A kind of production method of polished tile with jade stone texture

A production method and technology for polishing tiles, which are applied in the field of ceramic tiles and their production, can solve the problems of insufficient texture, poor light transmittance, harmful environment, etc., and achieve the effect of enhancing beauty and clear bottom flowers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with example the present invention is described in further detail:

[0026] The present invention is achieved in this way, including sodium content in 5-10wt% soda powder, feldspar, clay, talc with MgO content in 28-32wt%, calcium stone with CaO content in 2.0-4.0wt%, and CaO content in 45-50wt% of the ashes are made by powder, the green body is formed, fired at high temperature, and polished. When the green body is formed, more than one pile of granular powder is randomly placed on the distribution vehicle in the form of large particle powder. Then lay a layer of mixed powder around the granular powder, compact it with rollers, and then use tools to make it crack naturally, then fill the cracks with super-transparent jade material, and finally send it into the mold cavity for compression molding.

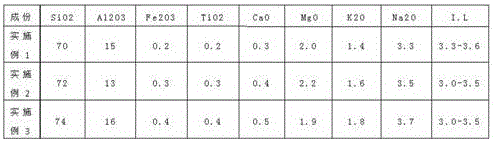

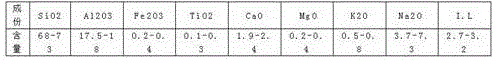

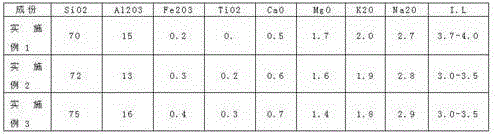

[0027] The composition content of large pellets is (unit: parts by weight):

[0028] A. Material consumption:

[0029]

[0030] B. Chemical compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com