Cadmium stannate metallographic specimen and preparation method thereof

A metallographic sample and cadmium stannate technology, which is applied in the field of cadmium stannate metallographic samples and their preparation, can solve the problems of metallographic observation of metallographic samples without preparing cadmium stannate targets, and achieve microstructure Clear, achieve the effect of grain size and uniformity, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

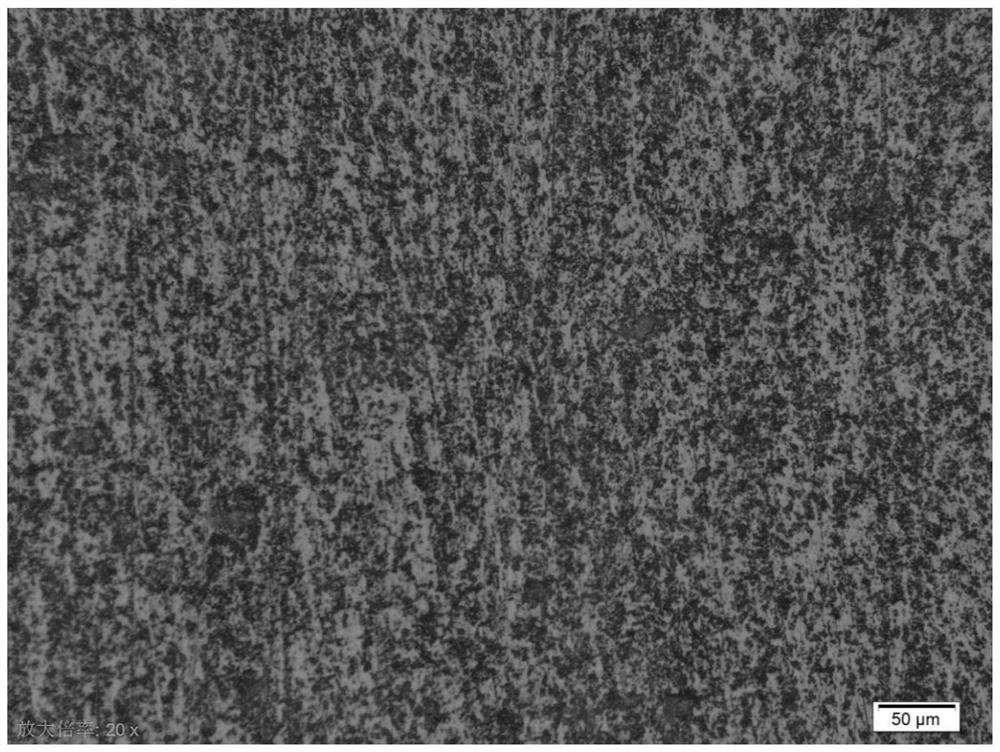

Embodiment 1

[0037] A kind of embodiment of the preparation method of cadmium stannate metallographic sample of the present invention, comprises the following steps:

[0038] (1) According to the metallographic sample preparation standard, the cadmium stannate target material is cut into cadmium stannate sample A by wire cutting;

[0039] (2) Grinding the cadmium stannate sample A: the sample is first polished with 400 mesh water-based sandpaper, and the sandpaper of a predetermined specification is fixed on the electric turntable of the polishing machine during grinding, and pure water is used as a wetting agent. Let the electric turntable rotate clockwise and set the speed at 200r / min to grind for 1min. When polishing, place the cadmium stannate sample A in the direction perpendicular to the wire cutting pattern and the rotation tangent of the electric turntable, and apply 20N vertical downward force to the sample at the same time. Then the sample is rotated 180 ° and polished for 1min i...

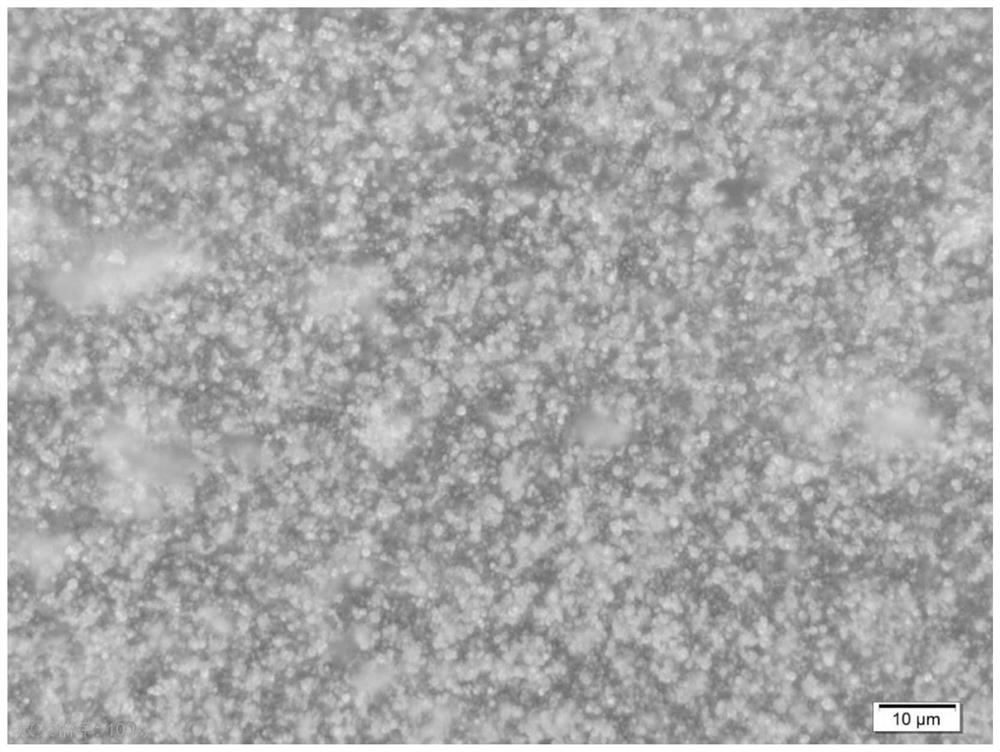

Embodiment 2

[0044] A kind of embodiment of the preparation method of cadmium stannate metallographic sample of the present invention, comprises the following steps:

[0045] (1) According to the metallographic sample preparation standard, the cadmium stannate target material is cut into cadmium stannate sample A by wire cutting;

[0046] (2) Grinding the cadmium stannate sample A: the sample is first polished with 400 mesh water-based sandpaper, and the sandpaper of a predetermined specification is fixed on the electric turntable of the polishing machine during grinding, and pure water is used as a wetting agent. Let the electric turntable rotate clockwise and set the speed at 200r / min to grind for 1min. When polishing, place the cadmium stannate sample A in the direction perpendicular to the wire cutting pattern and the rotation tangent of the electric turntable, and apply 20N vertical downward force to the sample at the same time. Then the sample is rotated 180 ° and polished for 1min i...

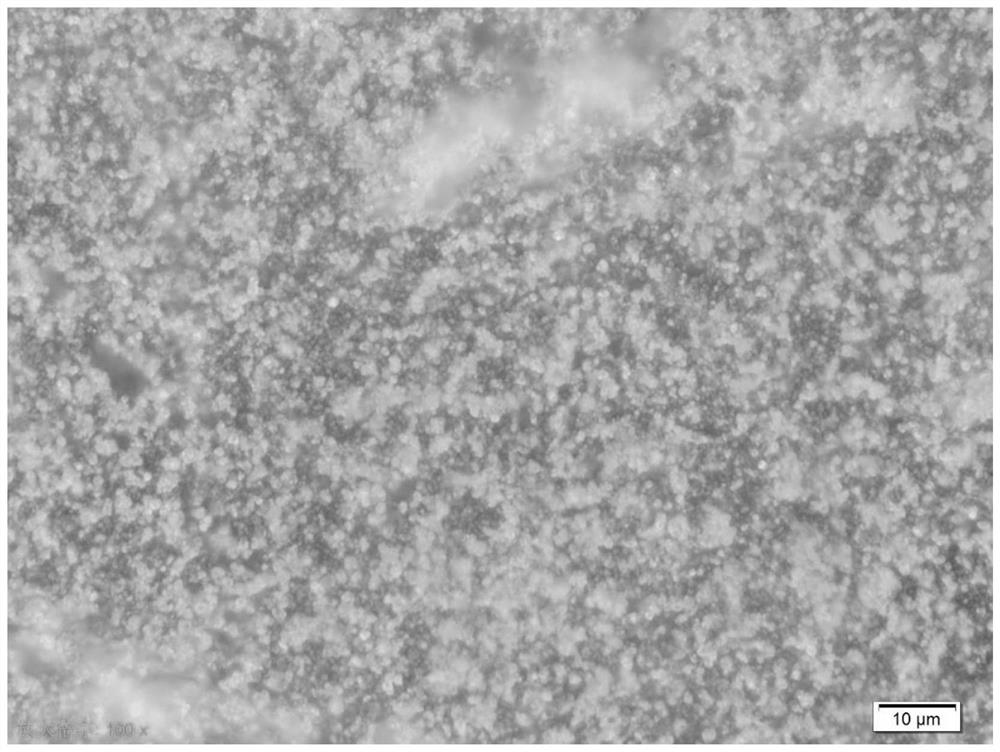

Embodiment 3

[0051] A kind of embodiment of the preparation method of cadmium stannate metallographic sample of the present invention, comprises the following steps:

[0052] (1) According to the metallographic sample preparation standard, the cadmium stannate target material is cut into cadmium stannate sample A by wire cutting;

[0053] (2) Grinding the cadmium stannate sample A: the sample is first polished with 400 mesh water-based sandpaper, and the sandpaper of a predetermined specification is fixed on the electric turntable of the polishing machine during grinding, and pure water is used as a wetting agent. Let the electric turntable rotate clockwise and set the speed at 100r / min to grind for 2 minutes. When polishing, place the cadmium stannate sample A in the direction perpendicular to the wire cutting pattern and the tangent of the electric turntable rotation. At the same time, apply 20N vertical downward force to the sample. Then the sample is rotated 180 ° and polished for 2min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com