An adjustable column formwork construction reinforcement process and its device

A reinforcement device and column formwork technology, which is applied to formwork/formwork/work frame, joints of formwork/formwork/work frame, and preparation of building components on site, which can solve the problem that the splicing angle cannot be adaptively adjusted. , Self-adaptive adjustment of column formwork width, uneven force of column formwork, etc., to improve stability and construction efficiency, realize integrated design, increase performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

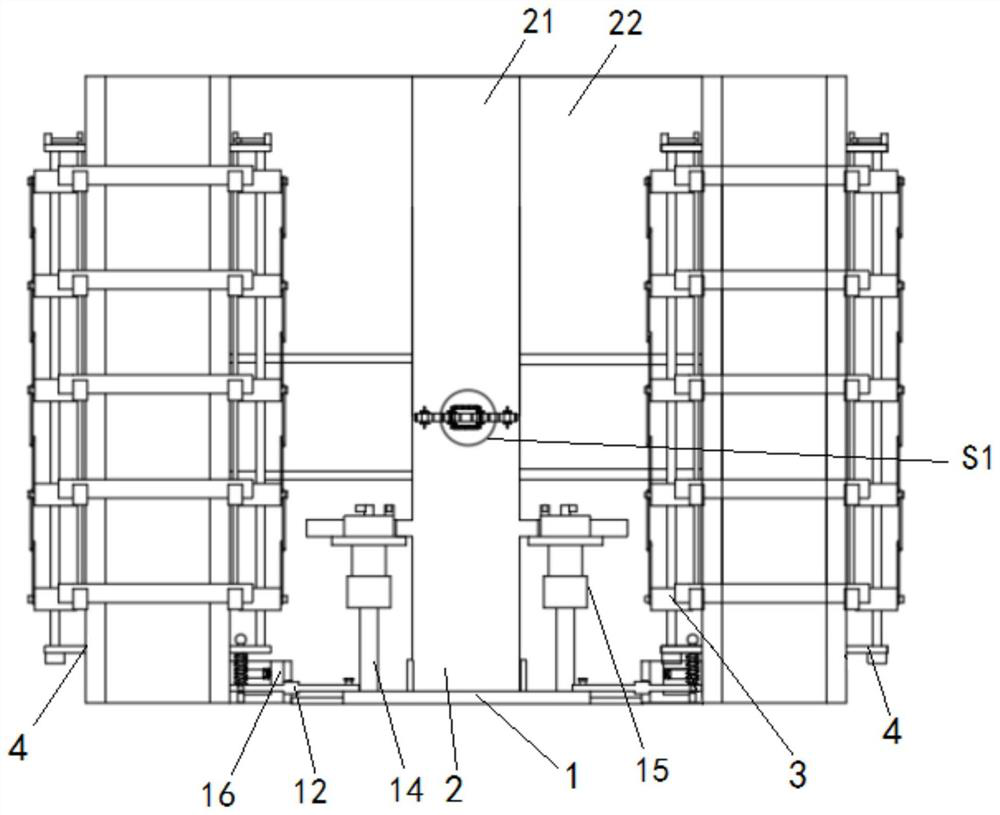

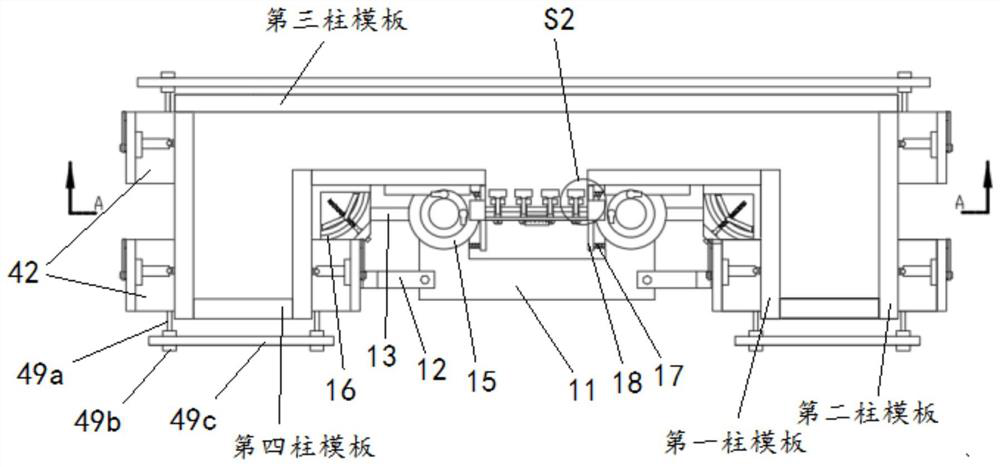

[0043] see Figure 1-8 As shown, an adjustable column formwork construction reinforcement process, the construction reinforcement process uses the column formwork construction reinforcement device to carry out construction reinforcement adjustment on the column formwork, especially for the reinforcement of the steel concrete column formwork connected with the shear wall, the specific reinforcement The process steps are as follows:

[0044] S1. Place formwork: place the first column formwork, the second column formwork, the third column formwork, the fourth column formwork and the adjustable side formwork 2 around the shear wall to be poured in sequence;

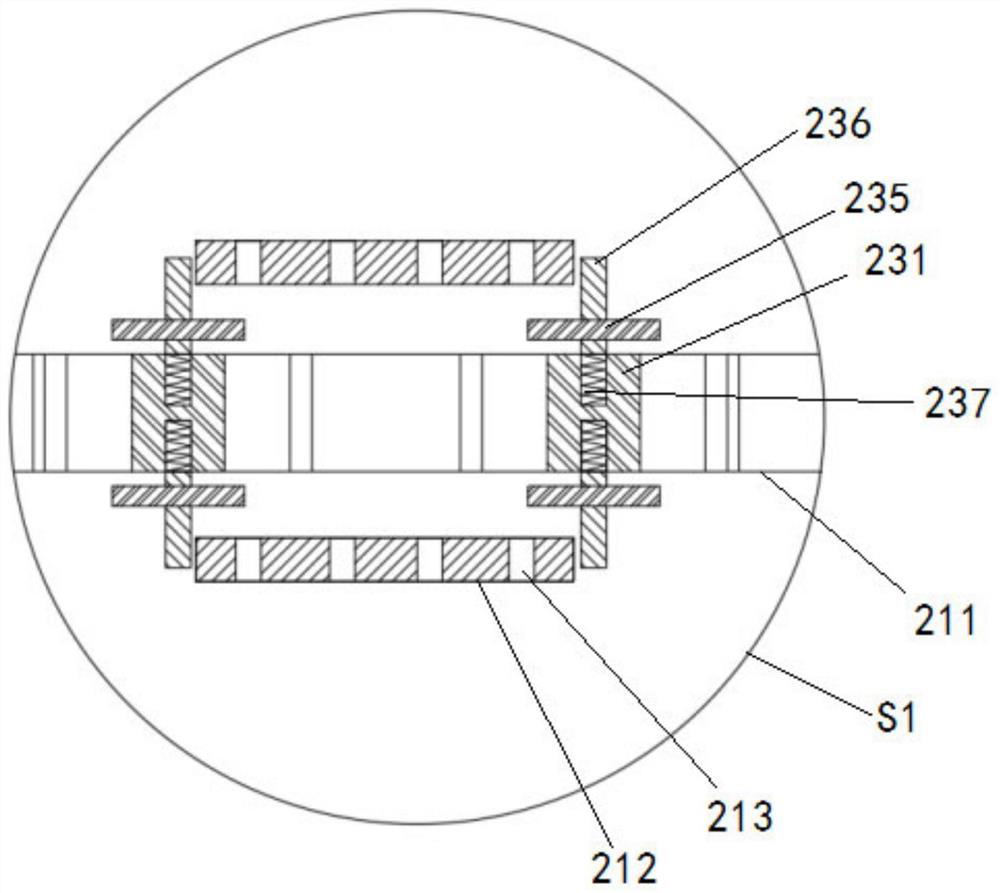

[0045] S2. Side formwork width adjustment: Manually adjust the relative position of the width extension mechanism 21 and the moving side formwork 22, and adjust the position of each extension filler 23 in the width extension mechanism 21, so as to satisfy the adjustment of the adjustable side formwork 2 according to the shear...

Embodiment 2

[0062] Preferably, a buffer guide rod 17 is installed in the conduction holes on both sides of the fixed connection seat 11, a buffer compression spring is set on the buffer guide rod 17, and a clamping plate 18 is fixed on the end surface of the buffer guide rod 17, and the buffer compression spring Under the action, the position of the width extension mechanism 21 is further fixed.

[0063] The rotary compression mechanism 15 is used to rotate and compress the width extension mechanism 21 on the adjustable side template 2 and the movable side template 22, so as to avoid relative sliding between the movable side template 22 and the width extension mechanism 21, and the rotary compression mechanism 15 It includes a mounting seat 151 installed on the first electric push rod 14, a transmission feeding cylinder 152, a rotating pressing base 153, a transmission track limit cylinder 154, a driving rack 155, a rotating pressing block 157 and a rotating power part. The upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com