Quantitative feedstuff feeder

A feeding machine and feed technology, which is applied in the field of poultry and livestock breeding, can solve the problems of feed feeding impact, high manual workload requirements, uncontrollable feed quantity, etc., to improve quality, avoid uncertainty, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

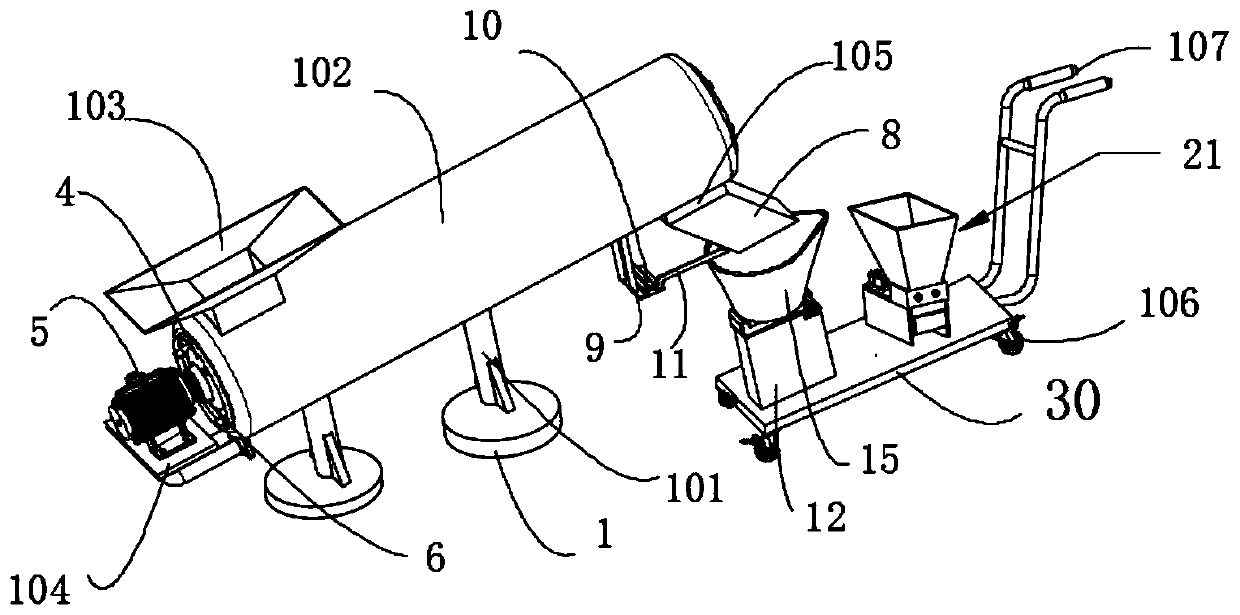

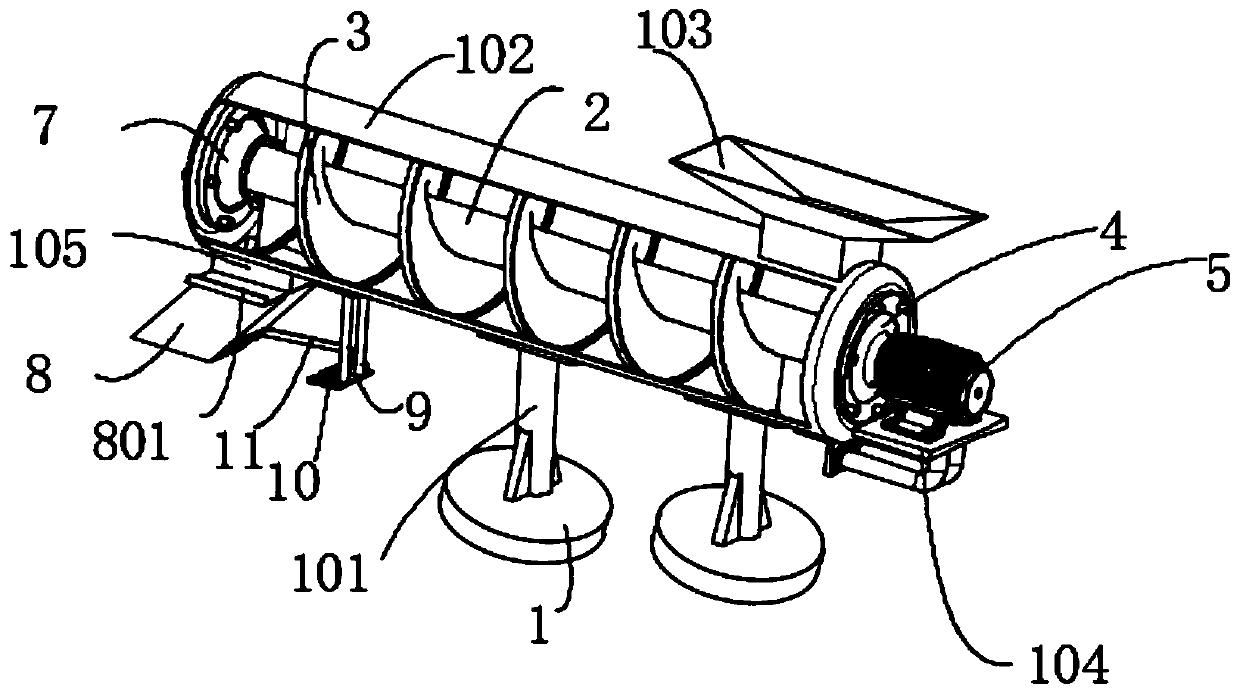

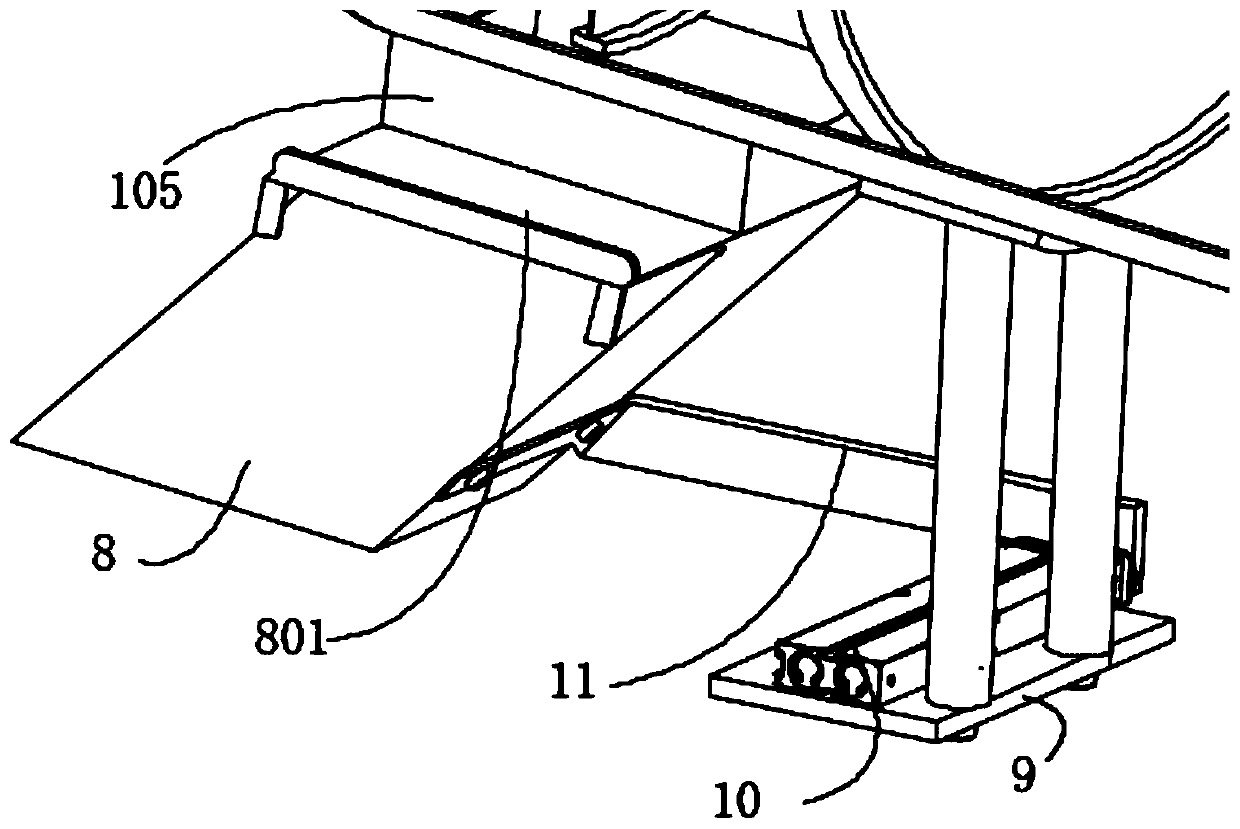

[0043] Embodiment: Feed quantitative delivery machine, constitutes as figure 1 and figure 2 As shown, including the base 1, the base 1 is provided with a support column 101, the support column 101 is provided with an auger 102, the auger is generally arranged in the feed warehouse, or is arranged at the feed transport vehicle, and the auger 102 is provided with an inlet. The feed opening 103, the auger 102 is provided with a rotating shaft 2, the rotating shaft 2 is provided with a helical blade 3, one end of the rotating shaft 2 is provided with a left end cover 4, and one side of the auger 102 is provided with a motor fixing frame 104, and the motor is fixed The frame 104 is provided with a motor 5, the extended end of the motor 5 is provided with a coupling 6, the rotating shaft 2 is connected with the motor 5 through the coupling 6, and the other end of the rotating shaft 2 is provided with a right end cover 7; the auger 102 is provided with a discharge port 105, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com