Novel 45CrNi4VA steel corrosion solution

A corrosion solution and a new type of technology, applied in the preparation of test samples, etc., can solve the problems of time-consuming and increased production costs, and achieve the effects of clear display, cost-saving, and shortened metallographic sample preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

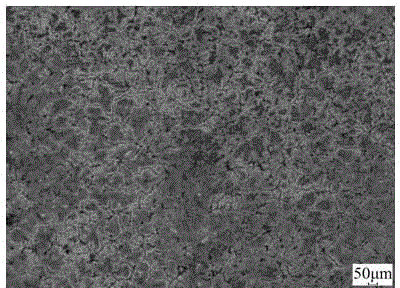

[0013] A new type of 45CrNi4VA steel corrosion solution, using mixed acid as raw material, is prepared by a conventional solution preparation method. 4.5ml of nitric acid, 8ml of hydrochloric acid and 2ml of alcohol are added to 85ml of distilled water, and then stirred evenly with a glass rod.

[0014] The corrosion solution prepared through the above steps is used to corrode 45CrNi4VA steel, see the specific effect figure 1 , it can be seen that the effect of the pure aluminum corrosion solution of the present invention is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com