Wood waste crushing and grinding machine

A wood waste and grinding machine technology, applied in the field of wood processing, can solve the problems of accelerating equipment loss, increasing equipment damage, falling metal materials, etc., achieving the effect of uniform size, improving work efficiency, and reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

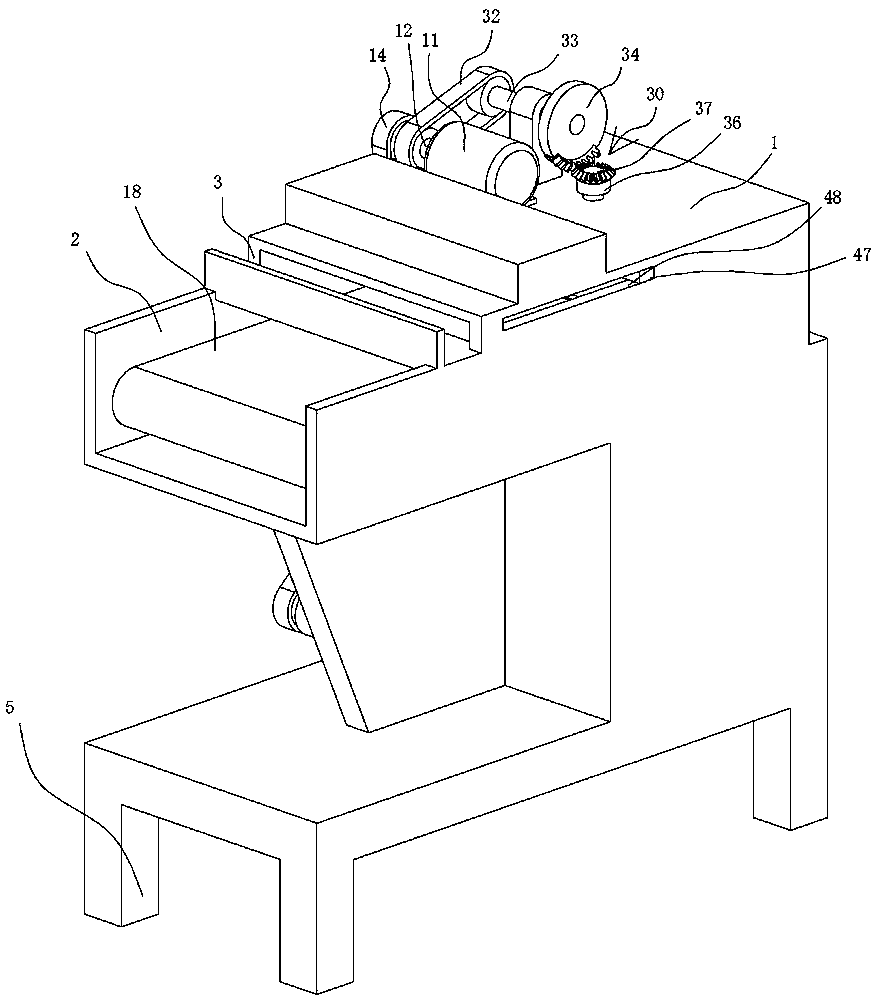

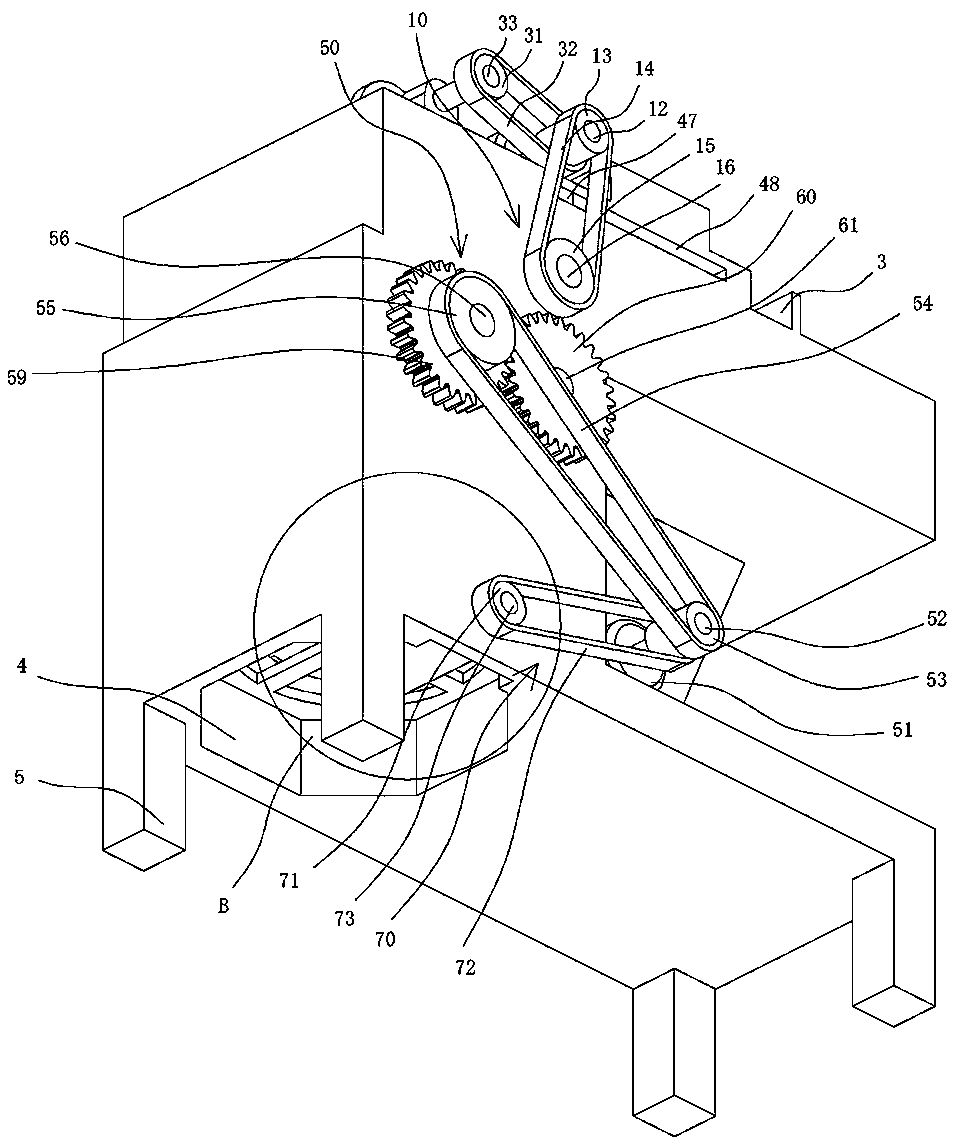

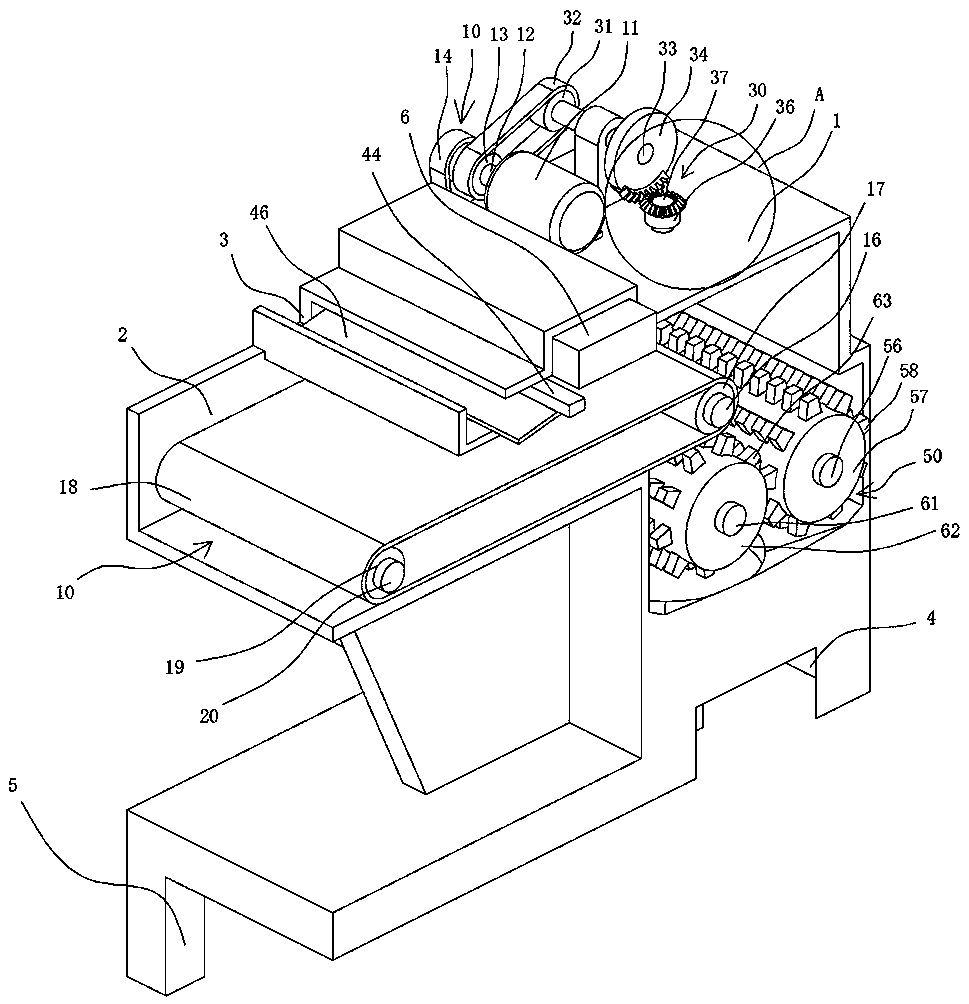

[0024] Such as figure 1 with figure 2 As shown, the wood waste grinding and grinding machine of the present invention includes a body 1, the left end of the body 1 is provided with an inlet 2, the right end of the body 1 is provided with a discharge port 4, the left side of the body 1 is provided with a discharge port 3, and the bottom end of the body 1 is provided There are four evenly distributed outriggers 5, the left end of the body 1 is provided with a transport mechanism 10, the right side of the transport mechanism 10 is provided with an intermittently rotating transmission mechanism 30, the lower end of the transmission mechanism 30 is provided with a sieve mechanism 40, and the left end of the sieve mechanism 40 is provided On the upper side of the transport mechanism 10, a pulverizing mechanism 50 is provided at the lower end of the machine body 1, a grinding mechanism 70 is provided on the lower side of the pulverizing mechanism 50, and the grinding mechanism 70 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com