Preparation method of metallographic samples of zirconium and zirconium alloy

A technology for metallographic samples and alloys, applied in the field of metallographic sample preparation of zirconium and zirconium alloys, can solve the problems of long-term exploration, easy environmental pollution by waste liquid, strict parameter requirements, etc. High-definition, low-tech effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

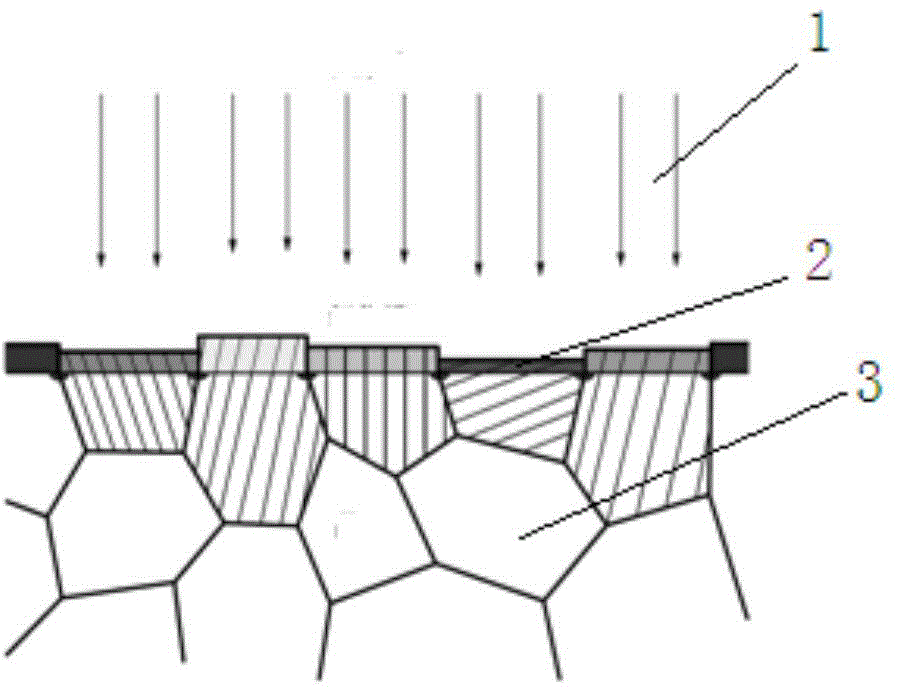

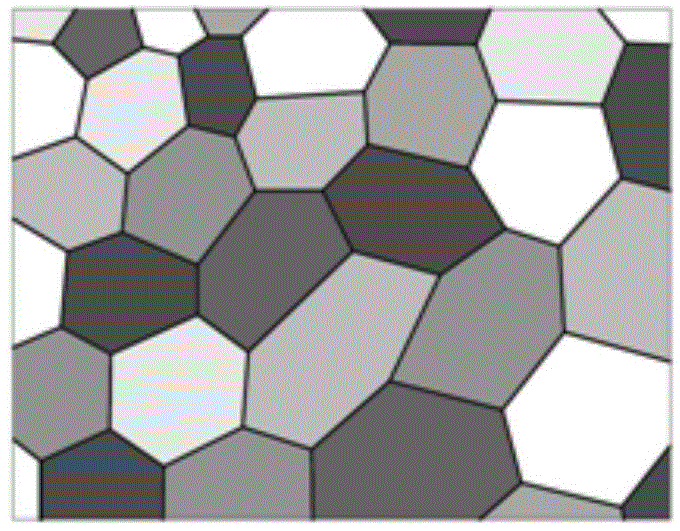

[0029] In this embodiment, the cold-rolled Zr-Sn-Nb-Fe alloy plate in the recrystallization annealed state is taken, and the metallographic sample of the zirconium alloy is prepared and observed according to the following preparation process, as follows: figure 2 Shown:

[0030] a. Sampling and cleaning: Sampling the plate, the size of the sample is 10mm×10mm, and ultrasonically cleaning the sample with acetone to remove surface oil;

[0031] b. Coarse grinding - fine grinding: Grind the cleaned sample on metallographic sandpaper. The grades of the sandpaper used are: 400#→800#→1200#→2000#→3000#. The grinding process requires a balanced force , when replacing sandpaper with different particle sizes, the grinding direction should be 90° to the direction of the wear marks of the previous sandpaper, and the next step should be performed after the previous wear marks are completely eliminated;

[0032] c. Chemical polishing: by volume ratio HF: HNO 3 :H 2 O=10:45:45 is carried...

Embodiment 2

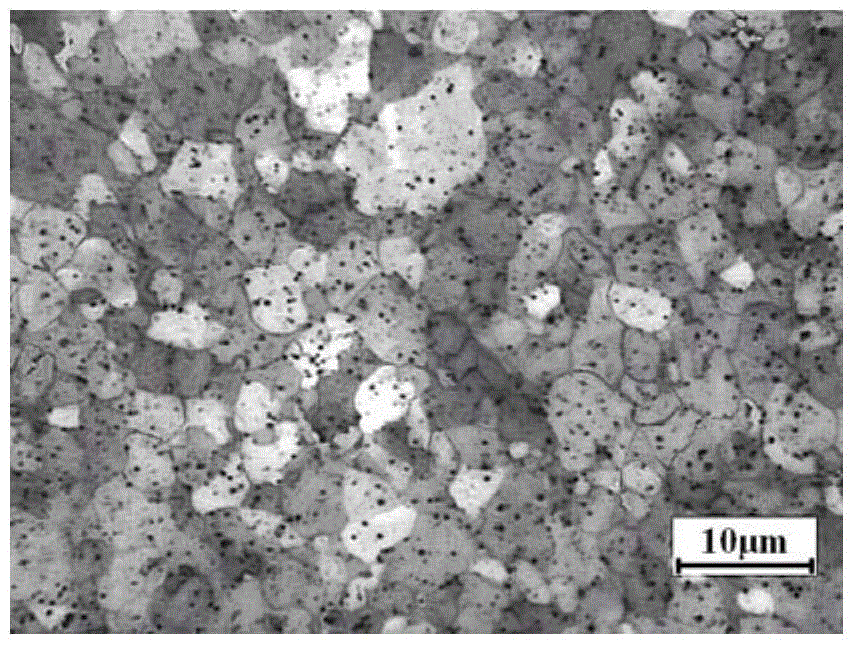

[0036] The Zr-Sn-Nb-Fe alloy was kept at 650°C for 15 hours and quenched in water. The metallographic samples of the zirconium alloy were prepared and observed according to the following preparation process, as shown in image 3 Shown:

[0037] a. Sampling and cleaning: Sampling the plate, the size of the sample is 10mm×10mm, and ultrasonically cleaning the sample with acetone to remove the oil on the surface of the sample;

[0038] b. Coarse grinding - fine grinding: Grind the cleaned sample on metallographic sandpaper. The grades of sandpaper used are: 400#→800#→1200#→2000#→3000#. The grinding process requires a balanced force , when replacing the sandpaper with different particle sizes, the grinding direction should be 90° to the direction of the wear marks of the previous number one sandpaper, and the next step should be performed after the previous wear marks are completely eliminated;

[0039]c. Chemical polishing by volume ratio HF: HNO 3 :H 2 O=10:45:45 is carried o...

Embodiment 3

[0043] The Zr-Sn-Nb-Fe alloy was kept at 800°C for 40 minutes and quenched in water, and the metallographic sample of the zirconium alloy was prepared and observed according to the following preparation process, as shown in Figure 4 Shown:

[0044] a. Sampling and cleaning: Sampling the plate, the size of the sample is 10mm×10mm, and ultrasonically cleaning the sample with acetone to remove surface oil;

[0045] b. Coarse grinding - fine grinding: Grind the cleaned sample on metallographic sandpaper. The grades of the sandpaper used are: 400#→800#→1200#→2000#→3000#. The grinding process requires a balanced force , when replacing sandpaper with different particle sizes, the grinding direction should be 90° to the direction of the wear marks of the previous sandpaper, and the next step should be performed after the previous wear marks are completely eliminated;

[0046] c. Chemical polishing: by volume ratio HF: HNO 3 :H 2 O=10:45:45 is carried out solution preparation, dips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com