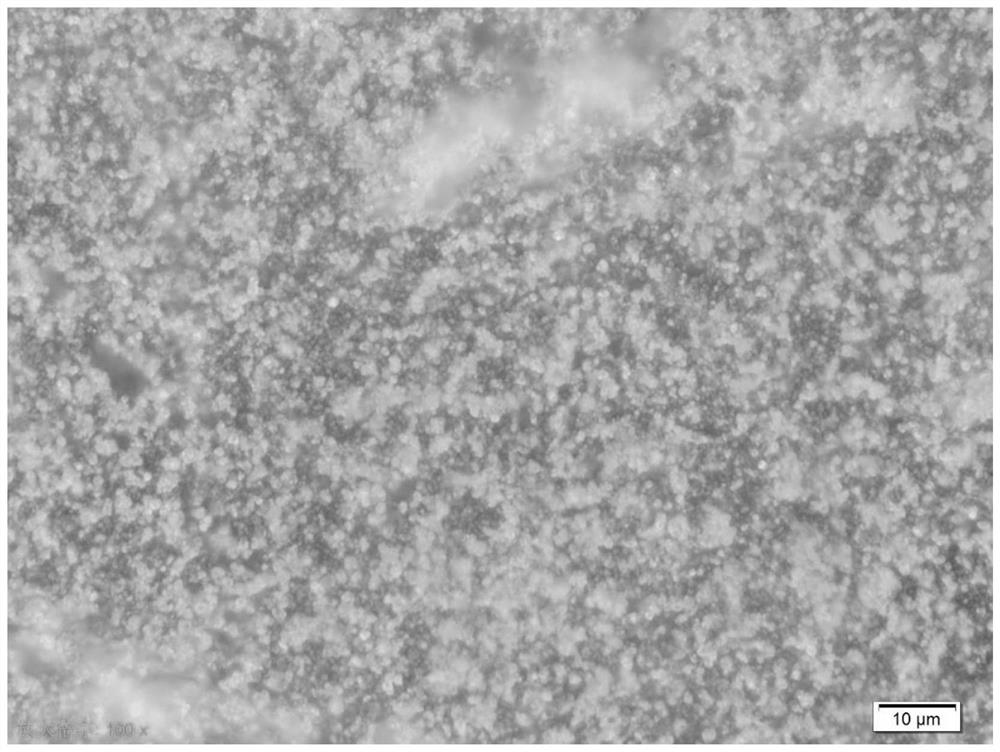

Cadmium stannate metallographic specimen and preparation method thereof

PendingCN113092199AAvoid ambiguous defectsAvoid slopesPreparing sample for investigationMicroscopic observationPolishing

The invention discloses a cadmium stannate metallographic specimen and a preparation method thereof, and belongs to the field of industrial material preparation. According to the preparation method of the cadmium stannate metallographic specimen, the cadmium stannate specimen is subjected to specific grinding and mechanical polishing treatment, so that the defect that the metallographic phase is blurred during observation due to the fact that an inclined plane appears in the traditional grinding process can be effectively avoided; after the metallographic sample is subjected to subsequent surface chemical corrosion treatment, the microscopic structure can be clearly and completely observed under microscopic observation, and the sample has no obvious scratch, defect or pit defect; the method has the advantages of simple operation steps, low cost and short time consumption, and has practical significance in the aspects of evaluating the grain condition of the cadmium stannate target material and researching the performance. The invention further discloses the cadmium stannate metallographic specimen obtained through the preparation method of the cadmium stannate metallographic specimen, the surface of the product is flat, smooth and flawless, the microstructure is clear under microscopic observation, and effective evaluation on the grain size and uniformity of the product can be achieved.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

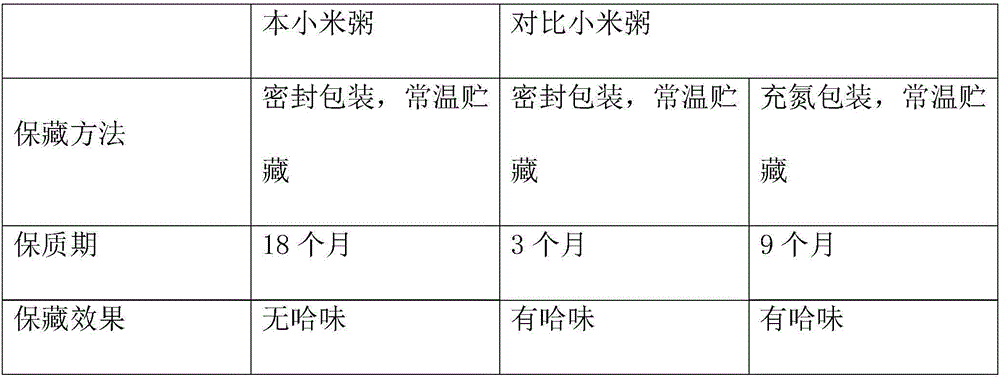

Instant millet congee and preparation method thereof

ActiveCN106509607AExtended shelf lifeImprove toughnessFood ingredient as antioxidantNatural extract food ingredientsFood processingChemistry

The invention relates to the technical field of instant food processing, and especially relates to instant millet congee and a preparation method thereof. The instant millet congee is prepared from the following raw materials in parts by weight: 85-90 parts of millet, 10-15 parts of trehalose, 3-5 parts of dried white fungi, 0.4-0.8 part of modified soybean lecithin, 0.3-0.6 part of citric acid, and 0.04-0.05 part of an antioxidant of bamboo leaves. The instant millet congee is rich in soup, relatively good in taste, convenient to eat, and not liable to become rancid. The instant millet congee overcomes the disadvantages of dewatered millet congee, namely long re-watering time, relatively hard granule feel after re-watering, weak soup taste, and so on.

Owner:武夷学院

Method for preparing Al-7Mg-5Si-3Mo alloy corrosion solution

The invention discloses a method for preparing an Al-7Mg-5Si-3Mo alloy corrosion solution. The corrosion solution is prepared by adding a certain amount of nitric acid, hydrochloric acid and hydrofluoric acid into distilled water, wherein the volume fractions of nitric acid, hydrochloric acid and hydrofluoric acid are respectively 6.5 percent, 7 percent and 15.5 percent, and the rest is the distilled water. During preparation, nitric acid, hydrochloric acid and hydrofluoric acid are added successively. After Al-7Mg-5Si-3Mo alloy is corroded by the corrosion solution, the crystal boundary and the crystalline grain of the Al-7Mg-5Si-3Mo alloy are clearly showed. The corrosion effect is good, the metallographic sample preparation time is greatly shortened, and the corrosion time is short.

Owner:李达

Processing technology of broadleaf holly leaves

InactiveCN108812953AImprove tea aromaEnhance fragrance concentrationPre-extraction tea treatmentTea flavoringVegetable oilToughness

The scheme discloses a processing technology of broadleaf holly leaves in the technical field of tea processing. The technology is as follows: carrying out enzyme deactivation on tea leaves after withering, preparing a hot stir-frying pan during the enzyme deactivation, smearing vegetable oil on the wall of the pan, then pouring clear water, boiling the clear water, putting the obtained withered tea leaves into the pan with stirring, heating the tea leaves in boiling water for 30-60s, and filtering out the tea leaves; putting the tea leaves into cold water for cooling immediately after the filtering, and conducting primary rolling at 58-68 DEG C for 15-20min after dehydration; and conducting standing for 15-20min, conducting re-rolling, and then carrying out drying. The scheme of the invention is combined with a special enzyme deactivation mode, the tea leaves are flexible in texture and not easy to tear up after the enzyme deactivation; then the rapid cooling avoids the internal texture of tea leaves from destructive changes due to persistent high temperature; and under the early-stage preparation conditions, with the primary rolling and re-rolling process and the drying mode, theobtained broadleaf holly leaves have distinct particles, are granular, are high in toughness, and are not easy to break by external force.

Owner:余庆县玉笏春茶业有限责任公司

Etchant solution for Al-4.5Mg-Zr-Si-Ce alloy

InactiveCN105297016AClear grain boundaryClear grainPreparing sample for investigationEtchingDistilled water

The invention discloses an etchant solution for Al-4.5Mg-Zr-Si-Ce alloy. Mixed acid is made by adding a certain amount of hydrofluoric acid, hydrochloric acid and nitric acid into distilled water. The mixed acid comprises, by volume, 3% of the hydrofluoric acid, 4.4% of the hydrochloric acid, 2.6% of the nitric acid, and the balance the distilled water. Besides, the nitric acid, the hydrochloric acid and the hydrofluoric acid are added in sequence. Through the manufactured etchant solution, metallographic etching of the Al-4.5Mg-Zr-Si-Ce alloy is made to be simple and fast, the cost is reduced, and the etchant solution is especially suitable for etching of the Al-4.5Mg-Zr-Si-Ce alloy.

Owner:胡磊磊

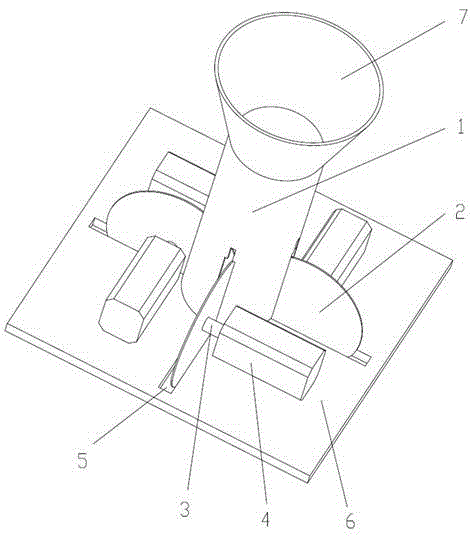

Biological feed pelleting device capable of regulating size of particles

InactiveCN111616390ASimple structureEasy to operateFeeding-stuffRotary stirring mixersBiotechnologyEngineering

The invention discloses a biological feed pelleting device capable of regulating a size of particles. The biological feed pelleting device comprises a main body; a stirring cavity with a feeding inleton the upper side is formed in the main body; a stirring assembly is arranged in the stirring cavity; the lower side of the stirring cavity is communicated with a blanking cavity by a discharging port; a cover board chute of which the right side is communicated with the blanking cavity is formed around the discharging port; an L-shaped cover board is arranged in a sliding mode in the cover boardchute; the L-shaped cover board is provided with a cover board through hole which can be matched with the discharging port; and the left side of the L-shaped cover board is connected with the left side wall of the cover board chute by a spring. When the device carries out pelleting, an opening size of a pelleting hole can be regulated as required by regulating a position of a regulation handle; after a downward pressing block presses down a biological feed, a cutter cuts to enable biological feed particles to fall onto a conveying belt; simultaneously, a drying assembly dries the biological feed particles; and the particles are distinct.

Owner:台州黄岩博友智能技术有限公司

Making equipment of chopped red peppers

PendingCN108651956ARealize automatic choppingClear grainRotary stirring mixersTransportation and packagingPush and pullEngineering

The application of the invention discloses making equipment of chopped red peppers, and belongs to the field of red pepper processing. The making equipment comprises a mixing mechanism and a cutting and chopping mechanism, wherein the mixing mechanism comprises a mixing barrel, a discharging opening is formed in the bottom of the mixing barrel, and a push and pull plate is in slip connection to the discharging opening; the cutting and chopping mechanism comprises a material accommodating barrel, chopping knives and supporting rods; a barrel opening of the material accommodating barrel communicates with the discharging opening; the two supporting rods are fixedly connected with the bottom of the mixing barrel; a roller is rotatably connected to the bottom end of each of the two supporting rods; a transmission belt is in sleeving connection between the two rollers; a connecting rod is rotatably connected to each roller; the same horizontal rod is rotatably connected to one ends away fromthe rollers, of the two connecting rods; the lower surface of the horizontal rod is connected with the chopping knives; a base is arranged under the material accommodating barrel; a second motor is arranged in the base; and a fixing rod is connected between the base and the mixing barrel, and is located on the outer wall of the base and the outer wall of the mixing barrel. Through the adoption ofthe scheme of the making equipment of the chopped red peppers disclosed by the invention, the problem that in conventional chopped red pepper mechanical processing, the mouth feel of the made choppedred peppers is poor because red pepper pulp and red pepper skins are separated is solved.

Owner:贵州胤通农业发展有限公司

A kind of production method of polished tile with jade stone texture

A production method of polished tiles having a jade stone texture, wherein the polished tiles is prepared from following raw materials: high-whiteness albite powder being 5-10 wt% in the content of sodium, feldspar, clay, talcum being 28-32 wt% in the content of MgO, anorthite being 2.0-4.0 wt% in the content of CaO and bone ash being 45-50 wt% in the content of CaO. The production method includes following steps: powder producing, blank body moulding, high-temperature sintering and polishing. During the blank body moulding, firstly more than more than one stacks of a granular powder material is randomly arranged on a material arranging trolley in the form of a large-granular materials, and then a layer of mixed powder material is arranged at the periphery of the granular powder material. The powder materials are press-compacted by a press roller and then are cracked naturally, wherein the cracks are filled with a super-transparent jade material. Finally the prepared materials are fed into a die cavity for being compression-moulded. Compared with a method in the prior art, the production method is free of addition of a reinforcing agent and a whitening agent (such as zirconium silicate) which are harmful to environment. The polished tile has a super-transparent sense just like jade stone, is fine-and-smooth and has a layered sense, is clear in bottom pattern, and has such an excellent jade-like texture.

Owner:广东博华陶瓷有限公司

Low-sugar preserved fruits and preparation method thereof

InactiveCN107348087AAvoid denuclearization difficultiesHardened withConfectionerySweetmeatsCapsicum extractSugar

The invention discloses low-sugar preserved fruits and a preparation method thereof. The preparation method takes elaeagnus conferta fruits with a low degree of maturity as a raw material and uses a chili extract, thereby giving full play to the respective advantages and enriching the variety of preserved fruits. The preparation method comprises the following steps: conducting cleaning, removal of astringency, coring, color protection, hardening, penetration promotion, filling, sugar infusion in vacuum and baking on the elaeagnus conferta fruits, thereby preparing the low-sugar preserved elaeagnus conferta fruits with the characteristics of golden yellow color, translucency, thick texture, unique taste, long storage time, separated and non-sticky fruits and the like.

Owner:TIANJIN AGRICULTURE COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com